New oil, lights last longer

advertisement

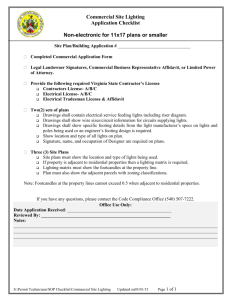

16 www.FarmProgress.com - June 2010 Kansas Farmer Crop Production New oil, lights last longer By WILLIE VOGT U SED to be when it came to equipment service, there were a few simple rules. Check the oil and grease the tractor every morning before heading out, and change the oil every 200 hours. However, those rules are changing as new technologies come into the market, adding service life to fluids and even changing the way you light your fields. The advent of ultra-low-sulfur diesel use has already changed the kind of oil you’re using in most tractors, and there are other consequences as well. “One issue we’re finding interesting, with CJ4 oils, is that the total base number is lower,” says Gary Parson, global original equipment manufacturer and industry liaison, Chevron. “[TBN] is an indication of the oil’s ability to neutralize acids, and in the past we rated oil quality by that number. But with ultra-low-sulfur NEW-TECH BRIGHT: LED lights offer plenty of light for night work, but also use less power and last up to 20 times longer than high-intensity discharge lighting. O P TE C H SH diesel, and lower formation of crankcase acids, we’re finding that TBN is not as critical.” Parson explains that this reduced acid level is extending oil service life. “We’re seeing 60,000-mile drain intervals for long-haul trucks, which is a lot longer than I remember,” he notes. “In our testing, you can safely operate equipment with a TBN below 2. That can extend vehicle service intervals, provided there aren’t other limiting factors,” he notes, pointing out that the high dirt and dusty environment farm equipment operates in can cut fluid service life. Yet, major manufacturers are already pushing up service intervals. It’s not uncommon to see 500-hour measures between oil changes with the latest long-life fluids. Low-power, brighter light Get the parts you need, around the clock At John Deere, we’re about making your life easier. That’s why we offer Parts OnSite. You can stock parts right on your farm, so you can get what you need right away – 24 4 hours a day. And since there’s no waiting, there’s less downtime. We’ll even help keep up your inventory with our recommended stocking lists, so you’re prepared for each season. Because as much as we’d like to see you at the parts counter, we’d rather see you in the ÷eld. That’s the John Deere difference. www.JohnDeere.com/AgParts In your home you might be using new light bulbs to save power, like compact fluorescent light bulbs. And at Christmas, you may be trying out those new lightemitting diode, or LED, lights. Both technologies reduce energy use and have longer life. Turns out those LEDs have value as farm equipment lighting, too. Over the past few years, lighting companies have turned to LEDs as a new light source, and they’ve cranked up some pretty bright task lighting that’s making its way to farm equipment, too. If you’re looking at new lighting, you might consider the jump from halogen or high-intensity discharge lighting to LED sources. Ryan Mayrand, who works in product marketing for J.W. Speaker Corp., notes several advantages to LED lighting. “The longevity of the light itself is much higher,” he notes. “In most cases, an LED light has a 40,000- to 60,000-hour service life. Compare that to a halogen with perhaps 200 to 400 hours, or HID lighting at 2,500 hours.” He notes that since the LED has no bulbs, it eliminates risk of filament breakage, and the lights can resist shock and vibration a lot better. That cuts downtime costs, too. Those lights are also more energy-efficient. “A halogen light, for example, will give 80% of its energy to heat, compared to just 20% with LEDs,” Mayrand notes. “LEDs are also more environmentally friendly in that there is no mercury used in their manufacture.” Another plus is that these lights are less of a drain on your charging system, which can improve equipment efficiency. For example, John Deere notes that LED lights it offers consume 75% less energy than halogen lights.