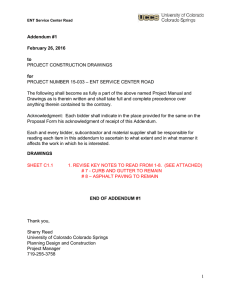

Addendum No. 5 - Eastern Municipal Water District

advertisement