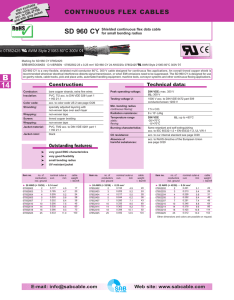

cables for railway technology

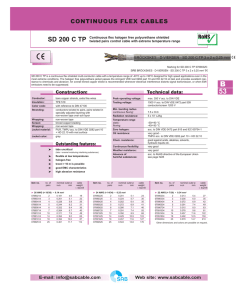

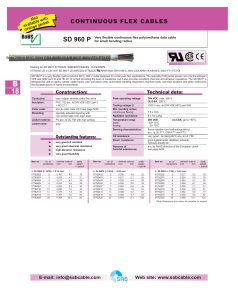

advertisement