variable speed drives

advertisement

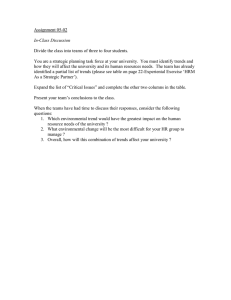

VARIABLE SPEED DRIVES Why Trend Variable Speed Drives? Energy Savings Reduced Installation Costs Energy efficiency and environmental considerations are Not only are significant operational savings possible but attracting intense interest in the design of HVAC systems so are savings on installation costs, as switchgear and the energy performance throughout the 'whole-life' associated with the motor control is eliminated, motor operation of these systems is now seen as a key design cables are reduced from six to three wires and power consideration. Consequently HVAC system designs factor correction capacitors are no longer required. increasingly incorporate variable speed drives (VSDs) As starting current is always kept within the nominal value, enabling motors to be used with maximum efficiency, size and cost of cabling and fuses are also minimised. resulting in significant energy savings. 100% DIRECT ON LINE POWER 700% STAR DELTA 50% ELECTRONIC SOFT START INVERTER 500% 400% 300% 200% 22% FULL LOAD AND SPEED % FULL LOAD CURRENT 600% 100% 90 HZ MOTOR SPEED/FLOW 60% 80% 100% SPEED Trend's variable speed drives can be applied across a wide Both the Trend NX and NXL ranges are amongst the most range of industrial and commercial applications, however compact per kW in design available in the HVAC industry in an HVAC environment they enable motors on fans and (typically up to 30% smaller in footprint than competitors pumps to regulate flows of air and water in variable flow product). They are available in IP54 and IP21 packages; applications. Such systems are inherently more efficient, being slim they can easily be mounted on the wall or in an avoiding the wasteful pumping and heating or cooling of enclosure, even if space is limited. The “bookshelf” design water for only a proportion of the delivered media to be means side-by-side installation makes the most of the used. In applications where flow rates can be reduced, tightest of spaces, saving cost on installations. motor energy can be significantly reduced as the relationship between flow rate and motor power follows a Putting Trend variable speed drives to work couldn't be cube-law i.e. reducing the flow rate by 20% reduces power easier. The NXL range has a quick setup routine that consumed by approximately 50%. allows the drive to be configured in 4 simple steps, minimising the amount of time required to commission The payback on the investment is dependent on the cost the drive. of electricity, the number of hours per week the fan or pump is running, the size of the fan or pump and the Additionally software tools are available for both the NX amount of reduction that can be made to the flow rate. and NXL range of drives for commissioning, developing and loading more complex applications. Typically we have found the payback period for retrofitting a variable speed drive to be less than 2 years and sometimes as little as three months. See the payback calculator CD ROM included with this brochure. VARIABLE SPEED DRIVES Reduces energy costs All Trend VSDs qualify for the government (UK only) backed ECA (Enhanced Capital Allowance) scheme. This enables 100% first year capital allowances to be claimed against the investment in Trend VSDs. Keypad display panel Providing complete control of the system which can be tailored with or without optional cards. Intelligent networking The NX range of drives have the option of network cards that allow it to reside on a Trend LAN or a Trend Virtual LAN over TCP/IP. Easy installation means reduced costs Compact size and flexible installation makes Trend drives ideal when space is at a premium. Drives can be easily mounted using a DIN rail or they can be wall mounted. VARIABLE SPEED DRIVES NX Range The NX is designed to be a high performance, easy-to-use drive for a wide range of applications. It is based on an advanced sensorless vector control concept, which provides excellent motor control in all circumstances. An automatic torque maximiser feature is available, ensuring that loads can be started reliably. The drive also includes an automatic energy saving feature, which optimises the motor flux as a function of motor load and speed. The basic drive operation is also suitable for multi-motor applications. Trend variable speed drives are built on the principles of modularity. This creates robust drives that can be modified according to customer requirements. The control section contains the microprocessor required for advanced motor control and the keypad display panel. It can also accommodate a range of input, output and interface options, including the NXNI and NXIP. NXNI is an interface card, which can be installed into an NX variable speed drive. It enables the drive to be connected directly to the Trend current loop local network (LAN). NXIP takes all of the features of the NXNI and Key Features places them onto Ethernet. It enables the drive to be n Trend LAN fully compatible connected to an IQ system network running on Ethernet. n Compact physical size n ECA certified (UK only) With these interfaces the drives can be integrated into n Metric gland plate up to 30kW the Trend system for interaction with controllers and for n Low torque ripple user supervision. n High immunity to resonant vibrations n Starting torque > 200 %, depending on motor Both interface cards can eliminate the wiring of fault, and drive sizing start, stop and ramp signals thus further reducing the installation Applications costs. They also allow the supervisor to view all of the internal parameters of the drive that would otherwise only be available at the display panel. Select the software application best matching the characteristics of the actual function. This simplifies set up, because only those parameters relevant to the application will be visible. For each application there is a start-up wizard that guides the user through the start-up process and parameter settings. The drive is also capable of identifying motor parameters, further easing start-up. VARIABLE SPEED DRIVES NXL Range The NXL is designed as an economical drive ideal for the HVAC industry. The compact size and flexible installation options make the NXL suitable for applications where space is at a premium. The small MF2 frames can be mounted using a DIN rail either at the back or at the side of the drive; the larger MF3 - MF6 frames are wall mounted, and use the same power section enclosures as the NX drives. The drives are easy to program with a quick setup routine consisting of only 4 steps. In addition to the standard I/O in the basic drive, there is space for two option cards providing additional I/O or other functionality. The NXL builds on the modular design concept of the NX family of drives and are all delivered with a keypad display panel. The drives come in different enclosure classes: the Microdrives, with the small MF2 and MF3 frames, are IP20, whereas the Ecodrives drives, with MF4 - MF6 frames, are available in IP21 and IP54. Key Features n Quick 4 step configuration n Compact physical size n ECA certified (UK only) n Metric gland plate n Low torque ripple n High immunity to resonant vibrations n Starting torque > 200 %, depending on motor and drive sizing Multi-Control Application The NXL includes an easy-to-use and flexible multi-control application, keeping parameter adjustments to a minimum. The versatile features include full motor protection, flying start function, sleep function and a PID controller, with the option to control multiple pumps. VARIABLE SPEED DRIVES Trend Variable Speed Drives 0.37 to 250 kW Trend’s range of variable speed drives is designed to cover most industrial and commercial applications and are easy to use, by both installers and end users. Trend's general purpose and high performance variable speed drives are provided with filtering suitable for conventional commercial applications and a range of expansion cards are available to meet most requirements. All Trend drives come with detachable keypads as standard and the NX keypad can be used to store the active parameters and transfer them between drives. NXL Microdrives NXL Ecodrives NX High Performance Power & Voltage EMC Enclosure Options 208 - 240V Single Phase* 0.37 - 1.5 kW 380 - 500V Three Phase 0.55 - 0.75 kW N IP20 NXOPTAA Expansion Card** Keypad Door Mounting Kit H Level Filter Kit Din Rail Mounting Kit RS232 Adapter Kit 380 - 500V Three Phase 1.1 - 30 kW H, T IP21 or IP54 NXOPTAA Expansion Card** Keypad Door Mounting Kit RS232 Adapter Kit 380 - 500V Three Phase 1.1 - 160 kW H, T IP54 NXOPTA1 Expansion Card*** NXOPTA3 Expansion Card**** NXOPTB5 Expansion Card***** Trend LAN Network Card Trend LAN TCP/IP Network Card Keypad Door Mounting Kit Keypad Blanking Kit *NXL 208 - 240V single phase input, three phase 208 - 204V output **NXOPTAA - NXL input option card AA - 3*DI, 2*DO (1 relay output, 1 open collector) ***NXOPTA1 - NX input option card A1 - 2*AI, 6*DI, 1*AO, 1*DO (open collector) ****NXOPTA3 - NX output card A3 - 1*AI (thermistor input), 2*DO (1 changeover, 1 normally open) *****NXOPTB5 - NX output card B5 - 3*DO (normally open) VARIABLE SPEED DRIVES Like to save 50% off fan and pump running costs? See the savings with the Trend VSD Payback Calculator CD missing? Call +44 (0)1403 216451 Energy savings for Pumps and Fans Enhanced Capital Allowance (ECA) Variable speed control of centrifugal Installation of a VSD is easy and the fans and pumps offers a significant payback is fast, typically measured All Trend VSDs qualify for the opportunity to reduce building in months not years. government (UK only) backed ECA (Enhanced Capital Allowance) running costs. Reducing their speed by just 20% will give you an energy Use the VSD calculator to get an scheme. This enables 100% first saving of around 50%. idea of the level of savings that can year capital allowances to be be achieved. The size of the motor claimed against the investment in This saving can be achieved by the and the time it operates is all that is Trend VSDs. installation and correct application required - the calculator can do the rest. Detailed information can be found of a Variable Speed Drive (VSD). at the ECA website www.eca.org.uk The VSD will provide the capability to accurately control the speed of a fan or pump motor and consequently its energy usage. To run the CD Simply insert into the CD disc drive and follow the instructions. If the CD does not auto start, view the contents of the CD and double click the vsd.exe file. Trend Controls c/o Novar Austria GmbH Fernkorngasse 10 Vienna A-1100 AUSTRIA Telephone +43 1 600 6030 151 Facsimile +43 1 600 6030 906 Trend Control Systems c/o Honeywell (China) Co. Ltd. 35F Tower A City Center 100 Zunyi Road Shanghai 200051 CHINA Telephone: +86 (21) 5257 4568 Facsimile: +86 (21) 5855 5856 Trend Control Systems Østergade 23-29, 3. sal DK8000 Århus C DENMARK Telephone +45 7020 9955 Facsimile +45 7020 9957 Trend Control Systems 9, Avenue du Marais Parc des Algorithmes Immeuble Sophocle 95815 Argenteuil FRANCE Telephone: +33 (0)1 39964964 Facsimile: + 33 (0)1 39964951 Novar GmbH Bereich Trend Kaiserleistraße 39 63067 Offenbach GERMANY Tel.: +49 (0)69 / 80 64 - 100 Fax: +49 (0)69 / 80 64 - 101 Trend Control Systems c/o Honeywell Automation India Ltd. No.2234, 23rd Cross, K. R. Road Banashankari llnd Stage Bangalore 560070 INDIA Telephone: +91 80 5514 6587 Facsimile: +91 80 5514 6566 Trend Control Systems Via del Tintoretto, 15 Cassano Magnago (VA) 21012 Milan ITALY Telephone +39 0331 704779 Facsimile +39 0331 704780 Trend Control Systems Ltd Laarderhoogtweg 18 1101 EA Amsterdam Z.O THE NETHERLANDS Telephone +31 (0)20 56 56 395 Facsimilie +31 (0)20 56 56 314 Trend Control Systems Kompleks Perusahaan LTAT Jalan Pengapit 15/19 40000 Shah Alarm Selangor Darul Ehsan MALAYSIA Telephone: +603-55191198 Facsimile: +603-55104259 Trend Control Systems Avenida de la Vega 1 Edificio Veganova Edificio 2°, Planta 1a, Of. 1 28108 Alcobendas Madrid SPAIN Telephone +34 91 657 35 84 Facsimile +34 91 657 35 87 Trend Control Systems c/o Honeywell (Middle East) Suite 307, 3rd Floor, Mini Tower Oud Metha Office Complex PO Box 60832 Dubai UAE Telephone: +971 (4) 324 4240 Facsimile: +971 (4) 324 1343 Trend Control Systems USA 6670, 185th Avenue NE Redmond WA 98052 USA Telephone +1 425 897 3900 Facsimile: +1 425 869 8445 Trend Control Systems Limited P.O.Box 34, Horsham, West Sussex, RH12 2YF, United Kingdom Tel:+44 (0)1403 211888 Fax:(UK)+44 (0)1403 241608 Fax:(Int)+44 (0)1403 210982 www.trend-controls.com SA104615 V4