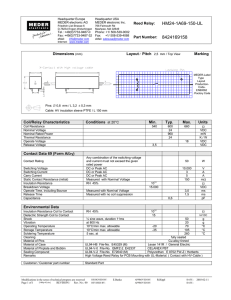

reed switches - STG Germany GmbH

advertisement