High Voltage Reed Relays

advertisement

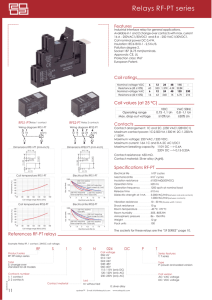

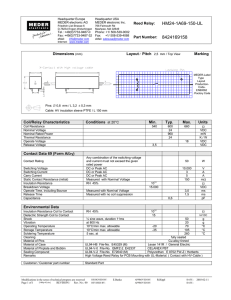

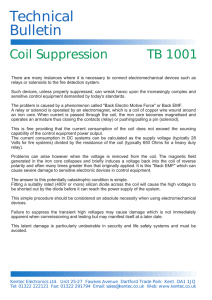

radio frequency, high voltage and custom reed relays radio frequency, high voltage and custom reed relays Crydom Magnetics Limited, an ISO9001 registered production facility based in our aim is to form close partnerships with our customers, working with them at all levels Wimborne, England, has been set up as CrydomÕs centre of excellence for reed switches and relays, liquid level, flow, proximity sensors and transformers. The company has been manufacturing reed switch and coil based products for over thirty years. This site is equipped with a state-of-the-art class 100 clean room facility, supplying high quality reed switches into many of CrydomÕs reed-based products. This ensures that Crydom controls production, delivery and above all else, quality. The companyÕs objective is to achieve profitable growth every year by providing high quality products, backed by innovative engineering and quality driven manufacturing processes. With design, development and manufacturing under one roof, our aim is to form close partnerships with our customers, working with them at all levels from early feasibility studies to delivering production quantities. In order to achieve this, Crydom have established a team of Agents and Distributors world-wide to service customer requirements in local markets. For further details visit the Cr ydom Magnetics website at www.crydom.co.uk. radio frequency, high voltage and custom reed relays radio frequency reed relays (DC to 30MHz) Developed from Crydom’s expertise in high vacuum RF reed switches, the RF Reed Relay range offered today is a result of many years research and development, working with the worldÕs top HF radio system manufacturers. With relay solutions to suit all HF applications requiring voltage isolation up to 9kV and carry currents up to 20Amps (RMS at 30MHz), Crydom has the engineering expertise and experience to meet your exacting requirements. Crydom Magnetics is unique in the industry as being a manufacturer of RF vacuum reed switches and reed relays, not a relay manufacturer primarily packaging other company’s reed switches. As a result, Crydom have full control of the whole RF reed relay product ensuring the best in performance and quality. A wide range of Crydom standard designs are offered with many coil screening options to suit performance requirements and budgets. Two new miniature RF reed relay designs are introduced for the first time. The 4 Series offers a low cost and flexible package in all popular contact and coil configurations and the 5 Series extends the RF performance with the first fully screened miniature coil assembly offering ultra-low RF losses. high voltage reed relays Crydom’s 30 year experience in manufacturing high vacuum reedswitches is prominent with the D and S-Series High Voltage Reed Relays. Capable of withstanding up to 15kV DC, the D-Series High Voltage Reed Relay is suitable for high reliability applications such as cardiac defibrillators, cable, transformer and semiconductor test applications as well as high voltage ISO 9001 registered production facility, high voltage & radio frequency reed relays for over thirty years power supplies. New mounting and electrical connection options are now offered alongside the popular PCB ‘through-hole’ relay. If PCB space is at a premium, the miniature S Series High Voltage Reed Relay is available in a 30mm size package. Capable of isolating up to 5kV DC, the S Series was developed specifically for the high voltage ATE market, where size, performance and reliability are paramount. custom reed relays If the products featured in this catalogue do not quite meet your application requirements, please contact us. Having supplied many hundreds of relay designs to the marketplace over the last 20 years, Crydom are geared towards providing custom RF, high voltage and general purpose reed relays, drawing on standard, readily available components, thus minimising development costs. A Custom Relay Selector is provided on page 26 to help you specify your requirements. Please fill in and return the form and we will be pleased to consider your specifications. Alternatively fill in the on-line form at www.crydom.co.uk 7 Application Notes selector guide radio frequency reed relays Page FRD12000 Series Screened. 8kV, 6A 8-9 FRD13000 Series Fully Screened. 9kV, 6A 10-11 FRD30000 Series Fully Screened. 6.5kV, 20A 12-13 FRS12000 Series Miniature Single RF 14-15 FRS12000 Series Screened. 2kV, 5A 16-17 FRS22012 Fast Latching, Screened. 3.5V, 1.5A 18-19 4 Series Screened. 3.5kV, 3.5A 20-21 6 Series Fully Screened. 3.5kV, 4A 22-23 high voltage reed relays D Series 15kV, 50W 24-25 S Series 15kV, 50W 26-27 dip and sip reed relays Dip Series 28-29 Sip Series 30-31 custom products Custom Relay Selector 32 6 application notes General High Voltage Reed Relays The principal function of a high voltage reed relay is to isolate as high Relays manufactured by Crydom have one of the following contact a voltage as possible. In order to achieve this all Crydom high voltage reed relays employ evacuated reed switches. These switches are arrangements: available with either Tungsten or Rhodium contacts depending upon Form A : Normally open - energise to close contacts the switching characteristics required. As with all reed relays they Form B : Normally closed - energise to open contacts are susceptible to mutual magnetic interference when mounted Latching : Contact is bistable - energise ÒsetÓ coil to close in close proximity to each other. These parameters are discussed in contacts; energise ÒresetÓ coil to open contacts greater detail below. Contact Arrangement Coil Suppression Isolation Voltage It is recommended that all relay coils be suppressed by a diode. This The isolation voltages specified correspond to DC or AC peak. At is essential for latching relays. Operate and release times for the mains frequencies (e.g. 50 or 60Hz) the two may be considered relays are quoted with coil suppression fitted. directly equivalent. Soldering & Cleaning CrydomÕs reed relays are high performance products and the materials and methods of construction are significant factors in achieving performance specifications. The following guidelines should therefore be followed when adopting assembly, soldering and cleaning processes: 1) Soldering. Crydom propose that either low residue fluxes are used in the soldering process (to eliminate the need for cleaning), or that the reed relays are fitted onto the PCB after the cleaning process has taken place. If a solder bath is employed the maximum immersion time recommended is 10 seconds at 250¡C or 3 seconds at 350¡C. Contact Material - Rhodium vs Tungsten Rhodium contacts should be used where very low contact resistance is required or when power switching at <1000V is undertaken. Tungsten contacts perform best when switching high voltages (1-10kV) at very low current. It should be noted that switching power will reduce relay operating life - the factory should be contacted for advice on specific applications. Magnetic Screening Crydom high voltage reed relays are generally supplied with magnetic screening fitted. However, this is not absolute and so, if the minimising of interference is critical, the mounting configuration in figure 1 below is recommended. FRD12000/13000 Series: Electrical connection to the contacts of the FRD12000/13000 Series relay is via the reedswitch leadout. Care must be taken when hand soldering, as physical and thermal shocks can damage the glass to metal seals. A thermal shunt (aluminium clamp) carefully applied to the reedswitch leadout, adjacent to the glass seal will reduce the chances of breakage due to thermal shocks. Alternatively, the relays should be warmed prior to soldering. 2) Cleaning. It is impossible for Crydom to offer blanket approval of methods, due to the many and varied automatic cleaning systems now available to conform to recent legislation. If, after the soldering process, the customer wishes to clean PCBÕs containing Crydom reed relays then the use of post operative cleaners such as IPA or HCFC based solvents with low pressure brush applicators is recommended. Any customer wishing to use Figure 1 : Recommended Mounting for ‘S’ and ‘D’ Series High Voltage Reed Relays an alternative cleaning system should ensure that the fluids and processes are appropriate for application on Crydom reed relays. CrydomÕs devices are not hermetically sealed and as such, exposure to certain fluids can result in the degradation of the relay materials and subsequently a reduction in the electrical performance. Please contact Crydom for further information on the suitability of various cleaning solutions. RF Reed Relays The basic requirements of RF reed relays are to provide minimal RF signal loss and very low contact resistance over a long operating lifetime. This is achieved in Crydom RF reed relays through the use of copper plated reed switches with Rhodium contacts in conjunction with carefully designed coil assemblies. They are intended for use across the frequency range 1-30MHz and typical RF parameters for an RF reed relay across this band (measured in a 50 Ohm system) are shown in figure 2 below: As an illustration of the effect of relay screening on ESR, measurements taken under load at 30MHz (i.e. the worst case frequency) are shown in figure 3 below for fully, partially and unscreened ÒFRDÓ series reed relays. 7 Figure 3: Effects of screening on ESR Magnetic Screening Figure 2 : Typical Parameters of Crydom RF Reed Relays When power is supplied to the coil of a reed relay a magnetic field is produced. When relays are mounted in close proximity this can result Particular to RF reed relays are the effects of RF and magnetic in mutual magnetic interference. However, Crydom RF reed relays screening and these are discussed in more detail below. Also, high are generally not fitted with magnetic screens, as the presence voltage isolation considerations are specific to RF conditions. of ferromagnetic material around the coil can adversely affect ESR and RF coil heating as described above. For applications where RF Screening relays are mounted in close proximity the recommended mounting When an RF current is passed through the switch of a reed relay an configuration is shown in figure 4 below. electromagnetic coupling between reed switch and coil results in some energy being dissipated in the coil. This dissipation manifests itself as an addition to the effective series resistance (ESR) of the relay and, at currents of several amps, heating of the relay coil. RF coil heating is greatest at high frequencies and varies in proportion to the square of the RF current carried in the switch. It is this factor which limits maximum carry current at high frequencies and ambient temperatures. The purpose of RF screening is to reduce these losses and extend relay performance at high frequencies and high ambient temperatures. Crydom RF reed relays are available with no screening, partial screening and full RF screening of the coil, depending upon the requirements of the application. Relays without an RF screen have restricted current carrying capability at high ambient temperatures and frequencies (and a higher associated ESR). However, this suits many typical ATU applications well, as the highest currents occur only at the lower frequency bands (e.g. 2MHz). Relays with partial RF screening have extended current carrying performance at elevated ambient temperatures over unscreened variants. Figure 4 : Mounting Configurations to Minimise Magnetic Interference ( *Note Orientation) Isolation Voltage All withstand voltages are specified and tested at DC. However, high voltage breakdown mechanisms at high frequency differ to those at DC. In general, breakdown across the reed contacts occurs at a Relays with full RF screening represent the ultimate in low loss RF reed higher RF peak voltage than DC. Conversely, breakdown outside the relay design. The ESR and resulting coil heating are significantly lower switch (e.g. switch to coil or screen), caused by surface tracking, can than for other types and this makes them suitable for applications occur more readily at high frequency than at DC. Verification of any in high ÒQÓ circuits where high currents are present over the whole particular voltage and frequency combination can be undertaken by Crydom upon request. frequency range. 8 Up to 8kVDC Isolation 6A Carry Current (up to 30MHz) Excellent RF Performance Ideal for Antenna Tuning Units Form A/B Contact Configuration Customising Facility FRD12000 Series Screened. 8kV, 6A The FRD12000 series was one of Crydom’s first RF reed relay designs. With 8kV (DC) withstand voltage and 6A (30MHz) carry current capability, the FRD12000 series has satisfied countless HF radio system specifications over the years, finding applications in commercial maritime (GMDSS) equipment and military HF radio units worldwide. CONTACT UNITS CONDITIONS Action (form A, B or Latching) FRD12015 FRD12021 FRD12014 A B A FRD12049 B Switching Voltage V DC max 20 20 20 20 Switching Current A DC max 1 1 1 1 Carry Current A RMS max 6 6 6 6 Isolation kV DC max 8 8 8 8 pF coil/screen gnd 0.4 0.6 operations dry switching 109 109 Capacitance Lifetime 0.4 109 50 (15) 0.6 109 Contact Resistance mOhms maximum (typical) 50 (15) 50 (15) Insulation Resistance Ohms minimum (typical) 1010(1013) 1010 (1013) ESR at 4.5A, 30MHz mOhms typical 100 150 100 24 12 12 24 max 15 8 8 14 1010 (1013) 50 (15) 1010 (1013) 150 COIL at 20¡C Nominal Working Voltage VDC Must Operate VDC Must Release VDC min Nominal Resistance ohms +/10% RF Screening 2 2 2 4 1000 380 340 1500 Part - Part - RF Screening Connection pin position 1&4 1&4 Coil Connections pin position 2&3 2&3 2&3 2&3 RELAY Operate time (including bounce) ms 2 3 3 3 Release time ms 1 2 1 2 Isolation contact to all other terminals kV DC max 10 10 10 10 Isolation coil to screen kV DC max 0.5 N/A 0.5 N/A pF contacts open 2.0 2.5 2.0 2.5 Capacitance contact to all other terminals CONTACT US NOW UNITED KINGDOM CRYDOM T +44 (0)1202 897969 F +44 (0)1202 891918 E magnetics@crydom.com W www.crydom.co.uk USA CRYDOM T +1 858 715 7200 F +1 858 715 7280 E sales@crydom.com W www.crydom.com ENVIRONMENTAL Storage temperature range ¡C Operating temperature range ¡C Limited current* -40 to +85 Shock g 11ms 1/2 sine pk 100 Bump g 6ms 1/2 sine pk 40 Vibration g 10- 500Hz 10 *see graphical data -55 to +125 Available with either 12 or 24V coils, in both form A and B contact configurations, this proven design is fully approved to MIL standards of bump, shock and vibration and features one of Crydom’s in-house manufactured, high vacuum reed switches for unsurpassed RF performance and reliability. Offering a cost effective alternative to vacuum ceramic relays, the FRD12000 Series RF Reed Relay has a greater lifetime, imperative for frequency hopping systems. As well as HF radios, the FRD12000 Series has also found applications in electromedical, sonar and test equipment, which require high isolation and inherent reliability. MECHANICAL radio frequency reed relays 9 10 ● New Fully Screened Coil for Low RF Loss ● Up to 9kVDC and 6A at 30MHz ● Drop-in replacement for FRD12000 Series ● Ideal for Antenna Tuning Units ● Customising Facility FRD13000 Series Fully Screened. 9kV, 6A A development of the FRD12000 series, this design has a complete RF screen around the coil assembly, offering a very low loss transmission path. This results in better carry current performance at elevated temperatures. This device also features an anti-corona sleeve shrouding the reed switch contact for improved peak RF voltage isolation. CONTACT UNITS CONDITIONS FRD13503 FRD13504 A B Action (form A, B or Latching) Switching Voltage V DC max 20 20 Switching Current A DC max 1 1 Carry Current A RMS max 6 6 Isolation kV DC max 9 9 Isolation kV RF peak (f=2MHz) 8 8 Capacitance pF coil/screen gnd 0.5 0.5 operations dry switching 109 109 mOhms maximum (typical) 50 (15) 50 (15) Insulation Resistance Ohms minimum (typical) 10 (10 ) 1010 (1013) ESR at 4.5A, 30MHz mOhms typical 30 30 24 24 Lifetime Contact Resistance 10 13 COIL at 20°C Nominal Working Voltage VDC Must Operate VDC max 15 16 Must Release VDC min 3 3 Nominal Resistance Ohms +/10% RF Screening 900 900 Full Full RF Screening Connection pin position 1&8 1&8 Coil Connections pin position 4&5 4 & 5(+) RELAY Operate time (incl. bounce) mS 2 1 Release time mS 1 2 Isolation contact to all other terminals kV DC max 9 9 Isolation coil to screen kV DC max 0.5 0.5 Capacitance contact to all other terminals pF contacts open 1.5 1.5 ENVIRONMENTAL CONTACT US NOW UNITED KINGDOM CRYDOM T +44 (0)1202 897969 F +44 (0)1202 891918 E magnetics@crydom.com W www.crydom.co.uk USA CRYDOM T +1 858 715 7200 F +1 858 715 7280 E sales@crydom.com W www.crydom.com Storage temperature range °C Operating temperature range °C Limited current* -40 to +85 Shock g 11ms 1/2 sine pk 100 Bump g 6ms 1/2 sine pk 40 Vibration g 10- 500Hz 10 *see graphical data -55 to +125 11 MECHANICAL radio frequency reed relays 12 ● Up to 20A Carry Current at 30MHz ● 6.5kV DC Isolation ● Fully Screened Coil for Low RF Loss ● Cost Effective alternative to Vacuum Ceramic Devices ● Suitable for 1 kW HF Transmitters FRD30000 Series Fully Screened. 6.5kV, 20A This flagship relay series offered by Crydom employs multiple high vacuum reed switch contacts ensuring excellent performance and reliability for high voltage and heavy carry current applications. The two basic models, FRD32061 and FRD32062 will carry currents of 12 and 20A respectively at 30MHz and feature silver plated, fully screened coil assemblies for ultra-low RF losses. Typical applications include over the horizon (OTH) HF radar systems and 1kW base station transmitters. CONTACT UNITS CONDITIONS FRD32061 A A Switching Voltage V DC max 20 20 Switching Current A DC max 1 1 Carry Current A RMS at 30MHz max 12 20 Isolation kV DC max 6 6.5 Capacitance (max.) pF coil/screen gnd 2 operations dry switching 10 24V, 1A 10 -10 Action (form A, B or Latching) Lifetime Contact Resistance Insulation Resistance FRD32062 2 109 9 7 107-108 8 mOhms maximum (typical) 50 (10) 50 (10) Ohms minimum (typical) 1010 (1013) 1010 (1013) 24 24 16 16 COIL at 20’C Nominal Working Voltage VDC Must Operate VDC max Must Release VDC min 4 4 Nominal Resistance Ohms +/10% 430 270 Full Full pin number Via Mounting Screws Via Mounting Screws RF Screening RF Screening Connection RELAY Operate time (incl. bounce) mS 5 5 Release time mS 3 3 Isolation contact to all other terminals kV DC max 10 10 Isolation coil to screen kV DC max 0.5 0.5 pF contacts open 6.0 6.0 Capacitance contact to CONTACT US NOW UNITED KINGDOM CRYDOM T +44 (0)1202 897969 F +44 (0)1202 891918 E magnetics@crydom.com W www.crydom.co.uk USA CRYDOM T +1 858 715 7200 F +1 858 715 7280 E sales@crydom.com W www.crydom.com all other terminals ENVIRONMENTAL Storage temperature range °C -55 to +125 Operating temperature range °C -40 to +85 13 MECHANICAL (. " radio frequency reed relays 14 • Up to 3KV Isolation • 3A Carry Current (up to 30MHz) • Excellent RF Characteristics • Designed for HF FRS12000 Series Miniature Single RF Reed Relay Offering outstanding RF performance for their size, the FRS12000 series can withstand RF voltages up to 3kV and carry RF currents of 3A at 30MHz. Utilising plastic and encapsulant materials with exceptional RF and temperature characteristics, the FRS12000 Series RF Reed Relays feature in house manufactured reedswitches, with copper plating and high vacuum much revered in the industry for their high power performance and reliability. • Compact Package on 0.1 " Pin Pitch Designed on a standard 0. 1" pin pitch (some variants available on 0.15"), the FRS12000 series can be fully customised to your requirements, with options for open frame or encapsulated, magnetic screening, coil voltages, and contact configuration. Crydom have also recently developed a 5kV version with contact pins exiting the cover for flying lead connection. Contact Crydom for details. • Full Customising Facility Typical applications for the FRS12000 Series include antenna tuning units, as well as harmonic and co-site filtering over the HF band. Applications Operating temperatur e range ¡C CONT ACT UNITS -40 CONDITIONS FRS12517 to +85 FRD32062 UNITS CONDITIONS FRS12517 A A Switching Voltage V DC max 20 20 Switching Current A DC max 0.5 0.5 3 CONTACT Action (form A, B or Latching) FRS12518 Carry Current A RMS at 30MHz max 3 Isolation kV DC max 0.3 3 Capacitance pF coil/screen gnd 0.2 0.2 pin position 5&8 5&8 Contact Connections COIL at 20°C Nom. Working Voltage VDC 24 12 Working Voltage Range VDC 18-32 8-16.5 Must Operate VDC max 16 7 Must Release VDC min 2 1 Nominal Resistance ohms +/10% 1500 700 Inner/Outer/Full I I&0 RF Screening RF Screening Connection pin position 11 11 Coil Connections pin position 3 &10 3 &10 Single With Cover 1 RELAY Construction CONTACT US NOW Operate time (incl. bounce) mS Single Open Frame 0.6 Release time (incl. bounce) mS 0.4 0.5 Contact to all other terminals kV DC max 0.1 1.5 UNITED KINGDOM CRYDOM T +44 (0)1202 897969 FF +44 (0)1202 891918 E magnetics@crydom.com W www.crydom.co.uk Coil to screen kV DC max 0.1 0.5 pF contacts open 1.5 2.0 Storage temperature range °C USA CRYDOM T +1 858 715 7200 F +1 858 715 7280 E sales@crydom.com W www.crydom.com Operating temperature rang Lifetime °C ops ops g g g Capacitance contact to all other terms ENVIRONMENTAL Shock Bump Vibration -55°C to +125°C dry switching Rated load 11ms 1/2 sine pk 6ms 1/2 sine pk 60-500Hz -40°C to +85°C 109 Consult factory 100 40 20 MECHANICAL 9.80 Max 28.65 Max (1.13“) (0.38“) 15 11.50 (0.45“) SINGLE WITH COVER SINGLE WITH COVER 10.00 (0.39“) 11.50 (0.15“) SINGLE OPEN FRAME 25.40 (1.00“) 20.32 (0.80“) 8.00 Max (0.31“) 1 5 2.54 (0.10“) 17 5.08 (0.20“) 2.54 (0.10“) 2 3 6 7 8 11 12 9 10 12 5 9 4 PIN SIZE (SINGLE) PINS 3, 10 & 11 0.63 SQUARE (0.025“) PINS 5 & 8 0.7 (0.027“) dia. 3 4 6 10 13 14 SINGLE OPEN FRAME 7 11 8 12 PIN SIZE (DOUBLE-EXTENDED FOOT) PINS 3, 11 & 17 0.63 SQUARE (0.025“) PINS 5 & 8 0.7 (0.027“) dia. 15 16 30.60 (1.20“) radio frequency reed relays 16 Up to 3KV Isolation 5A Carry Current (up to 30MHz) Excellent RF Characteristics Designed for HF Applications Compact Package on 0.1" Pin Pitch Full Customising Facility FRS12000 Series Screened. 2kV, 5A Crydom’s FRS12000 series feature two Crydom reed switches connected in parallel for higher current capability. Available in both open frame and covered construction (depending upon voltage isolation requirements), the FRS12000 series utilises materials with exceptional RF and temperature performance characteristics. In addition the coils are partially screened offering extended RF performance over the HF band. CONTACT UNITS CONDITIONS FRS12030 Action (form A, B or Latching) FRS12208 A A Switching Voltage V DC max 20 20 Switching Current A DC max 0.5 0.5 Carry Current A RMS 5 5 Isolation kV DC max 0.5 2 Capacitance pF coil/screen gnd 0.3 0.3 pin position 5&8 5 &12 operations dry switching 109 109 Contact Resistance mOhms maximum (typical) Insulation Resistance Ohms minimum (typical) ESR at 4.5A, 30MHz mOhms Contact Connections Lifetime typical 80 (30) 80 (30) 10 (10 ) 10 (1013) 10 13 10 90 90 24 24 COIL at 20¡C Nominal Working Voltage VDC Must Operate VDC max 15 15 Must Release VDC min 4 4 ohms +/10% 1150 1000 Part Part Nominal Resistance RF Screening RF Screening Connection pin position 17 15 Coil Connections pin position 3 & 11 4 & 13 Open Frame Covered RELAY Construction Operate time (incl. bounce) mS 2 2 Release time (incl. bounce) mS 1 1 Contact to all CONTACT US NOW UNITED KINGDOM CRYDOM T +44 (0)1202 897969 FF +44 (0)1202 891918 E magnetics@crydom.com W www.crydom.co.uk USA CRYDOM T +1 858 715 7200 F +1 858 715 7280 E sales@crydom.com W www.crydom.com other terminals kV DC max 0.5 2 Coil to screen kV DC max 0.5 0.5 Capacitance contact to all other terminals pF contacts open 2.5 3.0 ENVIONMENTAL Storage temperature range ¡C Operating temperature range ¡C Limited current* -40 to +85 Shock g 11ms 1/2 sine pk 100 *see graphical data -55 to +125 Many other variants in the FRS12000 family are available with different coil and contact configurations, as well as a number of pin footprints for drop-in replacements. 17 MECHANICAL radio frequency reed relays 18 Bistable Latching Relay 0.5 ms Coil Pulse length 3.5kV DC Isolation 1.5A Carry Current RF & Magnetic Screening Approved to MIL standards for Bump, Shock and Vibration FRS22012 Fast Latching, Screened. 3.5kV, 1.5A The FRS22012 latching RF reed relay designed for manpack portable HF radio systems where power resources are limited. The relay is capable of withstanding 3.5kV between contacts and carrying 1.5A current at 30MHz. The device features RF and magnetic screening, allowing close mounting, and a unique coil design enabling switching with coil pulse lengths down to 0.5ms, further reducing power supply demands. The FRS22012 is an ideal choice for applications where board space is at a premium but where RF performance is demanded. CONTACT UNITS CONDITIONS Action (form A, B or Latching) Switching Voltage FRS22012 Latching V DC max 20 Switching Current A DC max 0.5 Carry Current A RMS at 30MHz 1.5 Isolation kV DC max 3.5 Capacitance pF coil/screen gnd 0.2 pin number 3&4 operations dry switching 109 Contact Connections Lifetime Contact Resistance mOhms Insulation Resistance Ohms ESR at 1.5A, 30MHz mOhms maximum (typical) minimum (typical) typical 80 (30) 10 10 (1013) 400 COIL at 20¡C Nom. Working Voltage VDC 12 Min. pulse length ms Minimum 0.5 Operate time ms diode fitted 0.5 ms diode fitted 0.5 ohms +/10% 500 Release time Nominal Resistance RF Screening Part RF Screening Connection Coil Connections pin number Set pin number Reset 7 1 & 2(+) 5 & 6(+) RELAY CONTACT US NOW UNITED KINGDOM CRYDOM T +44 (0)1202 897969 FF +44 (0)1202 891918 E magnetics@crydom.com W www.crydom.co.uk USA CRYDOM T +1 858 715 7200 F +1 858 715 7280 E sales@crydom.com W www.crydom.com Isolation contact to coil/screen kV DC max 4 Capacitance contact to all other terminals pF contacts open 2.5 Capacitance contact to all other terminals pF contacts closed 4.0 ENVIRONMENTAL Operating temperature range ¡C -40 to +85 Storage temperature range ¡C -40 to +125 19 MECHANICAL 1 7 radio frequency reed relays 20 ● Low Cost ● Form A, B or Latching Contacts ● Excellent RF Characteristics ● High Isolation Voltage ● Excellent Lifetime Characteristics ● Reed switch connections via PCB ‘through-hole’ or flying lead 4 Series Screened. 3.5kV, 3.5A Developed for RF applications (in the band 1-30MHz) the 4 series reed relay offers a highly fexible, low cost package available with form A (NO),form B (NC) and latching (bistable) contact configurations as well as switch connections for either PCB or flying lead mounting. The use of Crydom’s vacuum reed switches with rhodium contacts means that high isolation voltages, low contact resistance and long operating lifetimes are achieved. Additionally, RF screening is available to further enhance RF performance for more demanding applications. CONTACT UNITS CONDITIONS kV DC or AC peak Max. carry current A DC or AC rms* Max. switching power W Max. switching voltage V DC or AC peak 20 20 20 Max. switching current A DC or AC peak 0.5 0.5 0.5 Contact Material Isolation across contacts Capacitance across contacts FORM A FORM B LATCHING Rhodium Rhodium Rhodium 3 3 3.5 3.5 3.5 1.5 10 10 10 pF coil/screen grounded <0.1 <0.1 <0.1 Lifetime operations dry switching 109 109 109 Lifetime operations 10W switching 108 108 108 mOhms maximum (typical) 80 (30) 80 (30) 80 (30) Ohms minimum (typical) 10 (10 ) 10 (10 ) 1010 (1013) ESR at 30MHz (no screen) mOhms typical 95 @ 3A rms 95 @ 3A rms 200 @ 1.5A rms ESR at 30MHz (part screen) mOhms typical 180 @ 1.5A rms Contact Resistance Insulation Resistance 10 COIL AT 20°C 13 10 13 80 @ 3A rms 80 @ 3A rms 5V 12V 24V 5V 12V 24V 5V 12V Must Operate V DC 3.5 8 15 3.5 8 15 3 7 Must Release V DC 1 2 4 1 2 4 N/A N/A Min Pulse Length ms N/A N/A N/A N/A N/A N/A 2.0 2.0 Operate Time ms 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 0.5 0.5 0.5 0.5 0.5 0.5 1.0 1.0 70 380 1500 65 350 1200 100 500 Release Time Resistance ms diode fitted Ohms RELAY Isolation contact to coil kV DC or AC peak 3 3 3.5 pF Contacts open <1.0 <1.0 <1.0 pF Contacts closed <1.5 <1.5 <1.5 Operating temperature range °C Limited Current* -40 to +100 -40 to +100 -40 to +100 Storage temperature range °C -40 to +125 -40 to +125 -40 to +125 Capacitance contact to all other terminals Capacitance contact to all other terminals CONTACT US NOW UNITED KINGDOM CRYDOM T +44 (0)1202 897969 F +44 (0)1202 891918 E magnetics@crydom.com W www.crydom.co.uk USA CRYDOM T +1 858 715 7200 F +1 858 715 7280 E sales@crydom.com W www.crydom.com ENVIRONMENTAL *see graphical data PART NUMBERING SYSTEM Reedswitch Size - S Contact Form A: Form A, B: Form B, L: Latching Contact Material R: Rhodium Relay Series Number Coil Voltage 5: 5V, 12: 12V, 24: 24V Screening S: Screened, N: Unscreened Contact Pin Orientation D: PCB U: Flying Lead S A R 4 05 S U ° MECHANICAL radio frequency reed relays 21 22 ! Robust shell construction ! Versatile contact pin configuration ! Fully screened miniature relay ! Excellent RF Characteristics ! Carry current up to 4 amps (RMS) @ 30 MHz 6 Series Miniature, Fully Screened, Open Frame. 3.5kV, 4A Developed closely with RF design Engineers in the radio communications industry, this new fully screened reed relay series, offers low RF loss and high current carrying capability. The robust shell construction enables the customer to specify contact pin configuration. The relay coil section is totally enclosed in a copper screen, resulting in lower self-heating and RF loss. Together with Crydom's vacuum reed switches, benefits include higher carry currents for a given frequency and ambient temperature. Peak RF isolation voltages up to 3.5kV are achieved by clever coil design maximising pin spacing. Switch connections are offered for either PCB or Flying Lead mounting Contact Contact Material Isolation across contacts Units Conditions Form A Form B Latching kV DC or AC peak Rhodium 3 Rhodium 3 Rhodium 3.5 DC or AC rms* Max. carry current A Max. switching power W Max. switching voltage V Max. switching current Capacitance across contacts 4 4 1.5 10 10 10 DC or AC peak 20 20 20 A DC or AC peak 0.5 0.5 0.5 pF coil/screen grounded <0.1 <0.1 <0.1 Lifetime operations dry switching 109 109 109 Lifetime operations 10W switching 108 108 108 mOhms maximum (typical) 80 (30) Contact Resistance Insulation Resistance Ohms 10 minimum (typical) 80 (30) 13 10 10 (10 ) COIL 80 (30) 13 1010 (1013) 10 (10 ) 5V 12V 24V 5V 12V 24V 5V 12V Must Operate V DC, 20°C 3.5 8 15 3.5 8 15 N/A N/A Must Release V DC, 20°C 1 2 4 1 2 4 3 7 Min Pulse Length ms N/A N/A N/A N/A N/A N/A 2.0 2.0 Operate Time ms 1.0 1.0 1.0 1.0 1.0 1.0 1.0 1.0 0.5 0.5 0.5 0.5 65 350 1200 Release Time ms diode fitted 0.5 0.5 Ohms 20°C 70 380 1500 kV DC or AC peak Operating temperature range °C Limited Current* Storage temperature range °C Resistance 1.0 1.0 100 500 CONSTRUCTION Isolation contact to coil CONTACT US NOW UNITED KINGDOM CRYDOM T +44 (0)1202 897969 F +44 (0)1202 891918 E magnetics@crydom.com W www.crydom.co.uk USA CRYDOM T +1 858 715 7200 F +1 858 715 7280 E sales@crydom.com W www.crydom.com 3 3 3.5 ENVIRONMENTAL -40 to +100 -40 to +100 -40 to +100 -40 to +125 -40 to +125 -40 to +125 5 S *see graphical data PART NUMBERING SYSTEM Reedswitch Size - S Contact Form A: Form A, B: Form B, L: Latching Contact Material R: Rhodium Relay Series Number Coil Voltage 5: 5V, 12: 12V, 24: 24V Screening S: Fully Screened Contact Pin Orientation D: PCB U: Flying Lead S A R 05 U SAR6xxSx / SBR6xxSx SLR6xxSx Max Current vs. Frequency Max Current vs Frequency 4.5 2 4 1.5 3 Current (A) Current (A) 3.5 2.5 2 65°C 1.5 up to 100°C 0.5 85°C 1 1 100°C 0.5 0 0 0 0 5 10 15 20 Frequency (MHz) 25 30 5 10 15 20 25 30 Frequency (MHz) MECHANICAL 15.0 max. (0.59”) 29.5 max. (1.16”) 10.0 max. (0.39”) 29.5 max. (1.16”) 15.0 max. (0.59”) Circuit diagram, Form A Circuit diagram, Form B (+) (all views from above) Pins require 1mm diameter holes Circuit diagram, Latching Set - - 5.08 (0.2”) 5.08 (0.2”) 10.16 (0.4”) 25.4 (1.0”) + Reset radio frequency reed relays 23 24 15kV Isolation Low Contact Resistance High Power Switching PCB or Panel Mount Flying Lead & Solder Turret Options Excellent AC Characteristics D Series 15kV, 50W Capable of withstanding voltages up to 15kV, the D-series High Voltage Reed Relay is suitable for high reliability applications such as cardiac defibrillators, test equipment and high voltage power supplies. Two contact materials are available for low contact resistance or power switching applications. Standard coil voltages of 5, 12 and 24 volts are available with form A and B contact configurations. The D-series, range is now available with a new panel mounting option via nylon studs, as well as a choice of electrical connection methods (solder turret tag and flying lead) complementing the standard PCB ‘through-hole’ device. Choose the most appropriate device for your application using the part numbering system below. CONTACT UNITS CONDITIONS Contact material Isolation across contacts kV 10KV FORM A 10KV FORM B 15KV FORM A Rhodium Tungsten Rhodium Tungsten Tungsten DC or AC peak 10 10 5 5 15 Max. switching power W 50 50 50 50 50 Max. switching voltage V DC or AC peak 1000 7000 1000 7000 10000 Max. switching current A DC or AC peak 3 2 3 2 2 pF coil/screen grounded Capacitance across <0.2 <0.2 <0.2 <0.2 Lifetime operations contacts dry switching 10 9 10 9 10 9 10 9 10 9 Lifetime operations 50W switching 10 6 6 6 6 10 8 Contact resistance mOhms Insulation Resistance Ohms 10 10 10 maximum (typical) 50 (15) 250 (100) 50 (15) 250 (100) 250 (100) minimum (typical) 10 (10 ) 10 (10 ) 10 (10 ) 10 (10 ) 1010 (10 13) 5V 12V 24V 5V 12V 24V 3.7 3.7 COIL AT 20¡C Must Operate <0.2 10 13 5V V DC 10 13 12V 24V 3.7 9 20 10 13 10 9 20 V DC 0.5 1.25 4 ms diode fitted 3.0 3.0 3.0 2.0 2.0 2.0 3.0 3.0 3.0 ms diode fitted 2.0 2.0 2.0 3.0 3.0 3.0 2.0 2.0 2.0 28 150 780 38 240 925 16 Ohms 0.5 1.25 20 Operate Time Resistance 4 9 Must Release Release Time 0.5 1.25 13 4 95 350 RELAY Isolation contact to coil kV DC or AC peak Insulation resistance contact to all other terminals Ohms minimum (typical) 17 10 10 (10 13 ) 17 17 10 10 (10 13 ) 10 10 (10 13 ) ENVIRONMENTAL CONTACT US NOW UNITED KINGDOM CRYDOM T +44 (0)1202 897969 F +44 (0)1202 891918 E magnetics@crydom.com W www.crydom.co.uk USA CRYDOM T +1 858 715 7200 F +1 858 715 7280 E sales@crydom.com W www.crydom.com Operating temperature range PART NUMBERING SYSTEM Reedswitch Size - D Contact Form A: Form A, B: Form B Contact Material R: Rhodium T: Tungsten Moulding Ref. No. Coil Voltage 05: 5V, 12: 12V, 24: 24V ¡C - D A T 20 to +70 7 24 15 -20 to +70 -20 to +70 F Mounting Style: No suffix standard PCB mount F: Flying lead contact terminals T: Turret contact terminals P: Panel mount via nylon studs, turret contact/coil terminals Isolation Between Contacts 10: 10kV 15: 15kV (DAT only) MECHANICAL 25 + T 0.63mm square pin 0.63mm square pin T71210P) 0.63mm square pin high voltage reed relays 26 ● Compact Footprint ● Designed Specifically for High Voltage ● Rhodium Contacts for Low Resistance ● 3 or 5kV Isolation between Contacts ● Excellent Lifetime Characteristics S Series 5kV, 10W Developed for the high voltage ATE market, where PCB space is at a premium, the S Series High Voltage Reed Relay offers a 3 or 5kV isolation performance in a 30mm size package. With low contact resistance, the S Series High Voltage Reed Relay will satisfy the many high voltage applications at DC and low frequency, where performance and reliability are paramount. CONTACT UNITS CONDITIONS 3KV FORM A 5KV FORM A Rhodium Rhodium Contact material Isolation across contacts kV DC or AC peak 3 5 Max. carry current A DC or AC rms (60Hz) 2 2 Max. switching power W 10 10 Max. switching voltage V 20 20 DC or AC peak Max. switching current A DC or AC peak 0.5 0.5 Capacitance across contacts pF coil/screen grounded <0.1 <0.1 Lifetime operations dry switching 109 109 Lifetime operations 10W switching 108 108 mOhms maximum (typical) 80 (30) 80 (30) Ohms minimum (typical) 1010 (1013) 1010 (1013) Contact resistance Insulation Resistance COIL AT 20°C 5V 12V 24V 5V 12V 24V Must Operate V DC 3.7 9 20 3.7 9 20 Must Release V DC 0.5 1.25 3 0.5 1.25 3 Operate Time ms diode fitted 1.0 1.0 1.0 1.0 1.0 1.0 Release Time ms diode fitted 0.5 0.5 0.5 0.5 0.5 0.5 140 600 1000 140 600 1000 Resistance Ohms CONSTRUCTION Isolation contact to coil to all other terminals kV DC or AC peak 5 Ohms minimum (typical) 10 (10 ) 10 (1013) -20 to +70 -20 to +70 10 5 13 10 ENVIRONMENTAL Operating temperature range °C CONTACT US NOW UNITED KINGDOM CRYDOM T +44 (0)1202 897969 F +44 (0)1202 891918 E magnetics@crydom.com W www.crydom.co.uk USA CRYDOM T +1 858 715 7200 F +1 858 715 7280 E sales@crydom.com W www.crydom.com PART NUMBERING SYSTEM Reedswitch Size - S Contact Form A: Form A Contact Material R: Rhodium Moulding Ref. No. Coil Voltage 05: 5V, 12: 12V, 24: 24V Isolation Between Contacts 03: 3kV 05: 5kV S A R 9 12 05 27 MECHANICAL high voltage reed relays 28 • Low Profile Package DIP Series Reed Relay • Standard and Non Standard Pin Configurations available Moulded Dual-in Line package reed relays designed for ATE, telecom, alarm and other general purpose systems. Coils with optional diodes and/or screens and mercury wetted contacts are available. Please contacts sales office for details. • IC-pin compatible CONTACT FORM • Interface Directly with TTL-logic COIL • Up to 4.25 KVDC Insulation available in 02L configuration CONTACT DIAGRAM NOMINAL COIL MUST OPERATE MUST RELEASE MAXIMUM MAXIMUM RATED TYPE VOLTAGE RESISTANCE VOLTAGE VOLTAGE VOLTAGE VOLTAGE POWER +/-10% MAXIMUM MINIMUM 20°C 60°C 1A 01L/D/A 02 02L/D Ohm voc VDC VDC VDC mw 5 500 3.5 0.75 23.0 14.0 50 12 1000 8.4 1.8 33.0 20.0 144 2000 10.5 2.2 48.0 30.0 113 24 2000 16.8 3.6 48.0 30.0 288 5 1000 3.5 0.75 33.0 20.0 25 High ohms type 12 2000 8.4 1.8 48.0 30.0 72 500 3.5 0.75 6.5 6.5 50 Flat package 01 02 Flat package VDC 15 05 1A • Variants UL approved 01 01L H 01 03L 1B 02 03D 05 High package 2A 01 04L 02 04D 05 High package Flat package 1C 5 12 1000 8.4 1.8 15.6 15.6 144 15 2000 10.5 2.2 19.5 19.5 113 24 2000 16.8 3.6 31.2 30.0 288 5 200 3.5 0.75 14.0 9.0 125 12 500 8.4 1.8 23.0 14.0 288 15 2000 10.5 2.2 48.0 30.0 113 24 2000 16.8 3.6 48.0 30.0 288 5 200 3.5 0.75 14.0 9.0 125 12 500 8.4 1.8 23.0 14.0 288 05L 20 High package 05D 15 2000 10.5 2.2 48.0 30.0 113 24 2000 16.8 3.6 48.0 30.0 288 Please note that the types with contact 05 form 1A and 1B have a reduced coil resistance of 2OOohms and 120ohms respectively. MECHANICAL Flat package High package 19.30 max (0.76") CONTACT US NOW UNITED KINGDOM CRYDOM T +44 (0)1202 897969 F +44 (0)1202 891918 E magnetics@crydom.com W www.crydom.co.uk USA CRYDOM T +1 858 715 7200 F +1 858 715 7280 E sales@crydom.com W www.crydom.com 2.54 (0.10") 15.24 (0.60") 7.00 max (0.27") 3.20 (0.126") 0.50 (0.02") 7.50 max (0.30") 19.30 max (0.76") 2.80 (0.11“) 5.70 (0.22“) 15° 0.25 x 0.50 (0.01") (0.02") (0.08“) 2 3.20 (0.126“) 7.62 (0.30") 2.54 (0.10") 15.24 (0.60") 7.62 (0.30") 6.40 max (0.25“) 5.10 max (0.20") 15° 0.25 x 0.50 (0.01") (0.02") PART NUMBERING SYSTEM - DIP SERIES D Series Dual in line package (DIP) Coil Voltage 5V, 12V, 24V Contact Form 1A, 1B, 2A, 1C Contact Type 01, 02, 05, 20 12 - 1A 01 01 - L H High Resistance Version Options L : without diode D : Diode on pins 2 & 6 A : Diode on pins 6 & 9 Configuration 01, 02, 03, 04, 05 01, 02, 03, 04, 05 CONTACT CONDITIONS UNITS A/dry A/dry Contact Form 01 02 A/d ry 05 20 C/d ry Rated Power max W 10 15 10 3 Switching Voltage max VDC 200 200 500 175 Switching Current max Carry Current A 0,5 1,0 0,5 0,25 A 1,0 1,25 1,0 1,2 Contact resistance max 0Q 150 150 200 150 Breakdown Voltage (contact/contact) min VDC 250 250 1'500 200 Operate time incl. bounce MS 0,5 0,5 0,5 0,7 Release time MS 0,1 0,1 0,1 1,0 RELAY CONDITIONS UNITS Shock at 11ms max G Vibration at 50-500Hz max 35 920 OperatingTemperature oc 20+70 Storage Temperature oc 35 +95 1,5 DC (4,25 DC /3,0 AC diagram 02L) Isolation coil/contact min kV Insulation coil/contact min GQ 100 Life expectancy Dependent upon load, consult sales office Solder time/temperature max 10 sec,/260'C Washability Fully Sealed Data at 140% of the nominal voltage and 20'C. Other switches against inquiry. CONFIGURATION 01 02 14 8 1 7 03 8 14 6 2 04 14 1 14 8 1 7 05 8 14 8 1 7 7 high voltage reed relays 29 30 • Designed to EN60950 • High Sensitivity Coils up to 2,000 Ohms @ 12V • Line Sense Relay Option available • Magnetic and Diode option available • Insulation Voltage up to 4.25kVdc • Variants UL approved SIP Series Reed Relays The SIP series reed relays are available in both voltage and current driven (line sense) versions. The SIP range requires only half the PCB area of the DIP series. The construction of the SIP series corresponds to the creepage and clearance requirements of the new European Standards; EN60950. CONTACT CONTACT DIAGRAM NOMINAL COIL MUST OPERATE MUST RELEASE MAXIMUM MAXIMUM RATED FORM TYPE VOLTAGE RESISTANCE VOLTAGE VOLTAGE VOLTAGE VOLTAGE POWER +/-10% COIL 1A VDC 02 05 1A 02 Ohm MAXIMUM VDC VDC MINIMUM VDC 20°C 60°C VDC mW 01 5 500 3.5 0.75 23 14 50 L/M/D/Q 02 L/M/D/Q 03L 12 1000 8.4 1.8 33 20 144 15 2000 10.5 2.2 47 29 112 24 2000 16.8 3.6 47 29 288 01L M 5H 1000 3.5 0.75 33 20 25 02LM 12H 2000 8.4 1.8 47 29 72 Please note that the 5V types with contact 05 have a reduced coil resistance of 2OO. CONTACT CONTACT DIAGRAM NOMINAL COIL MUST OPERATE MUST RELEASE MAXIMUM MAXIMUM RATED FORM TYPE VOLTAGE RESISTANCE VOLTAGE VOLTAGE VOLTAGE VOLTAGE POWER +/-10% Line Sense MAXIMUM MINIMUM 20°C 60°C Ohm VDC VDC VDC VDC mH 15 15 5 240 149 3,45 Relay 1A 11 01M Other coils on request CONFIGURATION 01 02 03 PART NUMBERING SYSTEM-SIP SERIES S 12 - 1A 02 01 - L H CONTACT US NOW UNITED KINGDOM CRYDOM T +44 (0)1202 897969 F +44 (0)1202 891918 E magnetics@crydom.com W www.crydom.co.uk USA CRYDOM T +1 858 715 7200 F +1 858 715 7280 E sales@crydom.com W www.crydom.com Series Dual in line package (SIP) Coil Voltage 5V, 12V, 24V Contact Form 1A Contact Type 02, 05, 11 High Resistance Version Options L : without diode M : with magnetic screen 01D : Diode on pins 3 & 5, no magnetic screen 01Q : diode pins 3 & 5, with magnetic screen 02D : diode pins 2 & 6, no magnetic screen 02Q : diode pins 2 & 6, with magnetic screen Configuration 01, 02, 03 CONTACT CONDITIONS UNITS Contact Form 02 05 11 A/dry A/d ry A/d ry Rated Power max W 15 10 5 Switching Voltage max VDC 200 500 90 Switching Current max Carry Current A 1,0 0,5 0,5 A 1,25 1,0 1,0 31 Contact resistance max mohms 150 200 200 Breakdown Voltage (contact/contact) min VDC 250 1'500 100 Operate time incl. bounce ms 0,5 0,5 0,5 Release time ms 0,1 0,1 0,1 RELAY CONDITIONS UNITS Shock at 11ms max g Vibration at 50-500Hz max g 20 OperatingTemperature °C -20/+70 Storage Temperature °C -35/+95 1,5 DC (4,25 DC /3,0 AC at diagram 03L) 35 Isolation coil/contact min kV Insulation coil/contact min Gohms 100 Life expectancy Dependent upon load, consult sales office Solder time/temperature max 10 sec,/260°C Washability Fully Sealed Data at 140% of the nominal voltage and 20°C. Other switches against inquiry. MECHANICAL 19.80* max (0.78") 15.24 (0.60") 7.80** max (0.31") 0.60 max (0.023") 5.08 (0.20") 5.08 max (0.20") 0.25 (0.10") 3.5±0.20 (0.14")(0.008") 19.60* max (0.78") 2.54 (0.10") 15.24 (0.60") 3.20 min (0.126") 4.60 max (0.18") 0.60 max (0.023") 5.00**** max (0.196“) 3.5±0.20 (0.14") (0.008") 0.25 (0.10") Dimension with *(20.50 max)** (8.30 max) ***(6.80 max) **** (6.00 max) Magnetic screen(0.807") (0.33") (0.27") (0.24") high voltage reed relays 32 Please photocopy, complete and return this form and Crydom will review your custom requirements. Alternatively, fill in the on-line form at www.crydom.co.uk Custom Relay Selector Contact Specifications 1 2 Contact Form normally open closed Number of Poles 3 4 Other latching Isolating Voltage Across contacts (kV) _____________________ DC/peak AC/RMS* Contact to Contact (kV - for multiple contact relays) _______________________ DC/peak AC/RMS* Contact to Coil/Screen (kV) _________________ DC/peak AC/RMS* Switched Power Switching Voltage (kV) ____________________ Switching Current (A) _____________________ Total Switching Power (W) _________________ Contact Carrying Current (A) ________________ If not resistive please describe ________________ Signal Type DC/AC ........... Hz RF parameters: (dB or m ) Insertion loss/ESR ____________ isolation (dB) __________ return loss (dB) ________________ Contact resistance (m ) __________________________________ Coil Drive Specifications Nominal Coil Voltage (V) 12 5 24 Operating Voltage Range (V - if nominal voltage varies) ____________________________________ Maximum Coil Drive Current (A) ____________________________ General Magnetic Shielding? Electrostatic Shielding? Physical dimensions (mm) Mounting method Temperature Range ( ¡ C) L__________ W__________ H Panel Mount PCB Flying Leads ___________________ Shock and Vibration approvals ___________ Any other requirements? _____________________________________________________________ Briefly describe the application: _______________________________________________________ _________________________________________________________________________________ Customer Name: ______________________________ Position: _________________________________ Company Address: ______________________________________________________________________ ______________________________________________________________________________________ Tel. No. _________________________ Fax No. _______________________ Date: _________________ Quantity required: ___________ Purchase date: ____________ Purchasing contact: _________________ *Delete as applicable Circuit Diagram/Contact Form/pin layout CONTACT US NOW UNITED KINGDOM CRYDOM T +44 (0)1202 897969 F +44 (0)1202 891918 E magnetics@crydom.com W www.crydom.co.uk USA CRYDOM T +1 858 715 7200 F +1 858 715 7280 E sales@crydom.com W www.crydom.com Please return to your local representative or fax directly to +44 (0) 1202 891918 our aim is to form close partnerships with our customers, working with them at all levels Crydom Magnetics’ Product Portfolio Liquid Level Sensors Liquid Flow Sensors Fluid Control Reed Switches RF Reed Relays High Voltage Reed Relays UNITED KINGDOM CRYDOM MAGNETICS LTD 7 Cobham Road Ferndown Industrial Estate Wimborne Dorset England BH21 7PE Phone: +44 (0) 1202 897969 Fax: +44 (0) 1202 891918 email: magnetics@crydom.com Website:www.crydom.co.uk USA CRYDOM CORPORATION 9525 Chesapeake Drive San Diego CA 92123 USA Phone: +1 858 715 7200 Fax: +1 858 715 7280 e-mail: sales@crydom.com Website: www.crydom.com General Purpose Reed Relays DIP/SIP Reed Relays Transformers lnductors © 2000 CRYDOM Every effort has been made to ensure that the information in this brochure is accurate. Crydom is not responsible for printing/clerical errors or omissions. Specifications subject to change without prior notice. Printed in UK - Design by Visual Assets. VA7670. 10.00 RR2000UK