VDSL Over POTS - Rapid Electronics

advertisement

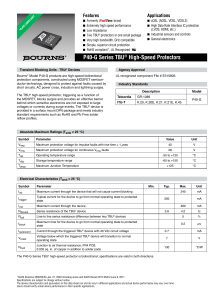

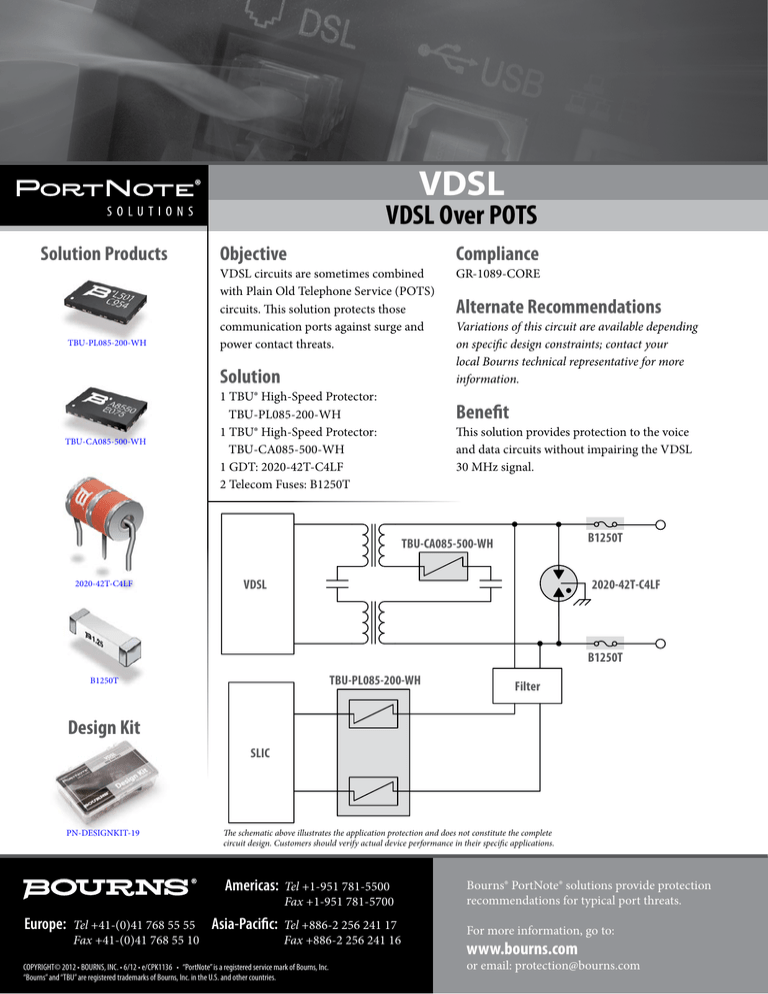

VDSL VDSL Over POTS Solution Products TBU-PL085-200-WH Objective Compliance VDSL circuits are sometimes combined with Plain Old Telephone Service (POTS) circuits. This solution protects those communication ports against surge and power contact threats. GR-1089-CORE Solution TBU-CA085-500-WH 1 TBU® High-Speed Protector: TBU-PL085-200-WH 1 TBU® High-Speed Protector: TBU-CA085-500-WH 1 GDT: 2020-42T-C4LF 2 Telecom Fuses: B1250T Alternate Recommendations Variations of this circuit are available depending on specific design constraints; contact your local Bourns technical representative for more information. Benefit This solution provides protection to the voice and data circuits without impairing the VDSL 30 MHz signal. B1250T TBU-CA085-500-WH VDSL 2020-42T-C4LF 2020-42T-C4LF B1250T TBU-PL085-200-WH B1250T Filter Design Kit SLIC PN-DESIGNKIT-19 The schematic above illustrates the application protection and does not constitute the complete circuit design. Customers should verify actual device performance in their specific applications. Americas: Tel +1-951 781-5500 Fax +1-951 781-5700 Europe: Tel +41-(0)41 768 55 55 Asia-Pacific: Tel +886-2 256 241 17 Fax +41-(0)41 768 55 10 Fax +886-2 256 241 16 COPYRIGHT© 2012 • BOURNS, INC. • 6/12 • e/CPK1136 • “PortNote” is a registered service mark of Bourns, Inc. “Bourns” and “TBU” are registered trademarks of Bourns, Inc. in the U.S. and other countries. Bourns® PortNote® solutions provide protection recommendations for typical port threats. For more information, go to: www.bourns.com or email: protection@bourns.com PL IA NT Features *R oH S CO M ■ ■ ■ ■ ■ For use in telecommunication circuit applications requiring low current protection with high surge tolerance Overcurrent protection to Telcordia GR-1089-CORE Issue 4 (B1250T only) & UL 1950/60950 Bourns® TISP® products are recommended for the overvoltage section of the circuit Agency recognition: File: E198545 RoHS compliant* Telefuse™ SMD Power Cross Protection Fuse Electrical Characteristics Model Number Ampere Rating (A) Voltage Rating (VRMS) B0500T B1250T B2000T 0.500 1.25 2.0 600 600 600 Temperature Range ........-55 ºC to +125 ºC Environmental Characteristics Thermal Shock ......................MIL-STD-202, Method 107, Test Condition B (-65 °C to +125 °C) Shock ..........MIL-STD-202, Method 213, Test Condition I (100 Gs peak for 6 milliseconds) Vibration ........MIL-STD-202, Method 201 (10-55 Hz, 0.06 inch total excursion) Salt Spray ....MIL-STD-202, Method 101, Test Condition B (48 hrs.) Insulation Resistance ........MIL-STD-202, Method 302, Test Condition A (after opening) 10,000 ohms minimum Solderability ..MIL-STD-202, Method 208 Resistance to Solder Heat ..................MIL-STD-202, Method 210, Test Condition J (235 °C, 30 sec.) Physical Characteristics Body Material ..........Ceramic with tin plated brass caps Solder ............................................Lead free Solder Reflow Temperature ..............................240 °C for 30 seconds 260 °C for 3 seconds Packaging ..............2,000 pcs. per 13 ” reel Typical Cold Resistance (ohms) 0.350 0.075 0.056 Volt-drop @ 100 % In (Volts) max. 0.23 0.18 0.16 Melting I2T < 10 msec (A2 sec.) Melting I2T @ 10 In (A2 sec.) 2 14 33 2.3 17 37 Maximum Power Dissipation (W) 0.20 0.40 0.52 Lightning Surge Withstand Capabilities Max. Rise/ Min. Decay (µs) 10/1000 10/360 2/10 10/360 2/10 8/20 Repetitions Total 50 50 20 10 2 2 Minimum Peak Each Polarity Voltage (V) 25 1000 25 1000 10 2500 5 1000 1 5000 1 5000 Minimum Withstand Peak Current (A) B0500T 25 30 120 30 120 75 B1250T 100 125 500 125 500 300 B2000T 120 150 600 150 600 350 Test Methods per GR-1089/TIA-968-A (FCC Pt. 68) AC Power Fault Tests Short GR-1089 Circuit 1st Level Voltage Current Test (VRMS) (A) 1 2 3 4 6 7 8 9 50 100 200,400, 600 1000 600 440 600 1000 0.33 0.17 Fuse Characteristics Applications Duration 1 15 min. 1 15 min. 1 60 1 sec. 1 0.5 2.2 3 5 60 1 5 5 5 1 sec. 30 sec. 2 sec. 1.1 sec. 0.4 sec. B0500T B1250T B2000T Parts pass all 1st Level tests Will open Will open Will open AC Current Limiting Protector Tests/Fusing Coordination Tests Maximum Time for Fuse to Open (Seconds) Asia-Pacific: TEL +886- (0)2 25624117 FAX +886- (0)2 25624116 Europe: TEL +41-41 7685555 FAX +41-41 7685510 The Americas: TEL +1-951 781-5500 FAX +1-951 781-5700 www.bourns.com Voltage (Vac) Current (A) 600 600 600 600 600 600 600 600 600 600 600 2.2 2.6 3.0 3.75 5 7 10 12.5 20 25 30 *RoHS Directive 2002/95/EC Jan 27 2003 including Annex. Specifications are subject to change without notice. Customers should verify device performance in their specific applications. Duration B0500T B1250T B2000T Up to 15 Min. 1.0 0.8 0.5 0.3 0.2 0.08 0.04 0.01 0.005 0.004 0.003 900 50 10 5 2 1 0.5 0.2 0.07 0.04 0.02 Will not open 2000 100 10 3 2 0.7 0.3 0.1 0.07 0.05 Telefuse™ SMD Power Cross Protection Fuse Time/Current Characteristic Curve Product Dimensions 1000 2.03 ± .102 (.080 ± .004) Current (Amperes) 100 10 9.65 ± .254 (.38 ± .01) B2000T B1250T 1 3.05 ± .127 (.120 ± .005) B0500T 3.05 ± .127 (.120 ± .005) 0.1 0.01 0.01 0.1 1 10 100 1000 10000 Recommended Pad Layout Time (Seconds) 3.81 (.15) 4.06 (.16) 5.08 (.20) DIMENSIONS: MM (INCHES) Solder Profile - 260 °C for 3 Seconds 300 PREHEAT ZONE 2 ZONE 3 REFLOW COOL 267 TEMPERATURE (°C) 233 200 167 133 100 67 33 0 0 48 95 143 190 238 286 333 381 429 SECONDS Specifications are subject to change without notice. Customers should verify actual device performance in their specific applications. Telefuse™ SMD Power Cross Protection Fuse Packaging Specifications 2.2 (.087) 20 (.787) 13.0 DIA. (.512) 1.55 ± 0.05 (.061 ± .002) DIA. 55.0 (2.165) DIA. 21.0 (.827) DIA. 0.40 ± 0.05 (.016 ± .002) 4.0 ± 0.1 (.157 ± .004) 2.0 ± 0.1 (.079 ± .004) 1.75 ± 0.1 (.069 ± .004) 1.6 ± 0.05 (.063 ± .002) DIA. CL 7.50 ± 0.1 (.295 ± .004) 10.0 ± 0.1 (.394 ± .004) R 3 ° REF. 3.50 ± 0.1 (.138 ± .004) 0.3 (.012) TYP. 16.0 ± 0.3 (.630 ± .012) 8.0 ± 0.1 (.315 ± .004) 3.50 ± 0.1 (.138 ± .004) 1.6 (.063) 330 (12.992) DIA. DIMENSIONS: REV. 01/09 “Telefuse” is a trademark of Bourns, Inc. Specifications are subject to change without notice. Customers should verify actual device performance in their specific applications. MM (INCHES) CL *R oH V SC AV ER OM AI SIO PL LA N IA BL S NT E Features Applications ■ Fast acting ■ Telecommunications ■ Balanced ■ Industrial electronics ■ Stable breakdown throughout life ■ Avionics ■ Designed to operate with TBU devices ® ■ RoHS compliant* versions available 2020 T-Series - Fast Acting 3-Electrode Miniature GDT Characteristics Model No. Characteristic Minimum DC Sparkover (100 V/s) Throughout Service Life Maximum Impulse Sparkover (5k V 1.2/50 µs) Throughout Service Life 2020-15T 2020-23T 2020-42T 60 V 180 V 360 V 500 V 650 V 850 V Impulse Transverse Delay ..................1000 V/µs ............................................................................... < 75 ns Insulation Resistance (IR) ..................50 V / 100 V............................................................................ > 10 9 Ω Glow Voltage ......................................10 mA ..................................................................................... ~ 70 V Arc Voltage .........................................>1 A ........................................................................................ ~ 10 V Glow-Arc Transition Current ............................................................................................................... < 0.5 A Capacitance........................................1 MHz ..................................................................................... < 1 pF DC Holdover Voltage (Network Applied per ITU-T K.12) 2020-15T .......................................52 V ........................................................................................ < 150 ms 2020-23T .......................................80 V ........................................................................................ < 150 ms 2020-42T .......................................135 V ...................................................................................... < 150 ms Service Life1 .......................................8/20 µs, 10 kA......................................................................... 1 operation 10/1000 µs, 1 kV, 200 A.......................................................... 100 operations2 2/10 µs, 6 kV, 2000 A.............................................................. 10 operations2 10/700 µs, 6 kV, 300 A............................................................ 50 operations2 8/20 µs, 500 A, 1.2/50 µs, 500 V ............................................ 150 operations2 600 V, 10 Arms, 0.2 sec.......................................................... 10 operations 600 Vrms, 0.5 A - 60 A ............................................................ Fail-Short activates3 230 Vrms, 0.5 A-25 A.............................................................. Fail-Short activates3 Operating and Storage Temperature .................................................................................................. -40 to +90 °C Climatic Category (IEC 60068-1) ....................................................................................................... 40 / 90 / 21 Notes: 1 The rated discharge current is the total current equally divided between each line to ground. 2 Surge polarity should be reversed between consecutive surges (+,-,+,-) 3 Applies only to GDT with optional Fail-Short. GDT operates and will survive with Fail-Short activation. • At delivery AQL 0.65 Level II, DIN ISO 2859. Applications Port Protection CanBus RS232 RS422 RS485 RS485 SDI VDSL GDT Device P/N 2020-23T 2020-23T 2020-23T 2020-23T 2020-42T 2020-23T 2020-15T “TBU” is a registered trademark of Bourns, Inc. in the United States and other countries. *RoHS Directive 2002/95/EC Jan. 27, 2003 including annex and RoHS Recast 2011/65/EU June 8, 2011. Specifications are subject to change without notice. Customers should verify actual device performance in their specific applications. TBU® Device P/N TBU-CA065-100-WH TBU-CA065-200-WH TBU-CA065-200-WH TBU-CA065-200-WH TBU-CA085-200-WH TBU-CA065-100-WH TBU-CA050-500-WH 2020 T-Series - Fast Acting 3-Electrode Miniature GDT Product Dimensions (additional lead form configurations available upon request) 2020-xxT-A1 7.9 2020-xxT-C4 FAIL-SHORT CONFIGURATION 2020-xxT-C2F SHOWN 11.2 REF. 8.1 7.5 9.6 1.0 DIA. 0.7 - 1.0 1.0 DIA. 6.1 6.1 2020-xxT-C2 2020-xxT-C8 DIMENSIONS: MILLIMETERS 13.0 MAX. UNITS WITH LEADS ARE BASED ON THE 2020-xxT-A1 BODY. 7.5 15.4 How to Order 1.0 DIA. 4.4 2020 - xxT - x x F LF 1.0 DIA. 4.5 Model Number Designator 4.4 2020-xxT-C3 Voltage 15 = 60 V 23 = 180 V 42 = 360 V 2020-xxT-C 1.0 mm dia. lead wire 30 LONG 2 PLCS. 7.5 Leads A = None/Cassette Applications C = 1 mm Dia. Leads/Through-hole Lead Shape (See Product Dimension Drawings) Fail-Short Option Blank = Standard Product F = With Fail-Short Mechanism 1.0 DIA. 4.4 4.75 4.75 1.0 DIA. 7.5 RoHS Compliant Option Blank = Standard Product LF = RoHS Compliant Product Model 2020-xxT ships in standard bulk pack, 100 pcs./tray. Specifications are subject to change without notice. Customers should verify actual device performance in their specific applications. 2020 T-Series - Fast Acting 3-Electrode Miniature GDT Switch-Grade Fail-Short Device Shorting Curve 2020-xxT-XF 30.0 Current (A) (ELTGS) 20.0 10.0 5.0 1.0 0.5 0.1 1 10 100 1000 Seconds ELTGS = Each Line to Ground Simultaneously NOTE: When using a GDT fail-short device, it is imperative that all components associated and connected to the GDT with failsafe be tested in their respective completely integrated environment (finished product) to assure desired operation. REV. D 03/12 Specifications are subject to change without notice. Customers should verify actual device performance in their specific applications. PL IA NT CO M *R oH S L C955401 Features Applications ■ Superior circuit protection ■ SLIC protection ■ Overcurrent & overvoltage protection ■ Cable & DSL ■ Blocks surges up to rated limits ■ MDU/MTU modems ■ High-speed performance ■ ONT ■ Small SMT package ■ Voice/DSL line cards ■ RoHS compliant* ■ Agency recognition: TBU-PL Series - TBU® High-Speed Protectors General Information Vdd The TBU-PL Series of Bourns® TBU® products are low capacitance dual bidirectional high-speed protection components, constructed using MOSFET semiconductor technology, and designed to protect against faults caused by short circuits, AC power cross, induction and lightning surges. In addition to overcurrent protection, an added feature is the voltage monitoring on the two lines. If the voltage on the line drops below Vss then the voltage will trigger the device to switch to the blocking state. Line 1 SLIC Line 1 Line 2 SLIC Line 2 The TBU® high-speed protector placed in the system circuit will monitor the current with the MOSFET detection circuit triggering to provide an effective barrier behind which sensitive electronics will not be exposed to large voltages or currents during surge events. The TBU® device is provided in a surface mount DFN package and meets industry standard requirements such as RoHS and Pb Free solder reflow profiles. Agency Approval UL Description File Number: E315805 Vss TBU ® Device Industry Standards (in Conjunction with OVP Device) Solutions available for GR-1089-CORE, ITU-T and a combination of both. Absolute Maximum Ratings (@ TA = 25 °C Unless Otherwise Noted) Symbol Parameter Vimp Peak impulse voltage withstand with duration less than 10 ms Vrms Continuous A.C. RMS voltage Top Tstg Tjmax ESD Operating temperature range Storage temperature range Maximum Junction Temperature HBM ESD Protection per IEC 61000-4-2 on line pads Part Number TBU-PL050-xxx-WH TBU-PL060-xxx-WH TBU-PL075-xxx-WH TBU-PL085-xxx-WH TBU-PL050-xxx-WH TBU-PL060-xxx-WH TBU-PL075-xxx-WH TBU-PL085-xxx-WH Value 500 600 750 850 300 350 400 425 -55 to +125 -65 to +150 +125 ±2 Unit V V °C °C °C kV Electrical Characteristics (@ TA = 25 °C Unless Otherwise Noted) Symbol Itrigger Rdevice Rmatch tblock IQ Iss Vreset Vto Vss Rth(j-l) Rth(j-l) Rth(j-l) Rth(j-l) Parameter Part Number Current required for the device to go from TBU-PLxxx-100-WH operating state to protected state TBU-PLxxx-200-WH Series resistance of the TBU® device Package resistance matching of the TBU® device #1 - TBU® device #2 Time taken for the device to go into current limiting Current through the triggered TBU® device with 50 Vdc circuit voltage Operating current with Vss = -50 V Forward Mode TBU-PLxxx-100-WH ® Reverse Mode Voltage below which the triggered TBU device will transition to normal operating state Forward Mode TBU-PLxxx-200-WH Reverse Mode Voltage threshold offset with 60 Hz applied voltage, with Vss -50 V (Vss - VlineSLIC) Operating voltage range relative to Vdd One side junction to package pads - FR4 using minimum recommended pad layout Both sides junction to package pads - FR4 using minimum recommended pad layout One side junction to package pads - FR4 using heat sink on board (6 cm2) (0.5 in.2) Both sides junction to package pads - FR4 using heat sink on board (6 cm2) (0.5 in.2) *RoHS Directive 2002/95/EC Jan. 27, 2003 including annex and RoHS Recast 2011/65/EU June 8, 2011. Specifications are subject to change without notice. Customers should verify actual device performance in their specific applications. Min. 100 200 40 Typ. 150 300 50 ±0.5 0.25 0.70 100 15 13 20 17 12 10 15 12 -1.0 -180 110 65 70 40 Max. 200 400 55 ±1.0 1 1.50 22 20 25 22 0.2 -20 Unit mA Ω Ω µs mA µA V V V °C/W °C/W °C/W °C/W TBU-PL Series - TBU® High-Speed Protectors Functional Block Diagram HIGH VOLTAGE SWITCH Line 1 SLIC Line 1 CURRENT SENSE Vdd + VOLTAGE COMPARATOR Vss Vdd Vss Vdd VOLTAGE COMPARATOR + Vss CURRENT SENSE HIGH VOLTAGE SWITCH Line 2 SLIC Reference Application Line 2 Basic TBU Operation The TBU-PL Series are high-speed protectors used in voice/ VoIP SLIC applications.The maximum voltage rating of the TBU® device should never be exceeded. Where necessary, an OVP device should be employed to limit the maximum voltage. A costeffective protection solution combines Bourns® TBU® protection devices with a pair of Bourns® MOVs. For bandwidth sensitive applications, a Bourns® GDT may be substituted for the MOV. If EN55024 EMC compliance is required, the TBU® device may require capacitors to be fitted between the Tip and Ring connections and ground. The TBU® device, constructed using MOSFET semiconductor technology, placed in the system circuit will monitor the current with the MOSFET detection circuit triggering to provide an effective barrier behind which sensitive electronics are not exposed to large voltages or currents during surge events. The TBU® device operates in approximately 1 µs - once line current exceeds the TBU® device’s trigger current Itrigger. When operated, the TBU® device restricts line current to less than 1 mA typically. When operated, the TBU® device will block all voltages including the surge up to rated limits. GND When the voltage on the SLIC output is driven below (Vbat – Vto) the TBU-PL series device switches to the blocking state, regardless of output current in the device. 2 Vdd Line 1 SLIC 4 Line 1 1 MOV C1 MOV C2 After the surge, the TBU® device resets when the voltage across the TBU® device falls to the Vreset level. The TBU® device will automatically reset on lines which have no DC bias or have DC bias below Vreset (such as unpowered signal lines). TBU® Device Line 2 SLIC Vss -VBAT Line 2 5 8 6 If the line has a normal DC bias above Vreset, the voltage across the TBU® device may not fall below Vreset after the surge. In such cases, special care needs to be taken to ensure that the TBU® device will reset, with software monitoring as one method used to accomplish this. Bourns application engineers can provide further assistance. Specifications are subject to change without notice. Customers should verify actual device performance in their specific applications. TBU-PL Series - TBU® High-Speed Protectors Bourns® TBU® Device Solutions Industry Standard Telcordia GR-1089-CORE Intra-building Port Type 4 Telcordia GR-1089-CORE Intra-building Port Type 4a Non-GR-1089-CORE Intra-building Specifications ITU-T Basic K.20, K.21, K.45 ITU-T Enhanced K.20, K.21, K.45 Surge & AC Withstand TBU® Device P/N 1500 V, 100 A 2/10 µs 120 Vrms, 25 A, 900 s TBU-PL050-100-WH 1 MOV-07D201K 2 1000 V, 100 A 10/1000 µs 120 Vrms, 25 A, 900 s TBU-PL060-100-WH 1 MOV-10D201K 2 TBU-PL085-100-WH 1 MOV-10D361K 2 TBU-PL085-100-WH 1 MOV-10D431K 2 TBU-PL075-100-WH 1 MOV-10D361K 2 TBU-PL060-100-WH 1 TISP4400M3BJ 2 TBU-PL085-100-WH 1 MOV-10D391K 2 TBU-PL060-100-WH 1 TISP4500H3BJ 2 5000 V, 500 A 2/10 µs 230 Vrms, 25 A, 900 s 1500 V, 100 A 2/10 µs 275 Vrms, 25 A, 900 s 4000 V, 40 Ω 10/700 µs 230 Vrms 10 Ω - 1000 Ω, 900 s 600 Vrms 600 Ω, 0.2 s 4000 V, 40 Ω 10/700 µs 230 V rms 10 Ω -1000 Ω, 900 s 600 V rms 600 Ω, 0.1 s 6000 V, 40 Ω 10/700 µs 240 Vrms 10 Ω - 1000 Ω, 900 s 600 Vrms 600 Ω, 0.2 s 600 Vrms 600 Ω, 1 s* 1500 Vrms, 200 Ω, 2 s* 6000 V, 40 Ω 10/700 µs 240 Vrms 10 Ω - 1000 Ω, 900 s 600 Vrms 600 Ω, 1 s 1500 Vrms, 200 Ω, 2 s Qty. OVP Device P/N Qty. * GDT Special Test Protector with DC breakdown (DCBD) of less than 330 V. Notes: 1) The Le9500, Le9520 and Le9530 (VE950 series) require a 200 mA Itrigger TBU® device for normal operation. Other SLIC types should use the 100 mA device. 2) The MOV maximum continuous rms voltage rating should not be exceeded. The exception is where the data sheet highlights withstand capability such as the 600 Vrms, 1 A for 0.2 s, for example. 3) If EN55024 EMC compliance is required, the TBU® device may require capacitors to be fitted between the Tip and Ring connections and ground (i.e. in parallel with the MOV device). The capacitance value can be chosen to meet levels as follows: • 10 nF for EN55024 Level 1 • 20 nF for EN55024 Level 2 • 47 nF for EN55024 Level 3 Selection of capacitor voltage rating depends upon TBU® part number selection. Recommendations include: • TBU-PL050 & TBU-PL060 Series: 120 VAC, 500 V Peak Surge Rated • TBU-PL075 & TBU-PL085 Series: 240 VAC, 750 V Peak Surge Rated Depending upon the SLIC type, it is usually possible to remove any EMI capacitors present between the output of the SLIC and ground when using capacitors C1 and C2 in parallel with the MOVs. Specifications are subject to change without notice. Customers should verify actual device performance in their specific applications. TBU-PL Series - TBU® High-Speed Protectors Performance Graphs Typical Trigger Current vs. Temperature Typical V-I Characteristics (TBU-PL085-200-WH) 1.8 1.6 ITRIGGER Normalized Trigger Current CURRENT (50 mA/div) VRESET VOLTAGE (5 V/div) 1.4 1.2 1.0 0.8 0.6 0.4 0.2 0.0 -75 -50 -25 0 25 50 75 100 125 Junction Temperature (°C) Typical Resistance vs. Temperature Tracking Voltage Characteristics 2.2 Vbat range of -25 V to -150 V 2.0 100 1.8 Normalized Resistance Resistance ( ) 90 80 70 60 50 40 -4 -3 -2 -1 0 1 2 3 4 Voltage threshold offset (V) 1.6 1.4 1.2 1.0 0.8 0.6 0.4 0.2 0.0 -75 -50 -25 0 25 50 75 100 125 Junction Temperature (°C) Typical Surge Response Power Derating Curve 3.0 Total Max. Power (W) Voltage: 100 V/div One Side, No PCB Cu One Side, 0.5 sq. in. PCB Cu Two Sides, No PCB Cu Two Sides, 0.5 sq. in. PCB Cu 2.5 2.0 Time: 250 ns/div 1.5 Current: 100 mA/div 1.0 0.5 0.0 20 40 60 80 100 Ambient Temperature (°C) 120 140 (TBU-PL050-100-WH with MOV-07D201K Using 1800 V 1.2/50 ms Surge Pulse) Specifications are subject to change without notice. Customers should verify actual device performance in their specific applications. TBU-PL Series - TBU® High-Speed Protectors Product Dimensions 0.70 (.028) 0.725 (.029) 0.825 (.032) 0.40 (.016) 0.825 (.032) 0.85 ± 0.05 (.033 ± .002) 6.50 (.256) 1.335 (.053) 0.30 (.012) 1.15 (.045) 1.275 (.050) 0.30 (.012) 1.35 (.053) 1.20 (.047) 4.00 (.157) 0.85 (.033) 0.85 (.033) 0.73 (.029) 1.35 (.053) 1.275 (.050) 1.20 (.047) 0.85 (.033) 0.85 (.033) PIN 1 & BACKSIDE CHAMFER 0.90 (.035) 0.85 (.033) 0.85 (.033) 1.335 (.053) 0.80 - 0.95 (.031 - .037) 1.275 (.050) 0.25 C PIN 1 (.010) 1.25 (.049) 0.75 (.030) 1.30 (.051) 0.70 (.028) 0.00 - 0.05 (.000 - .002) DIMENSIONS: 0.75 (.030) 0.40 (.016) MM (INCHES) 0.75 (.030) Recommended Pad Layout TBU® High-Speed Protectors have a 100 % matte-tin termination finish. For improved thermal dissipation, the recommended layout uses PCB copper areas which extend beyond the exposed solder pad. The exposed solder pads should be defined by a solder mask which matches the pad layout of the TBU® device in size and spacing. It is recommended that they should be the same dimension as the TBU® pads but if smaller solder pads are used, they should be centered on the TBU® package terminal pads and not more than 0.10-0.12 mm (0.004-0.005 in.) smaller in overall width or length. Solder pad areas should not be larger than the TBU® pad sizes to ensure adequate clearance is maintained. The recommended stencil thickness is 0.10-0.12 mm (0.004-0.005 in.) with a stencil opening size 0.025 mm (0.0010 in.) less than the solder pad size. Extended copper areas beyond the solder pad significantly improve the junction to ambient thermal resistance, resulting in operation at lower junction temperatures with a corresponding benefit of reliability. All pads should soldered to the PCB, including pads marked as NC or NU but no electrical connection should be made to these pads. For minimum parasitic capacitance, it is recommended that signal, ground or power signals are not routed beneath any pad. Thermal Resistance vs Additional PCB Cu Area 4 3 2 1 5 6 7 8 Dark grey areas show added PCB copper area for better thermal resistance. Thermal Resistance (°C/W) 120 Power in One Side of TBU® Device Total Power in Both Sides of TBU® Device 100 80 60 40 20 0 Specifications are subject to change without notice. Customers should verify actual device performance in their specific applications. 0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 Added Cu Area (Sq. In.) 1.6 1.8 2.0 ® 3312Series - 2 mm SMD Trimming Potentiometer TBU-PL - TBU High-Speed Protectors Reflow Profile Profile Feature Average Ramp-Up Rate (Tsmax to Tp) Preheat - Temperature Min. (Tsmin) - Temperature Max. (Tsmax) - Time (tsmin to tsmax) Time maintained above: - Temperature (TL) - Time (tL) Peak/Classification Temperature (Tp) Time within 5 °C of Actual Peak Temp. (tp) Ramp-Down Rate Time 25 °C to Peak Temperature Pb-Free Assembly 3 °C/sec. max. 150 °C 200 °C 60-180 sec. 217 °C 60-150 sec. 260 °C 20-40 sec. 6 °C/sec. max. 8 min. max. How to Order Typical Part Marking TBU - PL 085 - 100 - WH MANUFACTURER’S TRADEMARK TBU® Product PRODUCT CODE - 1ST DIGIT INDICATES PRODUCT FAMILY: L = TBU-PL SERIES - 2ND & 3RD DIGITS INDICATE IMPULSE VOLTAGE: 50 = 500 V 60 = 600 V 75 = 750 V 85 = 850 V Series PL = Dual Bidirectional Series - 4TH DIGIT INDICATES TRIGGER CURRENT: 1 = 100 mA 2 = 200 mA Impulse Voltage Rating 050 = 500 V 060 = 600 V 075 = 750 V 085 = 850 V PIN 1 MANUFACTURING DATE CODE - 1ST DIGIT INDICATES THE YEAR’S 6-MONTH PERIOD. - 2ND DIGIT INDICATES THE WEEK NUMBER IN THE 6-MONTH PERIOD. - 3RD & 4TH DIGITS INDICATE SPECIFIC LOT FOR THE WEEK. Trigger Current 100 = 100 mA 200 = 200 mA Hold to Trip Ratio Suffix W = Hold to Trip Ratio 6-MONTH PERIOD CODES: A = JAN-JUN 2009 C = JAN-JUN 2010 B = JUL-DEC 2009 D = JUL-DEC 2010 Package Suffix H = DFN Package E = JAN-JUN 2011 F = JUL-DEC 2011 Device Pin Out Pad Designation 2 Pin Out Pad # 1 Line 1 5 Line 2 SLIC 2 6 Vss (SLIC Negative Supply or -Vbat) 3 Vdd (SLIC Ground or 0 V) Not Used 7 Not Used 4 Line 1 SLIC 8 Line 2 Pad # 4 1 5 8 Pin Out 6 Specifications are subject to change without notice. Customers should verify actual device performance in their specific applications. 3312 - Series 2 mm SMD Potentiometer TBU-PL - TBU®Trimming High-Speed Protectors Packaging Specifications P0 E D t B P2 TOP COVER TAPE A N F W C D B0 K0 CENTER LINES OF CAVITY A0 P D1 EMBOSSMENT G (MEASURED AT HUB) USER DIRECTION OF FEED QUANTITY: 3000 PIECES PER REEL A Min. 326 (12.835) B Max. 330 (13.002) Min. 1.5 (.059) A0 Min. 4.30 (.169) B0 Max. 4.50 (.177) Min. 6.70 (.264) K0 Min. 1.0 (.039) C Max. 2.5 (.098) Min. 7.9 (.311) D Max. 13.5 (.531) D Max. 6.90 (.272) Min. 1.5 (.059) P Max. 1.2 (.047) Min. 12.8 (.504) Min. 1.5 (.059) Min. 3.9 (.159) E Max. - Min. 1.65 (.065) P2 Max. 4.1 (.161) Min. 1.9 (.075) G Ref. 16.5 (.650) Max. D1 Max. 1.6 (.063) P0 Max. 8.1 (.319) Min. 20.2 (.795) F Max. 1.85 (.073) Min. 7.4 (.291) Max. 0.35 (.014) Min. 15.7 (.618) t Max. 2.1 (.083) Min. 0.25 (.010) N Ref. 102 (4.016) max. 7.6 (.299) W DIMENSIONS: Asia-Pacific: Tel: +886-2 2562-4117 • Fax: +886-2 2562-4116 Europe: Tel: +41-41 768 5555 • Fax: +41-41 768 5510 The Americas: Tel: +1-951 781-5500 • Fax: +1-951 781-5700 www.bourns.com REV. 01/25/12 “TBU” is a registered trademark of Bourns, Inc. in the United States and other countries. Specifications are subject to change without notice. Customers should verify actual device performance in their specific applications. Max. 16.3 (.642) MM (INCHES) T PL IA N M CO *R oH S A E075050 5 Features Applications ■ Superior circuit protection ■ Voice / VDSL cards ■ Overcurrent and overvoltage protection ■ Protection modules and dongles ■ Blocks surges up to rated limits ■ Process control equipment ■ High-speed performance ■ Test and measurement equipment ■ Small SMT package ■ General electronics ■ Agency listing: TBU-CA Series - TBU® High-Speed Protectors General Information Agency Listing The TBU-CA Series of Bourns® TBU® Line In/ products are low capacitance single Line Out bidirectional high-speed protection components, constructed using MOSFET semiconductor technology, and designed to protect against faults caused by short circuits, AC power cross, induction and lightning surges. Line Out/ Line In Description File Number: E315805 UL TBU® Device The TBU® high-speed protector placed in the system circuit will monitor the current with the MOSFET detection circuit triggering to provide an effective barrier behind which sensitive electronics will not be exposed to large voltages or currents during surge events. The TBU® device is provided in a surface mount DFN package and meets industry standard requirements such as RoHS and Pb Free solder reflow profiles. Absolute Maximum Ratings (@ TA = 25 °C Unless Otherwise Noted) Symbol Parameter Vimp Peak impulse voltage withstand with duration less than 10 ms Vrms Continuous A.C. RMS voltage Top Tstg Tjmax ESD Operating temperature range Storage temperature range Maximum Junction Temperature HBM ESD protection per IEC 61000-4-2 Part Number TBU-CA025-xxx-WH TBU-CA040-xxx-WH TBU-CA050-xxx-WH TBU-CA065-xxx-WH TBU-CA085-xxx-WH TBU-CA025-xxx-WH TBU-CA040-xxx-WH TBU-CA050-xxx-WH TBU-CA065-xxx-WH TBU-CA085-xxx-WH Value 250 400 500 650 850 100 200 250 300 425 -55 to +125 -65 to +150 +125 ±2 Asia-Pacific: Tel: +886-2 2562-4117 • Fax: +886-2 2562-4116 Europe: Tel: +41-41 768 5555 • Fax: +41-41 768 5510 The Americas: Tel: +1-951 781-5500 • Fax: +1-951 781-5700 www.bourns.com *RoHS Directive 2002/95/EC Jan. 27, 2003 including annex and RoHS Recast 2011/65/EU June 8, 2011. Specifications are subject to change without notice. Customers should verify actual device performance in their specific applications. Unit V V °C °C °C kV TBU-CA Series - TBU® High-Speed Protectors Electrical Characteristics (@ TA = 25 °C Unless Otherwise Noted) Symbol Itrigger Rdevice tblock Parameter Part Number Min. Typ. Max. Unit Current required for the device to go from operating state to protected state TBU-CAxxx-050-WH TBU-CAxxx-100-WH TBU-CAxxx-200-WH TBU-CAxxx-300-WH TBU-CAxxx-500-WH 50 100 200 300 500 75 150 300 450 750 100 200 400 600 1000 mA Series resistance of the TBU device Vimp = 250 V Vimp = 250 V Vimp = 250 V Vimp = 250 V Vimp = 250 V Itrigger (min.) = 50 mA Itrigger (min.) = 100 mA Itrigger (min.) = 200 mA Itrigger (min.) = 300 mA Itrigger (min.) = 500 mA TBU-CA025-050-WH TBU-CA025-100-WH TBU-CA025-200-WH TBU-CA025-300-WH TBU-CA025-500-WH 13.3 7.1 4.2 3.2 2.6 15.3 8.2 4.8 3.8 3.0 Vimp = 400 V Vimp = 400 V Vimp = 400 V Vimp = 400 V Vimp = 400 V Itrigger (min.) = 50 mA Itrigger (min.) = 100 mA Itrigger (min.) = 200 mA Itrigger (min.) = 300 mA Itrigger (min.) = 500 mA TBU-CA040-050-WH TBU-CA040-100-WH TBU-CA040-200-WH TBU-CA040-300-WH TBU-CA040-500-WH 14.3 8.1 5.2 4.3 3.6 16.5 9.4 6.0 5.0 4.2 Vimp = 500 V Vimp = 500 V Vimp = 500 V Vimp = 500 V Vimp = 500 V Itrigger (min.) = 50 mA Itrigger (min.) = 100 mA Itrigger (min.) = 200 mA Itrigger (min.) = 300 mA Itrigger (min.) = 500 mA TBU-CA050-050-WH TBU-CA050-100-WH TBU-CA050-200-WH TBU-CA050-300-WH TBU-CA050-500-WH 15.7 9.5 6.6 5.6 5.0 18.0 10.9 7.5 6.5 5.7 Vimp = 650 V Vimp = 650 V Vimp = 650 V Vimp = 650 V Vimp = 650 V Itrigger (min.) = 50 mA Itrigger (min.) = 100 mA Itrigger (min.) = 200 mA Itrigger (min.) = 300 mA Itrigger (min.) = 500 mA TBU-CA065-050-WH TBU-CA065-100-WH TBU-CA065-200-WH TBU-CA065-300-WH TBU-CA065-500-WH 17.7 11.5 8.6 7.6 7.0 20.3 13.2 9.8 8.8 8.0 Vimp = 850 V Vimp = 850 V Vimp = 850 V Vimp = 850 V Vimp = 850 V Itrigger (min.) = 50 mA Itrigger (min.) = 100 mA Itrigger (min.) = 200 mA Itrigger (min.) = 300 mA Itrigger (min.) = 500 mA TBU-CA085-050-WH TBU-CA085-100-WH TBU-CA085-200-WH TBU-CA085-300-WH TBU-CA085-500-WH 21.4 15.2 12.3 11.3 10.7 24.5 17.4 14.0 13.0 12.2 Time for the device to go from normal operating state to protected state ® Ω 1 µs IQ Current through the triggered TBU device with 50 Vdc circuit voltage Vreset Voltage below which the triggered TBU® device will transition to normal operating state 0.25 0.50 1.00 mA 12 16 20 V Rth(j-l) Junction to package pads - FR4 using recommended pad layout 98 °C/W Rth(j-l) Junction to package pads - FR4 using heat sink on board (6 cm2) (1 in2) 40 °C/W Specifications are subject to change without notice. Customers should verify actual device performance in their specific applications. TBU-CA Series - TBU® High-Speed Protectors Reference Application Basic TBU Operation ® The TBU devices are general use protectors used in a wide variety of applications. The maximum voltage rating of the TBU® device should never be exceeded. Where necessary, an OVP should be employed to limit the maximum voltage. A costeffective protection solution combines Bourns® TBU® protection devices with a pair of Bourns® MOVs. For bandwidth sensitive applications, a Bourns® GDT may be substituted for the MOV. Line In / Line Out Line Out / Line In Equip. Line TBU ® Device OVP TBU ® Device OVP Line In / Line Out Line Out / Line In Line The TBU® device, constructed using MOSFET semiconductor technology, placed in the system circuit will monitor the current with the MOSFET detection circuit triggering to provide an effective barrier behind which sensitive electronics are not exposed to large voltages or currents during surge events. The TBU® device operates in approximately 1 μs - once line current exceeds the TBU® device’s trigger current Itrigger. When operated, the TBU® device restricts line current to less than 1 mA typically. When operated, the TBU® device will block all voltages including the surge up to rated limits. After the surge, the TBU® device resets when the voltage across the TBU® device falls to the Vreset level. The TBU® device will automatically reset on lines which have no DC bias or have DC bias below Vreset (such as unpowered signal lines). If the line has a normal DC bias above Vreset, the voltage across the TBU® device may not fall below Vreset after the surge. In such cases, special care needs to be taken to ensure that the TBU® device will reset, with software monitoring as one method used to accomplish this. Bourns application engineers can provide further assistance. Performance Graphs Typical V-I Characteristics (TBU-CA050-300-WH) Typical Trigger Current vs. Temperature 1.8 Normalized Trip Current (A) ITRIP CURRENT (100 mA/div) VRESET VOLTAGE (5 V/div) 1.6 1.4 1.2 1.0 0.8 0.6 0.4 0.2 0.0 -75 -50 -25 0 25 50 75 100 125 150 Junction Temperature (°C) Power Derating Curve Typical Resistance vs. Temperature 2.2 3.0 Normalized Resistance (Ω) No Additional PCB Cu 0.5 sq. in. Additional PCB Cu Total Max. Power (W) 2.5 2.0 1.5 1.0 0.5 0.0 20 40 60 80 100 120 140 Junction Temperature (°C) Specifications are subject to change without notice. Customers should verify actual device performance in their specific applications. 2.0 1.8 1.6 1.4 1.2 1.0 0.8 0.6 0.4 0.2 0.0 -75 -50 -25 0 25 50 75 100 125 150 Junction Temperature (°C) TBU-CA Series - TBU® High-Speed Protectors Product Dimensions 0.70 (.028) 0.80 (.031) 0.70 (.028) 1.85 (.073) 6.50 ± 0.10 (.256 ± .004) 0.85 ± 0.05 (.033 ± .002) 0.30 (.012) 4.00 ± 0.10 (.157 ± .004) 1.85 (.073) 3.40 (.134) 0.30 (.012) PIN 1 & BACKSIDE CHAMFER 0.00 - 0.05 (.000 - .002) DIMENSIONS: MM (INCHES) C 0.25 PIN 1 (.010) Pad Designation Pad # Pin Out 1 Line In/Out 2 NU 3 Line Out/In Recommended Pad Layout TBU® High-Speed Protectors have a 100 % matte-tin termination finish. For improved thermal dissipation, the recommended layout uses PCB copper areas which extend beyond the exposed solder pad. The exposed solder pads should be defined by a solder mask which matches the pad layout of the TBU® device in size and spacing. It is recommended that they should be the same dimension as the TBU® pads but if smaller solder pads are used, they should be centered on the TBU® package terminal pads and not more than 0.10-0.12 mm (0.004-0.005 in.) smaller in overall width or length. Solder pad areas should not be larger than the TBU® pad sizes to ensure adequate clearance is maintained. The recommended stencil thickness is 0.10-0.12 mm (0.004-0.005 in.) with a stencil opening size 0.025 mm (0.0010 in.) less than the solder pad size. Extended copper areas beyond the solder pad significantly improve the junction to ambient thermal resistance, resulting in operation at lower junction temperatures with a corresponding benefit of reliability. All pads should soldered to the PCB, including pads marked as NC or NU but no electrical connection should be made to these pads. For minimum parasitic capacitance, it is recommended that signal, ground or power signals are not routed beneath any pad. 3 2 1 Dark grey areas show added PCB copper area for better thermal resistance. Specifications are subject to change without notice. Customers should verify actual device performance in their specific applications. TBU-CA Series - TBU® High-Speed Protectors Reflow Profile Profile Feature Average Ramp-Up Rate (Tsmax to Tp) Preheat - Temperature Min. (Tsmin) - Temperature Max. (Tsmax) - Time (tsmin to tsmax) Time maintained above: - Temperature (TL) - Time (tL) Peak/Classification Temperature (Tp) Time within 5 °C of Actual Peak Temp. (tp) Ramp-Down Rate Time 25 °C to Peak Temperature Pb-Free Assembly 3 °C/sec. max. 150 °C 200 °C 60-180 sec. 217 °C 60-150 sec. 260 °C 20-40 sec. 6 °C/sec. max. 8 min. max. How to Order Typical Part Marking TBU - CA 085 - 500 - WH MANUFACTURER’S TRADEMARK TBU® Product PRODUCT CODE - 1ST DIGIT INDICATES PRODUCT FAMILY: A = TBU-CA SERIES Series CA = Bi-Series - 2ND & 3RD DIGITS INDICATE IMPULSE VOLTAGE: 25 = 250 V 40 = 400 V 50 = 500 V 65 = 650 V 85 = 850 V Impulse Voltage Rating 025 = 250 V 040 = 400 V 050 = 500 V 065 = 650 V 085 = 850 V - 4TH & 5TH DIGITS INDICATE TRIGGER CURRENT: 05 = 50 mA 10 = 100 mA 20 = 200 mA 30 = 300 mA 50 = 500 mA Trigger Current 050 = 50 mA 100 = 100 mA 200 = 200 mA 300 = 300 mA 500 = 500 mA PIN 1 MANUFACTURING DATE CODE - 1ST DIGIT INDICATES THE YEAR’S 6-MONTH PERIOD. - 2ND DIGIT INDICATES THE WEEK NUMBER IN THE 6-MONTH PERIOD. - 3RD & 4TH DIGITS INDICATE SPECIFIC LOT FOR THE WEEK. 6-MONTH PERIOD CODES: A = JAN-JUN 2009 C = JAN-JUN 2010 B = JUL-DEC 2009 D = JUL-DEC 2010 E = JAN-JUN 2011 F = JUL-DEC 2011 Hold to Trip Ratio Suffix W = Hold to Trip Ratio Package Suffix H = DFN Package Thermal Resistance vs Additional PCB Cu Area Thermal Resistance (°C/W) 120 100 80 60 40 20 0 0 Specifications are subject to change without notice. Customers should verify actual device performance in their specific applications. 0.2 0.4 0.6 0.8 1.0 1.2 1.4 Added Cu Area (Sq. In.) 1.6 1.8 2.0 TBU-CA Series - TBU® High-Speed Protectors Packaging Specifications P0 E D t B P2 TOP COVER TAPE A N F W C D B0 K0 CENTER LINES OF CAVITY A0 P D1 EMBOSSMENT G (MEASURED AT HUB) USER DIRECTION OF FEED QUANTITY: 3000 PIECES PER REEL A Min. 326 (12.835) B Max. 330 (13.002) Min. 1.5 (.059) A0 Min. 4.3 (.169) B0 Max. 4.5 (.177) Min. 6.7 (.264) K0 Min. 1.0 (.039) C Max. 2.5 (.098) Min. 7.9 (.311) D Max. 13.5 (.531) D Max. 6.9 (.272) Min. 1.5 (.059) P Max. 1.2 (.047) Min. 12.8 (.504) Min. 1.5 (.059) Min. 3.9 (.159) E Max. - Min. 1.65 (.065) P2 Max. 4.1 (.161) Min. 1.9 (.075) G Ref. 16.5 (.650) Max. D1 Max. 1.6 (.063) P0 Max. 8.1 (.319) Min. 20.2 (.795) F Max. 1.85 (.073) Min. 7.4 (.291) Max. 0.35 (.014) Min. 15.7 (.618) t Max. 2.1 (.083) Min. 0.25 (.010) N Ref. 102 (4.016) max. 7.6 (.299) W DIMENSIONS: Max. 16.3 (.642) MM (INCHES) REV. 10/12 “TBU” is a registered trademark of Bourns, Inc. in the United States and other countries. Specifications are subject to change without notice. Customers should verify actual device performance in their specific applications.