Design Aspects of Green Water Loading on FPSOs

advertisement

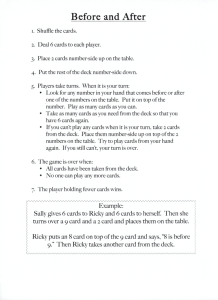

The 22nd International Conference on Offshore Mechanics & Arctic Engineering Cancun, Mexico 8-13 June, 2003 OMAE2003-37162 DESIGN ASPECTS OF GREEN WATER LOADING ON FPSOs Bas Buchner, MARIN ABSTRACT Green water is a significant problem for floating ship-type offshore structures, which needs to be assessed in the early design of the structure. First the present paper summarises a new semi-empirical design evaluation procedure that can assist in this design process. Then the practical design considerations related to the green water problem are discussed. There are different ways to solve the green water problem for a particular structure at a specific location: • Design the vessel and structures on the deck against the predicted green water impact load levels. • Optimise the bow shape (underwater shape and above water bow flare). • Increase the freeboard height such that green water is prevented completely. • Increase the freeboard height such that the green water loads are reduced to acceptable levels and design for these load levels. • Optimise the structures on the deck to minimise the green water impact loads. • Use protecting breakwaters in front of critical structures on the deck. All these options have their advantages and disadvantages. The semi-empirical design evaluation method and the different design options are discussed in a case study, focussing on a new DP FPSO concept. INTRODUCTION In heavy storms, the waves and ship motions can become so large that water flows onto the deck of a ship. This problem is generally known as ‘green water loading’. On ship-type offshore structures green water loading can result in risk for the ship, its crew and its sensitive equipment. Therefore, it should be taken into account in the design of such structures. Joaquín Lopez-Cortijo Garcia, IZAR FENE Shipyards Recent experience in the North Sea in both the UK and Norwegian sectors confirms the occurrence and importance of the green water problem. As reported by Morris, Millar and Buchner [1], from 1995 to date seventeen green water incidents have been identified on twelve UK FPSOs. Some installations have experienced more than one incident. Ersdal and Kvitrud [2] also report damage incidents in the Norwegian North Sea. In January 2000 the living quarters on the bow of the Varg FPSO was hit by green water. This resulted in the damage of a window on the second floor, flooding the area behind it. In Buchner [3] methods for the evaluation of green water on ship-type offshore structures were developed based on a clear description of the green water physics. A semi-empirical design evaluation method was proposed, to predict the green water problem from the input (extreme relative wave motions) to the output (predicted load levels). Using the results of this research, the present paper focuses on the practical design aspects of the green water-loading problem for the design of FPSOs: - Bow shape design. - Design of green water prevention methods (raised bulwarks, a tilted ‘canopy’). - Choice of effective protecting structures and breakwaters. - Structural design of these structures. In the paper the hydrodynamic aspects will be combined with the practical knowledge from shipbuilding experience. In Buchner et al. [4] a case study for a typical FPSO for the deepwater Gulf of Mexico was presented. Although in a real design the most critical weather conditions should be determined for a specific vessel (the maximum relative wave motions are strongly related to the ship length for instance), the present paper focuses on design methodology rather than the design for a specific area. Therefore, the present paper makes use of the 100-year Hurricane for the Gulf of Mexico, see Table 1. 1 Copyright © 2003 by ASME GREEN WATER EVALUATION METHODOLOGY Although numerical prediction methods utilising computational fluid dynamics (CFD) for green water loading are under development, they cannot be used as practical prediction methods at this time. Therefore a semi-empirical method for the prediction of green water loading is used, based on the early research presented in Buchner [6] and the systematic model test series presented in Buchner [3]. The method is semi-empirical, as the basis for the evaluation of the green water problem is a linear diffraction calculation at zero speed, coupled with results from a model test database. The linear diffraction model makes it possible to take into account the main characteristics of the vessel, such as its main dimensions, underwater hull shape and weight distribution. If necessary this linear diffraction calculation can be corrected for the effects of current speed. The model test database provides information that is used to define the non-linear interaction between the fluid and the structure. Similar approaches were presented by Hellan, Hermunstad and Stansberg [7]. Figure 1 provides a schematic of the green water evaluation methodology. The figure provides a flow chart that identifies the input required, the analysis to be performed, and the output that can be obtained. The dashed lines in Figure 1 represent the input required: • Vessel particulars with specific information on the parameters that influence green water occurrence. • Information from Metocean specialists to allow development of design environmental criteria specific to green water occurrence. Table 1: 100-year Hurricane for the Gulf of Mexico Parameter Significant wave height Spectral peak period JONSWAP gamma 100-year wave 12.5 13.0 3.3 Unit metre seconds - In the present study the FPSO under investigation is a DP FPSO, which is presently under development. DP aspects of this new concepts are discussed in various recent papers, see Cortijo et al. [5]. Although green water from the side can be a problem as well, the present paper focuses on the bow of the DP FPSO. Prior to developing and discussing the case study, the semi-empirical design methodology to evaluate the green water loading on various structures will be summarised. More details can be found in Buchner [3]. The present paper is a result of a co-operation between the authors as part of the SAFE-FLOW project. The SAFE-FLOW project (SAFE-FLOating offshore structures under impact loading of shipped green water and Waves) is funded by the European Community under the ‘Competitive and Sustainable Growth’ Programme (EU Project No.: GRD1-2000-25656). Its objective is to develop guidance, calculation methods and risk assessment procedures for green water and wave impact loading appropriate to each stage of a floater project, namely: concept development, detailed design and operation. The project also contains a research effort to further develop and validate the numerical simulation of the impact phenomena under investigation (ComFLOW program). Designer F, p Breakwater F, M Slender structures F, M h H RAO heading Spectral analysis s Extreme relative motions Storm duration Wave Hs,Tp,dir Wind V and dir Current V and dir Shape Position Flare angle Heading calculation Freeboard QTFs Heading control RAOs Current/wind coefficients Weight data Hull shape Linear diffraction Structures h Water height Water velocity H U s Extreme relative motions side and stern h Metocean specialist Figure 1: Overview of the semi-empirical design evaluation method 2 Copyright © 2003 by ASME ap Is again dependent on the bow shape (full or thin) and bowflare angle (0, 10, 30 and 50 degrees). A similar expression can be used for the total horizontal load on the structure (F): The following analyses are performed as represented by the blocks in the figure: 1. Calculate relative wave motion RAOs with linear 3D-diffraction analysis with correction for possible effects of current. 2. Calculation of the heading of the vessel with respect to the wave direction due to the combined wind, wave drift and current forces. This is an important parameter for the problem of green water from the side, which increases significantly when the angle between the waves and vessel increases. 3. Calculate linear relative wave motions for the wave spectra of interest resulting in the standard deviation (s) of the relative wave motions. 4. Perform a non-linear correction of the extreme relative wave motions, including the typical discontinuity at the freeboard level as presented in Buchner [3] and investigate the effects of bow flare angle and wave period. The methodology is based on a systematic model test series with different bow shapes (full or thin), bowflare angles (0, 10, 30 and 50 degrees with the vertical) and spectral peak periods (12, 14 and 16 s). The output is the expected maximum freeboard exceedence (h). 5. Determination of water height (H) and velocity (u) on the deck using the extreme freeboard exceedence (h) as input. These are also based on the empirical relations for different bow flare angles. The water height on the deck, H, was found to be a linear function of the freeboard exceedence at the bow according to: H = aH ⋅ h F = a F ⋅ h2 ap Is again dependent on the bow shape (full or thin) and bowflare angle (0, 10, 30 and 50 degrees). Determination of impact loading on pipes at the deck, using the water height (H) and velocity (u) on the deck. Evaluation of breakwaters to protect structures or equipment if necessary. Details of the method and parameters in the empirical relations can be found in Buchner [3]. For the possible green water loading from the side a similar approach is used. The method gives the designer the possibility to evaluate the relation between the available design parameters (dashed lines from the top) and the resulting green water effects. This allows the evaluation of the different options to solve the green water problem for a specific ship-type offshore structure: 1. Design the vessel and structures on the deck against the predicted green water impact load levels. 2. Optimise the bow shape (underwater shape and above water bow flare). 3. Increase the freeboard height such that green water is prevented completely. 4. Increase the freeboard height such that the green water loads are reduced to acceptable levels and design for these load levels. 5. Optimise the structures on the deck to minimise the green water impact loads. 6. Use protecting breakwaters in front of critical structures on the deck. (1) The parameter aH is dependent on position at the deck and the bow flare angle. The velocity of the water over the deck is related to the square root of the water height at the fore perpendicular H0 according to: u = au H0 GENERAL DESIGN CONSIDERATIONS FOR GREEN WATER EVALUATION The largest relative wave elevations occur when the wavelength is equal to the ship length. The bow shape also has a strong effect on the relative wave elevations as discussed below: • The effect of the buoyancy on the pitch motions - with a thin bow the pitch motions are significantly larger than with a full bow, which plays a role at the peak of the relative wave Response Amplitude Operator (RAO). • The reflection of the waves from the bow - the reflection is the largest for full cylindrical bows and plays an important role in the shorter waves (high frequency tail of the RAO). An optimum FPSO bow accounts for both effects described above - a bow that is not too full, but with sufficient buoyancy. This typically results in an elliptical type water line. Figure 2 compares the relative wave RAOs of FPSOs with a thin triangular bow, an elliptical bow, and a full cylindrical bow. The figure also shows the relative wave motion RAO of the DP FPSO bow described in the present case study. (2) Determination of impact loading on structures at the deck that interact with the green water flow. This is possible for different structural shapes and includes a prediction of the maximum pressure over the height of the structure. The loading of structures on the deck has to be determined in a number of steps: Step a: Determination of loads on reference (squared) structure. Step b: Correction for distance to forward perpendicular. Step c: Conversion to different structural shapes. Step d: Determination of load profile and total load. The following general expression was found for the pressure on the structure (p): p = a p ⋅ h2 (4) (3) 3 Copyright © 2003 by ASME Relative wave motion (m/m) e) The hull design must also account for constructability issues, i.e., a simpler structure is easier to built, inspect and maintain. In order to accomplish the above mentioned design requirements of the DP-FPSO, the vessel hull has been provided with the following features: - Hull forms typical for new-built FPSOs, with prismatic mid-body in way of the cargo tanks, sloped flat transom and triangular bow. Rounded bilge of adequate radius to accommodate bilge keels, as well as camber of suitable height. - The fore and aft ends have been designed to properly accommodate the envisaged number and size of thrusters (three forward and three aft). The triangular bow allows a suitable arrangement for the three forward thrusters, minimises the wind, current, wave drift forces and forward resistance, and yields a simpler construction. In order to provide room for installation of the offloading equipment and flare, the hull shape aft at main deck level will be square (full beam) in a cantilever structure of rounded shape to prevent slamming. - A forecastle deck of suitable height is provided to insure acceptable green water loads in extreme design conditions. However, this was decided after thorough evaluation of the alternatives for mitigating the green water loading described hereinafter. A poop deck is provided as well for similar reasons. Bulwark of reduced height (to avoid large induced loads on the stanchions and supporting deck) is fitted forward and aft as required. A bow flare angle of 30 degrees has been provided above the maximum draft. - A moonpool of diameter as specified by turret designer is located amidships. 4 3.5 3 cyl 2.5 ell 2 tri 1.5 1 0.5 0 0 0.5 1 1.5 wave frequency (rad/s) Figure 2: Relative wave motions RAOs for a thin triangular, an elliptical and a full cylindrical bow compared to the present DP FPSO bow (crosses) Bow flare (and rake) typically reduces the amount of water coming onto the deck as the flare pushes the water away from the deck. However, large flare/rake angles (above 40 degrees, say) are not recommended because they can cause significant bow flare slamming at the hull plating. The results presented in Buchner [3] illustrate that a flare angle of approximately 30 degrees is optimum, with the elevation of the foc’sle deck dependent on the estimated relative wave elevations and the philosophy for allowable green water on deck (described in more detail later). DP FPSO The hull of the DP-FPSO has been designed taking the following key aspects into consideration: a) Environmental forces induced by waves, wind and current should be minimised in order to keep the CAPEX/OPEX of the Unit within reasonable limits, as well as the emissions produced by the dual (diesel/gas) generators, which must be continuously running in a fully DP vessel. b) The hull configuration must allow for an adequate arrangement of the thrusters at the fore and aft ends, to avoid thruster-thruster and thruster hull/turret interactions. Moreover, the layout of the machinery spaces and the ease of thruster overhauling is significantly affected by the selected vessel hull forms. c) In heavy storms (hurricanes, squall events, etc.), the vessel behaviour against green waters and slamming occurrences must be acceptable, insuring adequate safety of the people onboard and sensitive equipment (fire fighting, lifesaving equipment, etc.). d) Layout requirements, such as: Accommodation forward (for navigation in sail away condition after disconnection), turret amidships (to minimise riser system dynamics and vessel motions for turret buoy (dis)connection operations), and offloading equipment at the stern for tandem offloading, have to be catered for in the design. In Figures 3 and 4 the artist impression and body plan of the vessel are shown. The initially chosen vessel characteristics are shown in Table 2. Figure 3: Artist impression of the DP FPSO 4 Copyright © 2003 by ASME Pressure Load Moment (H) 6.1 m (pdeck) 75.4 kPa (p) 241 Pa (FX) 7234 kN (FX) 7234 kN REDUCE THE AMOUNT OF GREEN WATER BY INCREASING THE FREEBOARD In principle it is possible to increase the freeboard to such a level that no (or a negligible amount of) green water comes onto the deck. For the present vessel and design environmental conditions and using the semi-empirical methodology, this results in an extreme freeboard height of 21.0 m. However, the question is whether such an increase is really necessary. Equipment on the decks of ships (designed according to normal ship rules) are designed to accept a certain amount green water loading and therefore it is not required to keep the deck completely dry. Although exact levels cannot be defined, it was proposed in by Morris, Millar and Buchner [1] to define typical susceptibility levels for green water loading: Table 2: Main particulars of the DP FPSO Value 214,757 260.0 46.0 28.0 20.5 (h) 8.2 m Now a number of options for the further optimisation of the design will be discussed: • Reduce the amount of green water by increasing the freeboard. • Optimise the structure at the deck to minimise the loading. • Protect critical equipment, using breakwaters. • Use a sloped deck (‘canopy’). Figure 4: Body plan of the DP FPSO Parameter Displacement (fully loaded) Length between perpendiculars Breadth Depth Draft (fully loaded) Pressure on deck Basic design Water height Design option Freeboard exceedance Table 3: Overview of green water loads for basic case design of the DP FPSO Unit Metric tonnes m m m m Although, as explained above, an elliptical bow seems to be the most suitable shape to prevent green waters while keeping the drift loads within reasonable limits, the combined effect of the triangular bow and the 30 degrees flare angle, provides an equivalent relative wave RAO and fairly good hydrodynamic behaviour. This can be observed in Figure 2, where the relative wave RAOs of FPSOs with full cylindrical, elliptical and triangular have been plotted together with the RAO of the DP-FPSO. At higher frequencies, the behaviour is in between the triangular and the elliptical shapes, whereas at the peak it is between the elliptical and the full cylindrical. 0 - 3 meter freeboard exceedance: 3 - 6 meter freeboard exceedance: 6 meter and higher freeboard exceedance: low medium high In general it is found that for freeboard exceedances lower than 3 m, the resulting loading is relatively low and can be handled by structures designed according to existing rules. For freeboard exceedances higher than 3 m, it is recommended to assess the loading on sensitive equipment in detail. This becomes critical for freeboard exceedance in excess of 6 m. In the present paper a freeboard exceedance of 2.8 m is assumed to the acceptable. This acceptable freeboard exceedance requires an increase of the foc’sle deck by 7 m for a total of 17.5 m. With the freeboard of 17.5 m the water height on deck is reduced to 2.1 m and the pressure on the superstructure is reduced to 27.5 kPa. GREEN WATER ANALYSIS AND OPTIMISATION OF THE DP FPSO Using the semi-empirical method described above, the green water occurrence and loading for the basic design of the DP FPSO was determined in the environmental conditions from Table 1. The results are shown in Table 3 , giving the: - Most Probable Maximum freeboard exceedance. - Water height on deck at the fore perpendicular. - Related pressure on the deck. - Estimated local peak pressure on the structure. - Total horizontal force on the structure. - Total moment on the superstructure with respect to the deck level. 5 Copyright © 2003 by ASME OPTIMISE THE STRUCTURE AT THE DECK TO MINIMISE THE LOADING Instead of increasing the freeboard, it is also possible to optimise the structure at the deck to minimise the green water impact loading. The magnitude of the loads on large structures on the deck is dependent on the shape of the structures relative to the flow direction. Structures deflect the high velocity flow, resulting in loads caused by the change in momentum. For structures that deflect the flow more gradually, impact loads are reduced significantly. To investigate the sensitivity of the impact load on structures on the bow for the structural shape, in Buchner [3] a series of seven different structures was tested. The structures can represent a protection structure around the turret for bow turret systems, as well as an accommodation superstructure for heading controlled FPSOs with the turret further aft. The following structural shapes were investigated: • Squared structure. • Tilted structure under 30 degrees angle with vertical. • Triangular structure with 45 degrees semi-angle. • Triangular structure with 60 degrees semi-angle. • Cylindrical structure. • Squared structure with triangular support. As an example, Photo 1 shows the tilted structure and the triangular structure with 60 degrees semi-angle. It is now possible to make a direct comparison between the loading on the different structural shapes with the same amount of green water on the deck. In Table 4 the peak pressure and total for the same condition as the base case design and the 100-year wave. Both the peak local pressure (p) and the horizontal FX-load are compared. The pressure (p) is for a circular force panel and presented as integrated pressure over the total area of the panel 1.43 m2. The loads on these structures are all significantly lower than on the squared structure. These differences are a result of the fact that the momentum in the x-direction is not deflected completely (and over a longer period of time) for these structures. Table 4: Overview of green water loads on different structural shapes Structure Squared structure 30 degrees with vertical Triangular 45 degrees Triangular 60 degrees Cylindrical Triangular support p in kPa 241 133 63 113 192 162 FX in kN 7234 4465 2907 4407 3762 6218 PROTECT CRITICAL EQUIPMENT, USING BREAKWATERS If it is not necessary to keep an installation on the deck completely dry, it is possible to use a breakwater (water deflector) in front of it. Such a structure can also be used as a first barrier for a lighter protective structure or a superstructure. For the design of this type of breakwaters, it is important to keep their purpose in mind: breaking or deflecting the green water that flows with a certain height at high velocity over the deck, to minimise the impact on the critical structure. This results in the following requirements: - The breakwater should be higher than the water height on the deck. - The breakwater has to deflect or break the green water flow efficiently, so that the amount of water that finally reaches the critical structure will be minimised in amount and/or velocity. - The breakwater and the underlying support structure should be strong enough to deal with the dynamic load due to the water impact on the breakwater itself. Photo 1: Tilted structure and triangular structure 6 Copyright © 2003 by ASME In Buchner [3] three different types of breakwaters were evaluated: - Traditional V-type breakwater. - Vertical wall breakwater with its upper side tilting forward. - Vane type breakwater. The different breakwater shapes are shown in Photo 2 and Figure 5. All breakwaters had a height of 4.98 m from the deck level. The breakwaters were placed at a position of 16 m in front of a squared structure, which was placed 30 m from the fore perpendicular. The different breakwater shapes are shown in Figure 5. The shaded areas in the figures indicate the parts at which the local load is measured. Also the global load and moment on the complete breakwater were measured. In front of closed breakwaters, such as the traditional V-type breakwater and vertical wall breakwater, the green water tends to run-up vertically as soon as the water front hits the breakwater. This fills the complete area in front of the breakwater, which results in the rest of the water flowing over the breakwater. This reduces the effective height of the breakwater, see Photo 3. To prevent this run-up as much as possible, the vane type breakwater is a good alternative, see Beynet [8]. This open breakwater with vertical vanes under an angle of 45 degrees, deflects the water away from critical structures, but does not completely block the fluid flow. This reduces the run-up in front of the breakwater as well as the impact loading on the breakwater itself. Photo 2: The three breakwater types tested Figure 5: Traditional V-type breakwater, vertical wall breakwater and vane type breakwater (from left to right) 7 Copyright © 2003 by ASME • To protect against the water height of 4.8 m on the deck, the traditional breakwater needs to be 5.9 m high. The vane type breakwater height can be limited to 5.3 m. • The horizontal load on the traditional breakwater is 15938 kN (moment with respect to the deck level 53651 kNm), whereas the horizontal load on the vane type breakwater is only 5938 kN (moment 17337 kNm). It can be concluded that the vane-type breakwater is an interesting concept, because it combines its protective features with an open access to the deck and low loads on the structure itself. The traditional breakwater has a larger horizontal load than that on the structure to be protected itself, due to its larger width. This load also needs to be supported by the underlying deck structure. Photo 3: Run-up of green water in front of the traditional breakwater Due to the run up problem, the breakwaters should be higher than the water height expected at the breakwater location. Based on the results presented in Buchner [3], a safety factor is defined for the required breakwater height, see Table 5. The water height on the deck has to be multiplied by this factor to find the required breakwater height. Table 5: Safety factors for the breakwater height Breakwater Traditional V Vertical wall Vane Safety factor 1.21 1.17 1.10 USE OF A SLOPED DECK (‘CANOPY’) Another interesting green water protection concept is the sloped deck (or canopy), a principle already applied on container vessels. It proved to be very effective during the Joint Industry Project ‘F(P)SO Green Water Loading’, see Buchner and van Ballegoijen [9]. With a sloped deck the green water flowing onto the deck is decelerated by the sloped deck. The water also stays at a high level at the moment that it is on the sloped deck. It does not flow away over the bulwark, as is the case for a normal deck. As a result of this, the flow of additional water onto the deck, which is dependent on the water level difference on the deck and outside the deck, is minimised. The result is a minimal thin sheet of water on the sloped deck with hardly any impact on the structure. In Buchner and van Ballegoijen [9] comparisons were made in regular waves using a full elliptical tanker bow with a traditional flat deck and the sloped deck, see Figure 6. The slope was only 10 degrees with the horizontal. Table 5 confirms that the vane type breakwater is the most effective in the prevention of run-up. The remaining water height behind the breakwater and the loading on the structure behind the breakwater (which is partially due to the flow from the sides behind the breakwater) are almost equal for all three breakwater types. Another point of concern is the peak load on the breakwater itself at the moment of impact. This load is important for the design of the breakwater structure itself, but also on the underlying support structure below the deck. The method to determine these loads is described in detail in Buchner [3]. For the present case study two breakwater types were studied: the traditional V-type breakwater and the vane type breakwater. Evaluation of the two breakwater types results in the following comparison: Figure 6: Sloped deck (or canopy) on the bow deck 8 Copyright © 2003 by ASME Photo 4: Comparison between the green water loads with flat deck (left) and with sloped deck (right) Photo 4 shows a visual comparison between two stages in the flow of the green water on the horizontal (above) and sloped (below) deck. Table 6 summarises the result of this comparison, showing the water height and pressure on the deck, as well as the load on a squared structure with its front 30 m from the fore perpendicular. Basic design Sloped deck - (H) (p deck) (p) (FX) 3.3 m 42 kPa 92 kPa 3080 kN 1.0 m 23 kPa 16 kPa 928 kN Pressure on squared structure Load on squared structure (h) 9m 8.5 m Pressure on deck Water height Design option Freeboard exceedance Table 6: Comparison between the green water loads with flat deck and with sloped deck - With similar freeboard exceedances (9.0 and 8.5 m), the water height on the deck is reduced significantly (with a factor 3). - The loading on the structure on the deck is even more reduced: the peak pressure with a factor of almost 6. The total horizontal load is a factor 3 lower. Although the amount of measurements with the sloped deck is limited, in Figure 7 a comparison is made between the regular wave test results with the sloped deck and the trends presented in Buchner [3] for a horizontal deck. Table 7 summarises the coefficients in Expressions (1)-(4) for the sloped deck (using a least fit) and the horizontal deck. Again significantly reduced heights and pressures are identified from these results. Table 7: Comparison between coefficients in the Expressions (1)-(4) with the flat deck and with sloped deck Horizontal deck The following can be concluded from the photos and table: The relative wave motions (and freeboard exceedance) are affected because the amount of green water on the deck of the ship affects the ship motions and because the flow onto the deck influences the relative wave motions around the ship as well. aH 0.56 0.10 ap 2.02 0.28 aF 9 Sloped deck 93.4 15.6 Copyright © 2003 by ASME a. Basic Design For the basic design, as indicated earlier, it has been derived a freeboard exceedance of 8.2 m, and a pressure on the front bulkhead of 241 kPa. Although the structure can be designed for this pressure, there are other considerations (safety of personnel, impact on sensitive equipment, ...) that require remedial actions to be implemented to take the amount of embarked water down to acceptable levels. The deck and superstructure front need to be reinforced with respect to Ruled design pressures (e.g., 178 kPa at the front according to DnV Rules). Horizontal load on structure (FX) in kN Impact pressure (p) in kPa Water height (H) in m 4 2 0 2 4 6 Exceedance of freeboard (h) in m 8 10 0 2 4 6 Exceedance of freeboard (h) in m 8 10 0 2 4 6 Exceedance of freeboard (h) in m 8 10 50 2000 1000 Figure 7: The relation between the freeboard exceedance (h) and the water heights on deck (above), local peak pressures (middle) and total horizontal load (bottom) for the flat deck (dashed line) and with sloped deck (solid line) Finally it can be concluded that the canopy type deck can be constructed much lighter than the normal deck structure: the water heights and pressures on the deck are much smaller. Due to the protecting canopy structure the underlying deck structure can be constructed lighter as well. DESIGN CONSIDERATIONS FOR DP FPSO In this section, the different alternatives proposed to mitigate the effect of the green water loading are assessed from a design standpoint, with a special focus of the DP FPSO design. b. Freeboard Increase As shown before, if the freeboard is increased from 10.5 m to 17.5 m, this results in a freeboard exceedance of 2.8 m (which is acceptable as it falls within the susceptibility level considered ‘low’), and a pressure on the superstructure of 27.5 kPa. The resulting pressure does not require any additional reinforcement to the forecastle deck or superstructure over that required by Class Rules (about 42 kPa according to DnV Rules). Although there is a significant impact on the vessel design and fabrication (for the present case study the estimated weight of the forecastle (7.5 m above main deck) is of approximately 500 tonnes, however, the following advantages can be highlighted: - The amount of embarked water is very limited and therefore it is not necessary to make additional reinforcements or to further protect sensitive equipment. The risk for personnel vanishes. - There is a large space available in the forecastle that can be used to accommodate equipment, stores, etc. If accounted for at the conceptual stage of the Project, other spaces can be relocated in this area. - The forecastle can be integrated typically with the bow structure (side shell, accommodation decks, transverse frames, etc.). The scantlings of elements below the forecastle deck can be reduced. Whenever the helideck is located over the forecastle deck, it provides adequate support and reduces the height of the supporting structure. c. Shape of Structure on Deck The design of the front bulkhead of a exposed structure on deck using one of the geometries outlined earlier (triangular, cylindrical, tilted, ...), bear basically problems related to the underdeck reinforcement and layout optimisation, especially for superstructures. For protective structures of turrets or other equipment, it may be a convenient solution. The lack of alignment between the front bulkhead and the deck structure deals to more complicated connections. Also, in the case of an accommodation block, shapes different from the square makes the layout of spaces more difficult to arrange and less rational. Additionally, if this alternative is the only applied, the risk for personnel and sensitive equipment is still unacceptable. d. Use of Breakwaters From the comparison between the traditional and the vane breakwaters, the following favourable conclusions can be drawn for the later: 10 Copyright © 2003 by ASME - It is more efficient and the loads induced lower (as mentioned earlier). This leads to a shorter and lighter structure. - It is easier to support on the deck as it can be properly aligned with existing transverse girders. Thus, necessary reinforcement is reduced compared to the traditional breakwater. - It provides an easier arrangement on deck and the interference with other equipment is less than that in a traditional breakwater. Besides the above advantages of the vane type breakwater, this alternative needs to be carefully evaluated, as there is still a significant water height on deck, which may impair the safety of personnel or other sensitive equipment. The dimensions of the required vane type breakwater are in any case quite large (say 30 m wide and 5.3 m high). The estimated weight of the traditional breakwater and underdeck reinforcement is of 50.0 tonnes, whereas for the vane type breakwater is if about 60.0 tonnes. Although the height of the vane type breakwater and the applied loads are lesser than in the traditional breakwater, the special configuration of the former yields a somewhat higher steel weight. e. Use of a Sloped Deck (‘Canopy’) The sloped is a smart solution to minimise green water loading on equipment and superstructures, as discussed earlier. Its efficiency (for a slope of 10 degrees) can be considered equivalent to that of raising the forecastle deck 7.0 m. As can be observed, the resulting impact pressures on the front bulkhead are quite similar. Nevertheless, there are several drawbacks (related to the sloped configuration of the deck) in this alternative for application to FPSOs that should be mentioned: - From a structural point of view, the connection area (‘wedge’ type) of the main deck to the ‘canopy’ deck is complicated because of the small angle between both decks (10 degrees). - Mooring and other deck equipment is more difficult to arrange in this option than in a conventional horizontal deck. Operating and safety aspects are better resolved in the later. - Support for the helideck supporting structure is more difficult in this alternative and the height of the supporting pillars significantly higher than in the ‘forecastle’ option. - The space below the ‘canopy’ deck can be hardly used. - Even though the steel weight of this alternative is much lesser than that of a 7.0 m forecastle (estimated weight 180.0 tonnes), the higher production rate (hours/tonne) and reduced efficiency associated to the items outlined above, lead to similar ‘as-built’ costs for both alternatives. - It is more complicated to integrate the sloped deck with the vessel bow than the forecastle. In both alternatives, the scantlings of structural elements below the deck can be reduced. Thus, for FPSO applications, it looks that to raise the forecastle deck up to an adequate height that reduces the freeboard exceedance down to a ‘low’ susceptibility level, is the most overall suitable option. This is confirmed by the fact that it is the alternative most frequently used in FPSOs. However, for applications different from the case study investigated in this paper, there may be other alternatives more convenient. CONCLUSIONS In the present paper the practical design considerations related to the green water problem are discussed. The following can be concluded: • Green water is a significant problem for floating offshore structures, which needs to be assessed in the early design of the structure. • The developed semi-empirical design evaluation procedure can assist in this process. • There are different ways to solve the green water problem for a particular structure at a specific location. They all have their advantages and disadvantages. It is the authors’ opinion that those solutions focussed on minimising the freeboard exceedance (increase freeboard or sloped deck) should be used as the primary choice. The other options are more suitable for protecting personnel or sensitive equipment, and to minimise green water loading which, in turn, can not be completely avoided. REFERENCES [1] Morris, W.D.M., Millar, J. and Buchner, B., 2000, “Green Water Susceptibility of North Sea FPSO/FSUs,” 15th Conference on Floating Production Systems (FPS), London. [2] Ersdal, G. and Kvitrud, A., 2000, “Green water on Norwegian Production Ships,” ISOPE2000, Seattle. [3] Buchner, B., 2002, “Green Water on Ship-type Offshore Structures,” PhD-thesis Delft University of Technology, 2002. [4] Buchner, B., Voogt, A.J., Duggal, A.S. and Heyl, C.N., 2002, “Green Water Evaluation for FPSOs in the GoM,” OTC, Houston. [5] Cortijo, J.L, Lago, F. and Mendez, A., 2002/2003, “New FPSO-Based Concepts for the Deep Water Challenge,” 17th Annual Conference on Floating Production Systems (December 2002, London) and Petrotech 2003 Conference (January 2003, New Delhi). [6] Buchner, B., 1995, “The Impact of Green Water on FPSO Design,” OTC paper 7698, OTC 1995, Houston. [7] Hellan, Ø., Hermunstad, O.A. and Stansberg, C.T., 2001, “Design Tool for Green Sea, Wave Impact, and Structural Response on Bow and Deck Structures,” OTC paper 13213, OTC 2001, Houston. [8] Beynet, P., 1994, “Personal communication on vane type breakwater.” [9] Buchner, B. and Ballegoijen, G. van, 1997, Joint Industry Project: “F(P)SO Green Water Loading,” A, B and C, MARIN report No. 13644-1-ZT, Wageningen. 11 Copyright © 2003 by ASME