- PowerLogic

advertisement

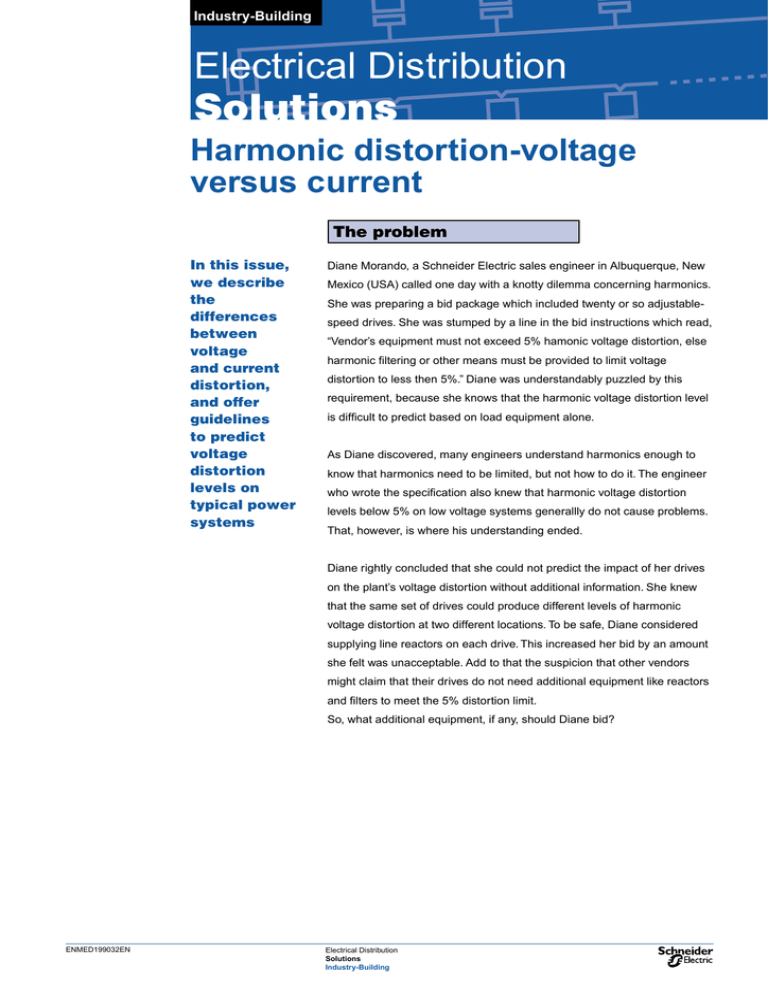

Industry-Building Electrical Distribution Solutions Harmonic distortion-voltage versus current The problem In this issue, we describe the differences between voltage and current distortion, and offer guidelines to predict voltage distortion levels on typical power systems Diane Morando, a Schneider Electric sales engineer in Albuquerque, New Mexico (USA) called one day with a knotty dilemma concerning harmonics. She was preparing a bid package which included twenty or so adjustablespeed drives. She was stumped by a line in the bid instructions which read, “Vendor’s equipment must not exceed 5% hamonic voltage distortion, else harmonic filtering or other means must be provided to limit voltage distortion to less then 5%.” Diane was understandably puzzled by this requirement, because she knows that the harmonic voltage distortion level is difficult to predict based on load equipment alone. As Diane discovered, many engineers understand harmonics enough to know that harmonics need to be limited, but not how to do it. The engineer who wrote the specification also knew that harmonic voltage distortion levels below 5% on low voltage systems generallly do not cause problems. That, however, is where his understanding ended. Diane rightly concluded that she could not predict the impact of her drives on the plant’s voltage distortion without additional information. She knew that the same set of drives could produce different levels of harmonic voltage distortion at two different locations. To be safe, Diane considered supplying line reactors on each drive. This increased her bid by an amount she felt was unacceptable. Add to that the suspicion that other vendors might claim that their drives do not need additional equipment like reactors and filters to meet the 5% distortion limit. So, what additional equipment, if any, should Diane bid? ENMED199032EN Electrical Distribution Solutions Industry-Building Key concepts and Terms Voltage Distortion vs Current Distortion Small transformer represents high impedance Non-electronic loads produce undistorted currents when energized from an undistorted (sinusoidal) source (see figure 1). Undistorted Current Undistorted Voltage Large transformer represents low impedance 10 kVA 4% Imped Transformer 100 kVA 4% Imped Transformer 10% THD Voltage– Excessive 10 Amps 40% THD 2% THD Voltage– Acceptable Identical Non-Linear Loads 10 Amps 40% THD Figure 3: The same nonlinear load can produce different levels of harmonic voltage distortion depending on the source impedance. Figure 1: Linear loads produce an undistorted current waveform when energized from an undistorted voltage source. Electronic loads, like adjustable-speed drives, produce distorted currents when energized from an undistorted source (see figure 2). Distorted Current Undistorted Voltage Figure 2: Nonlinear loads produce distorted currents when energized from an undistorted voltage source. Voltage distortion occurs when these distorted currents flow into the source impedance. The more source impedance, roughly, the more voltage distortion will result. In figure 3, the smaller transformer represents a higher impedance to the adjustable-speed drive than does the large transformer. An equal amount of current distortion produces more voltage distortion on the smaller system than on the larger circuit. In the diagram, the resulting voltage distortion is 10%. This level of distortion can cause operating problems and excessive heating, and reduce the lifetime of equipment energized from this transformer. ENMED199032EN Electrical Distribution Solutions Industry-Building Figure 3 indicates the level of harmonic distortion to illustrate the differences in impedance between the two systems. How is the distortion level determined before equipment is installed and energized? And, will this distortion level be excessive? The voltage and current THD can be predicted through computer modeling of the source impedance and adjustable-speed drive. The following guidelines may also help. Typical Harmonic Levels Small adjustable-speed drives (in the 5-100 hp range) are usually pulse-width modulated (PWM) drives. These three-phase loads may have current distortion levels over 100%, as shown in figure 4. DC drives in this category inject less harmonic current, usually about 30% or so. Switch-mode power supplies serve personal computers, fax machines, and other electronic office equipment. These single-phase devices inject currents with about 80% THD. Current Voltage Figure 4: Pulse-width modulated adjustable-speed Ac drives produce a characteristic double-hump current waveform that is rich in harmonics. Harmonic Distortion-Voltage versus Current The solution Voltage Distortion Rules of Thumb Commercial As indicated earlier, voltage distortion levels cannot be determined solely from the current distortion of the load. But there are guidelines that, with a little information about the electrical system to which the harmonic loads will be applied, may help determine whether excessive voltage distortion is likely to result. Caution: if power factor correction capacitors are or will be in service, the guidelines described below do not apply! Most electronic loads in a commercial building are single phase. Typical loads are personal computers, electronic ballasts, and other electronic office machines. In the U.S., these single-phase devices generally are served at 120 V, usually by a step-down transformer if the utility service is 480 V. Voltage distortion on the 480 V system is usually not seriously affected by the 120 V loads, but this guideline has exceptions. Office buildings with a high percentage of load in single-phase loads, coupled with many 480 V adjustable-speed drives (usually pulse-width modulated drives serving chillers, air handling fans, and pumps) can experience problems with voltage distortion. Voltage distortion should be less than 5% if total nonlinear loads are less than 20% of transformer capacity. Industrial Most industrial plants use three-phase six-pulse rectifiers serving dc or ac drives. The drives produce fifth and seventh harmonic currents. If the three-phase dc drives total less than about 30% of the transformer capacity, and there are not significant electronic loads or power factor correction capacitors, the resulting voltage distortion will probably be less than 5%. For ac pulse-width modulated drives, about 20% of transformer capacity can be adjustable-speed drives, without exceeding 5%. You can get a rough estimate of this criterion by assuming the drive horsepower approximately equals the drive kVA requirement. Since transformers are rated in kVA, the total drive horsepower (kVA) should be less than 20% (ac) or 30% (dc) of the transformer capacity. For example, twenty 50-hp dc drives (1000 kVA) on a 2000 kVA transformer exceeds the 30% guideline. These 20 drives should not be applied without a harmonic study or simulation. ENMED199032EN Electrical Distribution Solutions Industry-Building Morando Example The bid Diane was preparing included 16 PWM drives on one 750 kVA transformer, and two on another. The total horsepower was 390 in the first case, 100 in the second. Using the estimate that one hp equals one kVA, the first transformer would serve 390 KVA in electronic drives, out of a capacity of 150 kVA, or 52%. This loading considerably exceeds the guideline of 20%. The 16 drives should not be applied without a harmonic system analysis. In the second case, the electronic drives represent only 13% of the transformer capacity. This installation will not cause excessive voltage distortion if the drives are the only harmonic-producing loads served by the transformer. Conclusion Responding to a specification which sets requirements on voltage distortion requires careful thought. The amount of voltage distortion that will result from a given set of electronic loads depends on the characteristics of the electrical system serving the electronic loads, not just on the loads themselves. Without power factor correction capacitors, the amount of electronic load can be as much as 20% (ac drives) or 30% (dc drives) of the transformer capacity without exceeding 5% voltage distortion. With capacitors, excessive voltage distortion can occur at much lower levels of harmonic currents due to resonance. ENMED199032EN PowerLogic Circuit Monitors offer the benefit of monitoring harmonics at the drive or transformer to detect harmonic distortion before it becomes troublesome. Circuit Monitors should be included in any drive installation to ensure that power system harmonic levels can be tracked and controlled. Schneider Electric Industries SA Centre Merlin Gerin F - 38050 Grenoble cedex France Tel.: +33 (0)4 76 57 60 60 Fax: +33 (0)4 76 57 73 62 http://www.schneiderelectric.com service-commc4@mail.schneider.fr ART.28265 This paper was originally published as a part of the series PowerLogic Solutions, copyright Square D Company 1998. Used with permission. This document has been printed on ecological paper. Published by: Schneider Electric SA Design and layout by: Insign’ Printed by: 09/1999