Table of Contents - GE Industrial Solutions

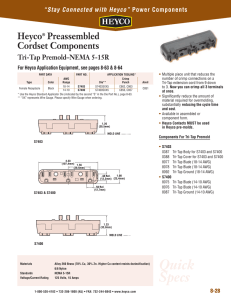

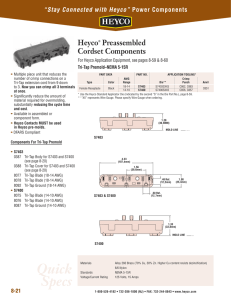

advertisement