Chapter 5 Description of the Proposed Expansion

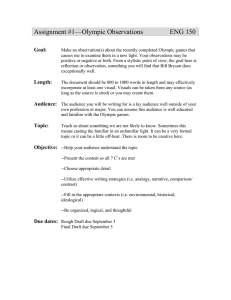

advertisement