SiC POWER MODULES - Mitsubishi Electric

advertisement

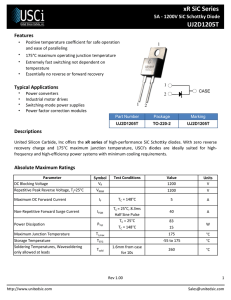

SiC POWER MODULES Innovative Power Devices for a Sustainable Future Traction, industrial equipment, building facilities, electric vehicles, renewable energies, home appliances... Power devices are a key component in power electronics products for contributing to the realization of a low-carbon society. Attracting attention as the most energy-efficient power device is one made using new material, silicon-carbide (SiC). The material characteristics of SiC have led to a dramatic reduction in power loss and significant energy savings for power electronics devices. Mitsubishi Electric began the development of elemental SiC technologies in the early 1990s and has since introduced them to achieve practical energy-saving effects for products manufactured using SiC. Innovative SiC power modules are contributing to the realization of a low-carbon society and more affluent lifestyles. SiC: Silicon Carbide-Compound that fuses silicon and carbon at a ratio of one-to-one. Traction • Size and weight of traction inverters reduced • Regenerative performance enhanced • Noise reduced Home appliances • Energy savings increased • Cooling system more compact • Equipment more compact/thinner Industrial equipment • High torque, high speed, size reduced • Cooling system more compact • Manufacturing productivity enhanced Merits of Incorporating SiC Power Modules Electric/Hybrid vehicles • Power loss reduced • Cooling system more compact • Regenerative power used efficiently Renewable energies • Energy conversion efficiency improved • Passive components downsized • Quieter high-speed operation Building facilities • Power loss reduced • Greater layout freedom as the result of smaller equipment 1 SiC with superior characteristics Si n+ p SiC Gate Source n - Source n+ Gate Source p p n+ SiC Source n+ nSiC substrate 3 times that of Si 1 10 Si substrate Large reduction in electrical resistance Drain electrode Si MOSFET structure High temperature Band gap Band gap is approx. Drain electrode SiC MOSFET structure Current flow Conduction band p Valence band Power loss reduced High-temperature operation SiC has approximately 10 times the critical breakdown strength of silicon. Furthermore, the drift layer that is a main cause of electrical resistance is one-tenth of the thickness. This allows a large reduction in electrical resistance and, in turn, reduces power loss. This SiC characteristic enables dramatic reductions in conductivity loss and switching loss in power devices. When the temperature increases, electrons are exited to the conduction band and the leakage current increases. At times, this results in abnormal operation. However, SiC has three times the band gap width of silicon, preventing the flow of leakage current and enabling operation at high temperatures. Si SiC Hybrid SiC power modules Si Turn-on switching waveform SiC High-speed switching operation realized Thermal conductivity rate is approx. 3 times that of Si Ic:500A/div Vce:250V/div t:1μs/div High-speed switching operation Heat dissipation With SiC, owing to the high dielectric breakdown, power loss is reduced and high-voltage is easier to achieve, it is possible to use Schottky Barrier Diodes (SBDs), which cannot be used with Si. SBDs can realize high-speed switching motion because they don't have accumulation carriers. As a result, high-speed switching can be realized. SiC has three times the heat conductivity of silicon, which improves heat dissipation. SiC power modules appropriated by application Application Product name Hybrid SiC-IPM Full SiC-IPM Full SiC-IPM for PV Applications Full SiC Power Modules Industrial equipment Hybrid SiC Power Modules for High-frequency Switching Applications Traction Home appliances Large Hybrid SiC DIPIPMTM for PV Application Hybrid SiC Power Modules Super-mini Full SiC DIPIPMTM Super-mini Hybrid SiC DIPPFCTM Super-mini Full SiC DIPPFCTM Model PMH200CS1D060 PMH75CL1A120 PMF75CL1A120 PMF75B4L1A060 FMF400BX-24A FMF800DX-24A CMH100DY-24NFH CMH150DY-24NFH CMH200DU-24NFH CMH300DU-24NFH CMH400DU-24NFH CMH600DU-24NFH PSH50YA2A6 CMH1200DC-34S PSF15S92F6 PSH20L91A6-A PSF20L91A6-A Rating Voltages[V] Current[A] Connection States 600 200 6 in 1 1200 75 6 in 1 600 1200 1200 4 in 1 4 in 1 2 in 1 2 in 1 Commercially available 600 1700 600 75 400 800 100 150 200 300 400 600 50 1200 15 Commercially available Sample available Sample available Sample available Commercially available Commercially available 4 in 1 2 in 1 6 in 1 600 20Arms Interleaved Commercially available Commercially available Commercially available Commercially available Commercially available 1200 Insert pages P3 P4 P5 P6 P7 Terminology SiC Silicon Carbide FWD-SW Diode switching loss DIPIPM Dual-In-Line Package Intelligent Power Module Tr-SW Transistor switching loss IPM DIPPFC SBD MOSFET IGBT Tr Intelligent Power Module Dual-In-Line Package Power Factor Correction Schottky Barrier Diode Metal Oxide Semiconductor Field Effect Transistor Insulated Gate Bipolar Transistor Transistor FWD-DC Tr-DC IGBT-SW IGBT-DC PV CSTBT Diode DC loss Transistor DC loss IGBT switching loss IGBT DC loss Photovoltaics Mitsubishi Electric’s unique IGBT that makes use of the carrier cumulative effect 2 600V/200A Hybrid SiC-IPM for Industrial Equipment PMH200CS1D060 Commercially available SiC-SBD incorporated in an IPM with a built-in drive circuit and protection functions Power loss reduction of approx. 20% contributes to enhancing the performance of industrial machinery Features • Hybrid combination of SiC-SBD and IGBT with current and temperature sensors implemented for IPM supplies high functionality and low loss enabling high torque and motor speed • Recovery loss (Err) reduced by 95% compared to the conventional product* • Package compatible with the conventional product* making replacement possible * Conventional product: Mitsubishi Electric S1 Series PM200SC1D060 Internal circuit diagram : SiC-SBD FWD_SW FWD_DC Power loss comparison IGBT_SW IGBT_DC P V 20% Power loss [W] U Approx. W reduction Si-IPM N Hybrid SiC-IPM Condition:Vcc=300V, Io=85Arms, fc=15kHz, VD=15V,P.F=1, Modulation=1, Three-phase modulation, Tj=125˚C 1200V/75A Hybrid/Full SiC-IPM for Industrial Equipment PMH75CL1A120/PMF75CL1A120 Sample available Built-in drive circuit and protection functions realize high functionality Features Main specifications • Incorporates SiC-MOSFET with current sensor and built-in drive circuit and protection functions to deliver high functionality • Significant reduction in power loss compared to the conventional product* • Package compatible with the conventional product* Rating Mounted Functions 1200V/75A 6in1 • Built-in drive circuit • Under-voltage protection • Short-circuit protection • Over-temperature protection (Monitoring IGBT chip surface) * Conventional product: Mitsubishi Electric IPM L1 Series PM75CL1A120 P :SiC-MOSFET Full SiC-IPM SiC-MOSFET with current sense terminal Drain U V W Gate Sense N 3 :SiC-SBD Source FWD_SW FWD_DC Power loss comparison Si-IPM Hybrid SiC-IPM Tr_SW Tr_DC Approx. Approx. reduction reduction 25% Power loss [W] Internal circuit diagram 70% Full SiC-IPM Condition:Vcc=600V, Io=31Arms (assuming a 15kW inverter), fc=15kHz, P.F=0.9, Modulation=1, Three-phase modulation, Tj=125˚C 600V/75A Full SiC-IPM for PV Applications Sample available PMF75B4L1A060 Improved power conversion efficiency and high-frequency drive enable reactor size to be reduced Features Main specifications • Incorporates SiC-MOSFET with current sensor, built-in Rating 600V/75A 4-in-1 drive circuit and protection functions to deliver higher • Built-in drive circuit functionality Functions • Under-voltage protection incorporated • Power loss reduced approx. 50% compared to • Short-circuit protection conventional product* • Improved power conversion efficiency and high-frequency drive enable reactor size to be reduced • Package compatible with conventional product* * Conventional product: Mitsubishi Electric IPM PM75B4LA060 Internal circuit diagram :SiC-MOSFET P :SiC-SBD Power loss comparison FWD_SW FWD_DC Tr_SW Tr_DC SiC-MOSFET with current sense terminal U V Gate Sense Approx. Power loss [W] Drain Source 50% reduction Si-IPM Full SiC-IPM Conditions : Vcc=300V, fc=20kHz, Io=27.5Arms, P.F=1, Modulation=1, Tj=125℃ N 1200V/400A・1200V/800A Full SiC Power Modules for Industrial Equipment FMF400BX-24A/FMF800DX-24A Commercially available Contributes to reducing size/weight of industrial-use inverters with the mounting area reduced by approx. 60% Features • Power loss reduced approx. 70% compared to the conventional product* • Low-inductance package adopted to deliver full SiC performance • Contributes to realizing smaller/lighter inverter equipment by significantly reducing the package size and realizing a mounting area approx. 60% smaller compared to the conventional product* *Conventional product:Mitsubishi Electric CM400DY-24NF(1200V/400A 2in1) 2pcs Power loss comparison Applications Rated voltage Industrial equipment 1200V Reted current Circuit configration 400A 4-in-1 800A 2-in-1 Comparison with conventional product package Package size (D ×W) 92.3 × 121.7mm Si power module 1200V/400A(2-in-1) 2pcs Approx. 60% Footprint reduction Full SiC power module 1200V/400A(4-in-1) 1pcs or 1200V/800A(2-in-1) 1pcs FWD_SW FWD_DC Tr_SW Tr_DC 1200V/800A Full SiC Power module Power loss [W] Product lineup Approx. 70% reduction IGBT module(Si) Full SiC module Condition:Vcc=600V, Io=222Arms (assuming a 110kW inverter), fc=15kHz, P.F=0.8, Modulation=1, Three-phase modulation, Tj=125˚C 4 Hybrid SiC Power Modules for High-frequency Switching Applications Commercially available For optimal operation of power electronics devices that conduct high-frequency switching Features • Power loss reduction of approx. 40% contributes to higher efficiency, smaller size and weight reduction of total system • Suppresses surge voltage by reducing internal inductance • Package compatible with the conventional product* Product lineup Industrial equipment * Conventional product: Mitsubishi Electric NFH Series IGBT Modules Rated voltage Model Applications Rated current Circuit configuration External size (DxW) CMH100DY-24NFH 100A 48 × 94mm CMH150DY-24NFH 150A 48 × 94mm CMH200DU-24NFH 200A 1200V CMH300DU-24NFH 2-in-1 300A 62 × 108mm 62 × 108mm CMH400DU-24NFH 400A 80 × 110mm CMH600DU-24NFH 600A 80 × 110mm Recovery waveform (FWD) FWD_SW FWD_DC Power loss comparison Approx. 40% Power loss [W] CM600DU-24NFH (Si-IGBT) IE:100A/div CMH600DU-24NFH (Hybrid SiC) reduction CM600DU-24NFH (Si-IGBT) 200ns/div Tr_SW Tr_DC CMH600DU-24NFH (Hybrid SiC) Condition:Vcc=600V, Io=600Ap, fc=15kHz, P.F=0.8, Modulation=1, Three-phase modulation, Tj=125˚C 600V/50A Large Hybrid SiC DIPIPMTM for PV Applications PSH50YA2A6 Commercially available More efficient power modules for PV power conditioner applications Features • Hybrid structure achieved with SiC Schottky barrier diode and 7th-generation IGBT chips • Power loss reduction of approx. 25% compared to the conventional product* • Helps downsize PV inverter system thanks to modified short-circuit protection scheme *Conventional product:Mitsubishi Electric Large DIPIPMTM PS61A99 Internal circuit diagram :SiC-SBD Power loss comparison FWD_SW FWD_DC IGBT_SW IGBT_DC P VWP1 VVPC WP VWPC LVIC LVIC VP V W VN1 VN WN FO VNC 25% reduction LVIC CFO 5 Approx. Power Loss [W] VVP1 CIN VSC N W N V Si DIPIPMTM Hybrid SiC DIPIPMTM Condition:Vcc=300V, Io=25Arms, P.F=0.8, fc=10kHz, Tj=125℃ 1700V/1200A Hybrid SiC Power Modules for Traction Inverters CMH1200DC-34S Commercially available High-power/low-loss/highly reliable modules appropriate for use in traction inverters Features Main specifications • Power loss reduced approximately 30% compared to the conventional product* • Highly reliable design appropriate for use in traction • Package compatible with the conventional product* Module Si-IGBT @150˚C SiC-SBD @150˚C 150˚C Max.operating temperature 4000Vrms Isolation voltage 2.3V Collector-emitter saturation voltage turn-on 140mJ Switching loss 850V/1200V turn-off 390mJ 2.3V Emitter-collector voltage 9.0μC Capacitive charge * Conventional product: Mitsubishi Electric Power Module CM1200DC-34N Internal circuit diagram 2 (E1) (C2) C2 E1 G1 G2 Si-IGBT C1 Power loss comparison FWD_SW FWD_DC Si-IGBT IGBT_SW IGBT_DC Approx. 30% Power loss [W] 4 :SiC-SBD reduction E2 3 (C1) 1 CM1200DC-34N (E2) CMH1200DC-34S Condition:Vcc=850V, Io=600Arms, fc=1kHz, P.F=1, Modulation=1, Three-phase modulation, Tj=125˚C 600V/15A Super-mini Full SiC DIPIPMTM for Home Appliances PSF15S92F6 NEW Contributes to extremely high power-efficiency in air conditioners, and easily applicable to industrial equipment Features • SiC-MOSFET achieves reduction in ON resistance, power loss reduced approx. 70% compared to conventional product* • Construct low-noise system by reducing recovery current • Numerous built-in functions: Bootstrap diode for power supply to drive P-side, temperature information output, etc. • Unnecessary minus-bias gate drive circuit using original high Vth SiC-MOSFET technology • As package and pin layout compatibility with conventional products* is ensured, simply replace with this product to improve performance *Conventional product: Mitsubishi Electric Super-mini DIPIPM™ Series Power loss comparison LVIC Module power loss [W] Internal block diagram HVIC NV NU W V U P Tr_SW Tr_DC Approx. 70% reduction Si DIPIPMTM NW Di_SW Di_DC Full SiC DIPIPMTM Vcc=300V, VD=15V(Si),18V(SiC), fc=15kHz, P.F=0.95, Modulation=0.8, Io=1.5Arms, Tj=125℃ 6 Super-mini Hybrid / Full SiC DIPPFCTM for Home Appliances PSH20L91A6-A / PSF20L91A6-A Commercially available Utilizing SiC enables high-frequency switching and contributes to reducing the size of peripheral components Features • Incorporating SiC chip in the Super-mini package widely used in home appliances • The SiC chip allows high-frequency switching (up to 40kHz) and contributes to downsizing the reactor, heat sink and other peripheral components • Adopts the same package as the Super mini DIPIPMTM to eliminate the need for a spacer between the inverter and heat sink, and to facilitate its implementation Power loss comparison Internal block diagram (Full SiC DIPPFCTM) :SiC-MOSFET L1 L2 LVIC CFo GND N2 Cin1 Cin2 N1 45% reduction Si DIPPFC™ Full SiC DIPPFC™ Condition:Vin=240Vrms, Vout=370V, Ic=20Arms, fc=40kHz, Tj=125˚C Interleaved PFC circuit configuration (for Hybrid SiC DIPPFCTM) :SiC-SBD Hybrid SiC DIPPFC™ P2 L1 Vin1 MCU High-frequency drive enables reactor size to be reduced P1 VD Vin2 L2 LV IC Fo CFo Si-IGBT N2 AC input N1 GND + To inverter part PFC circuit and drive IC integrated making it possible to reduce size including smaller mounting area and simplified layout pattern Merits of combined use of SiC DIPIPMTM and DIPPFCTM Interleave PFC circuit in the case of discrete element configuration In the case of using SiC DIPIPMTM and DIPPFCTM configuration High adjustment spacer Di Tr PFC control and protection circuit parts Di Tr No need to use spacer for adjusting Merit 1 height when attaching heat sink 7 Tr_DC Approx. Power loss [W] Vin1 Fo Tr_SWoff Tr_SWon P1 P2 VD Vin2 FWD_SW FWD_DC :SiC-SBD DIPIPMTM SiC DIPPFCTM DIPIPMTM Integration of PFC circuit and drive IC made it possible to Merit 2 reduce the mounting area and make components more compact such as simplifying the wiring pattern SiC Power Module Lineup Unit: mm 31.2 30 28 6.5 LABEL 23 23 12 94 23 17 21.14 18.49 Hybrid SiC Power Modules for High-frequency Switching Applications CMH 200DU-24NFH CMH 300DU-24NFH 7.5 17 12 6.72 22 39 110 93±0.25 (8.5) 7.5 14 23.72 6 6-M6 NUTS Hybrid SiC Power Modules for High-frequency Switching Applications CMH 400DU-24NFH CMH 600DU-24NFH Tc measured point 108 93±0.25 14 14 22 39 (8.5) TAB#110, t=0.5 16 +1 7 18 2.8 LABEL 600V/50A Large Hybrid SiC DIPIPMTM for PV Applications PSH50YA2A6 A = 2.54 ±0.3 B = 5.08±0.3 A B A A A B A (2.54×10) 2.54±0.3 2.8 B 18 19 12 13 14 15 1617 20 7 8 9 1011 41 42 4 56 31±0.5 7 18 LABEL 7 18 62±0.25 80 17.5 6 15 6 (9) TAB#110. t=0.5 57±0.25 130±0.5 4-M8 NUTS 57±0.25 29 30 31 32 Type name , Lot No. 12.7 18 40 34 2-ø4.5±0.2 33 4 2 3 1 124±0.25 140±0.5 23 B 21.5 20±0.1 A A 1 B 14 25 1700V/1200A Hybrid SiC Power Modules for Traction Inverters CMH1200DC-34S 30±0.2 B 14 25 TAB#110, t=0.5 4 LABEL 7 18 14 3-M6 NUTS 4 18 9.25 (10) 4-φ6.5 MOUTING HOLES 18.25 2.5 21.2 8.5 21.5 7.5 7 29 –0.5 29 –0.5 16 21.2 7.5 7 +1.0 16 25 +1.0 25 3-M6 NUTS 4-φ6.5 MOUNTING HOLES 2-φ6.5MOUNTING HOLES 29 –0.5 3-M5 NUTS 12 8.5 12 80±0.25 22 12 (22.2) 17.5 6 15 6 7 48±0.25 62 4 25.7 18 8.85 8.25 18 13 48 4 23 3.5 19- 0.5 (9) 17 3.81 3.81 3.81 13.64 23 *Tentative No. Hybrid SiC Power Modules for High-frequency Switching Applications CMH100DY-24NFH CMH150DY-24NFH 3.81 3.81 13.64 55 32 32.75 (21.14) 42.7 15- 0.64 3 10.75 6.5 SCREWING DEPTH 7.5 41.35 44 11.75 6-M5 NUTS 5-M4 NUT 19 7.75 19.05 121.7 110±0.5 94.5 39 22 57.5 50±0.5 19 19 57.15 3.75 19 13 4-φ5.5 MOUNTING HOLES 18.8 92.3 62 19 9 12 (SCREWING DEPTH) 7 15 2 11.6 1.1 2.5 7 5 13.5 10 25 2-R7 1 13 9 4.06 2-φ 5.5 MOUNTING HOLES 16 15.25 3-2 6-2 31 2-φ 5.5 MOUNTING HOLES 15 16 3-2 12 10 14.5 17.5 1.65 50 39 7 17.5 5-2.54 10.16 67.4 5.57 106 3.25 16 19.75 19.75 3-2 16.5 4 10.16 120 7 2-2.54 2-2.54 1 10.16 11 8.5 23.79 2-2.54 106 ±0.3 (20.5) 13 120 7 1200V/400A,1200V/800A Full SiC Power Modules for Industrial Use FMF400BX-24A FMF800DX-24A 7 1200V/75A Hybrid/Full SiC-IPM for Industrial Equipment PMH75CL1A120/PMF75CL1A120 600V/75A Full SiC-IPM for PV Applications PMF75B4L1A060 (3) 600V/200A Hybrid SiC-IPM for Industrial Use PMH200CS1D060 10±0.3 10±0.3 10±0.3 10±0.3 10±0.3 10±0.3 6-M4 NUTS 2.7 0.8 SCREWING DEPTH MIN. 7.7 2 11.85±0.2 18±0.2 44±0.2 57±0.2 55.2±0.3 6-φ7 MOUNTING HOLES SCREWING DEPTH MIN. 16.5 5±0.2 8 8.6 16 +1 1.8 16±0.2 40±0.2 53±0.2 38 -0 70 ±0.3 79 ±0.5 0.28 1.778±0.2 38±0.5 20x1.778(-35.56) 35±0.3 14-0.5 1 1 2- R 1.6 Type name Lot No. 3MIN 12 0.28 24±0.5 (2.2) 18 (1) 600V/15A Super-mini Full SiC DIPIPM™ PSF15S92F6-A Super-mini Hybrid / Full SiC DIPPFC™ PSH20L91A6-A / PSF20L91A6-A Long 18 2.54±0.2 4-C1.2 25 8-0.6 14x2.54(-35.56) 0.45 0.45 0.45 0.2 0.45 HEAT SINK SIDE 5.5±0.5 14±0.5 0.25 8 Development of Mitsubishi Electric SiC Power Devices and Power Electronics Equipment Incorporating Them Mitsubishi Electric began developing SiC as a new material in the early 1990s. Pursuing special characteristics, we succeeded in developing various elemental technologies. In 2010, we commercialized the first air conditioner in the world equipped with a SiC power device. Furthermore, substantial energy-saving effects have been achieved for traction and FA machinery. We will continue to provide competitive SiC power modules with advanced development and achievements from now on. 2010 January 2010 Developed large-capacity power module equipped with SiC diode Early 1990s 2011 January 2011 Verified highest power conversion efficiency*1 for solar power generation system power conditioner (domestic industry) October 2011 Commercialized SiC inverter for use in railcars Developed new material, silicon-carbide (SiC) power semiconductor, maintaining a lead over other companies 2000s October 2010 Launched "Kirigamine" inverter air conditioner Developed various elemental technologies 2006 January 2006 Successfully developed SiC inverter for driving motor rated at 3.7kW 2009 February 2009 Verified 11kW SiC inverter, world's highest value*1 with approx. 70% reduction in power loss November 2009 Verified 20kW SiC inverter, world's highest value*1 with approx. 90% reduction in power loss 9 Development of these modules and applications has been partially supported by Japan's Ministry of Economy, Trade and Industry (METI) and New Energy and Industrial Technology Development Organization (NEDO). 2012 March 2012 Developed motor system with built-in SiC inverter*2 September 2012 Verified built-in main circuit system for railcars 2014 February 2014 Developed EV motor drive system with built-in SiC inverter*2 Contributing to the realization of a low-carbon society and more affluent lifestyles May 2014 Began shipping samples of hybrid SiC power modules for high-frequency switching applications 2016 April 2016 Launched Super-mini Full SiC DIPIPM™ November 2014 Launched Large Hybrid SiC DIPIPMTM for PV Applications May 2016(Tentative) Launched package air conditioners with full SiC DIPIPMTM in Japan 2015 January 2015 Launched power conditioner for PV equipped with full SiC-IPM June 2015 Railcar traction system with full SiC power modules installed in Shinkansen bullet trains July 2012 Began shipping samples of hybrid SiC power modules December 2012 Launched CNC drive unit equipped with SiC power module 2013 February 2013 Developed SiC for application in elevator control systems*2 March 2013 Delivered auxiliary power supply systems for railcars February 2013 Developed technologies to increase capacities of SiC power modules*2 May 2013 Launched SiC power modules *1 Researched in press releases by Mitsubishi Electric. *2 Currently under development, as of April 2016. * The year and month listed are based on press releases or information released during the product launch month in Japan. December 2013 Launched railcar traction inverter with full SiC power module 10 Authorised Distributors for Mitsubishi Electric Power Semiconductors Austria GLYN AUSTRIA HY-LINE COMPONENTS GMBH Baltic countries ELGERTA LTD (Lithuania, Estonia, Latvia) Campus 21 / Businesspark Wien Süd Liebermannstr. A02/301, A-2345 Brunn am Gebirge Phone +43 (0)1 890 3202 0 Fax +43 (0)1 890 3202 20 Email: sales@glyn.at www.glyn.at Inselkammerstr. 10, D-82008 Unterhaching Phone +49 (0)89 61 45 03 10 Fax +49 (0)89 61 45 03 20 Email: power@hy-line.de www.hy-line.de The Elgerta Group Company Visoriu st. 2, LT-08300 Vilnius, Lithuania Phone +370 5 265 2683, 265 2689 Fax +370 5 265 0828, 272 0008 Email: lithuania@elgertagroup.com www.elgertagroup.com Belarus SYMMETRON MINSK Kulman Str. 1, 220013, Minsk, Belarus Phone +375 (17) 209-8020 Fax +375 (17) 292-6372 Email: minsk@symmetron.ru Benelux GLYN GMBH & CO KG, Benelux Division Ringstr. 88, D-41334 Nettetal Phone +49 2157 124 231 Fax +49 2157 124 232 Email: benelux@glyn.com www.glyn.com Bulgaria OHM BG EOOD Svetlina Street No. 11, 8800 Sliven, Bulgaria Phone +359 4468 7533 Fax +359 4468 7533 Email: teokay@ohm.com.tr www.ohm.com.tr Czech Republic STARMANS ELECTRONICS SRO V Zahradach 24/836, CZ-18000 Praha 8 Phone +420 (0) 2 8384 2063 Fax +420 (0) 2 8384 1067 Email: components@starmans.cz www.starmans.net Denmark GLYN DENMARK Slotsmarken 18, DK-2970 Hørsholm Phone +45 702 016 33, Fax +45 702 016 37 Email: sales@glyn-nordic.dk www.glyn-nordic.dk France ARCEL ZI du Tronchon - 2, rue des Aulnes F-69544 Champagne Au Mont D’or Cedex Phone +33 (0) 478 35 0221 Fax +33 (0) 478 35 6954 Email: paris@arcel.fr www.arcel.fr COMPELEC MultiParc du Jubin, Bâtiment A 27, chemin des Peupliers 69 570 Dardilly, France Phone +33 (0) 472 088 080 Fax +33 (0) 472 088 215 Germany GLYN GMBH & CO KG Am Wörtzgarten 8, D-65510 Idstein/Ts. Phone +49 (0) 6126 590 388 Fax +49 (0) 6126 590 188 Email: power@glyn.de www.glyn.de HY-LINE COMPONENTS GMBH Inselkammerstr. 10, D-82008 Unterhaching Phone +49 (0) 89 61 45 03 10 Fax +49 (0) 89 61 45 03 20 Email: power@hy-line.de www.hy-line.de INELTRON GMBH Hugenottenstr. 30, D-61381 Friedrichsdorf Phone +49 (0) 6172 49 98 23 0 Fax +49 (0) 6172 75 93 3 Email: info@ineltron.de www.ineltron.de IS-Power A Division of IS-LINE GmbH Edisonstrasse 16, D-85716 Unterschleißheim Phone +49 (0) 89 374 288 87-0 Fax +49 (0) 89 374 288 87-99 Email: info@is-power.de www.is-power.de Hungary INELTRON HUNGARY Fecske 16, H-1194 Budapest Phone +36 70 3666055 Email: i.laszlo@ineltron.hu Israel RAM N.S TECHNOLOGIES LTD 1, Hamasger St., Raanana 43653, Israel Phone +972-(0)77-920 8111 Fax +972-(0)77-920 8112 Email: nati@ram-tech.co.il www.ram-tech.co.il Italy Eletromeccanica ECC S.P.A Via Fratelli Rosselli, 33, I-20090 Trezzano sul Naviglio (MI) Phone +39 02 48 44 181 Fax +39 02 44 50 119 Email: info@eccmec.it www.eccmec.it Email: yfouletier@compelec.com Italy Melchioni SPA Poland DACPOL ineltron poland Via P. Colletta 37, 20135 Milano (Italy) Phone +39 025794 738 Fax +39 025413 4095 Email: m.sala@melchioni.it www.melchioni.it Ul. Pulawska 34, PL-05500 Piaseczno Phone +48 22 7035 100 Fax +48 22 7035 101 Email: dacpol@dacpol.com.pl www.dacpol.com.pl Ul. Julianowska 34/10, PL-05500 Piaseczno Phone +48 6069 79897 Email: d.gajda@ineltron.com.pl Romania ineltron romania Str. Lunetei 4, RO-400504 Cluj – Napoca Phone +40 735 986885 Email: i.laszlo@ineltron.hu Russia DIAL-COMPONENT Ltd Dmitrovskoe highway, Bld. 157, block 12. 127411, Moscow, Russia Phone +7 (495) 995 20 20 Fax +7 (495) 995 20 20 Email: sales@dialcomponent.ru www.dialelectrolux.ru efo ltd St. Petersburg, 194100, Novolitovskaya St. 15 lit. A, Business-center Akvilon, office 441 Phone +7 (812) 327-8654 Fax +7 (812) 320-1819 Email: power@efo.ru www.efo-power.ru PLATAN COMPONENTS 40-1, BlD. 2, Ivana Franko Str., RU-121351 Moscow Phone +7 495 97 000 99 Fax +7 495 73 75 999 Email: platan@aha.ru www.platan.ru SYMMETRON ELECTRONIC COMPONENTS Tallinskaya St. 7, RU-195196 St. Petersburg Phone +7 (812) 449 40 00 Fax +7 (812) 322 97 23 Email: npo@symmetron.ru www.symmetron.ru Spain and AICOX SOLUCIONES SA Portugal INELEC SA Avda. Somosierra, 12, 1°A, Email: informa@aicox.com E-28703 San Sebastián de los Reyes www.aicox.com Phone +34 91 65 92 970 Fax +34 91 65 31 019 Bocangel, 38, E-28028 Madrid Phone +34 91 726 35 00 Fax +34 91 726 33 34 Email: inelec@inelec.net www.inelec.net Sweden GLYN SWEDEN Tammsväg 13, SE-81576 Söderfors Phone +46 (0) 293 300 84 Fax +46 (0) 293 300 87 Email: sales@glyn.se www.glyn.se Switzerland ELEKTRON AG Riedhofstr. 11, CH-8804 Au (Zürich) Phone +41 (0) 44 781 01 11 Fax +41 (0) 44 781 06 04 Email: info@elektron.ch www.elektron.ch Turkey OHM ELEKTRONIK VE TIRCARET A.S. Kemeralti Cad. Ada Han No. 87, 5 Tophane, TR-80030 Istanbul Phone +90 212 292 05 90 Fax +90 212 244 27 72 Email: teokay@ohm.com.tr www.ohm.com.tr Ukraine Dacpol Ukraine Snovskaya str. 20, 02090 Kiev, Ukraine Phone +380 44 501 93 44 Fax +380 44 502 64 87 Email: kiev@dacpol.com www.dacpol.ua SymMetron Ukraine Raskovoy M. Str. 13, 02660 Kiev, Ukraine Phone +38 0 (44) 239-2065 Fax +38 0 (44) 239-2069 Email: kiev@symmetron.ua www.symmetron.ua United Kingdom JOHN G. PECK LTD Unit B1 Wymeswold Industrial Park, Wymeswold Lane, Burton on the Wolds, Loughborough, Leics. LE12 5TY Phone +44 1509 88 10 10 Email: info@jgpl.com www.jgpl.com SiC POWER MODULES Mitsubishi Electric Europe B.V. (European Headquarters) – Semiconductor European Business Group – Mitsubishi-Electric-Platz 1 / D-40882 Ratingen Phone +49 (0) 21 02 / 486 0 / Fax +49 (0) 21 02 / 486 41 40 Mitsubishi Electric Europe B.V. German Branch Semiconductor Sales Office Mitsubishi-Electric-Platz 1 D-40882 Ratingen Phone +49 (0) 21 02 / 486 34 30 Fax +49 (0) 21 02 / 486 72 20 Mitsubishi Electric Europe B.V. UK Branch Semiconductor Sales Office Travellers Lane, Hatfield GB-Herts. AL 10 8XB Phone +44 17 07 / 21 61 00 Mitsubishi Electric (Russia) LLC Semiconductor Sales Office Kosmodamianskaya Nab. 52 Bld. 1 113054 Moscow Phone +7 495 721 20 70 Fax +7 495 721 20 71 Mitsubishi Electric Europe B.V. French Branch Semiconductor Sales Office 25, Boulevard des Bouvets F-92741 Nanterre Cedex (Paris) Phone +33 1 / 55 68 55 68 Fax +33 1 / 55 68 57 39 Mitsubishi Electric Europe B.V. Italian Branch Semiconductor Sales Office Viale Colleoni 7 – Palazzo Sirio I-20041 Agrate Brianza (Milano) Phone +39 039 / 60 53 10 Fax +39 039 / 60 53 212 Spanish Representative Agent for Mitsubishi Electric Europe in Spain and Portugal C/ Las Hayas, 127 28922 Alcorcón (Madrid) Phone +34 9 / 16 43 68 05 Please visit our website for further details. www.MitsubishiElectric.com www.mitsubishichips.eu Revised publication, effective Apr. 2016. Superseding publication of HG-802C May 2015. Specifications subject to change without notice. HG-802C FU-1604 Printed in Japan <IP> 2016