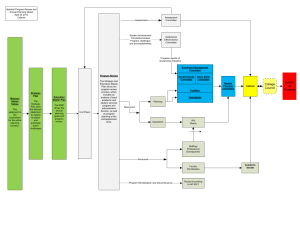

Variable speed drives Altivar Process ATV900

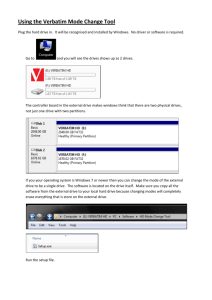

advertisement