4.1 MGM Brakes requires that an initial sample inspection

advertisement

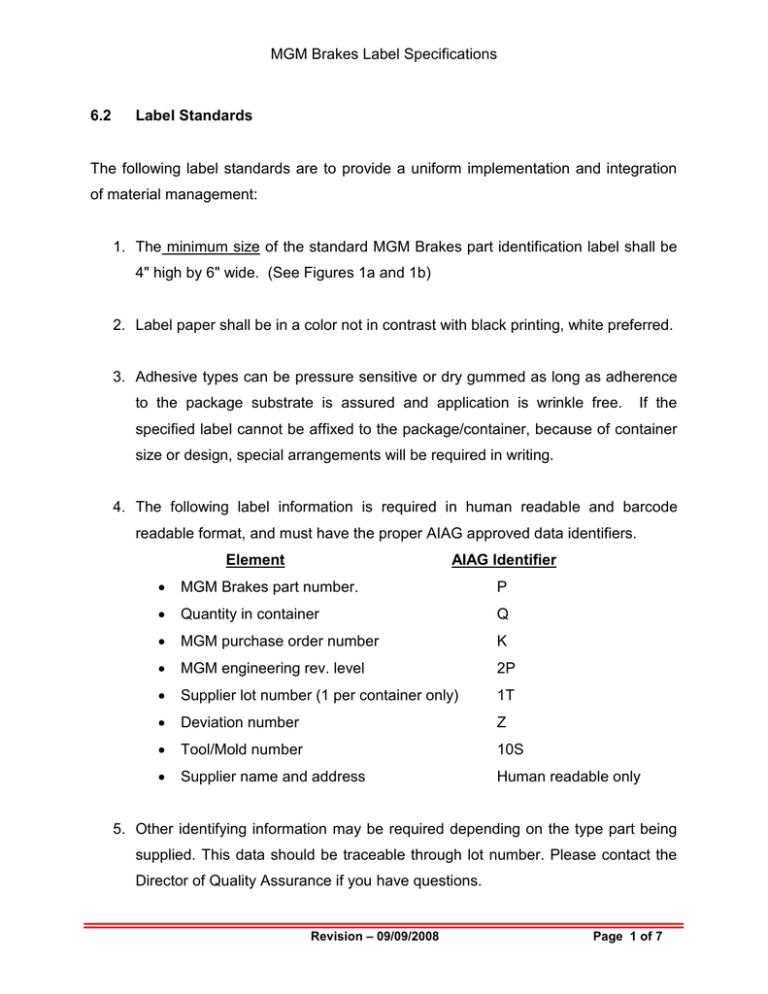

MGM Brakes Label Specifications 6.2 Label Standards The following label standards are to provide a uniform implementation and integration of material management: 1. The minimum size of the standard MGM Brakes part identification label shall be 4" high by 6" wide. (See Figures 1a and 1b) 2. Label paper shall be in a color not in contrast with black printing, white preferred. 3. Adhesive types can be pressure sensitive or dry gummed as long as adherence to the package substrate is assured and application is wrinkle free. If the specified label cannot be affixed to the package/container, because of container size or design, special arrangements will be required in writing. 4. The following label information is required in human readable and barcode readable format, and must have the proper AIAG approved data identifiers. Element AIAG Identifier MGM Brakes part number. P Quantity in container Q MGM purchase order number K MGM engineering rev. level 2P Supplier lot number (1 per container only) 1T Deviation number Z Tool/Mold number 10S Supplier name and address Human readable only 5. Other identifying information may be required depending on the type part being supplied. This data should be traceable through lot number. Please contact the Director of Quality Assurance if you have questions. Revision – 09/09/2008 Page 1 of 7 MGM Brakes Label Specifications 6.3 Label Format Our preferred label format contains a PDF417 2D barcode containing all the above required elements. For suppliers not capable of producing a PDF417 barcode, we will accept an alternative label format with barcode symbology code 39. 6.4 PDF417 2D Barcode Label 4“ 6“ Figure 1a Revision – 09/09/2008 Page 2 of 7 MGM Brakes Label Specifications 1. The PDF417 barcode consists of a Message Header, Format Header, part data, and Message Trailer. Each data field is separated by an At Sign („@‟). Sample PDF417 encoded data string [)>RS06@P8015196@Q10000@K0060630@2P123@1T1234567890@Z08999@10S10623-10 RSEOT Description of PDF417 data [)>RS 06 @ P 8015196 @ Q 10000 @ K 0060630 @ 2P 123 @ 1T 1234567890 @ Z 08-999 @ 10S 10623-10 R E S OT Message Header Format Header Delimiter AIAG Prefix for part number Part Number Delimiter AIAG Prefix for Quantity Quantity Delimiter AIAG Prefix for PO Number PO Number Delimiter AIAG Prefix for Rev Rev Delimiter AIAG Prefix for Lot Number Lot Number Delimiter AIAG Prefix for Deviation Number Deviation Number Delimiter AIAG Prefix for Tool Number Tool Number Message Trailer Revision – 09/09/2008 Page 3 of 7 MGM Brakes Label Specifications Decimal / Hex value for special characters Character Decimal Hex [ 91 5B ) 41 29 > 62 3E R S 30 1E 04 04 E 6.5 OT Barcode Label with Code 39 Symbology 4” 6” Figure 1b 1. Bar code symbology is code 39, (also known as 3 of 9). The barcode symbol height shall be a minimum of 0.5 inch (13mm). The range of the width of the narrow element (smallest space or bar) shall be from 0.013 to 0.017 inches. The Revision – 09/09/2008 Page 4 of 7 MGM Brakes Label Specifications ratio of the nominal width of the wide elements to the nominal width or the narrow elements shall be 3:1 with an allowable range of 2.8:1 to 3.2:1. 6.6 Data Area Characteristics MGM part number, quantity, purchase order number, revision number, lot number, tool number (if applicable), must be included on each label in the designated data area. If a part is under a deviation then the deviation number must be included on the label. All data may vary in the number of characters. 1. Part Number Area: „PART NUMBER (P)‟. The length of the part number is variable plus the data identifier (P). The part number shall be the designated number assigned by MGM Brakes. 2. Quantity Area: „QUANTITY (Q)‟. The maximum length of the quantity is 5 numeric characters plus the data identifier (Q). When unit of measure is pieces, no notation is required. When the unit of measure is not pieces (e.g., pounds), it shall be noted in human readable form only. When used, the unit of measure shall be directly to the right of the human readable quantity. The unit of measure shall not be bar coded. 3. Purchase Order Number Area: „PO Number (K)‟ The maximum length of the purchase order number is 7 characters plus the data identifier (K). The purchase order shall be the designated number assigned by MGM Brakes. 4. Revision Number Area: „REV NUMBER (2P)‟. The maximum length of the revision number is 3 numeric characters plus the data identifier (2P). The revision number shall be the designated number assigned by MGM Brakes. Revision level will usually be the current level on the MGM engineering production release drawing. However, the revision level must reflect the latest “approved” tooling modification. This situation typically applies, but is not limited to, aluminum die cast parts. 5. Lot Number Area: „LOT Number SPLR (1T)‟. The maximum length of the lot number is 10 characters plus the data identifier (1T). Supplier is responsible for Revision – 09/09/2008 Page 5 of 7 MGM Brakes Label Specifications assigning a lot number, (reference section 1.8). If parts are serialized, a lot number of „NA‟ must be provided. 6. Deviation Number Area: „DEV NUMBER (Z)‟. The maximum length of the deviation number is 6 characters plus data identifier (Z). The deviation number shall be the designated number assigned by MGM Brakes. If you have no deviation then field value should be „NA‟. If you have multiple deviations, then print the latest or most current one. 7. Tool/Mold Number Area: „Tool No: (10S)‟. The maximum length of the tool number is 8 characters plus the data identifier (10S). Supplier is responsible for assigning a tool number, (reference section 1.9). Tool/Mold number information is valuable when containment action is needed at MGM or supplier, especially when supplier uses multiple tools/molds to produce a part number. Tool/Mold number is required for, but not limited to, aluminum die cast parts, rubber diaphragms, and when the “approved” revision level of the tool is different than the “current” revision level. All suppliers are encouraged to provide this information when a multiple tools/molds condition applies; when it does not apply, provide “NA”. Revision – 09/09/2008 Page 6 of 7 MGM Brakes Label Specifications 6.7 Label Location 1. Illustrations of the most common shipping packs and recommended label locations are show in figures 2 through 4. All cartons and pallets should have two identical labels and label should face outward. Pallet labels should be placed on two adjacent sides, in the upper right hand corner. Carton labels should be placed on two adjacent sides. 2. If different parts are mixed on the same pallet, a Mixed Pallet label (example shown below) should be located on two adjacent sides. (Wrap around label acceptable) 4” 6” Figure 5 Revision – 09/09/2008 Page 7 of 7 MGM Brakes Label Specifications 6.8 Other Related Documents 1. Packing List. The packing list will be included with each shipment for each destination, showing Shipment Identification Number, MGM Brakes purchase order number, part numbers, and quantity per part number. One copy of the packing list is to be attached to the last container loaded of every shipment so that is readily available when the trailer is opened. The packing list is to be inserted in an envelope marked clearly: “Packing List”. 2. Advanced Shipment Notification (ASN). The data contained on the shipment identification label shall be consistent with data transmitted in the advanced shipment notifications. (reference section 5.1). 3. Invoices. The Shipment Identification Number (SID) will be included on all invoices. The SID number enables MGM Brakes to speedily process all invoices and, if problems arise, facilitates communication to suppliers. Revision – 09/09/2008 Page 8 of 7