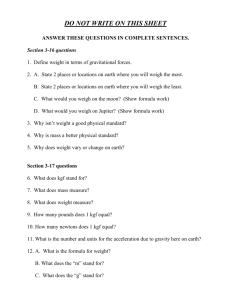

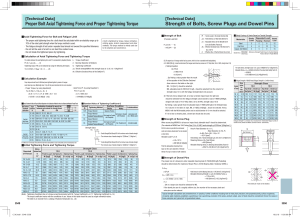

[technical data]strength of bolts, screw plugs, and dowel pins

advertisement

![[technical data]strength of bolts, screw plugs, and dowel pins](http://s2.studylib.net/store/data/018839973_1-fdecae9500da2905348177dc717c07a0-768x994.png)

D=√(4P) / (πτ) =√ / (4×800) (3.14×19.2) 1271-1272 d h r b d r =2.4674Dd2 c M 3D shape =πth(D-t) =πth(d+t) b πh V= 6 (3a 2+3b 2+h 2) A,a=Surface area of each end P D d When curve has circumference that is an arc: πℓ V= 12(2D 2+d 2) When curve has circumference that is a parabola V=0.209ℓ(2D2Dd+1/4d2) ℓ d 4 V= 3 πr3=4.1888r3 π = 6 d3=0.5236d3 ■Physical properties of metal materials Density Young´s modulus E Coefficient of thermal expansion [g/cm3] [kgf/mm2] [M10-6 /°C] Soft steel 7.85 21000 11.7 D2 7.85 21000 11.7 Powdered high-speed steel(HAP40) 8.07 23300 10.1 Carbide V30 a r h V= 3(A+a+ Aa) │ Zone of sphere r Sphere 4 V= 3 πab 2 Volume V π V= 3 r2h =1.0472r2h Truncated pyramid In the case of a rotating ellipsoidal body( b=c): a π V= 4 h(D2-d2) D a is the radius. 4 V= 3 πabc t Cone h d πh = 6(3a 2+h 2) Ellipsoidal body 14.1 Cast iron 7.3 56000 7500 ∼ 10500 6.0 9.2 ∼ 11.8 304 8.0 19700 17.3 Oxygen-free copper C1020 8.9 11700 17.6 6/4 brass C2801 8.4 10300 20.8 Aluminum A1100 2.7 6900 23.6 Duralumin A7075 2.8 7200 23.6 Titanium 4.5 10600 8.4 1kgf/mm2 =9.80665×106 Pa Do not use in such a way that load is applied to the threads. ■Finding the weight ■Finding dimensional changes resulting from thermal expansion ■Finding dimensional changes resulting from Young´s modulus E Weight W[g] ×Density =Volume[cm3] Example: Material: D2 Material: Soft steel [Example] Weight when D=φ16 and L= 50 mm is found as follows. L PD-11.indd =19.739Rr2 π2 = 4 Dd2 ℓ Hollow cylinder (tube) a Root diameter d1 The information provided here is only an example of calculating the strength. For actual selections, it is necessary to consider the hole pitch accuracy, hole perpendicularity, surface roughness, true roundness, plate material, parallelism, use of hardening, accuracy of the press machine, product production volume, tool wear, and various other conditions. Therefore the strength calculation value should be used only as a guide.(It is not a guaranteed value.) 1271 d π 2 V= 4 d(ℓ+ℓ ´ 3) D πh 2 V= 3 (3r-h) Fatigue strengths* have been excerpted from “Estimated values of fatigue limits for metal threads of small screws, bolts, and nuts”(Yamamoto)and modified. 52100 yield stress capabilityσb=120[kgf/mm2] Maximum allowable shear strengthτ=σb×0.8/(Safety factorα) =120×0.8/5 =19.2[kgf/mm2] F or an MS dowel pin, select a size of D8 or larger. In addition, selecting a single size for all dowel pins makes it possible to reduce items such as tools and inventory. V=2π2Rr2 R h Spherical crown Barrel shape ≒7.3 Circular ring d h1 h a r Strength class Effective Nominal cross-section 12.9 10.9 thread area Maximum Maximum * Fatigue strength* allowable load Fatigue strength allowable load As size mm2 kgf /mm2 kgf kgf /mm2 kgf M 4 8.78 13.1 114 9.1 79 M 5 14.2 11.3 160 7.8 111 M 6 20.1 10.6 213 7.4 149 M 8 36.6 8.9 326 8.7 318 M10 58 7.4 429 7.3 423 M12 84.3 6.7 565 6.5 548 M14 115 6.1 702 6 690 M16 157 5.8 911 5.7 895 M20 245 5.2 1274 5.1 1250 M24 353 4.7 1659 4.7 1659 Find a suitable size for a single dowel pin which is subjected to repeated (pulsating) shear loads of 800 kgf.(Dowel pin material: 52100 hardness 58 HRC or higher) =πD2τ/4 a Crossing cylinders h h V= 3 A= 6 arn A=Bottom surface area r=Radius of inscribed circle a=Length of 1 side of regular polygon n=Number of regular polygon sides =2.0944r2h (For threads: fatigue strength = count of 2 million) ■Bolt fatigue strength ■Dowel pin strength P=A ×τ h2 Pyramid 2 2 V= 3 πr2h D W=π - D2× L×Density 4 π =- ×1.62×5×7.85 4 ≒79[g] Example: Find strainλwhen load P=1000 kgf is applied to aφ10×L60 pin.(Material: D2) Example: The amount of dimensional change δ which occurs when a pin of D=φ2, L=100 mm PL is heated to 100℃ is the following. E= Aλ δ=Coefficient of thermal expansion×Total length×Temperature change 1000×60 PL λ= = 78.5×21000 =11.7×10−6×100 mm×100℃ AE =0.117[mm] ≒0.036mm 100 [20℃] π Cross-section area A= 4 D2 =78.5 0.117 φ10 λ Find the maximum allowable load P when a MSW30 screw plug is subjected to impact load. (MSW30 material: 1045, tensile strengthσb at 34~43 HRC 65 kgf/mm2) Assuming fracture due to shear Shear cross-section area A=Root diameter d1×π×L occurs at the MSW root diameter (Root diameter d1≒M-P) location, the maximum allowable A=(M-P)πL=(30-1.5)π×12 load P=τt×A. =1074[mm2] =3.9×107.4 Yield stress≒0.9×Tensile strengthσb=0.9×65=58.2 =4190 [kgf] Shear stress≒0.8×Yield stress =46.6 When the tap is a soft materials, Maximum allowable shear stressτt=Shear stress /(Safety factor 12) find the maximum allowable =46.6/12=3.9[kgf/mm2] shear from the inside thread root diameter. d ) a2+b2 π2 V= 4 d2 2 Pkgf L ■Screw plug strength ( h 1+h 2 π = 4 d2 2 For brittle materials=Fracture stress Volume V Conical section of sphere h From the table at right, for a strength class of 10.9 and a maximum allowable load of 200 kgf, the suitable bolt is a 318[kgf] M8. Therefore we select a 10 mm MSB10 with a M8 thread section. When the bolt is subjected to shear load, also use a dowel pin. 3D shape φ2 2) For stripper bolts and others which are subjected to tensile impact loads, the selection is made based on the fatigue strength.(The bolt is subjected to 200 kgf loads in the same way. Stripper bolt material: 4137 33~38 HRC, strength class 10.9.) π V= 4 d 2h Yield stress for strength class 12.9σb=112[kgf/mm ] Maximum allowable stressσt=σb/ (safety factor) (From table above, safety factor=5) =112/5 =22.4[kgf/mm2] Volume V Ellipsoidal ring b Example: Find a suitable size for a single hexagon socket head cap screw that will be subjected to repeated(pulsating)tensile loads of P=200 kgf.(Hexagon socket head cap screw material: 4137, 38~43 HRC, strength class 12.9) From formula(1): As=Pt/σt =200/22.4 =8.9[mm2] Finding the effective cross-section area larger than this value from the table at right shows that a 14.2[mm2] M5 cap screw should be selected. With additional consideration for the fatigue strength, and based on the strength class of 12.9 in the table, we select an M6 screw with maximum allowable load of 213 kgf. Safety factorα 3D shape ℓ´ Volume V Truncated cylinder h Pt=σt×As……(1) =πd2σt/4… (2) 3D shape h 1) When bolt is subjected to tensile load Pt : Tensile load in axial direction[kgf] ■Unwin safety factorαbased on tensile strength Repeated load σb: Bolt yield stress[kgf/mm2] Static Impact R load Pulsating Alternating load σt: Bolt maximum allowable stress 2 [kgf/mm ] Steel 3 5 8 12 (σt=σb/(safety factorα)) Cast iron 4 6 10 15 2 As : Bolt effective cross-section area[mm ] Copper, soft metals 5 5 9 15 As=πd2/4 d : Bolt effective diameter(root diameter) [mm] Shear stress= Standard strength Standard strength: F or ductile materials=Yield stress [TECHNICAL DATA]CALCULATION OF CUBIC VOLUME AND MATERIAL PHYSICAL PROPERTIES P ■Bolt strength OF BOLTS, SCREW PLUGS, AND DOWEL PINS h [TECHNICAL DATA]STRENGTH [120℃] 1272 2012/10/25 17:14:11