LM27961 - Texas Instruments

advertisement

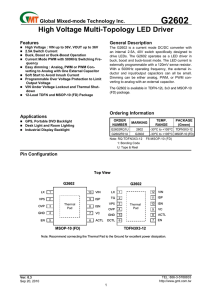

LM27961 www.ti.com SNVS326A – NOVEMBER 2004 – REVISED MAY 2013 LM27961 Dual-Display White LED Driver with 3/2x Switched Capacitor Boost Check for Samples: LM27961 FEATURES DESCRIPTION • The LM27961 is a charge-pump-based white-LED driver that is ideal for mobile phone display backlighting. It is intended to drive 4 LEDs for a main phone display backlight and 3 LEDs for a sub-display backlight. Regulated internal current sources deliver excellent current and brightness matching in all LEDs. 1 2 • • • • • • • Drives 4 Individual Common-Anode LEDs with up to 20mA each for a Main Display Backlight Drives 3 Individual Common-Cathode LEDs with up to 20mA each for a Sub-Display Backlight Independent Resistor-Programmable Current Setting Excellent Current and Brightness Matching High-Efficiency 3/2x Charge Pump Extended Li-Ion Input: 2.7V to 5.5V PWM Brightness Control: 100Hz - 1kHz 18-bump Thin DSBGA Package: (2.1mm x 2.4mm x 0.6mm) APPLICATIONS • • • • Mobile Phone Display Lighting Mobile Phone Keypad Lighting PDAs General LED Lighting The LED driver current sources are split into two independently controlled groups. The primary group (Group A) can be used to backlight a main phone display with up to 4 LEDs. The low-side current drivers of Group A accommodate common-anodetype LEDs. The second group (Group B) can backlight a secondary display with up to 3 LEDs. The high-side current drivers of Group B accommodate common-cathode-type LEDs. Both Group A and Group B can also drive standard two-terminal LEDs, and provide other general lighting functions (keypad lighting, fun lighting, etc). The brightness of the two LED groups can be adjusted independently with external resistors. The LM27961 works off an extended Li-Ion input voltage range (2.7V to 5.5V). Voltage boost is achieved with a high-efficiency 3/2×-gain charge pump. The LM27961 is available in TI’s chip-scale 18-bump DSBGA package. Typical Application Circuit C1 1 PF VIN 2.7V to 5.5V C1+ VIN C2 1 PF C1- C2+ C2- (1x when VIN > 4.7V) CIN ENA ENB POUT 3/2x Charge Pump CPOUT LM27961 1 PF D1A D2A D3A 1 PF D4A ISETA D1B D2B D3B ISETB GND RSETA RSETB Capacitors: TDK C1608X5R1A105K, or equivalent 1 2 Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet. All trademarks are the property of their respective owners. PRODUCTION DATA information is current as of publication date. Products conform to specifications per the terms of the Texas Instruments standard warranty. Production processing does not necessarily include testing of all parameters. Copyright © 2004–2013, Texas Instruments Incorporated LM27961 SNVS326A – NOVEMBER 2004 – REVISED MAY 2013 www.ti.com Connection Diagram 7 6 5 4 3 2 1 7 6 5 4 3 2 1 A B C D E E D Top View C B A Bottom View Figure 1. 18-Bump Thin DSBGA Package, Large Bump Package Number YZR0018 PIN DESCRIPTION Pin #s Pin Names C1 VIN Pin Descriptions Input voltage. Input range: 2.7V to 5.5V. D2 GND Ground A3 POUT Charge pump output. Approximately 1.5×VIN A1, B2, A5, E1 D6, E5, D4, E3 C1+, C1-, C2+, C2- Flying capacitor connections. D1A, D2A, D3A, D4A LED Outputs - Group A C5, B4, C3 D1B, D2B, D3B LED Outputs - Group B B6 EN-A Enable for Group-A LEDs (current outputs). Logic input. High = Group-A LEDs ON. Low = Group A LEDs OFF. Pulsing this pin with a PWM signal (100Hz-1kHz) can be used to dim LEDs. A7 EN-B Enable for Group-B LEDs (current outputs). Logic input. High = Group-B LEDs ON. Low = Group B LEDs OFF. Pulsing this pin with a PWM signal (100Hz-1kHz) can be used to dim LEDs. E7 ISETA Placing a resistor (RSETA) between this pin and GND sets the LED current for Group A LEDs. LED Current = 100 × (1.25V ÷ RSETA). C7 ISETB Placing a resistor (RSETB) between this pin and GND sets the LED current for Group B LEDs. LED Current = 100 × (1.25V ÷ RSETB). Table 1. Operational States ENA ENB Mode of Operation L L Shutdown H L Enabled. Group A LEDs ON. Group B LEDs OFF L H Enabled. Group B LEDs ON. Group A LEDs OFF H H Invalid for normal operation These devices have limited built-in ESD protection. The leads should be shorted together or the device placed in conductive foam during storage or handling to prevent electrostatic damage to the MOS gates. 2 Submit Documentation Feedback Copyright © 2004–2013, Texas Instruments Incorporated Product Folder Links: LM27961 LM27961 www.ti.com SNVS326A – NOVEMBER 2004 – REVISED MAY 2013 Absolute Maximum Ratings (1) (2) (3) VIN pin voltage -0.3V to 7.1V ENA, ENB pin voltages -0.3V to (VIN+0.3V)w/ 6.0V max IDxx Pin Voltages -0.3V to (VPOUT+0.3V)w/ 6.0V max Continuous Power Dissipation Internally Limited (4) Junction Temperature (TJ-MAX) 150ºC Storage Temperature Range -65ºC to +150º C Maximum Lead Temperature (Soldering, 10 sec.) 265ºC ESD Rating (5) Human Body Model - IDxx Pins: Human Body Model - All other Pins: Machine Model - IDxx Pins: Machine Model - All Other Pins: 1.0kV 2.0kV 100V 200V (1) (2) (3) (4) (5) Absolute Maximum Ratings indicate limits beyond which damage to the component may occur. Operating Ratings are conditions under which operation of the device is guaranteed. Operating Ratings do not imply guaranteed performance limits. For guaranteed performance limits and associated test conditions, see the Electrical Characteristics tables. If Military/Aerospace specified devices are required, please contact the TI Sales Office/Distributors for availability and specifications. All voltages are with respect to the potential at the GND pin. Internal thermal shutdown circuitry protects the device from permanent damage. Thermal shutdown engages at TJ = 160°C (typ.) and disengages at TJ = 120°C (typ.). The thermal shutdown function is guaranteed by design. The Human body model is a 100pF capacitor discharged through a 1.5kΩ resistor into each pin. The machine model is a 200pF capacitor discharged directly into each pin. MIL-STD-883 3015.7 Operating Rating (1) (2) Input Voltage Range 2.7V to 5.5V Junction Temperature (TJ) Range -30°C to +125°C Ambient Temperature (TA) Range -30°C to +85°C (3) (1) (2) (3) Absolute Maximum Ratings indicate limits beyond which damage to the component may occur. Operating Ratings are conditions under which operation of the device is guaranteed. Operating Ratings do not imply guaranteed performance limits. For guaranteed performance limits and associated test conditions, see the Electrical Characteristics tables. All voltages are with respect to the potential at the GND pin. In applications where high power dissipation and/or poor package thermal resistance is present, the maximum ambient temperature may have to be derated. Maximum ambient temperature (TA-MAX) is dependent on the maximum operating junction temperature (TJ-MAX-OP = 125°C), the maximum power dissipation of the device in the application (PD-MAX), and the junction-to ambient thermal resistance of the part/package in the application (θJA), as given by the following equation: TA-MAX = TJ-MAX-OP – (θJA × PD-MAX). Thermal Properties Juntion-to-Ambient Thermal Resistance (θJA), (1) (1) 100°C/W Junction-to-ambient thermal resistance is highly dependent on application and board layout. In applications where high maximum power dissipation exists, special care must be paid to thermal dissipation issues in board design. Submit Documentation Feedback Copyright © 2004–2013, Texas Instruments Incorporated Product Folder Links: LM27961 3 LM27961 SNVS326A – NOVEMBER 2004 – REVISED MAY 2013 www.ti.com Electrical Characteristics (1) (2) Limits in standard typeface are for TJ = 25°C, and limits in boldface type apply over the full operating temperature range. Unless otherwise specified: VIN = 3.6V; VDxA = 0.6V; VDxB = 3.6V; ENA = 1.5V and ENB = GND, or ENA = GND and ENB = 1.5V; RSETA = RSETB = 8.35kΩ; CIN, C1, C2 , and CPOUT = 1µF. Specifications related to output current(s) and current setting pins (IDxx and ISETx) apply to both Group A and Group B. (3) Symbol Parameter Condition 3.0V ≤ VIN ≤ 4.2V, and VIN = 5.5V 0.45V ≤ VDxA ≤ 3.8V or 2.5V ≤ VDxB ≤ 3.8V; RSET = 8.35kΩ IDxx Output Current Regulation Min Typ Max Units 13.5 (10%) 15 16.5 (+10%) mA (%) 3.0V ≤ VIN ≤ 5.5V; 0.6V ≤ VDxA ≤ 3.8V or 2.5V ≤ VDxB ≤ 3.8V; RSET = 6.25kΩ 20 mA 3.0V ≤ VIN ≤ 5.5V; 0.3V ≤ VDxA ≤ 3.8V or 2.5V ≤ VDxB ≤ 3.8V; RSET = 12.5kΩ 10 mA 2.7V ≤ VIN ≤ 3.0V; 0.45V ≤ VDxA ≤ 3.8V or 2.5V ≤ VDxB ≤ 3.8V; RSET = 8.35kΩ 15 mA 0.6 % IDxx-MATCH Current Matching Between Any Two Group A Outputs or Group B Outputs VIN = 3.0V IQ Quiescent Supply Current 2.7V ≤ VIN ≤ 4.2V; No Load Current, ENA or ENB = ON 4.4 6.75 mA ISD Shutdown Supply Current 2.7V ≤ VIN ≤ 5.5V, ENA and ENB = OFF 2.3 5 µA VSET ISET Pin Voltage 2.7V ≤ VIN ≤ 5.5V 1.25 IDxx/ISET Output Current to Current Set Ratio ROUT Charge Pump Output Resistance (5) (4) V 100 VIN = 3.0V 2.7 Ω 320 mV VHR I = 95% X IDxx (nom) Current Source Headroom Voltage Dxx RSET = 8.35kΩ Requirement (6) (IDxx (nom) ≈ 15mA) fSW Switching Frequency 3.0V ≤ VIN ≤ 4.2V tSTART Start-up Time IDx = 90% steady state 350 µs 1.5x to 1x Threshold 4.75 V 1.5x/1x Charge pump gain cross-over: Gain = 1.5 when VIN is below threshold. Gain = 1 when VIN is above threshold. 1x to 1.5x Threshold 4.55 V 375 500 625 kHz Logic Pin Specifications: EN, ENA, ENB VIL Input Logic Low 2.7V ≤ VIN ≤ 5.5V 0 0.5 V VIH Input Logic High 2.7V ≤ VIN ≤ 5.5V 1.1 VIN V (1) (2) (3) (4) (5) (6) 4 All voltages are with respect to the potential at the GND pin. Min and Max limits are guaranteed by design, test, or statistical analysis. Typical numbers are not guaranteed, but do represent the most likely norm. CIN, CPOUT, C1, and C2 : Low-ESR Surface-Mount Ceramic Capacitors (MLCCs) used in setting electrical characteristics For the two groups of outputs on a part (Group A and Group B), the following are determined: the maximum output current in the group (MAX), the minimum output current in the group (MIN), and the average output current of the group (AVG). For each group, two matching numbers are calculated: (MAX-AVG)/AVG and (AVG-MIN)/AVG. The largest number of the two (worst case) is considered the matching figure for the group. The matching figure for a given part is considered to be the highest matching figure of the two groups. The typical specification provided is the most likely norm of the matching figure for all parts. Output resistance (ROUT) models all voltage losses in the charge pump. ROUT can be used to estimate the voltage at the charge pump output (POUT): VPout = (1.5 × VIN) – (ROUT × IOUT). In the equation, IOUT is the total output current: the sum of all active Dxx output currents and all current drawn from POUT. The equation applies when the charge pump is operating with a gain of 3/2 (VIN ≤ 4.75V typ.). Headroom voltage: VHR = VPout – VLEDx . If headroom voltage requirement is not met, LED current regulation will be compromised. Submit Documentation Feedback Copyright © 2004–2013, Texas Instruments Incorporated Product Folder Links: LM27961 LM27961 www.ti.com SNVS326A – NOVEMBER 2004 – REVISED MAY 2013 Electrical Characteristics(1)(2) (continued) Limits in standard typeface are for TJ = 25°C, and limits in boldface type apply over the full operating temperature range. Unless otherwise specified: VIN = 3.6V; VDxA = 0.6V; VDxB = 3.6V; ENA = 1.5V and ENB = GND, or ENA = GND and ENB = 1.5V; RSETA = RSETB = 8.35kΩ; CIN, C1, C2 , and CPOUT = 1µF. Specifications related to output current(s) and current setting pins (IDxx and ISETx) apply to both Group A and Group B. (3) Symbol ILEAK (7) Parameter Input Leakage Current Condition VENx = 0V VENx = 3V Min Typ Max 0.1 (7) 10 Units µA There is a 300kΩ(typ.) pull-down resistor connected internally between each enable pin (ENA, ENB) and GND. Submit Documentation Feedback Copyright © 2004–2013, Texas Instruments Incorporated Product Folder Links: LM27961 5 LM27961 SNVS326A – NOVEMBER 2004 – REVISED MAY 2013 www.ti.com Typical Performance Characteristics Unless otherwise specified: VIN = 3.6V; VLEDxA = 3.6V; VLEDxB = 3.6V; ENA = VIN and ENB = GND, or ENA = GND and ENB = VIN; RSETA = RSETB = 8.35kΩ; CIN, C1, C2 , and CPOUT = 1µF. LED Current (D1A, D2A,D3A, D4A) vs. Input Voltage 15.5 LED Current (DxA) vs. Input Voltage 15.6 TA = 25oC D1A - D4A Enabled D1A - D4A Enabled ID1A - DIODE CURRENT (mA) IDXA - DIODE CURRENT (mA) 15.6 15.4 15.3 15.2 15.1 15.5 TA = 85oC 15.4 15.3 TA = 25oC 15.2 15.1 TA = -40oC 15 2.7 3.1 3.5 3.9 4.3 4.7 5.1 15 2.7 5.5 3.1 VIN - INPUT VOLTAGE (V) 3.5 Figure 2. 4.3 4.7 5.1 5.5 Figure 3. Quiescent Current vs. Input Voltage, Charge Pump Output Voltage vs. Output Current 6.5 6 TA = 25oC TA = 85oC VPOUT - OUTPUT VOLTAGE (V) IQ - QUIESCENT CURRENT (mA) 3.9 VIN - INPUT VOLTAGE (V) 5.5 TA = 25oC 5 4.5 4 TA = -40oC 3.5 6 No Diodes Connected VIN = 5.5V VIN = 4.2V 5.5 VIN = 3.6V 5 VIN = 3.3V 4.5 VIN = 3.0V 4 VIN = 2.7V 3.5 3 2.7 3.2 3.7 4.2 0 VIN - INPUT VOLTAGE (V) 60 70 80 90 Figure 5. Charge Pump Output Voltage vs. Output Current Charge Pump Output Voltage vs. Input Voltage (No Load Current) 7 No Diodes Connected 5.4 5.35 VPOUT - OUTPUT VOLTAGE (V) VPOUT - OUTPUT VOLTAGE (V) 40 50 Figure 4. VIN = 3.6V TA = -40oC 5.3 5.25 TA = 85oC 5.2 5.15 TA = 25oC 5.1 10 20 30 40 50 60 70 80 90 IPOUT - OUTPUT CURRENT (mA) TA = 25oC 6.5 D1A - D4A Enabled 6 5.5 5 4.5 4 3.5 3 2.7 3.1 3.5 3.9 4.3 4.7 5.1 5.5 VIN - INPUT VOLTAGE (V) Figure 6. 6 30 IPOUT - OUTPUT CURRENT (mA) 5.45 0 10 20 Figure 7. Submit Documentation Feedback Copyright © 2004–2013, Texas Instruments Incorporated Product Folder Links: LM27961 LM27961 www.ti.com SNVS326A – NOVEMBER 2004 – REVISED MAY 2013 Typical Performance Characteristics (continued) Unless otherwise specified: VIN = 3.6V; VLEDxA = 3.6V; VLEDxB = 3.6V; ENA = VIN and ENB = GND, or ENA = GND and ENB = VIN; RSETA = RSETB = 8.35kΩ; CIN, C1, C2 , and CPOUT = 1µF. Charge Pump Output Resistance vs Output Current Input Current vs. Input Voltage 100 ROUT - OUTPUT RESISTANCE (:) 3.2 IIN - INPUT CURRENT (mA) 95 90 TA = 25oC 85 D1A - D4A Enabled 80 75 70 65 60 2.7 VIN = 3.6V No Diodes Connected 3 TA = 85oC 2.8 TA = 25oC 2.6 2.4 2.2 TA = -40oC 2 3.1 3.5 3.9 4.3 4.7 5.1 5.5 10 VIN - INPUT VOLTAGE (V) 70 Figure 9. Charge Pump Switching Frequency vs. Input Voltage Diode Current (DxA) vs. Headroom Voltage (DxA) 520 D1A - D4A Enabled 510 500 TA = -40oC 490 TA = 25oC 480 470 460 90 18 VIN = 3.6V TA = 85oC TA = 25oC IDXA - DIODE CURRENT (mA) fSW - SWITCHING FREQUENCY (kHz) 50 Figure 8. 530 15 TA = -40oC 12 9 TA = 85oC 6 3 VIN = 3.0V 450 D1A - D4A Enabled 440 2.7 0 3.2 3.7 0 4.2 0.2 0.3 0.4 0.5 Figure 11. Diode Current (DxB) vs. Headroom Voltage (DxB) Diode Current (DxA or DxB) vs. PWM Duty Cycle (ENA or ENB) OUTPUT CURRENT BANKA OR BANKB (mA) Figure 10. 18 TA = -25oC 15 TA = -40oC 12 9 TA = 85oC 6 3 VIN =3.0V D1B - D3B Enabled 0 0 0.1 VHRA - HEADROOM VOLTAGE BANKA (V) VIN - INPUT VOLTAGE (V) IDXB - DIODE CURRENT (mA) 30 IPOUT - OUTPUT CURRENT (mA) 0.1 0.2 0.3 0.4 0.5 VHRB - HEADROOM VOLTAGE BANKB (V) Figure 12. 16 fPWM = 100 Hz. 14 12 10 8 6 4 2 0 0 20 40 60 80 100 ENA OR ENB PWM DUTY CYCLE (%) Figure 13. Submit Documentation Feedback Copyright © 2004–2013, Texas Instruments Incorporated Product Folder Links: LM27961 7 LM27961 SNVS326A – NOVEMBER 2004 – REVISED MAY 2013 www.ti.com Typical Performance Characteristics (continued) Unless otherwise specified: VIN = 3.6V; VLEDxA = 3.6V; VLEDxB = 3.6V; ENA = VIN and ENB = GND, or ENA = GND and ENB = VIN; RSETA = RSETB = 8.35kΩ; CIN, C1, C2 , and CPOUT = 1µF. IDXX - DIODE CURRENT BANKA OR BANKB (mA) Diode Current (DxA) vs. RSETx Input Voltage (Top) and Output Voltage (Bottom) Waveforms 35 30 25 20 15 10 5 0 0 20 40 60 RSET (:) 80 100 Vertical Scale = (100mV/div), Horizontal Scale = 1µs/div Figure 14. Figure 15. ENx Signal (Top) and Charge Pump Start-Up (Bottom) Waveforms Vertical Scale = (2V/div), Horizontal Scale = 100µs/div) Figure 16. 8 Submit Documentation Feedback Copyright © 2004–2013, Texas Instruments Incorporated Product Folder Links: LM27961 LM27961 www.ti.com SNVS326A – NOVEMBER 2004 – REVISED MAY 2013 BLOCK DIAGRAM POUT CPOUT 1 PF C1 1 PF C2 1 PF LM27961 BG D1A D2A D3A D4A + - VIN 2.7V to 5.5V 3/2x Charge Pump + Pass Mode GND CIN 100:1 DxA Gain Ctrl. 1 PF ENA 500 kHz. Switch Frequency ENB SoftStart 100:1 DxB Gain Ctrl. 1.25V Bandgap (BG) BG + ISETB GND D1B D2B + ISETA D3B RSETB RSETA CIRCUIT DESCRIPTION Overview The LM27961 is primarily intended for Lithium-Ion battery driven white-LED drive applications, and is well suited to drive white LEDs that are used for backlighting small-format displays. The part has seven matched constantcurrent outputs, each capable of driving up to 20mA (or more) through white LEDs. The well-matched current sources ensure the current through all the LEDs is virtually identical. This keeps brightness of all LEDs matched to near perfection so that they can provide a consistent backlight over the entire display. Charge Pump The core of the LM27961 is a 1.5x/1x dual-mode charge pump. The input of the charge pump is connected to the VIN pin. The recommended input voltage range of the LM27961 is 2.7V to 5.5V. The output of the charge pump is the POUT pin (“Pump OUTput”). The output voltage of the charge pump is unregulated and varies with input voltage and load current. The charge pump operates in the 1.5x mode when the input voltage is below 4.75V (typ.). In this mode, the input-to-output voltage gain of the charge pump is 1.5, and the voltage at the output of the charge pump will be approximately 1.5x the input voltage (V(POUT) ≈ 1.5 * VIN ). When in the 1.5x mode, the charge pump provides the voltage boost that is required to drive white LEDs from a Li-Ion battery. (White LEDs typically have a forward voltage in the range of 3.3V to 4.0V. A Li-Ion battery typically is not considered to be fully discharged until the battery voltage falls to 3.0V (approx.) ) The charge pump operates in the 1x mode when the input voltage is above 4.75V (typ.). In these conditions, voltage boost is not required to drive the LEDs, so the charge pump merely passes the input voltage to POUT (V(POUT) ≈ VIN). This reduces the input current and the power dissipation of the LM27961 when the input voltage is high. Submit Documentation Feedback Copyright © 2004–2013, Texas Instruments Incorporated Product Folder Links: LM27961 9 LM27961 SNVS326A – NOVEMBER 2004 – REVISED MAY 2013 www.ti.com Regulated Current Outputs The matched current outputs are generated with a precision current mirror that is biased off the charge pump output. Matched currents are ensured with the use of tightly matched internal devices and internal mismatch cancellation circuitry. There are seven regulated current outputs. These seven outputs are split into two groups, a group of 4 common anode outputs and a group of 3 common cathode outputs. There is an ON/OFF control pin for each group (ENA and ENB). The DC current through the LEDs is programmed with an external resistor. Changing currents on-the-fly can be achieved with the use of digital pulse (PWM) signals. Enable Pins: ENA, ENB The LM27961 has 2 enable pins. Both are active-high logic (HIGH = ON). There are internal pull-down resistors (300kΩ typ.) that are connected internally between each of the enable pins and GND. ENA and ENB can both enable and disable the part. When the voltage on both pins are low (<0.5V), the part is in shutdown mode. All internal circuitry is OFF and the part consumes very little supply current when the LM27961 is shutdown. When the voltage on either ENx pin is high (>1.1V), the part is active. The charge pump is ON, and the corresponding output current drivers are active. ENA and ENB are used to turn the output currents ON and OFF. ENA activates/deactivates the four GroupA outputs (D1A-D4A). ENB activates/deactivates the three GroupB outputs (D1B-D3B). Setting LED Currents The output currents of the LM27961 can be set to a desired value simply by connecting an appropriately sized resistor (RSETx) between the ISETx pins of the LM27961 and GND. RSETA sets the current for the GroupA outputs and RSETB sets the current for the GroupB outputs. The output currents (LED currents) are proportional to the current that flows out of the ISETx pins. The output currents are a factor of 100 greater than the ISETx current. The feedback loop of an internal amplifier sets the voltage of the ISETx pin to 1.25V (typ.). Placing a resistor between ISETx and GND programs the ISETx current, and thus the LED currents. The statements above are simplified in the equations below: IDxx = 100 × (VSETx / RSETx) RSETx = 100 × (1.25V / IDxx) (1) (2) Maximum Output Current, Maximum LED Voltage, Minimum Input Voltage The LM27961 can drive 4 LEDs at 15mA each from an input voltage as low as 2.7V, so long as the LEDs have a forward voltage of 3.5V or less (room temperature). The statement above is a simple example of the LED drive capabilities of the LM27961. The statement contains the key application parameters that are required to validate an LED-drive design using the LM27961: LED current (ILEDx), number of active LEDs (N), LED forward voltage (VLED), and minimum input voltage (VIN-MIN). The equation below can be used to estimate the total output current capability of the LM27961: ILED_MAX = ((1.5 x VIN) - VLED) / ((N x ROUT) + kHR) ILED_MAX = ((1.5 x VIN ) - VLED) / ((N x 2.7Ω) + 22mV/mA) (3) (4) ROUT – Output resistance. This parameter models the internal losses of the charge pump that result in voltage droop at the pump output POUT. Since the magnitude of the voltage droop is proportional to the total output current of the charge pump, the loss parameter is modeled as a resistance. The output resistance of the LM27961 is typically 2.7Ω (VIN = 3.0V, TA = 25°C). In equation form: VPOUT = 1.5×VIN – N×ILED×ROUT (5) kHR – Headroom constant. This parameter models the minimum voltage required to be present across the current sources for them to regulate properly. This minimum voltage is proportional to the programmed LED current, so the constant has units of mV/mA. The typical kHR of the LM27961 is 22mV/mA. In equation form: (VPOUT – VLED) > kHR×ILED 10 (6) Submit Documentation Feedback Copyright © 2004–2013, Texas Instruments Incorporated Product Folder Links: LM27961 LM27961 www.ti.com SNVS326A – NOVEMBER 2004 – REVISED MAY 2013 The "ILED-MAX" equation (Equation 3) is obtained from combining the ROUT equation (Equation 5) with the kHR equation (Equation 6) and solving for ILED. Maximum LED current is highly dependent on minimum input voltage and LED forward voltage. Output current capability can be increased by raising the minimum input voltage of the application, or by selecting an LED with a lower forward voltage. Excessive power dissipation may also limit output current capability of an application. Parallel Dx Outputs for Increased Current Capability Outputs D1A through D4A, or D1B through D3B may be connected together in any combination to drive higher currents through fewer LEDs. For example in Figure 17, outputs D1A and D2A are connected together to drive one LED. D3A and D4A are connected to drive a second LED. VPOUT VIN LM27961 LED2 D1B D2B D3B LED1 D3A and D4A D1A and D2A ILED1 = ID1A + ID2A ILED2 = ID3A + ID4A Figure 17. Two Parallel Connected LEDs With this configuration, two parallel current sources of equal value provide current to one of the LEDs. RSET should therefore be chosen so that the current through each output is programmed to 50% of the desired current through the parallel connected LED. For example, if 40mA is the desired drive current for the parallel connected LED, RSETx should be selected so that the current through each of the outputs is 20mA. Other combinations of parallel outputs may be implemented in similar fashions, such as in Figure 18. LED3A D3A LED4A D4A VPOUT VIN LM27961 LED2A D1B D2B D3B LEDB D1A D2A LED1A ILEDB = ID1B + ID2B + ID3B Figure 18. One Parallel Connected LED Connecting outputs in parallel does not affect internal operation of the LM27961 and has no impact on the Electrical Characteristics and limits previously presented. The available diode output current, maximum diode voltage, and all other specifications provided in the Electrical Characteristics table apply to parallel output configurations, just as they do to the standard application circuit on pg1 of the datasheet. Soft Start The LM27961 contains internal soft-start circuitry to limit input inrush currents when the part is enabled. Soft start is implemented with a controlled turn-on of the internal voltage reference. During soft start, the current through the LED outputs rise at the rate of the reference voltage ramp. Due to the soft-start circuitry, turn-on time of the LM27961 is approximately 350µs (typ.). Submit Documentation Feedback Copyright © 2004–2013, Texas Instruments Incorporated Product Folder Links: LM27961 11 LM27961 SNVS326A – NOVEMBER 2004 – REVISED MAY 2013 www.ti.com Thermal Protection Internal thermal protection circuitry disables the LM27961 when the junction temperature exceeds 160°C (typ.). This feature protects the device from being damaged by high die temperatures that might otherwise result from excessive power dissipation. The device will recover and operate normally when the junction temperature falls below 120°C (typ.). It is important that the board layout provides good thermal conduction. This will help to keep the junction temperature within specified operating ratings. APPLICATIONS INFORMATION Power Efficiency Efficiency of LED drivers is commonly taken to be the ratio of power consumed by the LEDs (PLED) to the power drawn at the input of the part (PIN). With a 1.5x charge pump, the input current is approximately 1.5x the output current (total LED current). For a simple approximation, the current consumed by internal circuitry can be neglected and the efficiency of the LM27961 can be predicted as follows: PLED E= PIN # VLED 1.5 × VIN (7) Neglecting IQ will result in a slightly higher efficiency prediction, but this impact will be no more than a few percentage points when several LEDs are driven at full power. Adjusting LED Brightness (PWM control) Perceived LED brightness can be adjusted using a PWM control signal to turn the LM27961 current sources ON and OFF at a rate faster than perceptible by the eye. When this is done, the total brightness perceived is proportional to the duty cycle (D) of the PWM signal (D = the percentage of time that the LED is on in every PWM cycle). A simple example: if the LEDs are driven at 15mA each with a PWM signal that has a 50% duty cycle, perceived LED brightness will be about half as bright as compared to when the LEDs are driven continuously with 15mA. A PWM signal thus provides brightness (dimming) control for the solution. The minimum recommended PWM frequency is 100Hz. Frequencies below this may be visibly noticeable as flicker or blinking. The maximum recommended PWM frequency is 1kHz. Frequencies above this may cause interference with internal current driver circuitry. In cases where a PWM signal must be connected to the ENx pins, measures can be taken to reduce the magnitude of the charge-pump turn-on voltage spikes. More input capacitance, series resistors and/or ferrite beads may provide benefits. If the current and voltage spikes can be tolerated, connecting the PWM signal to the EN pin does provide a benefit: lower supply current when the PWM signal is active. When the PWM signal is low, the LM27961 will be shutdown and input current will only be a few micro-amps. This results in a lower time-averaged input current. Capacitor Selection The LM27961 requires 4 external capacitors for proper operation. Surface-mount multi-layer ceramic capacitors are recommended. These capacitors are small, inexpensive and have very low equivalent series resistance (ESR <20mW typ.). Tantalum capacitors, OS-CON capacitors, and aluminum electrolytic capacitors are not recommended for use with the LM27961 due to their high ESR, as compared to ceramic capacitors. For most applications, ceramic capacitors with X7R or X5R temperature characteristic are preferred for use with the LM27961. These capacitors have tight capacitance tolerance (as good as ±10%) and hold their value over temperature (X7R: ±15% over -55°C to 125°C; X5R: ±15% over -55°C to 85°C). Capacitors with Y5V or Z5U temperature characteristic are generally not recommended for use with the LM27961. Capacitors with these temperature characteristics typically have wide capacitance tolerance (+80%, 20%) and vary significantly over temperature (Y5V: +22%, -82% over -30°C to +85°C range; Z5U: +22%, -56% over +10°C to +85°C range). Under some conditions, a nominal 1µF Y5V or Z5U capacitor could have a capacitance of only 0.1µF. Such detrimental deviation is likely to cause Y5V and Z5U capacitors to fail to meet the minimum capacitance requirements of the LM27961. The voltage rating of the output capacitor should be 10V or more. All other capacitors should have a voltage rating at or above the maximum input voltage of the application. 12 Submit Documentation Feedback Copyright © 2004–2013, Texas Instruments Incorporated Product Folder Links: LM27961 LM27961 www.ti.com SNVS326A – NOVEMBER 2004 – REVISED MAY 2013 Circuit Board Layout For optimal, low-noise performance, all capacitors (CIN, CPOUT, C1, C2) should be placed very close to the LM27961. A solid ground plane should be used for IC and component GND connections. Refer to the LM27961 Evaluation Board for an example layout. DSBGA Mounting The LM27961 is an 18-bump DSBGA with a bump size of approximately 300 micron diameter. The DSBGA package requires specific mounting techniques detailed in Application Note 1112 (AN-1112). Submit Documentation Feedback Copyright © 2004–2013, Texas Instruments Incorporated Product Folder Links: LM27961 13 LM27961 SNVS326A – NOVEMBER 2004 – REVISED MAY 2013 www.ti.com REVISION HISTORY Changes from Original (May 2013) to Revision A • 14 Page Changed layout of National Data Sheet to TI format .......................................................................................................... 13 Submit Documentation Feedback Copyright © 2004–2013, Texas Instruments Incorporated Product Folder Links: LM27961 IMPORTANT NOTICE Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment. TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily performed. TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide adequate design and operating safeguards. TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the third party, or a license from TI under the patents or other intellectual property of TI. Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered documentation. Information of third parties may be subject to additional restrictions. Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice. TI is not responsible or liable for any such statements. Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use of any TI components in safety-critical applications. In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and requirements. Nonetheless, such components are subject to these terms. No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties have executed a special agreement specifically governing such use. Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and regulatory requirements in connection with such use. TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of non-designated products, TI will not be responsible for any failure to meet ISO/TS16949. Products Applications Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps DSP dsp.ti.com Energy and Lighting www.ti.com/energy Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial Interface interface.ti.com Medical www.ti.com/medical Logic logic.ti.com Security www.ti.com/security Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video RFID www.ti-rfid.com OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com Wireless Connectivity www.ti.com/wirelessconnectivity Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265 Copyright © 2013, Texas Instruments Incorporated