Firefly Algorithm based Optimal Power Flow for Sizing of Thyristor

advertisement

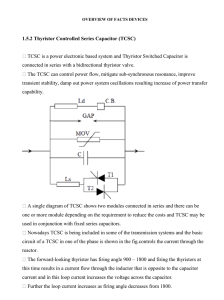

Journal of Electrical Engineering www.jee.ro Firefly Algorithm based Optimal Power Flow for Sizing of Thyristor Controlled Series Capacitor to enhance line based voltage stability Venkateswara Rao Bathina1, Venkata Nagesh Kumar Gundavarapu 2 1 Department of Electrical and Electronics, GITAM University, Visakhapatnam, Andhra Pradesh, INDIA Department of Electrical and Electronics, GITAM University, Visakhapatnam, Andhra Pradesh, INDIA vraobathina@yahoo.in, gundavarapu_kumar@yahoo.com 2 Abstract. Reactive Power compensation in transmission systems improves the stability of the system and also reduces the transmission line losses. Installing Flexible AC Transmission System (FACTS) devices are the effective means to control reactive power compensation. However, due to the high cost of FACTS devices, it is important to optimally place these controllers in the system. Out of the different FACTS devices, TCSC is the most effective device for series compensation. This paper presents a Sensitivity analysis based Complex Power Flow Sensitivity Index (CPSI) proposed for placing the TCSC at an appropriate location. Once the location to install TCSC is identified, the optimal sizing of TCSC is determined through Firefly Algorithm based multicriterion objective function comprising of four objectives minimize total real power loss, minimize total voltage magnitude deviations, minimize the fuel cost of total real power generation and minimize the branch loading to obtain the optimal power flow. Simulations have been carried out in MATLAB environment for the IEEE 14-bus system, the IEEE 30-bus system and IEEE57 bus system. The results have been taken for Firefly Algorithm based Optimal Power Flow without and with TCSC. The results obtained with Firefly Algorithm were compared with Genetic Algorithm (GA). The results indicate that FA is an easy to use and better optimization technique compared with GA. Keywords Firefly Algorithm, Optimal placement, Sensitivity index, TCSC. 1. Introduction Power systems are becoming increasingly more complex due to the interconnection of regional system and deregulation of the overall electricity market [1, 2]. It has become essential to better utilize the existing power networks to increase capacities by installing Flexible AC Transmission System (FACTS) controllers. The variables and parameter of the transmission line, which include line reactance, voltage magnitude, and phase angle are able to be controlled using FACTS controllers in a fast and effective way. The benefits derived from FACTS controllers include improvement of the stability of power system networks, such as voltage stability, line stability, small signal stability, transient stability, enhance power transfer capability and thus enhance system reliability. However, controlling power flows is the main function of FACTS [3-6]. Out of the several preventive and corrective measures suggested in literature to protect power system networks against voltage collapse, the placement of FACTS controllers has been established as an effective means. However, due to high cost of the FACTS devices, it is important to optimally place these controllers in the system. The Thyristor Controlled Series Capacitor (TCSC) is one of the most effective Flexible AC Transmission System devices [7-10]. It offers fast-acting reactive power compensation on high-voltage electricity transmission networks with much faster response compared to the traditional control devices [11]. This paper presents Sensitivity analysis based Complex Power Flow Sensitivity Index (CPSI) proposed for placing the TCSC at appropriate location. A new Meta heuristic optimization technique called Firefly Algorithm is introduced to find the optimal size of TCSC device to improve line stability. Its performance is compared with Genetic Algorithm (GA) [12-17] technique. The real and reactive power generation values and voltage limits for generator buses are taken as constraints, along with reactance limits of the TCSC, during the optimization. Computer simulations using MATLAB were done for the IEEE14 bus system, the IEEE 30 bus system and the IEEE57 bus system. In this paper, a new line-based voltage stability index is implemented to evaluate the line stability condition in a power system. 2. Problem Formulation In this paper, the multi objective function is formulated to find optimal sizing of TCSC device by minimizing certain objective functions subject to satisfying some network constraints. The multi-objective problem can be written mathematically as follows. 1 Journal of Electrical Engineering www.jee.ro Sk is the apparent power in line k and S kmax is the maximum apparent power in line k. 2.1. Objective function For a given system load, the best configuration of TCSC device is obtained by minimizing the objective function: 5) Equality constraints: N Min F = min(W1 ∗ FC + W2 ∗ FPloss + W3 ∗ FVD + W4 ∗ FS (1) Where W1, W2, W3, W4 are the weighting factors W1 + W2 + W3 + W4 = 1 PGi = i=1 PDi + PL N N Q Gi = Reactance of TCSC has been added as a control variable along with real power generation of the generator buses for optimization problem. TCSC limits are given as: min X TCSC ≤ X TCSC ≤ X max TCSC (2) 1) Fuel cost: The objective function considering the minimization of total generation cost can be represented by following quadratic equation ng ai PGi2 + bi PGi + ci (3) i=1 i=1 Q Di + Q L 8 i=1 Where i=1,2,3,.......,Nbus and Nbus = no. of. buses PL is total active power losses QL is total reactive power losses 6) Inequality constraints: Generator bus Voltage limits: min max VGi ≤ VGi ≤ VGi (9) Where i=1,2,3,.......,Nbus and Nbus = no.of. buses Real power generation limit: PGimin ≤ PGi ≤ PGimax Where ng = no. of generator buses (7) i=1 Where i=1,2,3,.......,Nbus and Nbus = no. of. Buses W1 = W2 = W3 = W4 = 0.25 FC = min N (10) Where i=1,2,3,......,ng and ng= no.of.generator buses a, b, c are the fuel cost coefficients of a generator unit Reactive Powergeneration limits: 2) Active Power Loss: The objective of this function is to minimize real power losses in the transmission lines. It can be expressed as ntl real (Sijk + Sjik ) FPLoss = min (4) k=1 Where ntl=no. Of transmission lines Sij is the total complex power flow of line i – j 3) Voltage Deviation: To have a good voltage performance, the voltage deviation at each bus must be made as small as possible. The Voltage Deviation (VD) can be expressed as: Nbus ⋮ Vk − Vkref ⋮2 FVD = min max Qmin Gi ≤ Q Gi ≤ Q Gi (11) 2.2. Fast Voltage Stability Index (FVSI) Several techniques were proposed to analyse the static voltage stability condition in a system. Some of them were utilized the voltage stability indices referred either to a bus or to a line as an indicator to voltage collapse. In this paper, a new line-based voltage stability index is proposed to evaluate the line stability condition in a power system. This index is called as Fast Voltage Stability Index (FVSI). The system becomes unstable if FVSI is equal to or greater than unity. FVSI can be expressed as 5 FVSIij = k=1 Vk is the voltage magnitude at bus k 4 Z2 Qj Vi2 X 12 Where Z is the line impedance Vkref is the reference voltage magnitude at bus k X is the line reactance 4) Branch loading: Qj is the reactive power at bus j (receiving end bus) The objective of minimizing the branch loading in the transmission lines is to enhance the security level of the system. It can be expressed as ntl FS = min S = min k=1 ⋮ Sk ⋮ ( max )2 ⋮ Sk ⋮ (6) Vi is the voltage magnitude at bus i (sending end bus) Any line in the system that exhibits FVSI close to unity indicate that the line is may lead to system violation. Therefore, FVSI has to be maintained less than unity in order to maintain a stable system. 2 Journal of Electrical Engineering www.jee.ro 3. Thyristor controlled capacitor (TCSC) series The basic Thyristor-controlled series capacitor scheme proposed in 1986 by Vithaythil with others is a method of “rapid adjustment of network impedance”. Apart from controlling the line power transfer capability, TCSC also enhances system stability [18-21]. The basic module of the TCSC is shown in Fig. 1. It consists of a series compensating capacitor shunted by thyristor controlled reactor [22-24]. Thyristor inclusion in the TCSC module enables it to have a smoother control of reactance against to system parameter variations. In view of a huge power system, TCSC implementation requires several such basic compensators to be connected in series to obtain the desired voltage rating and operating characteristics. It is modeled as a controllable reactance, inserted in series with the transmission line to adjust the line impedance and thereby control the power flow. Ii jBii Ij jBji jBij Vi jBjj Vj (16) For capacitive operation, we have Bii = Bjj = 1 (17) XTCSC Bij = Bji = − 1 (18) XTCSC For inductive operation the signs are reversed The active and reactive power equations at bus k are: Pi = Vi Vj Bij sin( θi − θj ) (19) Q i = −Vi2 Bii − Vi Vj Bij cos( θi − θj ) (20) The series reactance regulates the amount of active power flowing from bus i to bus j the change in reactance of TCSC is (i−1) ∆XTCSC = X iTCSC − XTCSC (21) The state variable XTCSC of the series controller is updated based on optimization rules. 4. Fig. 1: Basic TCSC model In this paper, the reactance of the transmission line is adjusted by TCSC directly. The TCSC is modeled as variable impedance [25, 26]. It is shown in Fig.2. The rating of TCSC depends on the reactance of the transmission line where the TCSC is located: Complex Power Flow Sensitivity Index for Optimal Placement of TCSC A method based on the sensitivity of the sum of variations of complex power flow in all lines with respect to the change of reactance of a line is proposed. The TCSC has been modelled as a variable series capacitive reactance XTCSC, resulting in a decrease of the total line reactance. The index is computed using Newton Raphson power flow. CPSIj at a line j is given as: 𝑛𝑡𝑙 ∆S n CPSIj = 𝑛=1 ∆X j (22) Where n=1, 2, 3,......., ntl and ntl = no.of transmission lines. ∆Sn is change in complex power flow in line n ∆Xj is the reactance of the line j Fig. 2: Block diagram of TCSC Zij = R ij + Xij (13) Zline = R line + Xline (14) Xij = X line + XTCSC (15) Where XTCSC is reactance of TCSC, to avoid over compensation, the working range of the TCSC is chosen between -0.8Xline and 0.6Xline. The transfer admittance matrix of the TCSC is given by This index is calculated for all the lines. The minimum and maximum values of CPSI are obtained. Normalized complex power flow sensitivity index is defined as: CPSInj = CPSIj − CPSImin CPSImax − CPSI min (23) Where CPSInj is the normalized complex power flow sensitivity index at line j. Highest positive normalized complex power flow sensitivity index is the best location for placement of TCSC. 3 Journal of Electrical Engineering www.jee.ro From the Tab. 1 it is observed that highest positive value for CPSIn(j) is 1 for line no 7. So it is the best location for placement of TCSC in the IEEE 14 bus system. From the Tab. 2 it is observed that highest positive value for CPSIn(j) is 1 for line no 9. So it is the best location for placement of TCSC in the IEEE 30 bus system. Tab.1: Complex power flow sensitivity indexes for all lines in the IEEE 14 bus system. Line Line CPSIn(j) S. No Line CPSIn(j) 1 1-2 2 2-3 0.8331 11 4-9 0.4319 0 12 7-9 0.5345 3 4 2-4 0.4189 13 9-10 0.482 1-5 0.2641 14 6-11 0.4657 5 2-5 0.8747 15 6-12 0.4977 6 3-4 0.6675 16 6-13 0.4155 7 4-5 1 17 9-14 0.4727 8 5-6 0.3855 18 10-11 0.4722 9 4-7 0.5619 19 12-13 0.4832 10 7-8 0.4829 20 13-14 0.4759 .No Tab.2: Complex power flow sensitivity indexes for all lines in the IEEE 30 bus system. Line Optimal sizing of TCSC using the Firefly Algorithm The Firefly algorithm has been used to find the optimum sizing of TCSC. It was developed by Dr Xin-She Yang at Cambridge University in 2007. FA is based on natural behaviour of the firefly, developed for solving the multimodal optimization problem [27, 28]. Fireflies called as lighting bugs, are one of the most special and fascinating creatures in nature. For simplicity, the following three ideal rules are introduced in FA development those are 1) All the fireflies are gender-free that is every firefly will attract the other firefly substantive of their sex, 2) Attractiveness depend on their brightness. The less bright one will move towards the brighter one, 3) the landscape of the objective function affects the firefly brightness. Let us consider the continuous constrained optimization problem where the task is to minimize multi objective function f(x). Firefly algorithm is a dynamic converging algorithm. The solution for the algorithm depends on the selection of swarm size, maximum attractiveness value, the absorption coefficient value and the iteration limit. The basic steps of the FA can be summarized by the pseudo code [29, 30]. Firefly Algorithm Line CPSIn(j) S. No Line CPSIn(j) 1 1-2 0.4232 21 16-17 0.7326 2 1-3 0.7943 22 15-18 0.7082 3 2-4 0.7952 23 18-19 0.7266 4 3-4 0.8800 24 19-20 0.7576 5 2-5 0 25 10-20 0.6973 6 2-6 0.6968 26 10-17 0.7564 7 4-6 0.8331 27 10-21 0.7547 8 5-7 0.8282 28 10-22 0.5547 9 6-7 1.0000 29 21-22 0.9930 10 6-8 0.8254 30 15-23 0.5485 11 6-9 0.6773 31 22-24 0.4224 12 6-10 0.5921 32 23-24 0.5465 13 9-11 0.6805 33 24-25 0.6404 14 9-10 0.4868 34 25-26 0.6914 15 4-12 0.6793 35 25-27 0.6360 16 12-13 0.7023 36 28-27 0.5564 17 12-14 0.7236 37 27-29 0.6963 18 12-15 0.4829 38 27-30 0.6745 19 12-16 0.7365 39 29-30 0.6954 20 14-15 0.7215 40 8-28 0.7008 --- --- ---- 41 6-28 0.6973 .No 5. ……………………………………………….. Objective function f(x), x = (x1,…,xd)T Generate initial population of fireflies xii ( i=1, 2…, n) Light intensity Iii at xii is determined by f(xii) Define light absorption coefficient γ while ( t < MaxGeneration) for ii = 1: n all n fireflies for jj = 1: ii all n fireflies if (Ijj > Iii), More firefly ii towards jj in d-dimension; end if Attractiveness varies with distance r Evaluate new solutions and modify the light intensity end for jj end for ii Rank all the fireflies and find the current best firefly end while Post process results and visualization …………………………….. Pseudo code of the FA. 6. Results and Discussion In order to find the effectiveness of the proposed Firefly Algorithm for Optimal Power Flow with TCSC, the IEEE14, IEEE30 and IEEE 57 bus systems are taken. An OPF program using Firefly algorithm is implemented in MATLAB software without and with TCSC. The results are presented and analysed. The input parameters of Firefly Algorithm for the test system are given in the Tab. 3. 4 Journal of Electrical Engineering www.jee.ro Tab.3: Input parameters of FA Algorithm S.No Tab.4: GENERATOR CHARACTERISTICS OF IEEE 14 BUS SYSTEM Parameters Quantity 1 Number of fireflies 20 2 Max Generation 50 3 Alpha (random movement factor) 0.5 4 Beta (attractiveness parameter) 0.5 5 Gama (absorption parameter) a Generator BUS NO In the IEEE 14 bus system bus no 1 is considered as a slack bus and bus numbers 2,3,6,8 are considered as a PV buses all other buses are considered as load buses. This system has 20 interconnected lines. A MATLAB program is written for the test system and the results have been presented and analysed. Table. 4 indicates the generators coefficients, minimum and maximum limit of real power generation for generator buses. Table. 5 indicates the voltage magnitudes in FA-OPF without TCSC and FA-OPF with TCSC (By placing TCSC at line No 7). The results indicate that there is a good improvement in voltage profile with TCSC in Firefly Algorithm based OPF. The active power generation and power loss for the IEEE 14 bus test system without and with TCSC is shown in Tab.6 and it is observed that active power losses are reduced to 5.0631 MW from 5.4104 MW by placing TCSC in Firefly Algorithm based Optimal Power Flow. TCSC value was tuned to 0.0220 ohms using Firefly Algorithm. In case of Genetic Algorithm based Optimal Power Flow the TCSC value has been tuned to 0.031 ohms. Table. 7 represents the voltage deviation, TCSC reactance value, total active power generation cost, branch loading, FVSI for all lines, Objective function value and active power losses for the IEEE 14 bus system without TCSC and with TCSC using GA-OPF and FAOPF. The results clearly indicate the effectiveness of Firefly Algorithm over Genetic Algorithm. Table 8 & 9 indicates the FVSI values for Firefly Algorithm based Optimal Power Flow without and with TCSC with different reactive load conditions at bus number 14. From these tables it can be inferred that increase in reactive load would result in FVSI value to unity leading to less line stability. By installing the TCSC in Firefly Algorithm based Optimal Power Flow can improve the FVSI that means line stability has been improved. ($/MW hr) 1 6.1. For 14 bus system b ($/MW2/ Tab.5: 𝑷𝒎𝒂𝒙 𝑮 ($/hr) (MW) (MW) 1 0.005 2.45 105 10 400 2 0.005 3.51 44.1 20 80 3 0.005 3.89 40.6 20 50 6 0.005 3.25 0 10 35 8 0.005 3 0 10 30 Comparison of bus voltages for 14 bus system using GA-OPF and FA-OPF without and with TCSC GA-OPF BUS No /hr) 𝑷𝒎𝒊𝒏 𝑮 c without TCSC GA-OPF with TCSC connected at Line No 7 Voltage FA-OPF without TCSC FA-OPF with TCSC connected at Line No 7 Voltage (p.u) Voltage (p.u) (p.u) Voltage (p.u) 1 1.06 1.06 1.06 1.06 2 1.045 1.045 1.045 1.045 3 0.9872 1.01 0.9925 1.01 4 1.0015 1.0287 1.0022 1.0267 5 1.0114 1.0378 1.0118 1.038 6 0.9813 1.07 0.9819 1.07 7 0.9817 1.0372 0.9829 1.0363 8 1.0218 1.09 1.0232 1.09 9 0.948 1.01 0.949 1.0089 10 0.9454 1.01 0.9464 1.0118 11 0.9591 1.032 0.9599 1.0367 12 0.9578 1.043 0.9584 1.0463 13 0.9458 1.0333 0.9465 1.0331 14 0.883 0.96 0.8839 0.9606 TCSC node voltage Tab.6: 1.0372 1.0347 Comparison of Real power loss for 14 bus system without and with TCSC (TCSC placed at line number 7) Parameter Active Power Generation in MW Reactive Power Generation in MVAR Active Losses in MW Reactive Losses in MVAR TCSC size FA –OPF without TCSC FA-OPF with TCSC 264.4104 264.0631 117.97 50 115.2766 113.3547 6.9251 6.4339 5.4104 5.0631 14.2728 11.468 5 8.8766 6.6128 --- 0.031 ---- 0.0220 GA-OPF with out TCSC 265.925 1 GAOPF with TCSC 265.43 39 120.672 8 5 Journal of Electrical Engineering www.jee.ro Tab.7: Comparison of objective function parameters before and after installation of TCSC Objective function parameters Total Real FA –OPF without TCSC FA-OPF with TCSC GA-OPF with out TCSC 6.9251 GAOPF with TCSC 6.4339 5.4104 5.0631 0.5718 0.2819 0.5593 0.2773 Power Losses Total Voltage Deviation(p.u) Branch loading Fuel cost FVSI for all lines Objective function value 2.6532 2.6199 1280.32 1278.4 10 76 2.1963 1.7489 367.037 336.20 9 11 2.3502 2.3280 1206.3879 1105.2432 1.9871 1.6300 364.2483 333.6814 Tab.8: Comparison of FVSI by changing the reactive load at bus 14 before and after installation of TCSC FVSI (Q14=30 FVSI MVAR) MVAR) FA –OPF without TCSC 0.0249 1 2 0.1277 0.06 0.1443 0.0599 3 0.0918 0.013 0.1242 0.0073 4 0.1176 0.0202 0.1455 0.0223 5 0.0772 0.0247 0.1074 0.0222 6 0.0071 0.0429 0.0101 0.0367 7 0.0204 0.0171 0.0235 0.0186 8 0.1116 0.1309 0.1686 0.1343 9 0.0751 0.038 0.1184 0.0274 10 FA-OPF with TCSC 0.0251 0.2213 0.1821 0.2395 11 0.1965 0.0651 0.2576 0.0888 12 0.1307 0.1011 0.1551 0.1144 13 0.0083 0.0144 0.0063 0.0214 14 0.0586 0.0998 0.0672 0.1152 15 0.0604 0.0589 0.0765 0.0712 16 0.1086 0.1091 0.1406 0.1339 17 0.2602 0.1847 0.3671 0.2572 18 0.0404 0.0879 0.0483 0.1051 19 0.0578 0.0603 0.0804 0.0785 20 0.2363 0.2551 0.3343 1.6299 2.5824 Total 0.175 FA-OPF with TCSC 0.0254 1.98 FVSI FVSI (Q14=60 MVAR) (Q14=70 MVAR) FA-OPF with TCSC 0.0228 FA –OPF without TCSC 0.2463 FA-OPF with TCSC 1 FA-OPF with out TCSC 0.1017 2 0.1899 0.0673 77824.08 0.0247 0.0073 9758.097 0.0019 79.3714 0.0051 Line NO 3 0.207 0.028 0.0194 4 0.2769 5 0.1777 0.0146 4265.893 0.0119 6 0.0532 0.0309 0.3591 0.0143 7 0.0413 0.0235 2.6996 0.0196 8 0.3341 0.1467 4.5429 0.1834 9 0.2482 0.0046 0.686 0.0037 10 0.2145 0.2797 0.3403 0.3069 11 0.4383 0.23 0.1571 12 0.2409 0.1461 0.5752 0.1646 13 0.0019 0.0357 0.8769 0.0455 14 0.0951 0.1459 0.7784 0.1661 15 0.13 0.0418 0.1119 16 0.2462 0.1866 4.8691 0.2168 17 0.6884 0.4137 23.1054 0.4961 18 0.0747 0.1414 2.6273 0.1663 19 0.1561 0.1173 7586.467 0.1399 20 0.6324 0.4974 2.9831 0.5862 4.5485 2.5475 99558.87 2.8414 0.141 (Q14=40 FA-OPF with out TCSC 0.0257 Line NO Tab.9: Comparison of FVSI by changing the reactive load at bus 14 before and after installation of TCSC Total 0.097 From fig 3 it can be observed that by increasing the reactive load at bus number 14, total FVSI value also increases. Incorporating the TCSC in Firefly Algorithm based Optimal Power Flow total FVSI value has been reduced that indicates that line stability has been improved. 0.335 1.914 6 Journal of Electrical Engineering www.jee.ro Tab.11: Comparison of bus voltages for 30 bus system using GA-OPF and FA-OPF without and with TCSC BUS No 6.2. For 30 Bus System In IEEE 30 bus system bus no 1 is considered as a slack bus and bus no‟s 2,5,8,11,13 are considered as a PV buses all other buses are considered as load buses. This system has 41 interconnected lines. A MATLAB program is coded for the test system and the results have been tabulated. Table.10 represents the generators a coefficient, minimum and maximum limits of real power generation for generator buses. Table.2 indicates that the optimal location for TCSC is line no 9. By placing the TCSC at line no 9 in both Genetic Algorithm and Firefly Algorithm based Optimal Power Flows and the results have been presented. Table.11 indicates the voltage magnitudes in FA-OPF without TCSC and FA-OPF with TCSC (By placing TCSC at line No 9). The results indicate that there is a good improvement in voltage profile with TCSC in Firefly Algorithm based OPF. The active power generation and power loss for IEEE 30 bus test system without and with TCSC is shown in Tab.12 and it is observed that active power losses are reduced to 11.5926 MW from 12.5466 MW by placing TCSC in Firefly Algorithm based Optimal Power Flow. TCSC value was tuned to 0.0400 using Firefly Algorithm and for the same the TCSC value has been tuned to 0.0468 using Genetic Algorithm based Optimal Power Flow. Tab.10: GENERATOR CHARACTERISTICS OF IEEE 30 BUS SYSTEM 1 a ($/MW2/ hr) 0.00375 b ($/MW /hr) 2 2 0.0175 5 Generator BUS NO c ($/hr) 𝑷𝒎𝒊𝒏 𝑮 (MW) 𝑷𝒎𝒂𝒙 𝑮 (MW) 0 50 300 1.75 0 20 80 0.0625 1 0 15 50 8 0.00834 3.25 0 10 35 11 0.025 3 0 10 30 13 0.025 3 0 12 40 FA-OPF without TCSC FA-OPF with TCSC connected at Line No 9 Voltage (p.u) Voltage (p.u) Voltage (p.u) Voltage (p.u) 1.06 1.06 1.06 1.06 1 Fig. 3: Fig: 3 FVSI values for different reactive load conditions GA-OPF with TCSC connected at Line No 9 GA-OPF without TCSC 2 1.045 1.045 1.045 1.045 3 1.0145 1.0196 1.0196 1.0219 4 1.0044 1.0106 1.0107 1.0135 5 1.01 1.01 1.01 1.01 6 0.9981 1.0043 0.999 1.0056 7 0.9946 0.9988 0.995 0.9988 8 1.01 1.01 1.01 1.01 9 0.9647 0.991 0.9663 0.9912 10 0.908 0.9379 0.9093 0.9371 11 1.0427 1.082 1.0446 1.082 12 0.9461 0.9853 0.9532 0.9884 13 1.0085 1.071 1.0142 1.071 14 0.8874 0.9273 0.8944 0.9303 15 0.8917 0.9302 0.8974 0.9322 16 0.9218 0.9576 0.9262 0.9587 17 0.906 0.938 0.9082 0.9377 18 0.8832 0.9193 0.8873 0.9202 19 0.8819 0.9164 0.8851 0.9167 20 0.8875 0.9209 0.8902 0.9209 21 0.8735 0.9047 0.8751 0.904 22 0.8679 0.8993 0.8696 0.8986 23 0.8371 0.8741 0.8417 0.8754 24 0.7748 0.8095 0.7777 0.8097 25 0.8374 0.8624 0.8388 0.8621 26 0.8157 0.8414 0.8172 0.841 27 0.8883 0.9066 0.889 0.9062 28 0.9865 0.9928 0.9873 0.9938 29 0.865 0.8839 0.8657 0.8834 30 0.8516 TCSC node Voltage 0.8708 0.8523 0.8703 0.9976 0.9989 Tab.12: Comparison of Real power loss for 30 bus test system without and with TCSC (TCSC placed at line number 9) Parameter Active Power Generation in MW Reactive Power Generation in MVAR Active Losses in MW Reactive Losses in MVAR TCSC size GA-OPF with out TCSC GA-OPF with TCSC FA –OPF without TCSC FA-OPF with TCSC 300.1323 298.9865 295.9466 294.9926 256.8372 253.2349 239.7242 237.0999 16.7323 15.5865 12.5466 11.5926 51.9372 47.8382 34.8242 31.9679 ------ 0.0468 ------ 0.0400 7 Journal of Electrical Engineering www.jee.ro Tab.13: Comparison of objective function parameters before and after installation of TCSC Objective GA-OPF with out TCSC function parameters Total Real 16.7323 Power Losses Total Voltage 2.4521 GAOPF with TCSC 15.586 5 1.7663 FA –OPF without TCSC 12.5466 2.3984 FA-OPF with TCSC 11.5926 1.7642 Deviation(p.u) Branch loading Fuel cost FVSI for all lines Objective 5.4414 5.4378 4.6713 1122.22 1118.1 1023.981 83 96 5 5.8644 5.243 5.6015 324.097 function value 0 322.32 312.9326 4.6066 1021.4473 5.1077 311.6005 Tab.14: Comparison of FVSI by changing the reactive load at bus 14 before and after installation of TCSC in IEEE 30 bus system FVSI (Q14=20 MVAR) 26 0.0035 0.0073 0.0119 0.0051 27 28 0.1399 0.131 0.1477 0.1346 0.1679 0.1572 0.1776 0.1617 29 0.0313 0.0291 0.0335 0.0301 30 0.2451 0.2458 0.2401 0.2425 31 0.4728 0.4429 0.5016 0.4565 32 0.3157 0.3182 0.3068 0.3126 33 0.4662 0.381 0.5201 0.3961 34 0.0719 0.0681 0.0744 0.069 35 0.2959 0.2504 0.3228 0.258 36 0.3497 0.3135 0.3687 0.3192 37 0.0412 0.0396 0.0422 0.0399 38 0.0529 0.051 0.054 0.0513 39 0.0169 0.0162 0.0173 0.0164 40 0.0953 0.0683 0.107 0.0737 41 0.0412 0.0416 0.0421 0.0415 Total 5.6015 5.1076 6.2404 5.4621 Tab.15: Comparison of FVSI by changing the reactive load at bus 14 before and after installation of TCSC FVSI (Q14=40 FVSI (Q14=30 MVAR) FVSI (Q14=50 MVAR) MVAR) 1 FA-OPF with out TCSC 0.0196 FA-OPF with TCSC 0.0234 FA –OPF without TCSC 0.0164 FA-OPF with TCSC 0.0208 2 0.1094 0.0934 0.1258 0.0949 3 0.1038 0.0783 0.126 0.0813 4 0.0238 0.0199 0.0278 5 0.0451 0.0492 6 0.0958 7 1 FA-OPF with out TCSC 0.0247 FA-OPF with TCSC 0.0314 FA –OPF without TCSC 3.5638 FA-OPF with TCSC 0.0599 2 0.1824 0.1074 0.0039 0.0495 3 0.1912 0.0892 0.2326 0.0897 0.0202 4 0.0422 0.0233 59484.73 0.0081 0.037 0.042 5 0.0396 0.0486 5.0783 0.0108 0.0929 0.0977 0.0914 6 0.2091 0.1001 0.8509 0.0728 0.039 0.0198 0.0215 0.0157 7 0.0736 0.0163 33.8875 0.0076 8 0.0719 0.058 0.0792 0.0617 8 0.149 0.0626 0.8762 0.0818 9 0.0101 0.0005 0.0152 0.002 9 0.0674 0.0027 19.3619 0.0154 10 0.0488 0.0192 0.0609 0.0252 10 0.0236 0.0276 0.0487 0.0538 11 0.1268 0.0567 0.1543 0.0614 11 0.2022 0.0731 0.032 0.0728 12 0.3215 0.2484 0.3596 0.2599 12 0.4291 0.2824 9.5571 0.2903 13 0.3564 0.4066 0.3642 0.4204 13 0.3963 0.4384 529.776 0.4597 14 0.2178 0.2025 0.2372 0.2121 14 0.2731 0.2243 1210.433 0.2374 15 0.2096 0.0929 0.2704 0.1163 15 0.3885 0.1492 0.082 0.1631 16 0.2774 0.3667 0.2927 0.4148 16 0.3257 0.4612 899.0658 0.5289 17 0.2317 0.2234 0.3244 0.303 17 0.4516 0.3815 6297.134 0.4707 18 0.1943 0.1962 0.2154 0.2169 18 0.2579 0.2339 12763.23 0.2598 19 0.0757 0.0945 0.0599 0.0907 19 0.0501 0.0798 44823.85 0.0767 20 0.0741 0.0556 0.1965 0.154 20 0.3748 0.2718 12.5555 0.407 21 0.0537 0.0738 0.0372 0.0699 21 0.0244 0.0585 0.2975 0.0552 22 0.0004 0.0166 0.0219 0.0053 22 0.0491 0.0123 1.216 0.0256 23 0.0074 0.0031 0.0213 0.004 23 0.0389 0.0149 0.0648 0.023 24 0.0188 0.0122 0.027 0.0163 24 0.0385 0.0224 3.0378 0.0271 25 0.0612 0.0426 0.0831 0.0537 25 0.1136 0.0705 0.8907 0.083 Line NO Line NO 8 Journal of Electrical Engineering www.jee.ro Total 26 0.0207 0.0004 0.5833 0.0024 27 0.169 0.1383 0.0412 0.1436 28 0.2036 0.1664 0.0635 0.173 29 0.0393 0.0313 11.2937 0.0329 30 0.256 0.2325 3.196 0.2314 31 0.5752 0.4708 34.7376 0.491 32 0.3265 0.2979 0.2951 0.295 33 0.6558 0.4295 326.7163 0.4417 34 0.0846 0.0701 0.0046 0.0713 35 0.3939 0.2762 0.0093 0.2814 36 0.4197 0.3342 0.3417 0.3371 37 0.0472 0.0404 16.7764 0.0409 38 0.0599 0.0519 4835.505 0.0525 39 0.0194 0.0166 689.0327 0.0168 40 0.0896 0.0778 189.5542 0.098 41 0.0591 0.0432 1.0708 0.0384 7.8361 5.9609 132209.1 6.3771 6.3. For 57 Bus System In IEEE 57 bus system, bus 1 is considered as slack bus and buses 2,3,6,8,9,12 are considered as generator buses. It consists of 50 load buses and 80 transmission lines. From the Tab. 16 it is observed that highest positive value for CPSIn(j) is 1 for line no76. So it is the best location for placement of TCSC in the IEEE 57 bus system. After placing the TCSC consider all the parameters of the system, generation reallocation is carried out with a multi objective function which is formed by considering the cost of the real power generation, active power losses, voltage deviation and branch loading. Results are presented in Tab. 17 to 19. Tab.16: Complex power flow sensitivity Index values for all lines in the IEEE 57 bus system S .No 1 2 From Fig 4 it has been observed that by incorporating the TCSC in Firefly Algorithm based Optimal Power Flow Real power losses were minimized. Table.13 represents the voltage deviation, TCSC reactance value, total active power generation cost and active power losses for IEEE 30 bus system without TCSC and with TCSC using GAOPF and FA-OPF. Table.14 & 15 indicates the FVSI values for Firefly Algorithm based Optimal Power Flow without and with TCSC at different reactive load conditions at bus number 14. From this table it can be observed that by increasing the reactive load FVSI values reach towords one that indicates less line stability. By installing the TCSC in Firefly Algorithm based Optimal Power Flow can improve the FVSI that means line stability has been improved. 3 4 5 6 CPSIn(j) Line No S. No CPSIn(j) 76 1 41 80 0.8837 36 0.9987 42 32 0.88 73 0.9986 43 17 0.8666 35 0.9982 44 58 0.863 46 0.9951 45 6 0.8616 31 0.9915 46 50 0.8593 7 44 0.991 47 68 0.8551 8 54 0.99 48 39 0.8506 9 29 0.9889 49 15 0.8426 10 19 0.9836 50 10 0.8324 11 74 43 0.9833 0.9804 51 52 14 2 0.832 0.8316 30 0.9759 53 26 0.8217 14 20 0.9755 54 47 0.8142 15 56 0.9733 55 59 0.8055 16 75 0.9679 56 24 0.8032 17 55 0.9675 57 65 0.7947 18 19 20 21 22 23 24 25 26 27 28 29 30 31 11 77 34 0.9582 0.9523 0.9514 58 59 60 22 60 41 0.794 0.7883 0.7746 38 69 70 64 42 0.951 0.945 0.9434 0.9412 0.9351 61 62 63 64 65 21 25 40 57 28 0.7716 0.7583 0.7499 0.7478 0.7311 16 67 66 27 78 7 0.9348 0.9291 0.9283 0.9244 0.9241 0.9219 66 67 68 69 70 71 48 18 8 79 37 52 0.7248 0.7194 0.7106 0.6948 0.6865 0.6816 32 9 0.9195 72 13 0.6612 12 13 Fig. 4: Fig: 4 comparisons of Real Power Losses Line No 9 Journal of Electrical Engineering www.jee.ro 33 34 35 36 37 38 12 71 5 4 62 0.9141 0.9101 0.9079 0.8954 0.8922 73 74 75 76 77 63 0.8914 39 23 0.8909 40 72 0.8868 51 3 49 45 53 0.6058 0.5956 0.5916 0.5844 0.4902 78 1 0.4612 79 61 0.353 80 33 0 The results from Tab. 17 show that , for minimization of the multi objective function, Firefly algorithm with TCSC, the generation cost of the best solution is 46412.3565$/hr with 44.8432 MW line loss, 4.8530 voltage deviation and 12.7971 branch loading. The results in Tab.17 indicate the values of the different parameters of the multi objective function using Firefly algorithm and genetic algorithm considering without & with TCSC. From this table it is observed that Firefly algorithm gives better results compared to genetic algorithm. Tab.18 shows that after placing the TCSC in the system voltage profile has been improved. Tab. 19 shows the comparison of FVSI before and after installation of TCSC in IEEE 57 bus system. From this table it is observed that by incorporating the TCSC in the system improves the line based stability. Tab.17: Comparison of objective function parameters using GA and FAOPF considering without and with TCSC in IEEE 57 bus system Variables Total real power generation (MW) Total real power generation cost ($/hr) Active power Loss (MW) Voltage deviation (p.u) Branch loading (p.u) FVSI value for all lines (p.u) Reactance of TCSC (p.u) Objective function value GA-OPF without TCSC 1245.255 47701.16 49.4550 FA-OPF without TCSC 1241.847 46977.18 46.0472 GA OPF with TCSC at line no 76 1244.255 47689.09 49.2455 FA- OPF with TCSC at line no 76 1240.643 46412.35 44.8432 5.9295 5.7421 4.9056 4.8530 13.8480 13.3127 14.1600 12.7971 7.9431 7.6171 7.5205 7.3326 ---- 0.4201 ---11942.59 11760.57 11939.35 Tab.18: Comparison of bus voltages for 57 bus system using FA-OPF without and with TCSC Voltage (p.u) FA-OPF with TCSC at Line No 76 Voltage (p.u) 31 0.7224 0.8143 1.01 32 0.7406 0.8589 1 33 0.7376 0.8563 1.0017 0.9941 34 0.7888 0.9255 5 0.997 0.9945 35 0.7978 0.9362 6 1 1 36 0.8099 0.9485 7 0.985 0.9879 37 0.8201 0.9605 8 1.005 1.005 38 0.852 1 9 0.9902 1 39 0.8177 0.9569 10 0.9801 0.9979 40 0.8075 0.9443 11 0.9591 0.9831 41 0.8186 0.877 12 1.015 1.015 42 0.7778 0.8535 13 0.9706 0.9974 43 0.9191 0.9526 14 0.9445 0.9907 44 0.884 1.0033 15 1.0073 1.0167 45 0.964 1.023 16 1.0136 1.0142 46 0.9149 0.993 17 1.0186 1.0193 47 0.8797 0.9882 18 0.9625 0.9594 48 0.8732 0.9916 19 0.9005 0.9109 49 0.8943 0.9879 20 0.8754 0.8943 50 0.8982 0.9696 21 0.8542 0.8884 51 0.9633 0.9922 22 0.8508 0.8872 52 0.9244 0.9321 23 0.8498 0.8862 53 0.909 0.9171 24 0.85 0.8854 54 0.9385 0.947 25 0.7826 0.8419 55 0.9775 0.9864 26 0.8554 0.8885 56 0.7745 0.8645 27 0.9143 0.9312 57 0.7693 0.8698 28 0.9435 0.9542 29 0.9662 0.973 30 0.757 0.8264 FAOPF without TCSC FA-OPF with TCSC at Line No 76 Voltage (p.u) Voltage (p.u) 1 1.04 1.04 2 1.0334 3 1.0115 4 BUS No FA-OPF without TCSC Tab.19: Comparison of FVSI before and after installation of TCSC in IEEE 57 bus system Line No FVSI without TCSC FVSI with TCSC at Line No 76 1 0.0432 0.1334 2 0.0756 3 4 FVSI without TCSC FVSI with TCSC at Line No 76 41 0.0715 0.0573 0.0256 42 0.0828 0.0718 0.0247 0.0156 43 0.1156 0.095 0.0134 0.0059 44 0.052 0.0653 5 0.0145 0.0047 45 0.0109 0.0099 6 0.0696 0.0556 46 0.204 0.1991 7 0.0335 0.0276 47 0.0312 0.0292 8 0.0097 0.039 48 0.0409 0.0378 0.3111 11618.96 BUS No Line No 10 Journal of Electrical Engineering www.jee.ro 9 0.0299 0.0122 49 0.036 0.036 10 0.081 0.0757 50 0.1163 0.1184 0.0107 11 0.1591 0.1115 51 0.0096 12 0.0152 0.016 52 0.0093 0.0115 13 0.0882 0.0702 53 0.0002 0.0106 14 0.0826 0.0371 54 0.4858 0.4548 15 0.1165 0.1133 55 0.1007 0.0782 16 0.0247 0.0259 56 0.562 0.5083 17 0.0072 0.0067 57 0.13 0.0778 18 0.01 0.0595 58 0.1596 0.1094 19 0.1369 0.121 59 0.12 0.0914 20 0.1395 0.1236 60 0.1249 0.0933 21 0.0023 0.0063 61 0.0441 0.0279 22 0.0467 0.0388 62 0.119 0.0467 23 0.1517 0.1232 63 0.0432 0.0251 24 0.074 0.0676 64 0.2567 0.2195 25 0.2172 0.1782 65 0.0657 0.0589 26 0.0202 0.0207 66 0.2823 0.1699 27 0.0458 0.0466 67 0.1017 0.089 28 0.0878 0.0837 68 0.041 0.0338 29 0.1755 0.101 69 0.0874 0.1025 30 0.1032 0.0501 70 0.1082 0.1204 31 0.1014 0.0268 71 0.1587 0.1475 32 0.0207 0.0056 72 0.3095 0.1987 33 0.0026 0.0062 73 0.1506 0.1911 34 0.0144 0.0759 74 0.0272 0.0267 35 0.261 0.2361 75 0.0141 0.0329 36 0.261 0.2361 76 0.2117 0.24 37 0.026 0.0147 77 0.0144 0.028 38 0.2183 0.129 78 0.2596 0.1194 39 0.0805 0.0517 79 0.1328 0.0721 40 0.0615 0.0437 80 0.0493 0.0526 effectiveness of the proposed approach. The obtained results show that TCSC is the most effective series compensation device that can significantly increase the line stability of the power system. References [1] P. Kundur, Power System Stability and Control. New York: McGraw-Hill, Inc., 1993. [2] G W Stagg and A H El-Abid, „Computer Methods in Power System Analysis‟(Book), McGraw-Hill Book Co, 1968. [3] N. G. Hingorani and L. Gyugyi, “Understanding FACTS: Concepts and Technology of Flexible AC Transmission System”, IEEE Press, 2000. [4] Camacho Yuryevich Janson, Wong Po kit. Evolutionary programming based optimal power flow algorithm. IEEE Trans Power System 1999;14(4): 1245–50. [5] Varaprasad Janamala, Chandra Sekhar Koritala,“ OPTIMAL LOCATION OF UPFC FOR CONGESTION RELIEF IN DEREGULATED POWER SYSTEMS”, Journal of Electrical Engineering, pp.1-8, 2014. [6] Sung-Hwan Song, Jung-Uk Lim, Seung-Il Moon, “FACTS operation scheme for enhancement of power system security,” in Proc. 2003 IEEE Bologna Power Tech Conference, Vol. 3, pp. 36-41, June 2003. [7] Canizares C A and Faur Z T (1999), “Analysis of SVC and TCSC Controllers in Voltage Collapse”, IEEE Trans. on Power Systems, Vol. 14, No. 1, pp. 158-165. [8] Yunqiang Lu, Ali Abur, “Static security enhancement via optimal utilization of Thyristor-Controlled Series Capacitors,” IEEE Trans. Power System., vol.17, pp.324-329, May 2002. [9] R. benabid, M. Boudour, M.A. Abido, “ Optimal location and setting of SVC and TCSC devices using nondomonated sorting particle swarm optimization”, Electric Power Systems Research 79, 1668-1677, July 2009. [10] TLIJANI Kamel , GUESMI Tawfik , HADJ ABDALLAH Hsan and OUALI Abderrazak, “ 0ptimal location and parameter setting of TCSC based on Sensitivity analysis”, 2012 First international conference on renewable energies and vehicular technology (IEEE conference), pp. 420-424. [11] P. P. Narayana, M. A. Abdel Moamen, and B.J. Praveen Kumar “ Optimal location and initial parameter settings of multiple TCSCs for reactive power planning using genetic algorithm”, IEEE Power Engineering Society General Meeting, Vol.1, pp. 1110 – 1114, 6-10 June 2004. [12] Carpentier. J “Optimal Power Flows”, Electrical Power and Energy Systems, Vol.1, April 1979, pp 959-972. [13] Bakirtzis AG, Biskas PN, Zournas CE, Petridis V. Optimal power flow by enhanced genetic algorithm. IEEE Trans Power Syst 2002;17(2):229–36. [14] Ying Xiao, Y.H. Song and Y.Z. Sun, “Power flow 7. Conclusion In this paper, Sensitivity Analysis based Complex Power Flow Sensitivity Index (CPSI) has been implemented for optimal location of TCSC. After placing the TCSC in best location, a new swarm based Firefly Algorithm has been presented to solve the optimal sizing of TCSC. The effectiveness of Firefly Algorithm was presented. The results show that incorporating the TCSC in the IEEE 14, IEEE 30 and IEEE57 bus systems can reduce the total active power losses, improve the voltage profile of the system and enhance the line stability. For finding the best size of a TCSC, Firefly Algorithm based optimization technique, with the objective of reducing total generation cost, voltage deviation, active power losses and branch loading were implemented. The comparative study of the Firefly Algorithm based Optimal Power Flow with GA based Optimal Power Flow in solving the optimal tuning problem also reflected the 11 Journal of Electrical Engineering www.jee.ro control approach to power systems with embedded FCATS devices”,IEEE transaction on power systems, vol,17, No.4 ,Nov. 2002, pp. 943 – 950. [15] Gerbex R Cherkaoui and Germond A J (2001), “Optimal Location of Multi-Type FACTS Devices in a Power System by Means of Genetic Algorithms”, IEEE Transaction Power Systems, Vol. 16, August, pp. 537544. [16] T. Mirko, R. Dragoslav, "An initialization procedure in solving optimal power flow by genetic algorithm", IEEE Transactionson Power Systems, 2006, vol. 21, pp. 480-7. [17] P. Pezzini, O.G. Bellmunt, and A. S. Andrue, “Optimization Techniques to improve energy efficiency in power system,” International Journal Renewable and Sustainable Energy 2011, 2028-2041. [18] Acha E., Fuerte-Esquivel C, Ambriz-Perez H and Angeles C., “FACTS: Modelling and Simulation in Power Networks”. John Wiley & Sons, 2004. [19] D. Radu, and Y. Besanger, “ A multi-objective genetic algorithm approach to optimal allocation of multi-type FACTS devices for power system security,” IEEE Power Engineering Society General Meeting, pp. 8, 1822 June 2006. [20] Fuerte-Esquivel C , Acha E., Ambriz-Perez H., “A Thyristor Controlled Series Compensator Model for the Power Flow Solution of Practical Power Networks” IEEE Trans on Power Systems, Vol. 15, N0.1, pp.129136, February 2000. [21] Wei Shao, Vittal, V., “LP-Based OPF for Corrective FACTS Control to Relieve Overloads and Voltage Violations”, IEEE Trans. Power Syst. Vol. 21, No. 4, pp.1832-1839, Nov. 2006. [22] Srinivasa Rao Pudi, S.C. Srivastava, “Optimal Placement of TCSC Based on a Sensitivity Approach for Congestion Management”, in Proc. of Fifteenth National Power Systems Conference (NPSC), IIT Bombay, December 2008, pp. 558-563, Dec. 2008. [23] Ambriz-Pérez H., Acha E., Fuerte-Esquivel CR “TCSC-firing angle model for optimal power flow solutions using Newton's method”, International Journal of Electrical Power & Energy Systems, Volume 28, Issue 2, February 2006, Pages 77-85. [24] Shenghu Li “Power Flow Control Effect with TCSC on Operation Margin of Zone 3 Impedance Relays” International Journal of Electrical Power & Energy Systems, Vol. 32, No. 9, pp. 998-1004, November 2010. [25] Tinney W. F., Hart C. E., “Power Flow Solution by Newton‟s Method”, IEEE Transactions on Power Apparatus and Systems, Vol. PAS-86, No.11, pp. 18661876, November 1967. [26] N P Padhy and Abdel-Moamen M. A., “Power Flow Control and Solutions with Multiple and Multi-Type FACTS Devices” Electric Power Systems Research, Vol. 74, pp. 341-351, June 2005. [27] X.-S. Yang, "Firefly algorithms for multimodal optimization," Stochastic Algorithms: Foundation and Applications SAGA 2009, vol.5792, pp. 169-178, 2009. [28] X. S. Yang, “Firefly algorithm, Levy flights and global optimization,” in Research and Development in Intelligent Systems XXVI, pp. 209–218, Springer, London, UK, 2010. [29] X. S. Yang, Nature-Inspired Meta-Heuristic Algorithms, Luniver Press, Beckington, UK, 2008. [30] S. Lukasik and S. Zak, “Firefly algorithm for continuous constrained optimization tasks,” in Proceedings of the International Conference on Computer and Computational Intelligence (ICCCI ‟09), pp. 97–106, Springer, Wroclaw, Poland, October 2009. About Authors Author-Venkateswara Rao BATHINA was born in Ramabhadrapuram, Andhra Pradesh, India in 1978. He received his Bachelor degree in Electrical and Electronics Engineering from College of Engineering, Gandhi Institute of Technology And Management (GITAM), Visakhapatnam, India in 2000, and the Master degree in Electrical Power Engineering from the College of Engineering, JNTU, Hyderabad in 2007. He received his Doctoral degree from Jawaharlal Nehru Technological University, Hyderabad. He is presently working as Assistant Professor in the Department of Electrical and Electronics Engineering, GITAM University, Visakhapatnam. His research interests are Power system stability analysis, FACTS devices, Power system control and optimization. He has published several research papers in national, international conferences and journals. Co-author-Venkata Nagesh Kumar GUNDAVARAPU was born in Visakhapatnam, India in 1977. He graduated College of Engineering, Gandhi Institute of Technology and Management, Visakhapatnam, India, Masters Degree from the College of Engineering, Andhra University, Visakhapatnam. He received his Doctoral degree from Jawaharlal Nehru Technological University, Hyderabad. He is presently working as Associate Professor in the Department of Electrical and Electronics Engineering, GITAM University, Visakhapatnam. His research interests include gas insulated substations, FACTS devices, Power System Stability analysis, fuzzy logic and neural network applications, distributed generation, Partial Discharge Studies and Bearing less drives. He has published several research papers in national and international conferences and journals. He received “Sastra Award” , “Best Paper Award” and “Best Researcher Award”. He is a member of various societies, ISTE, IEEE, IE and System Society of India. He is also a reviewer for IEEE Transactions on Dielectrics and Electrical Insulation, Power Systems and a member on Board of several conferences and journals. 12