Technical Area/Site

advertisement

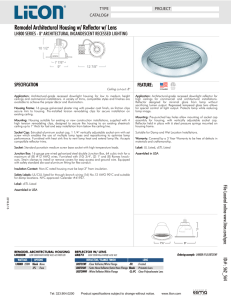

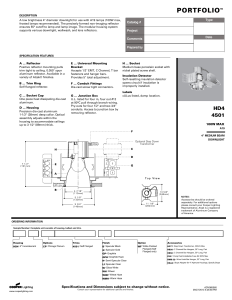

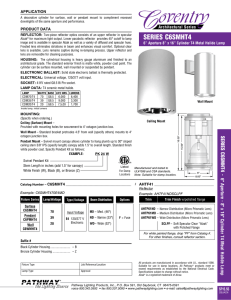

Technical Area/Site Ida approved fixture seal of approval technical Hubbell Outdoor and Spaulding brands are aware of the growing concern over glare, light trespass and sky glow created by improperly applied lighting fixtures. This wasted light is wasted energy. To address this concern, we have designed many of our new products with Full Cutoff (zero uplight) optics to provide greater control of light output from area and wall mounted fixtures. Hubbell Outdoor and Spaulding fixtures that meet Full Cutoff criteria are designated with the IDA fixture seal of approval logo. These fixture series or specific lens options will solve your need for excellent site lighting with an environmentally friendly reduced sky glow and are approved by the International Dark Sky Association. Recommended Mounting Height Guidelines Metal Halide Watts Mt. Height 70 PS 7 100 PS 10 175 PS 16 250 PS 20 400 PS 25 1000 PS 35 Recommended Illumination Guidelines High Pressure Sodium Watts Mt. Height 35 6 50 7 70 8 100 12 150 18 250 25 400 30 1000 38 Area Description Shopping center and store parking lot Entrance and exits - twice area level Public parking lot Security Avg. Maintained Footcandles Uniformity Ratio Avg. to Min. 2-4 Excellent 2:1 4-8 Good 4:1 1-2 1-0.5 Average 6:1 Acceptable 10:1 Recommended minimum (exceptions may be taken when diffuse lens or lamp is specified) Area/Site Luminaire Lens Choices Convex Lens Flat Lens Spaulding Lighting offers three lens enclosure configurations for many of our area/site luminaires. Flat, convex and dropped configurations offer distinctly different performance benefits and aesthetics values. Take the time to choose the correct configuration to ensure you meet all of your design criteria. Convex Lens Also referred to as a sag lens, the convex lens is a very popular choice for customers interested in achieving: • Maximum spacing between luminaires • Higher light levels between poles • Excellent light level uniformity Luminaires with a convex lens also offer a degree of “sparkle” a flat lens cannot. Used many times in retail commercial applications, a convex lens allows the lighting system to become an integral component of a business’ identity and advertising goals. Dropped Lens Flat Lens With today’s increased concern for lighting in an environmentally conscious manner, utilizing a flat lens may be your best choice. A flat lens offers the following: • Reduced luminaire glare • Reduced light trespass onto adjacent properties • Reduced night “sky glow” All of Spaulding’s luminaires configured with a flat lens are FULL CUTOFF classified per IES standards. Flat lens luminaires help reduce the potential negative impact of lighting in a commercial space. Dropped Acrylic or Polycarbonate Lens Luminaires featuring a dropped lens offer many of the benefits of the convex lens with a “softer” visual appearance. Dropped lens luminaires provide a square symmetric distribution of light and superior light level uniformity. Additionally, the rugged polycarbonate version is a great choice for areas needing a higher degree of luminaire protection. Spaulding Lighting has worked hard to strike a balance between the concerns of lighting in an environmentally conscious manner without sacrificing sound lighting design principles. 629 Technical Area/Site technical Area/Site Reflector Choices Choosing Spaulding Lighting for your area/site lighting gives you maxi- Multi-Faceted Hydroformed, traditional hydroformed, and multi-piece mum design flexibility when determining which product to use. From (forward throw) reflector designs. The table below details some of the the most demanding performance criteria to the most cost competitive benefits from each method of fabrication. project, Spaulding Lighting has the reflector system for any requirement. With up to six photometric distributions from either horizontal or vertically lamped configurations, Spaulding offers fully segmented, Patented Reflector 630 Features Results In Achieved Benefit Fully Segmented • Superior spacing between lumi- Multiple individual segments of pre- • The broadest photometric naires and poles resulting in distribution finished highly specular aluminum, reduced project costs machine punched and formed, then • Precise beam control at • The highest levels of visual acuity critical angles hand placed at precise angles into at grade resulting in increased the reflector’s rigid supporting “su- • Excellent light level uniformity safety and security per structure” for exact imaging of with reduced “hot spots” below the luminaire the lamps arc tube in each facet Patented Multi-Faceted Hydroformed Advanced multi-step, “deep well” hydroforming process followed by the application of Hubbell’s proprietary Anodal® reflector finish technology results in a one-piece, rigid semi-specular aluminum reflector with up to 1,350 miniature facets for precise optical control • Broader photometric distribution and uniformity levels usually only associated with more expensive fully segmented reflec tor designs • Minimal lamp imaging from miniature facets and the lowest levels of glare • Hard tooled repeatable performance reflector to reflector • Durable design withstands the rigors of shipment, installation, and maintenance • Broader spacing between luminaires and poles resulting in reduced project costs • Increased levels of visual acuity at grade resulting in increased safety, security as well as excellent visual comfort perception (VCP) • Consistent performance over the life of the installation Hydroformed Multi-step hydroforming process followed by the application of Hubbell’s proprietary Anodal® reflector finish technology results in a one-piece, rigid semispecular aluminum reflector • Good photometric distribution and uniformity levels • Reduced lamp imaging and low levels of glare • Hard tooled repeatable performance reflector to reflector • Durable design withstands the rigors of shipment, installation, and maintenance • Good spacing between luminaire and poles • Excellent value without sacrificing performance • Consistent performance over the life of the installation Multi-Piece (IES type IV - forward throw) Large individual pieces of prefinished semi-specular aluminum placed into the reflector’s rigid supporting “super structure” with the lamp placed deep within the reflector design • Sharp lamp cutoff • Minimal “house side spill” behind the reflector • Excellent forward projection of the lamp’s luminous flux • Ability to place the luminaire close to the property edge, eliminating or reducing light trespass • Maximum projection of light to target area Technical Area/Site Area/Site Reflector types H2P/H3P ies type iv (forward throw) H4P ies type Iv H2/H3 technical ies type ii ies type iii H4 ies type ii ies type iii •Advanced multi-step “deep well” •Multi-piece design with precision •Performance Series reflector design •Unique Split Beam Distribution hydroform design with Hubbell’s resulting from a multi-piece design formed pre-finished specular and with individual segments of pre proprietary Anodal® semi-specular finished highly specular aluminum, with precision formed pre-finished specular hammertone aluminum reflectors semi-specular aluminum reflectors machine punched and formed, finish then hand placed at precise angles that direct light both forward and •High efficiency (street/house side) •Broad photometric distribution and •Lower maximum candela vertical below the luminaire to each side into the reflector’s rigid supportuniformity levels typical of more beam angle plus lower candela val•Excellent forward projection of ing “super structure” for exact expensive fully segmented reflector ues at nadir (below the luminaire) light from a high 60 degree maxiimaging of the lamps arc tube in designs mum candela primary vertical beam •Sharp lamp cutoff behind the reflec- •Minimal lamp imaging from miniature each facet tor, lamp placed deep within the angle facets and the lowest levels of glare reflector (greater house side cutoff •Hard-tooled repeatable performance •Superior uniformity at grade provided with optional shield) between luminaires and increased reflector to reflector pole spacing between luminaires V5 ies type v ies type V •Advanced multi-step “deep well” hydroform design with Hubbell’s proprietary Anodal® semi-specular finish •Broad photometric distribution and uniformity levels typical of more expensive fully segmented reflector designs •Minimal lamp imaging from miniature facets- lowest levels of glare V1P ies type i H5 H5P ies type V V5P ies type v •Hydroform reflector design with •Performance Series reflector design •Performance Series reflector design with individual segments of preHubbell’s proprietary Anodal® semi- with individual segments of prefinished highly specular aluminum, finished highly specular aluminum, specular finish machine punched and formed, then •Very good photometric performance machine punched and formed, hand placed at precise angles into then hand placed at precise angles and luminaire efficiency the reflector’s rigid supporting “super into the reflector’s rigid supporting •Reduced lamp imaging and low “super structure” for exact imaging structure” for exact imaging of the levels of glare •Hard-tooled repeatable performance of the lamp’s arc tube in each facet lamp’s arc tube in each facet reflector to reflector V3P ies type III (forward throw) V4 ies type iv (forward throw) •Performance Series reflector design •Performance Series reflector design •Unique Split Beam Distribution resulting from a multi-piece design with individual segments of prewith individual segments of prefinished highly specular aluminum, finished highly specular aluminum, with precision formed pre-finished machine punched and formed, then semi-specular aluminum reflectors machine punched and formed, that direct light both forward and then hand placed at precise angles hand placed at precise angles into below the luminaire to each side the reflector's rigid supporting into the reflector's rigid support“super structure” for exact imaging •Excellent forward projection of light ing “super structure” for exact of the lamp’s arc tube in each facet from a high 60 degree max. candela imaging of the lamp’s arc tube in primary vertical beam angle each facet •Superior uniformity at grade between luminaires and increased pole spacing between luminaires 631