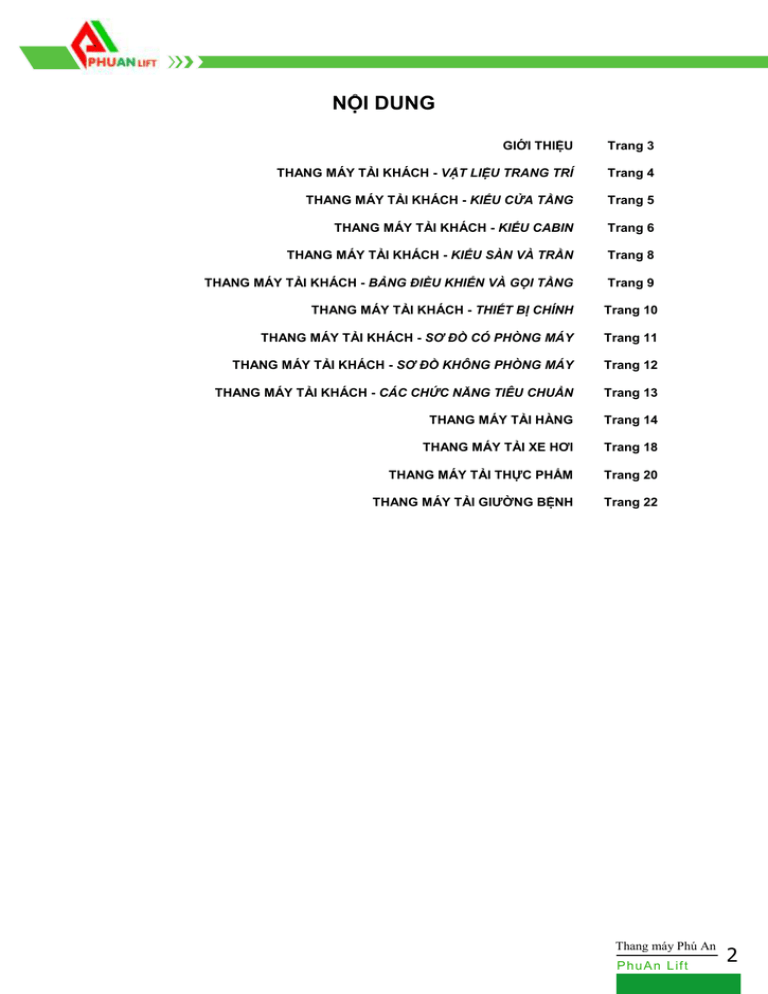

2 NỘI DUNG - công ty tnnhh dv - thương mại

advertisement