REPORT

443

FEBRUARY

2015

High Integrity Protection Systems –

Recommended Practice

plan

protect

Disclaimer

Whilst every effort has been made to ensure the accuracy of the information

contained in this publication, neither IOGP nor any of its Members past, present or

future warrants its accuracy or will, regardless of its or their negligence, assume

liability for any foreseeable or unforeseeable use made thereof, which liability is

hereby excluded. Consequently, such use is at the recipient’s own risk on the basis

that any use by the recipient constitutes agreement to the terms of this disclaimer.

The recipient is obliged to inform any subsequent recipient of such terms.

Copyright notice

The contents of these pages are © International Association of Oil & Gas Producers.

Permission is given to reproduce this report in whole or in part provided (i) that

the copyright of IOGP and (ii) the sources are acknowledged. All other rights are

reserved. Any other use requires the prior written permission of IOGP.

These Terms and Conditions shall be governed by and construed in accordance

with the laws of England and Wales. Disputes arising here from shall be exclusively

subject to the jurisdiction of the courts of England and Wales.

REPORT

443

FEBRUARY

2015

High Integrity Protection Systems –

Recommended Practice

Revision history

VERSION

DATE

AMENDMENTS

1.0

February 2015

First release

High Integrity Protection Systems RP

4

Acknowledgements

Standards Committee

Instrumentation & Automation Subcommittee

High Integrity Protection Systems Task Force

IOGP Instrumentation and Automation Subcommittee (IASSC) HIPS Task

Force having representation from the following companies:

• BG Group

• BP

• Maersk Oil

• Petrobras

• Repsol

• Siemens

• Statoil

• Total

• Yokogawa.

Photography used with permission courtesy of © ndoeljindoel/

iStockphoto and © Nostal6ie/iStockphoto (Front cover) and

© Sharif El-Hamalawi/iStockphoto (Back cover).

Contents

Foreword6

1 Scope

7

2 References

8

3 Terms and definitions

9

Abbreviations11

4 General recommendations

12

4.1 Safety Requirements Specification

12

4.1.1 Service conditions

13

4.1.2 HIPS reliability criteria

14

4.1.3 Reliability data

15

4.1.4 HIPS reaction and response time

15

4.2 Avoidance of common-mode failures

18

4.2.1 Sensor positioning

18

4.2.2 Sensor and final element selection

18

4.2.3 Logic solver selection 18

4.2.4 Maintenance and human intervention

19

4.2.5 Utility failure

19

4.3 Hardware considerations

20

4.3.1 Electrical connections

20

4.3.2 Heat tracing and winterization

20

4.3.3 Materials of construction

21

4.3.4 Protection enclosures

21

4.3.5 Cabinet

21

5 HIPS elements

22

5.1 Sensor(s) 22

5.1.1 Sensor selection

22

5.1.2 Sensor configuration and positioning 22

5.2 HIPS automation system

23

5.2.1 Interfaces and cyber security (Programmable Logic Solvers)

24

5.2.2 Interfaces and cyber security (solid state logic solvers)

25

5.3 Final element(s) 26

5.3.1 Valves

26

5.3.2 Circuit breakers

27

High Integrity Protection Systems RP

6

6 Design testing

29

6.1 Design Validation/Typical Test (DVT)

29

6.2 Factory Acceptance Tests (FAT)

29

6.3 Integrated Factory Acceptance Test (IFAT)

30

6.4 Yard and On-Site Tests/Pre-Commissioning Tests

30

6.5 Operational Testing (OT)/Site Acceptance Test (SAT)

31

6.6 Test administration

32

6.6.1 Preparation

32

6.6.2 Procedures

32

6.6.3 Recording

32

7 Operational testing

33

7.1 Design for test and maintenance

33

7.2 Operational proof testing

34

7.3 Valves

34

8 Safety life cycle for HIPS

35

8.1 Obsolescence management

35

8.2 Maintainability

35

8.3 Spare parts

35

9 HIPS dossier

37

High Integrity Protection Systems RP

7

Foreword

High integrity protection systems (HIPS) and especially high integrity

pressure protection systems (HIPPS) are an increasingly common feature

of oil and gas facilities worldwide.

They can provide an alternative to conventional mechanical protective

devices (e.g. relief valves) or reduce the load upon them.

In some cases, they present the only practical option to facilitate field

development and/or expansion.

The application of HIPS, and the manner in which they are implemented

across IOGP Members was considered worthy of investigation by the IOGP

Instrumentation and Automation Standards Subcommittee, with a view to

providing commonly agreed upon guidance on the subject.

This Recommended Practice is the result of that process.

The intended audience for this RP is those involved in the definition,

design, implementation or operation and maintenance of HIPS.

This RP does not provide guidance upon when, if and why a HIPS

should be utilized – to this end, companies should apply their own

internal methodologies.

This RP provides mainly technical recommendations.

High Integrity Protection Systems RP

8

High Integrity Protection Systems RP

9

1Scope

The objectives of this IOGP Recommended Practice are to:

• provide industry guidance in the provision, operation and

maintenance of HIPS throughout the IEC 61508 Safety Life cycle

• focus upon the instrumentation aspects of that provision

• support, clarify where appropriate, and not contradict or repeat

IEC 61511 and/or ISO 10418 as they apply to HIPS

• make it easier for vendors to deliver consistent systems across

the industry.

This IOGP Recommended Practice is intended for global application. The

following oil and gas production facility types are included:

• onshore

• offshore (not including subsea1)

• oil and gas transmission and transport systems.

This RP is applicable to all manner of high integrity protection systems,

be they pressure, temperature, level flow or any other parameter driven.

This RP is concerned with the instrumentation elements of HIPS. The

assumption is made that the dynamic requirements associated with

many HIPS have been satisfied in each case via a separate design and

verification exercise.

This RP is applicable to the Electrical, Electronic, Programmable

Electronic HIPS related Systems.

Other HIPS based on Mechanical Technology (e.g. using direct hydraulic or

pneumatic pilot valves) are not directly covered by this RP. However, much

of the guidance within this RP may also assist in their definition and use.

1

API RP 17O covers subsea HIPS

High Integrity Protection Systems RP

10

2References

The following documents, in whole or in part, are referenced in this

document and are recommended for its application.

API RP 14C, Analysis, Design, Installation, and Testing of Basic Surface

Safety Systems for Offshore Production Platforms

API RP 17O, Recommended Practice for Subsea High Integrity Pressure

Protection System (HIPPS)

API Standard 521, Pressure-relieving and Depressuring Systems

API Standard 598, Valve Inspection and Testing

EN 10204, Metallic products. Types of inspection documents

IEC 61508, Functional Safety of Electrical/Electronic/Programmable

Electronic Safety-related Systems (E/E/PE, or E/E/PES)

IEC 61511, Functional Safety – Safety instrumented systems for the process

industry sector

IEC 62442-3-3, Industrial communication networks – Network and system

security – Part 3 3: System security requirements and security levels

IEC 62443, Network and system security for industrial-process measurement

and control

IEC 62443-2-4, Security for industrial automation and control systems –

Network and system security – Part 2-4: Requirements for IACS solution

suppliers

ISO 5208, Industrial valves – Pressure testing of metallic valves

ISO 10418, Petroleum and natural gas industries – Offshore production

installations – Analysis, design, installation and testing of basic surface

process safety systems

ISO 23251, Petroleum, petrochemical and natural gas industries – Pressurerelieving and depressuring systems

ISO/TR 12489, Petroleum, petrochemical and natural gas industries –

Reliability modelling and calculation of safety systems

High Integrity Protection Systems RP

11

3 Terms and definitions

For the purpose of this document the following definitions apply.

bypass

Bypass (including overriding and inhibiting) input/output: action or facility

to prevent all or parts of the SIS functionality from being executed (refer

to IEC 61511).

common-mode failure (CMF)

According to UKAEA SRD R 196 (1981): “A common-mode failure (CMF)

is the result of an event(s) which because of dependencies, causes a

coincidence of failure states of components in two or more separate

channels of a redundancy system, leading to the defined system failing to

perform its intended function”.

For the purpose of this document, CMF is taken to include common cause

and dependent failures.

HIPS

Within the oil and gas industry, there are various company-specific

definitions as to what constitutes a HIPS. It is not the purpose of this RP

to define what constitutes a HIPS.

According to the ISO/TR 12489 definition, a non-conventional2 autonomous

safety instrumented system with sufficiently high safety integrity to protect

equipment against exceeding the design parameters is considered a HIPS.

One or more of the following may also be considered a HIPS:

• a final protection layer comprising a combination of partial

mechanical and instrumented protective function

• an instrumented protection layer having an integrity requirement of

SIL 3 or more

• an instrumented protection layer where the consequence of nonoperation is major to catastrophic or disastrous.

Deviations from industry standards describing mechanical protection systems (e.g.

ISO 23251 = API Standard 521, ISO 10418, API RP 14C) are treated as HIPS. An ultimate

protection relying principally, but not necessary solely, on Safety Instrumented Systems

(SIS) is qualified as HIPS, irrespective of its required Safety Integrity Level (SIL).

2

High Integrity Protection Systems RP

12

HIPPS

ISO/TR 12489 also defines HIPPS or OPPS as, “a HIPS exclusively devoted

to protection against overpressure”.

HIPS reaction time

The maximum allowable time in which the HIPS should prevent a

hazardous operational condition. It is thus the time between the process

threshold value occurring and the occurrence of the hazardous event.

HIPS response time

The time between the process threshold value occurring until the final

element has reached its safe state.

High Integrity Protection Systems RP

13

Abbreviations

BPCS

Basic Process Control System

BR

Base Requirement

CMF

Common-Mode Failure

DVT

Design Validation Test

FAT

Factory Acceptance Test

HIPS

High Integrity Protection Systems

HIPPS

High Integrity Pressure Protection Systems

HMI

Human Machine Interface

ICSS

Integrated Control and Safety System

IFAT Integrated Factory Acceptance Test

IS

Intrinsically Safe

ITP

Installation and Test Plan

LOPA

Layer of Protection Analysis

MCC

Motor Control Centre

MTTR

Mean Time to Repair

OPPS

Overpressure Protection System

OT

Operational Test

PFD

Probability of Failure on Demand

RE

Requirement Enhancement

SAT

Site Acceptance Test

SIF

Safety Instrumented Function

SIL

Safety Integrity Level

SIS Safety Instrumented System

SOE

Sequence of Events

SP

Security Program

SRS

Safety Requirements Specification

High Integrity Protection Systems RP

14

4 General recommendations

A HIPS is normally the last in a series of process protection layers.

The others typically comprise the process control, alarm (with manual

response) and process shutdown layers.

The HIPS function should thus be seen in the context of these other

protection layers and potential process deviations, and any changes to

such should not occur without considering the potential impact upon

the HIPS function.

For an over pressure HIPS (for instance), the following should be clearly

defined:

• sources of HIPS demand, and assumptions regarding how quickly

they will cause that demand

• process conditions

• other protection layer set points assumed in design of the HIPS.

All HIPS should be developed and implemented in accordance with the

requirements of IEC 61508 and 61511. Competency assurance through the

design, implementation and operational phases is a key requirement.

A single HIPS Integrator should be utilized to ensure that the combination

of the sensing elements, logic solver and final elements meet the

integrity, operability and maintainability targets.

4.1

Safety Requirements Specification

HIPS functions should be defined independently of other safety systems

in a specific HIPS Safety Requirements Specification (SRS), normally

produced by the end user. This should consider the complete system

comprising sensing element(s), logic solver and final element(s). The

HIPS should be developed and implemented in a similarly complete

system manner.

In addition to the requirements of IEC 61511 part 1 (SIS SRS which

includes performance requirements relating to Functionality, Availability,

Survivability and Interdependencies), the following should feature in a

HIPS SRS.

• The HIPS should execute all safety functions in automatic mode.

• The HIPS should be autonomous, with dedicated sensors, logic and

final elements.

• The HIPS should be a physically segregated system, interfaced

with the facility automation system for monitoring only. Any

communications with HIPS should not be able to impede or override

the safety function(s).

High Integrity Protection Systems RP

15

• The HIPS should be designed according to fail-to-safe principles.

• HIPS resetting should not be possible without a clear understanding

of the initiating cause and/or fault.

• Signals between sensors, logic solver and final elements should

be hardwired.

• The HIPS design should define and include allowance for test and

maintenance activities. Nonetheless, HIPS sensor, logic or final

element bypass functions should be avoided. When required, bypass

functions should be subject to a thorough assessment of the risk and

consequences for system integrity.

• The required performance of the HIPS will be based on the process

and facility conditions (e.g. production rates, plant line up) known/

assumed at the time of the system design and procurement. These

should be clearly identified such that the HIPS can be readily

assessed or re-validated against changing assumptions, conditions

(i.e. design basis) etc. during the plant life cycle.

• HIPS packages should be designated as ‘high’ focus with respect to

quality management.

4.1.1 Service conditions

A HIPS SRS should clearly identify and describe all credible process and

ambient service conditions, such as:

• process fluid compositions (all possible production scenarios)

• possibility of slugging flow

• fluids with plugging potential (e.g. wax, hydrates)

• rate of change in process pressure, temperatures, flows

• presence and worst case concentrations of H2S, CO2, solids, sand,

paraffin, etc.

• high and low extreme process pressure, temperatures, flows

• change of process fluid composition and properties over the facility’s

lifetime

• presence and worst case concentrations of injected chemical

products

• high and low extreme ambient outdoor and indoor conditions

• hazardous area classification

• EMC requirements.

High Integrity Protection Systems RP

16

The predicted or known occurrence and impact of each condition should

be clearly defined for each operational situation, e.g. shut-in, cool-down,

start-up, normal production.

This analysis will assist in defining material requirements of sensors

and final elements and the needs (if any) for heating and winterization of

HIPS components.

The HIPS should be suitable for any given situation/condition regardless

its duration (including temporary conditions such as methanol injection

or cool-down).

4.1.2 HIPS reliability criteria

HIPS components, including sensors, logic solver and final elements

should each be designed as fail-safe (i.e. failure of any component/

sensor/logic solver/power supply/motive fluids moves final elements

to the safe state).

According to IEC 61511, a HIPS integrity (SIL) assessment will be

performed and the integrity target (PFDavg or failure rate, whichever

applies according to the demand rate) included in the HIPS SRS.

HIPS components or sub-systems are then selected such that the

overall integrity (SIL) target of the HIPS Safety Instrumented Function

(SIF) is achieved.

This HIPS integrity demonstration should include a sensitivity study to

test the robustness of the HIPS integrity prediction against variances in

reliability data, the proof test period (e.g. min and max derived from an

analysis of the PFD as a function of time, as opposed to PFDavg) and

component MTTR.

The HIPS design should take into account the process availability

target, allowing for testing and maintenance activities (with or without

disturbing the process – e.g. partial stroke testing requirement) and the

predicted/allowable frequency of spurious trips, and reflect these within

the HIPS SRS.

Prototype or non-proven in-use components should not be used for a HIPS.

High Integrity Protection Systems RP

17

4.1.3 Reliability data

The HIPS operator should approve the reliability data utilized to

demonstrate the integrity achieved by the HIPS.

Reliability data sources include, in order of preference:

1. Reliability data collected and verified on the facilities (field data) –

but only where the quantity collected is sufficient to be considered

statistically significant

2. Databases/reference handbooks

Data should primarily be selected from Oil and Gas applications,

e.g. Offshore Reliability Data (OREDA3), PDS Data Handbook4, and

Stiftelsen for industriell og teknisk forskning (The Foundation for

Scientific and Industrial Research), (SINTEF5).

The data selection process should consider similar service and

environmental conditions, and maintenance regimes.

3. Failure Mode and Effect Analysis (FMEA) reports

This data needs to be suitably factored to account for potential

failures occurring due to process/operating conditions. The intended

use and stated failure modes should match the application.

4. Vendor data

The reliability data used should be adequately documented to allow

validation, including:

• source of the data

• assumptions underlying selection.

4.1.4 HIPS reaction and response time

The process safety time, HIPS reaction time and HIPS response time

should be defined in the HIPS SRS.

www.oreda.no

www.sintef.no/projectweb/PDS-main-page

5

www.sintef.no

3

4

High Integrity Protection Systems RP

18

Process Safety Time (refer IEC 61511-2)

HIPS

Reaction Time

HIPS

Response Time

Process or

BPCS failure

SIS trip

initiation

HIPS

initiation

Hazardous event

occurrence

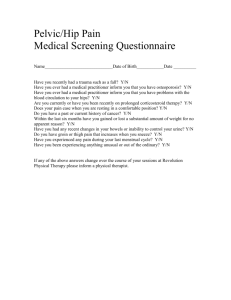

Figure 1: Process safety, reaction and response times (showing typical

protection layers)

The HIPS response time should be determined with reference to the

process safety time and HIPS reaction time. The HIPS SRS should require:

HIPS response time < х(HIPS reaction time)

(Where ‘х’ is less than 1, and specified with reference to the system

dynamics and practicality, design uncertainties and equipment wear

and tear)

The HIPS response time is a summation of the following:

• sensor response time

• logic solver response time, including input cards

• final element response time, up to final safe state.

4.1.4.1 Sensor response time

The sensor response time is defined by summation of the following parts:

• lag time of the process tapping, e.g. thermal inertia of a thermowell

• lag time of the sensing element

• processing (cycle) time of electronic instrument/transmitter

• signal conditioning, e.g. dampening or filtering.

High Integrity Protection Systems RP

19

4.1.4.2 Logic solver response time

The logic solver response time is defined by the summation of the

following parts:

• worst (longest) processing (cycle) time of any input card

• processing time of the logic part and output.

In general, the processing time of the logic part and output is considered

negligible for solid state technology.

For a programmable logic solver, the response time will depend on the

processing (cycle) time of all the components.

4.1.4.3 Final element response time

The final element response time is defined by the summation of

the following:

Actuated valves case:

• the response time of all control circuit components

(e.g. solenoid valves, pilot valves, and quick exhaust valves) of the

motive fluid feeding the actuator

• the time required to depressurize the motive fluid before the

actuator starts to move

• the inertia and mechanical slack of the moving parts in the

actuator and valve (i.e. stroking time), until the valve has reached

its safety position.

Electrical equipment case:

• the response time of all control circuit components

(e.g. interposing relay, switchgear, relay and switchgear drawer)

• the inertia of the machinery, until it has reached safe state

(e.g. fully stopped).

High Integrity Protection Systems RP

4.2

20

Avoidance of common-mode failures

In order to achieve the necessary levels of integrity, HIPS typically utilize

redundancy in the sensing and final element groups. Whilst increasing

system dependability, this also introduces the potential for common-mode

failure (CMF). The HIPS should be designed to minimize CMF between

HIPS subsystems, hardware or application software.

This should be managed with reference to IEC 61511-1:2003, 9.4 and the

following recommendations.

4.2.1 Sensor positioning

Sensors should be separated as far as reasonably practicable to reduce

the likelihood of external (environmental) and/or internal (process

e.g. wax/hydrates) factors affecting more than one simultaneously.

4.2.2 Sensor and final element selection

Within HIPS: the use of identical sensors/final elements in a voting

(e.g. two out of three/2oo3) configuration has the advantage of simplifying

procurement and maintenance activities, but will increase the potential

for CMF.

For SIL 3 (and below) HIPS, it is usually acceptable to utilize identical

sensing/final element devices, but for higher integrity service diverse

(i.e. make/model) sensing and final element devices should be deployed.

At SIL 3, the potential benefits of diverse sensing and final element

devices verses the potential detriment to system maintenance should

be considered.

Within other protection layers: if identical make and model of sensing and/

or final element is utilized for both the HIPS and other protection layers,

the potential for CMF between the HIPS and other protection layers

should be addressed.

4.2.3 Logic solver selection

A HIPS logic solver should be of programmable or Solid State type.

For SIL 3 (and below) HIPS, it is generally acceptable to employ the same

logic solver type as that used for other protection layers (not including

BPCS). However, it should be fully independent of them in every respect

(I/O, PSU, CPU where applicable, etc.).

High Integrity Protection Systems RP

21

For higher integrity than SIL 3, the HIPS logic solver type should differ from

those used in other protection layers

Programmable Logic Solver: development, implementation, maintenance

and modification of the HIPS application program should be by competent

individuals who have not been involved in the application development for

other protective layers.

Logic Solver Input: Where a SIF has more than one sensor, each sensor

should be routed through a different logic solver input card.

Logic Solver Output: Where a SIF has more than one final element, each

final element output should be routed through a different logic solver

output card.

4.2.4 Maintenance and human intervention

CMF should be considered in the development of HIPS maintenance

routines. Particular attention should be paid where multiple simultaneous

process isolations are required, e.g. when testing a sensor voting system.

As a minimum, procedures should be defined to cover the management

of HIPS sensor line isolations. However, car seal or interlocking of sensor

line isolations is preferred.

Regular inspections to verify correct position of HIPS sensor isolation

valves are recommended.

4.2.5 Utility failure

HIPS will often need to share utilities (e.g. instrument air drying system)

with other protection layers. Where this is the case, the shared utility

should be analysed for potential common faults and where these are

considered significant diverse utilities for HIPS and other protection

layers should be deployed.

HIPS power should be from two diverse supplies, e.g. one UPS sourced,

the other from a critical systems/emergency bus.

DC power supplies can be either floating, or have positive or negative

referenced to earth. The merits of these two approaches should be

considered. In the former, the system will be less susceptible to tripping

on earth fault, but an earth fault detection system would be required.

Consistency with other facility DC earthing arrangements should also be

considered.

High Integrity Protection Systems RP

4.3

22

Hardware considerations

4.3.1 Electrical connections

All HIPS field devices should be hard-wired directly into the HIPS cabinet

via individual armoured instrument cables, without intermediate junction

boxes or intermediate marshalling facilities. This also applies to cables

run from the HIPS cabinet to MCC switchgear.

An exception to the direct-cable rule is given to particular field devices

which have by design a short length of cable encapsulated into the device,

such as limit switches or heater blocks. In those cases, multiple devices

of the same type might be hooked-up to a local junction box.

Junction box and cabinet terminals should be of the spring-loaded type

for both signal and power cabling. Screw type terminals should only be

permitted inside final field devices (e.g. sensors, solenoids), earth bars,

and for the power feeders and distribution inside the HIPS system cabinet.

4.3.2 Heat tracing and winterization

In colder climates, heat tracing and/or winterization of the HIPS may

be required:

• heat tracing ensures that the process fluid inside the HIPS sensor

assembly and process tapping (and standpipe if any) remain

adequately fluid, i.e. avoiding potential clogging due to fluid cool-down

• winterization ensures that electronic devices remain above a certain

minimum temperature.

An assessment of the expected ambient conditions and process fluid

should be made to determine which, if any, of these is required and the

HIPS SRS should include such requirement.

The heating element for each sensor should have its own dedicated

circuit breaker.

Where heat tracing of HIPS sensor assembly, process tapping,

standpipe/bridle is required, self-regulating resistive block heaters,

self-regulating heat tracing wire under thermal insulation around

quarter-turn ball valves, process tappings, level sensor chambers (and

standpipe if any), including liquid drain lines as well as the sensors/

transmitters should be provided.

High Integrity Protection Systems RP

23

Temperature and feeder monitoring and alarms facilities should also be

provided and transmitted to the operator interface. The HIPS SRS should

clearly state the action to be taken upon failure of a heating element,

ranging from manual intervention to automated HIPS activation after a set

time delay.

4.3.3 Materials of construction

All outdoor HIPS equipment, including sensors, manifolds, associated

mounting accessories and protection equipment, should be suited to the

environment. Where required, protection against mechanical damage (e.g.

dropped objects) should be provided.

Process wetted parts (e.g. valves, sensors, manifolds) should be as per

applicable piping class, including material certificates (e.g. EN 10204).

4.3.4 Protection enclosures

All HIPS sensors, including the process isolation valves/manifold, should

be protected against impact and environment. Therefore, enclosures

should be considered for HIPS sensor assemblies. All connections should

be bottom-mounted with the relevant cable gland assembly.

4.3.5Cabinet

Where a cabinet is required for part of the HIPS system (typically the

logic solver), this should be separate from other equipment cabinets and

dedicated to the HIPS function only. It should preferably be located in an

acclimatized room.

Dampening systems may be provided in case of presence of vibration or

tilt effects.

Forced ventilation should be avoided. Where required, this typically

consists of redundant air extraction on the top with redundant air inlet

filters on the bottom of the front doors.

Ingress protection requirements should be defined in the SRS and

maintained throughout the HIPS life cycle.

High Integrity Protection Systems RP

24

5 HIPS elements

5.1Sensor(s)

5.1.1 Sensor selection

Sensor models specifically designed for safety service are preferred.

The failure modes of concern should be identified and failure rates

pertaining to those considered in the sensor selection process, as should

the availability or otherwise of auto-diagnostic capabilities.

Process transmitters are preferred over switches.

Interfaces with other systems (e.g. asset management systems) should

be ‘read-only’. Adjustment of HIPS sensor parameters (e.g. calibration

and configuration) should be possible only from the HIPS logic solver

cabinet or locally at the sensor, requiring either password input or ‘dip’

switch adjustment.

HART or other fieldbus communication protocols should be used for

diagnostic purposes only.

Wireless sensors are not considered suitable for HIPS application.

5.1.2 Sensor configuration and positioning

For SIL 3 systems, three sensor elements with a two out of three (2oo3)

trip logic are normally selected, each sensor being configured to go to

‘trip state’ after a detected failure occurs. This 2oo3 voting should revert

to a 1oo2 voting during a single sensor maintenance or fault detected.

The HIPS should be fitted with the necessary equipment to facilitate sensor

tests as required by the SRS, and defined within the test procedure.

Each sensor should have a dedicated process tapping.

Discrepancy HIPS sensors alarms may be configured in the HIPS,

SIS or BPCS.

HIPS sensor positioning should take into account other protection layers

(e.g. BPCS) sensor positioning.

High Integrity Protection Systems RP

5.2

25

HIPS automation system

The HIPS automation system consists of the complete engineered and

tested cabinet, from input terminals to output terminals, typically including:

• signal converters, isolators, IS barriers and anti-surge devices

• logic solver

• HMI devices

• engineering and maintenance workstations.

The HIPS automation system should be dedicated to HIPS safety functions

and physically segregated from other safety or control systems. Any nonessential functionality should be removed.

The HIPS automation system should include a capability to record

Sequence Of Event (SOE) data, diagnostic information and logic solver

status for post-incident data analysis.

A HIPS logic solver containing more than one HIPS SIF should be avoided.

If necessary, more than one SIF can be deployed in the same logic

solver, but only where it can be demonstrated that each of these is fully

independent of the others. That is, the failure of any HIPS SIF, and/or the

occurrence of the hazard it is designed to prevent, could not cause one or

more of the other hazards, or compromise one of the other SIFs.

In addition, each HIPS logic solver should have the capability to be

verified independently of other HIPS logic solvers dedicated to another

safety functions.

Since the final elements normally consume the majority of the PFD

budget, the HIPS logic solver should typically not consume more than

15% of the PFD budget.

Response speed of the HIPS automation system, including electrical

propagation time of the I/O channels and signal convertors, should be

assessed for each application as part of the overall process safety time.

Programmable HIPS logic solvers should have at least 60% spare CPU

load and memory capacity.

Trip thresholds (set points) should be protected/locked to prevent

adjustment through human error.

High Integrity Protection Systems RP

26

5.2.1 Interfaces and cyber security (Programmable

Logic Solvers)

Interfaces between HIPS and other systems should be minimized.

HIPS cyber security should conform to IEC 62443.

HIPS programmable components capabilities type should as a minimum

be SL-3 (see IEC 62442-3-3).

HIPS Asset Owner should specify the Security Program (SP) capabilities

requirements (see IEC 62443-2-4) to the HIPS Integrator in the Safety

Requirement Specification. The SP requirements are composed of the

base requirements (BRs) and requirement enhancements (REs).

For example:

• For SIL 2 and below HIPS the security requirement may be made of all

the BRs and all the REs(1)

• For SIL 3 and above HIPS security requirement may be made of all the

BRs, all REs(1), all REs(2), all REs(3) and all REs(4).

In particular, the following steps are recommended:

• Malware prevention: Ensure malware cannot transit between HIPS

and other protection layers by restricting communications between

these layers.

• Any monitoring interface between HIPS and facility automation

systems should be either hardwired or dedicated serial.

• Remote access (off-facility) connections should not be permitted.

• Temporary engineering machines (e.g. supplier laptops) should

not be connected to the HIPS logic solver until it has been verified

that anti-virus software is installed and fully updated and that a full

system scan has been performed showing the system to be free from

malware/infection.

• The HIPS logic solver and associated workstations should be subject

to access control:

• Physical – by key-locked cabinets

• Software – by means of strong password.

High Integrity Protection Systems RP

27

5.2.2 Interfaces and cyber security (solid state logic solvers)

Despite the use of solid state technology, cyber threats can still pose a

direct or indirect threat to the integrity of a HIPS package.

The following design requirements should therefore be applied.

• The HIPS may only be interfaced with BPCS or SIS through hardwired or ModBus links.

• Remote maintenance/engineering and associated networks should

not be permitted.

• The SOE function should be embedded inside the HIPS. Hard-wired

signals to BPCS/SIS input cards should be used for time-critical events.

• Data storage is generally not required. Main data, alarms and trips

should be registered by via the BPCS through serial bus and/or

hard-wired links.

• The Solid State Logic Solver should not be interfaced with any

support system (e.g. Plant Information, Real Time Data Base and

Instrumentation Management Systems).

The use of IT-based technology for the HIPS HMI and/or communication

links is generally not permitted. HIPS HMI should be solid state mimic

panel type.

High Integrity Protection Systems RP

5.3

28

Final element(s)

Final element selection should be done taking into account the particular

application, process conditions and the suitability for use in safety

applications. Final elements with a demonstrable, trusted and proven

track record in safety service should be selected over lesser alternatives.

A high and continual focus should be placed upon quality control during

the final element manufacturing and test process.

An exception alarm should be generated if a HIPS final element (e.g.

valve) is not in the required position. The necessary response to such an

alarm should be defined in the SRS.

HIPS final element assembly should be considered as a whole. This

should be taken into account in the design, the fabrication and the testing.

The relevant documentation should be managed by the same principle.

5.3.1Valves

Where a valve is the final element, this should be considered, designed

and tested as a complete assembly including the valve body, the actuator

and the associated actuator controls.

In pressure protection, HIPPS the valve should be specified to account

for the capacity of the downstream system to absorb valve leakage when

closed. Although valves may be specified as zero, or close to zero leakage

(e.g. ISO 5208 or API Standard 598), in reality it should be assumed that

some leakage in service will always occur. As such, the downstream

process system should be able to handle a degree of leakage.

The leakage rate to be designed should be determined in conjunction with

Process design Engineers and will typically be based upon the greatest of:

• 100% Flow through a valve bypass (if installed) when open

• that experienced following total collapse of soft seats (where fitted)

• a percentage of design flow (assessed in discussion with valve

manufacturer) for metal seated valves.

High Integrity Protection Systems RP

29

Where a HIPS bypass is required (e.g. for pressure equalization post HIPPS

activation), this should not compromise the HIPS integrity. For example the bypass

should be locked closed or similar (e.g. interlocked) to prevent being left in the

open position. Leak tightness specification for the bypass should be equivalent to

that of the main HIPPS valves.

HIPPS re-open inhibits may also be required either to protect the valves from damage

due to opening against high differential pressure, or to prevent a rapid pressure rise

scenario should the HIPPS be re-opened onto a blocked downstream system.

As the integrity of these inhibit functions are also high, they should be part of

the HIPPS.

5.3.1.1 Fail-safe function

The valve fail-safe function should be achieved by spring return actuators. Other

solutions such as operating pressure inside the valve or double acting piston

actuators should only be considered if there are justifiable reasons not to use the

spring return option.

5.3.1.2 Actuator force and drive train

For ball valves, the actuator output torque should be at least 1.3×, and preferably

2.0×, the required valve torque throughout all stages of the opening and closing

strokes as determined by workshop tests which should simulate or otherwise be

representative of:

• actual service in which the valve will be employed, i.e. gas service or liquid service

• maximum design differential pressures across the valve

• actual valve configurations i.e. seat type, stem extensions, etc.

• closure within specified time (speed of closure affects torque required).

5.3.2 Circuit breakers

Circuit breakers and control relays are generally accepted as final elements

for specific applications due to extensive operating experience and their

mature technology, but such devices should be carefully selected considering

characteristics and available track record (proven for the application).

It should be ensured that any failure data provided covers the full breaker function,

both electrical and mechanical.

High Integrity Protection Systems RP

30

Failure rate data pertaining to the ‘fail to disconnect mode’ should be

available and, where possible, safe fail fraction and hardware fault

tolerance data should be sought.

Circuit breakers and control relays should be fail-to-safe, i.e. contacts are

de-energized to open. Note in some cases (e.g. certain HV breakers)

energize to break is the only option.

Circuit breakers and control relays should be specified according to

following criteria:

• coil provided with gravity dropout or dual springs

• provision should be made for preventing HIPS relay contacts from

welding closed (e.g. energy limiting load resistance, contact arc

suppression) when dealing with high power and /or inductive loads at

the interface with breakers.

High Integrity Protection Systems RP

31

6 Design testing

Testing activities should be performed during several design and

development phases such as:

• Design Validation/Typical Test (DVT)

• Factory Acceptance Tests (FAT) of each HIPS component

• Integrated Factory Acceptance Test (IFAT)

• Yard and On-Site Tests/Pre-commissioning

• Operational Testing (OT)/Site Acceptance Test (SAT)

• HIPS Performance Tests.

The aim of these tests is to demonstrate that the HIPS supply and

configuration meet the HIPS SRS at each one of the above stages.

A HIPS testing plan should document which of these tests will take place,

and address the items listed in the remainder of this section.

6.1

Design Validation/Typical Test (DVT)

Design validation testing may apply to the logic solver(s) and smart valve

testing systems only. It is a validation test of the interface principles and

technologies between the HIPS logic solver and other systems including

smart valve testing systems.

The purpose is to define and test how HIPS data are transferred to other

Systems as well as the SL-3 requirement level (IEC 62442-3-3) and the

Security Program (SP) requirements BRs and (REs) (IEC 62443-2-4).

6.2

Factory Acceptance Tests (FAT)

Separate factory acceptance tests (FAT) should be conducted for all HIPS

components. All test and measurement equipment should have valid

calibration certificates and labels from a certified laboratory.

The purpose of the FAT is to ensure that the HIPS sensors assembly, the

HIPS Logic Solver and the HIPS Final elements function as per the HIPS

SRS. The FAT should also consider the interface with other systems testing.

High Integrity Protection Systems RP

6.3

32

Integrated Factory Acceptance Test (IFAT)

An IFAT should be performed after successful completion of the individual

components FATs. The HIPS arrangement during IFAT should reflect the

final HIPS configuration on-site. All HIPS components should be hooked-up

and connected together. Interfaces with other systems (dummy systems

during the IFAT) should be part of the IFAT.

Simulation of physical measurement for actuating some sensors

(e.g. pressure and level) should be included in the IFAT.

During the IFAT, ‘black-out’ (after which the HIPS will fail safe) and

‘black-start’ (after which the HIPS will remain in the fail safe state)

tests should be performed.

6.4

Yard and On-Site Tests/Pre-Commissioning Tests

Once the HIPS components have arrived in the yard or site after IFAT,

the HIPS should be unpacked, installed and the HIPS components should

be hooked-up.

The pre-commissioning should consist a series of tests to demonstrate

that:

• the integrity of HIPS components has not been affected in transport

• the components are installed in the correct way, segregated from

other systems, etc.

• field components are adequately protected against impact, flooding, etc.

• interconnections between actuators and control panels are adequate

(length, protection, etc.)

• power supply to cabinets and heat tracing are adequately installed,

segregated, etc.

• heat tracing and thermal insulation are adequately applied, etc.

• interfaces with other systems (e.g. BPCS) are fully operational

• cabling of installed sensors and final elements is adequately

installed and functions.

High Integrity Protection Systems RP

6.5

33

Operational Testing (OT)/Site Acceptance Test (SAT)

Once the HIPS pre-commissioning and facility commissioning has been

completed, an OT/SAT should be performed prior to facility start-up.

The purpose of the OT/SAT is to verify and test the following:

• HIPS installation and pre-commissioning successful

• linking with other systems (e.g. ICSS)

• safety and Interlocking logic

• energizing the sensors and the final elements by the HIPS

• interacting between HIPS and BPCS and other systems (if any)

• integration of the HIPS mimics in the BPCS (if required)

• storage of HIPS data in the relevant SOE

• HIPS trip functions (sensors – including combinations of voted

components)

• HIPS performance test (end to end, including full closure where the

final elements are valves)

• HIPS SOE recording.

The HIPS performance test should demonstrate that the achieved HIPS

response time is equal to or better than target. As far as practical, the OT/

SAT should be performed by creating real process conditions. In addition

a confirmation that valves are sealing adequately should be sought.

High Integrity Protection Systems RP

6.6

34

Test administration

6.6.1Preparation

Prior to each test phase, a comprehensive Inspection & Test Plan (ITP)

should be prepared covering the following:

• full set of test procedures (see below)

• testing schedule, including Manufacturer’s internal tests

• resources and equipment list

• predefined test report and correction (punch) list for each test

• HIPS test log (see below).

6.6.2Procedures

Dedicated test procedures should be issued for each test phase, covering

individual HIPS components and overall HIP system as required:

• sensors, including isolation valves, heating and protective enclosures

• logic solvers

• valve control panels, including smart valve testing systems

• valve actuator

• HIPS valves

• electrical switchgear

• end-to-end HIPS.

Test procedures should clearly indicate the test criteria (values) which

are to be met, referencing the appropriate (e.g. company) standard from

which the criteria are derived.

6.6.3Recording

After each test, a test log should be issued. It should include the following

as a minimum:

• test procedure

• test results/report

• correction/punch/exception lists.

High Integrity Protection Systems RP

35

7 Operational testing

The appropriate testing of HIPS is fundamental to ensuring that the

integrity requirements for the safety function are satisfied6. The required

proof test interval for the HIPS function should have been established via

reliability analysis.

Any proposed changes in test frequency throughout a HIPS life should

be validated via an update to such analysis (this should in any case be

covered by facility management of change procedures).

Unrealistically short test intervals (e.g. less than three months) should be

avoided. (The more frequent testing becomes, the greater the impact on

production availability for components that cannot be tested off-line.)

One potential downside of increased test frequency is increased

intervention, given that each intervention may present opportunities to

compromise the HIPS (e.g. by not returning the system to operation state

following test).

Whilst the operation of individual HIPS loop components may be tested

separately, an overall system performance test should be conducted in

line with the test interval embedded in the SRS. This test should verify

both the ‘end to end’ HIPS function and its response time (sensing to

completed trip/closure).

7.1

Design for test and maintenance

HIPS should be designed to facilitate the required testing, of the complete

HIP function, with minimal operational impact. Description of required

tests (including high level procedures) should form part of the SRS.

Proof test procedures should be produced by the system designer in

conjunction with the Operator as part of the design deliverables package.

These should be completed early enough in the system design life cycle to

enable any additional testing facilities to be provided.

Similarly maintenance procedures should be developed as part of the

design package and implications for facility operation (e.g. shutdown

requirements, access requirements) should be communicated to the

Operator by the system designer to enable appropriate facilities to be

provided in the wider facility design and operational plan.

A performance standard should be provided for every HIPS, which should capture test

interval, trip setting, maximum allowed response time, underlying assumptions (e.g. on

flowrate, process conditions, plant line-up). Any proposed change in any parameter in the

performance standard should only occur with full management of change applied.

6

High Integrity Protection Systems RP

7.2

36

Operational proof testing

HIPS typically comprise redundant elements (e.g. 2oo3 sensors and 1oo2

solenoids). HIPS testing should be planned and procedures produced

such that the correct function of each and every redundant element is

verified at each proof test and the outcome recorded.

7.3Valves

Where the final element is a valve a leakage test may be required, typically

carried out by means of pressure build up. Where required, this is unlikely

to be able to detect small volume leaks (such as can be found in factory

acceptance testing) and should be designed with a view to detect gross

leakage (albeit within the capacity of the downstream relief device) only.

If the ability to detect very small leaks is required, consideration may be

given to acoustic valve leak detection techniques.

Partial stroke testing can provide a benefit in terms of improved HIPS

PFD, and/or increased interval between full proof tests. The downside is

the provision of partial stroke capability increases the complexity of an

otherwise simple system. And partial stroke means partial coverage –

a significant portion of the HIPS (particularly the valve stroke) remains

untested and should eventually be covered via full stroke testing.

Valve signatures can be obtained via monitoring and recording of the valve

closure characteristic. These can then be used to provide timely indication

of impending valve problems. This typically requires actuator pressure

monitoring and valve position indication (via transmitter) and may be

supplied as part of a partial test system.

High Integrity Protection Systems RP

37

8 Safety life cycle for HIPS

HIPS should be designed, constructed, tested, operated and maintained

according to the IEC 61511 and IEC 61508.

• Integrity targeting for the overall HIPS function should be performed

according to IEC 61511 part 3 utilizing either the LOPA or quantified

analysis methodologies.

• HIPS verification should be managed by the Operator and not

deferred to the system provider, ensuring adequate levels of

independence.

Table 1 takes the IEC 61511 safety life cycle and suggests the key

elements required at each of the normal HIPS development phases.

8.1

Obsolescence management

A dedicated obsolescence management plan should be established for

the HIPS. The HIPS supplier should provide an inventory list with all

lifetime statuses.

As part of the obsolescence management strategy, local (e.g. in-country)

support from the HIPS supplier or agent should be considered.

8.2Maintainability

A maintenance management plan should be prepared for each HIPS

detailing maintenance procedures and intervals, and listing required

equipment. This should be developed by the HIPS Integrator, reviewed and

approved by the operator.

8.3

Spare parts

Commissioning and operational spares should be identified, procured and

stored commensurate firstly with the maintenance plan, and secondly

allowing for unexpected failures.

Reference should be made to each HIPS component MTTR when

determining spares quantities and storage locations.

Stored items should be subject to a preservation plan.

High Integrity Protection Systems RP

Safety Life cycle Phase

38

Objectives

Inputs

Outputs

Process Hazard

analysis (PHA)

Identification, description and

evaluation of hazardous events

and scenarios

PFDs, P&IDs, Layouts,

Operating philosophy, Manning

Philosophy, ESD and Blowdown

Philosophy, safety targets

HAZID and HAZOP reports

2.

Safety Integrity (SIL)

Targeting

To assign a numerical (RRF) and

Integrity (SIL) target to each SIF

HAZID and HAZOP reports and

all inputs detailed above

Integrity (SIL) Targeting Report

(detail targets for each HIPS)

3.

HIPS Specification

(User)

To specify the user requirements

pertaining to each HIPS such

that an equipment provider can

generate a specification specific

to their equipment offering

Integrity (SIL) Targeting Report

HIPS Safety Requirements

Specification

HIPS Specification

(Supplier)

To generate an equipment

specific specification that meets

the requirements of the HIPS

SRS

HIPS Safety Requirements

Specification

Functional Design Specification

(FDS) for each HIPS

Dynamic analysis

Comprises hardware (including

System Architecture) and

software requirements

1.

4.

Relevant Philosophies

Identify SIFs requiring HIPS

Verify Phase 4 with 3

5.

HIPS Design

To generate a hardware and

software HIPS design that

meets the FDS requirements

HIPS SRS and FDS

System diagrams AFC (e.g. Hook

up drawings, panel layouts)

Software algorithms (e.g. flow

charts, C&E)

Verify Phase 5 with 3

6.

HIPS Engineering

To engineer the HIPS in

compliance with the design

To verify the design against the

numerical (RRF) and integrity

target

FDS

Physical hardware

System diagrams AFC

Software code

Software algorithms

SIL Verification report

Operation and Test procedures

Verify Phase 6 with 5 (FAT)

7.

HIPS installation,

commissioning and

validation

To integrate and test the HIPS.

To validate that the HIPS meets

the SRS

To install and commission the

HIPS

8.

HIPS Operation and

Maintenance

To ensure the integrity of the

HIPS is maintained during

operation and maintenance

HIPS Safety Requirements

Specification

Fully functioning HIPS in

conformance with the SRS

HIPS FDS

Verify Phase 7 with 5 (SAT)

Test and Validation Plan

FSA Report

Commissioning and handover

Workpacks

As-built documentation

HIPS Safety Requirements

Specification

Maintenance plan

Proof testing and routine

maintenance procedures

Maintenance records

Maintenance schedule updates

Spares listing

9.

HIPS Modification

10. Decommissioning

To make corrections,

enhancements or adaptations

to the HIPS, ensuring that the

required safety integrity level is

achieved and maintained

To ensure proper planning for

decommissioning

HIPS Safety Requirements

Specification

MOC approvals

Management of Change (MOC)

Procedures (including software

change control)

Documentation (Philosophy/

SRS/FDS/drawings etc.)

updates as required to maintain

alignment with installed system

FSA Report

FSA Report update

MOC Procedures

HIPS placed out of service

To remove HIPS from service

without compromising the safety

integrity of the facility

Table 1: Key elements in the IEC 61511 safety life cycle

High Integrity Protection Systems RP

39

9 HIPS dossier

Whilst the HIPS performance standard (within the SRS) provides a

summary of the key elements and basis for each HIPS, it is also important

to develop and retain concise documentation covering all aspects of the

design for each HIPS, both as a record of the work done and a basis for

life cycle maintenance and update of the HIPS.

A HIPS Dossier should therefore be compiled and maintained for each

HIPS by the operator and should include as a minimum the following

elements from the safety and instrumentation perspective:

• justification for HIPS selection, design and configuration

• HIPS SRS – Performance standards (Response time, Integrity

requirement etc.)

• dynamic analysis

• HIPS drawings (e.g. P&IDs, architecture, wiring, hook-ups, system

schematic, block diagrams)

• hazard and consequence analysis studies/reports – Assumptions

pertinent to the Hazard analysis and integrity target

• quantified/reliability analysis supporting selection of PFD/SIL targets

and relevant test intervals, capturing assessment of diagnostic

coverage of failures and common cause failure analysis

• pertinent cause and effect charts

• HIPS maintenance, testing and repair plans/procedures and records

• HIPS operating and re-start procedures (including bypass etc.)

• FSA report (according to IEC 61511)

• HIPS Obsolescence plan.

All HIPS should be added to the facility safety critical systems/items register.

Registered Office

Level 5

209–215 Blackfriars Rd

London SE1 8NL

United Kingdom

Brussels Office

Bd du Souverain,165

4th Floor

B-1160 Brussels

Belgium

T +44 (0)20 3763 9700

F +44 (0)20 3763 9701

reception@iogp.org

T +32 (0)2 566 9150

F +32 (0)2 566 9159

High integrity protection systems

(HIPS) and especially high integrity

pressure protection systems

(HIPPS) are an increasingly

common feature of oil and gas

facilities worldwide.

They can provide an alternative to

conventional mechanical protective

devices (e.g. relief valves) or reduce

the load upon them.

In some cases, they present the

only practical option to facilitate

field development and/or expansion.

This RP provides mainly technical

recommendations for those

involved in the definition, design,

implementation or operation and

maintenance of HIPS.

www.iogp.org