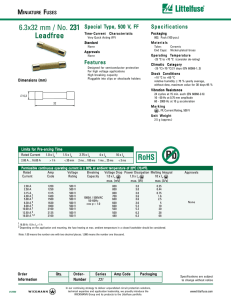

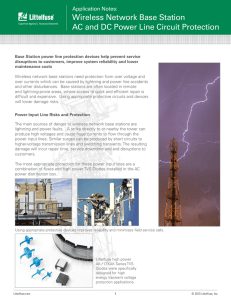

Transient Voltage Suppression (TVS) Diode Products

advertisement