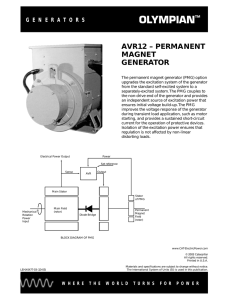

Unified Control for the Permanent Magnet Generator and Rectifier

advertisement