Designs and Tests of Compensation Coils to Reduce Screening

advertisement

2LPO1E-03

1

Designs and Tests of Compensation Coils to

Reduce Screening Currents Induced in HTS Insert

Coils for NMR Magnet

Kazuhiro Kajikawa, Member, IEEE, Gwendolyn V. Gettliffe, Yong Chu, Daisuke Miyagi, Thibault P. Lécrevisse,

Seungyong Hahn, Juan Bascuñán, and Yukikazu Iwasa

Abstract—Two types of compensation coils are focused on to

reduce screening currents induced in solenoid coils wound with

high temperature superconducting (HTS) tapes. One is a pair

of copper compensation coils located coaxially inside and outside

the HTS coil to apply an AC magnetic field in the axial direction.

The other is an HTS compensation coil with notch located only

outside the HTS coil to minimize the radial components of local

AC fields applied to windings of the HTS coil as small as possible.

It is found that the copper compensation coils yield the allowable

amount of power dissipation in liquid helium. The effectiveness of

the HTS compensation coil to reduce screening-current-induced

fields (SCFs) generated by another magnetized HTS coil is also

validated experimentally in liquid nitrogen using a commercially

available coated conductor with narrow width.

Index Terms—AC magnetic field, compensation coils, HTS

wires, screening current.

I. I NTRODUCTION

IGH temperature superconducting (HTS) wires with

long length such as Bi-2223 Ag-sheathed wires and

coated conductors based on either Y-123 or RE-123 have been

developed and become commercially available. These HTS

wires are in the form of a tape with the width of several

millimeters. Although the Bi-2223 Ag-sheathed tape has a

multifilamentary structure, its filamentary region whose cross

section has the aspect ratio of about 20 behaves like a bulk

superconductor due to an electromagnetic coupling between

the filaments [1]. The coated conductor also includes a very

thin superconducting (SC) layer with the thickness of a few

micrometers, so that its aspect ratio becomes more than 1000.

When these HTS tapes with large aspect ratios are wound as

windings for nuclear magnetic resonance (NMR) or magnetic

resonance imaging (MRI) magnet, the magnetic fields generated by screening currents induced in HTS tapes significantly

H

Manuscript received August 12, 2014. This work was supported by JSPS

KAKENHI Grant Number 24360110, and was also supported by the National

Institute of Biomedical Imaging and Bioengineering and the National Institute

of General Medical Sciences, both of the National Institutes of Health under

Award Number R01RR015034.

K. Kajikawa was with the Francis Bitter Magnet Laboratory, Massachusetts

Institute of Technology, Cambridge, MA 02139 USA. He is now with the Research Institute of Superconductor Science and Systems, Kyushu University,

Fukuoka 819-0395 Japan. Phone: +81-92-802-3836; fax: +81-92-802-3829;

e-mail: kajikawa@sc.kyushu-u.ac.jp.

G. V. Gettliffe is with the Department of Aeronautics and Astronautics,

Massachusetts Institute of Technology, Cambridge, MA 02139 USA.

Y. Chu, D. Miyagi, T. P. Lécrevisse, S. Hahn, J. Bascuñán, and Y. Iwasa

are with the Francis Bitter Magnet Laboratory, Massachusetts Institute of

Technology, Cambridge, MA 02139 USA.

degrade the field homogeneity in the central part of the

magnet [2]–[7]. Therefore, the reduction of the screeningcurrent-induced fields (SCFs) is one of very important key

technologies to realize HTS magnets for NMR/MRI.

A useful method to eliminate the effect of the screening

current in the HTS tape has been proposed [8], [9] on the basis

of the abnormal transverse-field effect [10]–[13] or the vortex

shaking effect [14]–[16]. In this method, an AC magnetic

field is provisionally applied to the HTS tape in the direction

parallel to its wide surface or along with its wire axis. After

this treatment, the distribution of the screening current is

changed and the direction of magnetization becomes parallel

to the AC field, so that the initial screening current induced

in the wide surface of the HTS tape finally disappears. The

proposed method has also been validated experimentally by

using an HTS coil wound with a Gd-based coated conductor

and a pair of copper coils located coaxially inside and outside

the HTS coil to generate the AC magnetic field [8], [9].

In this study, an HTS insert and copper compensation coils

are designed to assess the possibility of removal of screening

currents induced in HTS tapes wound for full-scale NMR

magnet. Another type of compensation coil wound with HTS

tapes is also designed and fabricated to suppress the power

dissipation in liquid helium, and the decays of SCFs are

experimentally observed by using the HTS compensation coil.

II. D ESIGNS OF HTS I NSERT AND C OPPER

C OMPENSATION C OILS

A low temperature superconducting (LTS) insert coil for a

500-MHz NMR magnet developed previously [17] is considered to be replaced by a coil wound with a coated conductor.

The main part of the original 500-MHz NMR magnet consists

of the LTS insert, an LTS main coil, and two sets of LTS

correction coils cooled at 2.3 K using liquid helium under

subatmospheric pressure, and the operating current of 108.1 A

generates the central magnetic field of 11.71 T. When the

combination of these coils except for the LTS insert is cooled

at 4.2 K using liquid helium under atmospheric pressure,

the operating current of 87.1 A can generate the central

field of 7.05 T corresponding to the resonance frequency of

300 MHz [3], [18]. It is assumed that an HTS insert coil to

be replaced generates the central field of 2.35 T (100 MHz)

inside the 300-MHz LTS background magnet at 4.2 K.

Tables I and II summarize the specifications of HTS insert

and copper compensation coils, respectively. Since the HTS

2LPO1E-03

2

50

Parameter

Value

Tape size (width × thickness)

Thickness of SC layer

Inner/outer diameter of HTS insert

Height of HTS insert

Number of turns of HTS insert

Current applied to HTS insert

Central magnetic field

Minimum local Ic (and load factor)

Maximum local Ic (and load factor)

Maximum full penetration field

4.05 mm × 0.3 mm

0.2 µm

82.2 mm/118.2 mm

399 mm

60 × 80 turns

160.3 A

2.35 T

186 A (0.863)

314 A (0.510)

49.4 mT

Critical current density, Jc (MA/cm2)

TABLE I

S PECIFICATIONS OF D ESIGNED HTS I NSERT

40

30

20

5T

10

10 T

0

0

30

60

90

120

Field angle, θ (deg.)

TABLE II

S PECIFICATIONS OF D ESIGNED I NNER /O UTER C OPPER C OILS

Value

1 mm

2 layers/2 layers

78.2 mm/118.2 mm

82.2 mm/122.2 mm

399 mm

68.8 mT

60 Hz

0.531 nΩ·m@RRR = 30, 4.2 K

1.50 mm

40 W/60 W

3.81 W

200

7.5

8

7

200

250

80

85

150

z (mm)

Parameter

Thickness of copper tape

Number of layers of coil

Inner diameter of coil

Outer diameter of coil

Height of coil

Amplitude of AC magnetic field

Frequency of AC magnetic field

Resistivity of copper

Skin depth, δ

Wattage of Joule heating

AC loss of HTS insert

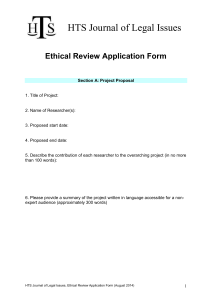

Fig. 1. Approximated curves for experimental results of critical current

densities at 4.2 K in 4-mm-wide coated conductor with SC layer of 1.1 µm

in thickness [19].

300

100

8.5

9

50

7

(b)

(c)

8 7.5

90

0

40 45 50 55 60 40 45 50 55 60 40 45 50 55 60

r (mm)

r (mm)

r (mm)

(a)

insert has to be sandwiched by a pair of compensation coils

to reduce screening currents induced in the HTS windings,

their total size is almost identical to the original LTS insert.

The coated conductor has the width of 4 mm and the thickness

of 0.25 mm, and it is surrounded by an electrical insulator of

25 µm in thickness. The HTS insert is composed of 80 single

pancake coils with 60 turns of the coated conductor, and the

operating current of 160.3 A generates the central field of

2.35 T. The inner and outer compensation coils are wound

with a rectangular copper wire of 1 mm in thickness, and the

number of layers is two for each coil. The heights of the HTS

insert and copper compensation coils are identical.

The local distribution of critical currents inside the HTS

insert is numerically estimated by taking into account their

dependence on the magnitudes and orientations of local magnetic fields, B. Fig. 1 plots the experimental results of critical

current densities at 4.2 K in a 4-mm-wide coated conductor

with the SC layer of 1.1 µm in thickness as a function of field

angle θ in the fixed external fields of 5 T and 10 T [19]. The

angle θ = 0◦ means that the external field is perpendicular to

the wide surface of the coated conductor, whereas the angle

θ = 90◦ is parallel. In this study, these experimental results

are approximated by means of the least-square technique in

the range of 0◦ ≤ θ ≤ 90◦ for the equations

Jc (|B|, θ) = √

−Γ

α |B|

[ π ( θ )m ]

[ ( )m ] ,

2

cos 2 90◦

+ γ12 sin2 π2 90θ◦

(1)

Fig. 2. Profiles of (a) field magnitude (T), (b) field angle (deg.), and (c) critical

current (A) inside upper half of HTS insert combined with LTS background

magnet. The total central field is 9.40 T.

[

m = ln

2

π

√

]

(

2

arcsin 4(γ3γ2 −1) / ln 1 −

γ = p + q |B| ,

θ0

90◦

)

,

(2)

(3)

where (2) ensures that the off-axis double Ic [19], which

represents the angle off the ab-plane axis at which the critical

current Ic becomes twice the Ic in the perpendicular orientation, is constant for the fixed field magnitude |B| under the

assumption of (1). A set of fitting parameters is obtained for Jc

(A/m2 ) and B (T) as α = 3.43×1011 , Γ = 0.717, θ0 = 21.3◦ ,

p = 2.20, and q = 0.346. The approximated curves are drawn

as thick solid lines in Fig. 1, and thin lines are for 6 T to 9 T

at even intervals of 1 T.

Figs. 2(a) and (b) show the profiles of magnitudes and

angles of local magnetic fields inside the HTS insert having

the transport current of 160.3 A (2.35 T) combined with the

LTS background magnet generating the central field of 7.05 T.

The profiles for only the upper half of the HTS insert are

given for the sake of symmetry. By using Figs. 2(a), (b),

and (1), the distribution of critical currents inside the HTS

insert is also calculated in Fig. 2(c), where the thickness of

SC layer is assumed to be 0.2 µm as listed in Table I. The

2LPO1E-03

3

minimum local critical current is estimated as 186 A around

the middle of uppermost pancake coil, which is larger than

the operating current. On the other hand, the maximum local

critical current is 314 A around the middle of outermost layer,

which corresponds to the full penetration field of 49.4 mT.

If the residual resistivity ratio (RRR) of copper in high

magnetic field is assumed to be 30 [20], its resistivity at 4.2 K

is 0.531 nΩ·m [21]. In this case, the skin depth δ of 1.50 mm

for the frequency of 60 Hz is larger than the half thickness of

copper tape. Therefore, the major part of power dissipation for

copper windings might be the Joule heating, which could be

estimated as 40 W and 60 W for the inner and outer copper

compensation coils, respectively, if the AC field amplitude of

68.8 mT, which is 1.39 times larger than the maximum full

penetration field, is generated by these compensation coils. On

the other hand, if the both sides of the coated conductor have

copper stabilizing layers including very thin silver overlayers

with the total thickness t of 99.5 µm each in addition to

that for the other components of 51 µm [22], the maximum

temperature can be estimated as less than 250 K for the heating

duration time of 3 s on the basis of a theory for thermal

runaway under an adiabatic condition [23].

If an AC field with the amplitude Hm is applied to an SC

infinite slab of d in width with the direct transport current I,

the hysteresis loss Wh per unit volume per cycle under the

assumption of the Bean model [24] is given by [25]–[27]

{

1 3

k ,

Hm ≤ Ht

2

)

(

)

Wh = 2µ0 Hp × (3

, (4)

1 + i2 k − 32 1 − i3 , Hm > Ht

where Hp = Jc d/2, k = Hm /Hp , i = I/Ic , and Ht =

Hp (1 − i). The eddy-current loss We per unit volume per

cycle for two metal plates with the thicknesses t and the gap

2g is also given by [28]

We =

2π

3

2

∆2 {1 + 3g/(2t)} ,

µ0 Hm

∆ ≪ 1,

(5)

where ∆ = t/δ. By using (4) and (5), the hysteresis loss in the

SC layer and the eddy-current loss in the copper stabilizing

layers are estimated as 0.34 W and 3.47 W, respectively.

The abnormal transverse-field effect [10]–[16] can exponentially decay the magnetization due to a screening current

induced by an external DC field if an external AC field larger

than the full penetration field is applied perpendicular to the

DC field. The characteristic number of cycles, Nc , which is

defined by the AC cycle required for the magnitude of the

magnetization to fall to 1/e of its initial value, is given by [16]

Nc = A /(8.02 k) ,

(6)

where A is the aspect ratio of cross section of SC layer and

equals 20000 here. When k = 1.39 is used in (6) for the

windings around the middle of outermost layer in the HTS

insert, the characteristic number of cycles is estimated as

Nc = 1790, which corresponds to the period of 29.8 s for the

frequency of 60 Hz under consideration. Since the latent heat

of evaporation of liquid helium is 2.59 kJ/L, the total heating

of 104 W for 29.8 s consumes 1.20 L of liquid helium.

The axial magnetic field BSCF at the origin generated by

the radial magnetic moment loop of mr per unit length located

at the position (r, z) can be expressed by

{ (

)5/2 }

BSCF = 3µ0 mr r2 z / 2 r2 + z 2

.

(7)

Let us consider a single pancake coil wound in the pitch of

p using an SC strip with the width of 2w and the thickness

of d, which could be approximated by an infinite slab with

the width of 2w. If the Bean model [24] is used, the full

penetration field of the approximated infinite slab, Bp , is given

by Bp = µ0 λJc w with λ = d/p. When the radial magnetic

field Br and the transport current I are simultaneously applied

to one of strips under consideration in the pancake coil, the

magnetic moment mr per unit length can be expressed as

0 ≤ Br < B i

Br (i − 1) ,

2ap Bp 2

Br2

×

, (8)

mr =

2 i + 2Bp − Br , Bi ≤ Br < Bp

µ0

)

Bp ( 2

Br ≥ Bp

2 i −1 ,

where Bi = Bp i. When an SCF in the HTS insert is calculated using (7) and (8), it could be underestimated somewhat

because the end effect is ignored and the minor contribution

from a few turns in both the innermost and outermost is not

taken into account [29]. The SCF just after the energization of

the HTS insert and the LTS background magnet is estimated

as −1.88 mT, whose magnitude corresponds to 200ppm of the

central field of 9.40 T. After that, the application of the AC

magnetic field to the HTS insert for 180 s using the copper

compensation coils leads to the SCF of −3.08 µT (0.33ppm),

and it evaporates about 7 L of liquid helium.

III. D ESIGN AND T ESTS OF HTS C OMPENSATION C OIL

In order to avoid the excess energy dissipation in the copper

compensation coils and keep the inside bore wide for NMR

system, a new type of compensation coil is discussed here.

The compensation coil is wound using another HTS tape and

located only outside an HTS coil intended for the reduction

of induced screening currents. The HTS tape with a narrow

width might be used for the compensation coil because the

SCF caused by this HTS compensation coil itself after the AC

operation should be suppressed as small as possible. Since

a few layers for the HTS compensation coil are enough to

generate an AC magnetic field larger than the full penetration

field, the contribution to the SCF is expected to be slight.

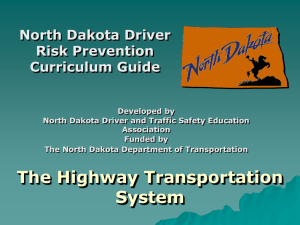

An HTS compensation coil is designed and fabricated as

shown in Fig. 3 and Table III. The existing HTS insert has

been wound with Bi-2223 Ag-sheathed tapes of 3.1 mm in

width and 0.25 mm in thickness [18], [30]. The HTS insert is

comprised of 50 double pancake coils, and the total number

of turns is 7200. The inner and outer diameters of the HTS

insert are 78.2 mm and 120.3 mm, respectively, and its height

is 327.6 mm. On the other hand, the HTS compensation coil

is wound with three pieces of coated conductors of 2.01 mm

in width and less than 0.1 mm in thickness. Their critical

currents at 77 K in self-field are 53 A to 56 A. The inner

diameter and height of the HTS compensation coil are 130 mm

and 360 mm, respectively. The number of layers is two,

and the second layer has the notched length h of 300 mm.

Hence, the number of turns of the first layer is 164, whereas

the number of turns of the second layer is 14 × 2. This

2LPO1E-03

4

Compensation coil

h

LTS magnet

HTS insert

Fig. 3. Schematic illustration of HTS insert, HTS compensation coil, and

LTS magnet. The LTS magnet is used to induce the screening currents in the

windings of the HTS insert.

TABLE III

S PECIFICATIONS OF HTS C OMPENSATION C OIL

Parameter

Value

Tape width

Tape thickness

Critical currents of tapes at 77 K in self-field

Inner diameter of coil

Height of coil

Number of layers of coil

Notched length in 2nd layer, h

Number of turns of 1st layer

Number of turns of 2nd layer

Critical current of coil at 77 K in self-field

2.01 mm

92, 95, 92 µm

54, 53, 56 A

130 mm

360 mm

2

300 mm

164

14 × 2

45 A

Screening-current-induced field (mT)

5

±40 A@1.5 A/s

±40 A@15 A/s

±30 A@15 A/s

±5 A@15 A/s

4

3

2

1

0

0

20

40

60

80

100

Cycle

Fig. 4. Experimental results of decay property of SCFs for number of cycles

of applied AC magnetic field.

type of notched solenoid is expected to minimize the radial

components of local magnetic fields applied to the windings

of the HTS insert. There are no electrical insulations for the

coated conductors, so that insulated 40 AWG gauge nichrome

wires and 1-mil-thick polyimide sheets are used for turn-toturn and layer-to-layer insulations, respectively. Although the

total length of winding is about 80 m, the piece lengths of

the coated conductors are limited around 35 m. Therefore,

three pieces of the coated conductors are soldered in series

to wind the HTS compensation coil. Several samples with

the configuration of lap joint are prepared in advance, and

their joint resistances and critical currents in liquid nitrogen

are evaluated experimentally. The last sample made from the

53-A coated conductor shows the joint resistance of 52 nΩ for

the joint length of 136 mm and the critical current of 52.3 A

for the criterion of 1 µV/cm. The critical current of the HTS

compensation coil is also measured as 45 A in liquid nitrogen.

The HTS insert and HTS compensation coil are located

coaxially and immersed in liquid nitrogen. This HTS insert

is magnetized in advance to induce the screening currents

inside it by using an LTS magnet with larger clear bore. The

LTS magnet is firstly charged up to 1.25 T and discharged

down to 0 T. The inactive period of about 15 min is spared

until the decay of the screening currents due to flux creep

becomes negligible. After that, the SCFs in the axial direction

are measured using a Hall probe located in the center of the

HTS insert. Fig. 4 shows the experimental results of the decay

property of SCFs for the number of cycles of AC magnetic

field generated by the HTS compensation coil. A bipolar power

supply is connected to the HTS compensation coil and outputs

trapezoidal currents to it. Two different sweep rates of currents

of 1.5 A/s and 15 A/s are used in this experiments. The

amplitude of current is also fixed at 40 A, 30 A, or 5 A. The

conversion factor of current to the central magnetic field is

analytically estimated from the specifications of the fabricated

HTS compensation coil as 0.55 mT/A. It can be seen in Fig. 4

that the SCF for the case of 15 A/s to ±40 A decays with

increasing the number of cycles and becomes one tenth of the

initial value in 66 cycles. It is also found that the change of

sweep rate scarcely affects the decay property of SCFs, which

is almost determined by the number of cycles of AC field

as plotted in Fig. 4. On the other hand, the decrease in the

current amplitude leads to the slow decay of SCF. The Bi2223 tapes used for the HTS insert have the 77-K self-field

critical currents of 60 A to 84 A [30], which correspond to

the full penetration fields of 12 mT to 17 mT. This means

that the field amplitude for the current of 30 A applied by the

HTS compensation coil is roughly close to the full penetration

fields of the Bi-2223 tapes for the HTS insert. Therefore, the

significant decays of SCFs can be expected for the cases of

the applied currents larger than 30 A.

IV. C ONCLUSION

The HTS insert wound with the RE-123 coated conductors

were designed as well as a pair of copper compensation coils

to reduce the screening currents. The total power dissipation

during the AC operation was estimated as 104 W, and several

liters of liquid helium were evaporated within a few minutes.

The HTS compensation coil was also designed and fabricated

to suppress the power dissipation. The SCFs of another HTS

insert wound with the Bi-2223 tapes in the previous research

project were successfully reduced by applying the AC magnetic fields using the fabricated HTS compensation coil.

R EFERENCES

[1] K. Kajikawa, M. Nishimura, H. Moriyama, M. Iwakuma, and K. Funaki,

“Quantitative evaluation of perpendicular-field losses in stacked high-Tc

superconducting tapes,” Electr. Eng. Jpn., vol. 141, no. 3, pp. 50–57,

2LPO1E-03

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

[18]

[19]

[20]

[21]

[22]

[23]

Nov. 2002 [Trans. IEE Jpn., vol. 121-B, no. 10, pp. 1283–1289, Oct.

2001].

N. Amemiya and K. Akachi, “Magnetic field generated by shielding

current in high Tc superconducting coils for NMR magnets,” Supercond.

Sci. Technol., vol. 21, no. 9, 095001, Sep. 2008.

S. Hahn, J. Bascuñán, H. Lee, E. S. Bobrov, W. Kim, M. C. Ahn, and

Y. Iwasa, “Operation and performance analyses of 350 and 700 MHz

low-/high-temperature superconductor nuclear magnetic resonance magnets: A march toward operating frequencies above 1 GHz,” J. Appl.

Phys., vol. 105, no. 2, 024501, Jan. 2009.

M. C. Ahn, T. Yagai, S. Hahn, R. Ando, J. Bascuñán, and Y. Iwasa,

“Spatial and temporal variations of a screening current induced magnetic

field in a double-pancake HTS insert of an LTS/HTS NMR magnet,”

IEEE Trans. Appl. Supercond., vol. 19, no. 3, pp. 2269–2272, June 2009.

Y. Koyama, T. Takao, Y. Yanagisawa, H. Nakagome, M. Hamada,

T. Kiyoshi, M. Takahashi, and H. Maeda, “Towards beyond 1 GHz

NMR: Mechanism of the long-term drift of screening current-induced

magnetic field in a Bi-2223 coil,” Physica C, vol. 469, no. 13, pp. 694–

701, July 2009.

D. Uglietti, Y. Yanagisawa, H. Maeda, and T. Kiyoshi, “Measurements of

magnetic field induced by screening currents in YBCO solenoid coils,”

Supercond. Sci. Technol., vol. 23, no. 11, 115002, Nov. 2010.

A. Miyazoe, M. Sekino, T. Kiyoshi, and H. Ohsaki, “Magnetic field

induced by screening current in short and straight coated conductors,”

IEEE Trans. Appl. Supercond., vol. 20, no. 3, pp. 1557–1560, June 2010.

K. Kajikawa and K. Funaki, “A simple method to eliminate shielding currents for magnetization perpendicular to superconducting tapes

wound into coils,” Supercond. Sci. Technol., vol. 24, no. 12, 125005,

Dec. 2011.

K. Kajikawa and K. Funaki, “Reduction of magnetization in windings

composed of HTS tapes,” IEEE Trans. Appl. Supercond. 22 4400404.

K. Funaki and K. Yamafuji, “Abnormal transverse-field effects in

nonideal type II superconductors I. A linear array of monofilamentary

wires,” Jpn. J. Appl. Phys., vol. 21, no. 2, pp. 299–304, Feb. 1982.

K. Funaki, T. Nidome, and K. Yamafuji, “Abnormal transverse-field

effects in nonideal type 2 superconductors. II. Influence of dimension

ratios in a superconducting ribbon,” Jpn. J. Appl. Phys., vol. 21, no. 8,

pp. 1121–1126, Aug. 1982.

K. Funaki, M. Noda and K. Yamafuji, “Abnormal transverse-field effects

in nonideal type 2 superconductors. III. A theory for an AC-induced

decrease in the semi-quasistatic magnetization parallel to a DC bias

field,” Jpn. J. Appl. Phys., vol. 21, no. 11, pp. 1580–1587, Nov. 1982.

K. Funaki, T. Nidome, and K. Yamafuji, “Abnormal transverse-field

effects in current-carrying superconducting wires,” Tech. Rep. Kyushu

Univ., vol. 56, no. 1, pp. 45–51, Jan. 1983.

E. H. Brandt and G. P. Mikitik, “Why an ac magnetic field shifts the

irreversibility line in type-II superconductors,” Phys. Rev. Lett., vol. 89,

no. 2, 027002, July 2002.

G. P. Mikitik and E. H. Brandt, “Theory of the longitudinal vortexshaking effect in superconducting strips,” Phys. Rev. B, vol. 67, no. 10,

104511, Mar. 2003.

E. H. Brandt and G. P. Mikitik, “Shaking of the critical state by a

small transverse ac field can cause rapid relaxation in superconductors,”

Supercond. Sci. Technol., vol. 17, no. 2, pp. S1–S5, Feb. 2004.

J. E. C. Williams, L. J. Neuringer, E. Bobrov, R. Weggel, D. J. Ruben,

and W. G. Harrison, “Magnet system of the 500 MHz NMR spectrometer

at the Francis Bitter National Magnet Laboratory: I. Design and development of the magnet,” Rev. Sci. Instrum., vol. 52, no. 5, pp. 649–656,

May 1981.

J. Bascuñán, H. Lee, E. S. Bobrov, and Y. Iwasa, “A low- and hightemperature superconducting NMR magnet: Design and performance

results,” IEEE Trans. Appl. Supercond., vol. 13, no. 2, pp. 1550–1553,

June 2003.

V. Braccini, A. Xu, J. Jaroszynski, Y. Xin, D. C. Larbalestier, Y. Chen,

G. Carota, J. Dackow, I. Kesgin, Y. Yao, A. Guevara, T. Shi, and V. Selvamanickam, “Properties of recent IBAD-MOCVD coated conductors

relevant to their high field, low temperature magnet use,” Supercond.

Sci. Technol., vol. 24, no. 3, 035001, Mar. 2011.

Y. Iwasa, Case Studies in Superconducting Magnets, 1st ed. New York:

Plenum, 1994, p. 393.

Cryogenic Materials Thermal Properties Database CryoComp. [Online].

Available: http://www.eckelsengineering.com

H. Song, P. Brownsey, Y. Zhang, J. Waterman, T. Fukushima, and

D. Hazelton, “2G HTS coil technology development at SuperPower,”

IEEE Trans. Appl. Supercond. 23 4600806.

Y. Iwasa, Case Studies in Superconducting Magnets, 2nd ed. New York:

Springer Science+Business Media, 2009, pp. 472–473.

5

[24] C. P. Bean, “Magnetization of hard superconductors,” Phys. Rev. Lett.,

vol. 8, no. 6, pp. 250–253, Mar. 1962.

[25] T. Ogasawara, Y. Takahashi, K. Kanbara, Y. Kubota, K. Yasohama, and

K. Yasukochi, “Alternating field losses in superconducting wires carrying

dc transport currents: Part 1 single core conductors,” Cryogenics, vol. 19,

no. 12, pp. 736–740, Dec. 1979.

[26] K. Kajikawa, H. Shiraishi, A. Takenaka, M. Iwakuma, and K. Funaki,

“Applicability of a ‘simple electromagnetic method’ to AC loss measurements in more general electromagnetic configurations,” Adv. Cryo.

Eng. Mater., vol. 46, part B, pp. 1035–1042, Aug. 2000.

[27] K. Kajikawa, K. Funaki, K. Shikimachi, N. Hirano, and S. Nagaya,

“Numerical and theoretical evaluations of AC losses for single and

infinite numbers of superconductor strips with direct and alternating

transport currents in external AC magnetic field,” Physica C, vol. 470,

no. 20, pp. 1321–1324, Nov. 2010.

[28] K. Funaki and F. Sumiyoshi, Multifilamentary Wires and Conductors.

Tokyo: Sangyo Tosho, 1995, pp. 129–130.

[29] K. Kajikawa, S. Awaji, and K. Watanabe, “Numerical evaluation of

AC losses in an HTS insert coil for high field magnet during its

energization,” submitted for publication.

[30] H. Lee, J. Bascuñán, and Y. Iwasa, “A high-temperature superconducting

double-pancake insert for an NMR magnet,” IEEE Trans. Appl. Supercond., vol. 13, no. 2, pp. 1546–1549, June 2003.