SOUTH INLAND RAW WATER PS

BOSSIER CITY PROJECT P14-02

SUBMITTAL FOR

Raw Water Intake Screens

D-11100-001-B

Submittal Number

7/15/14

Date

Roy Thompson

Max Foote Construction

Certification Statement: By this submittal, I hereby represent that I have determined and

verified all field measurements, field construction criteria, materials, dimensions, catalog

numbers and similar data and I have reviewed and approved this submittal and checked and

coordinated each item with other applicable approved shop drawings and all contract

requirements.

Johnson Screens® Passive Intake Screens

& Hydroburst Air-Backwash System

Submittal Package Rev B

Bossier City, LA

South Inland Raw Water Pump Station

Bilfinger Water Technologies, Inc.

1950 Old Hwy 8 NW

New Brighton, MN 55112

USA

Phone +1 651 636 3900

Fax +1 651 638 3132

usa.water@bilfinger.com

www.water.bilfinger.com

Purchase Order 275-11100

Max Foote Construction Company, LLC

Sales Order 4745

Bilfinger Water Technologies, Inc.

Response to Submittal Review Comments

From Manchac Consulting Group, Inc.

1. Provide dry contact outputs for the following points: Inremote status, common failure for both the air burst system

and air compressor, and valve fully closed. Refer to drawing

E-10.

Bilfinger Water Technologies, Inc.

The dry contacts have been added and are shownon sheet 4

of 5 of drawing D000845688 Rev B.

2. Provide information on the control panel nameplates.

Confirm the control panel and associated equipment are

labeled as indicated on drawings P-01 and E-10

Sheet 5 of 5 of drawing D000845688 Rev B shows the

nameplate location on the control panel. This will be a plastic

nameplate with a black background and white lettering.

We will also provide nameplates for the air compressor

(RWP-AC-421), butterfly valve assembly 1 (RWP-FCV-421)

and butterfly valve assembly 2 (RWP-FCV-422). These

nameplates will be made of stainless steel with black

embossed lettering.

3. Provide local-off-remote switch that controls whether the air

burst system is initiated at the local control panel or remotely

by the plant control system. When the switch is in Local the

air busrst system shall be initiated by the local control panel.

When the switch is in Remote the air burst system shall be

initiated by the plant control system. Refer to specification

section 16904 paragraph 3.05 for description of operation.

The switch has been added to the control panel for localremote system operation.

1950 Old Hwy 8 NW

New Brighton, MN 55112

USA

Phone +1 651 636 3900

Fax +1 651 638 3132

usa.water@bilfinger.com

www.water.bilfinger.com

Diana Roddy

Environmental Technical Sales, Inc.

7731 Office Park Blvd.

Baton Rouge, LA 70809

Re:

Max Foote Construction Company, LLC

Purchase Order # 275-11100

Bilfinger Water Technologies Sales Order 4745 SO

Bilfinger Water Technologies Submittal Package, Rev B:

D000845661 Rev A - T-54x36 Intake, Dished x Cone

D000845663 Rev A - T-54x36 Intake, Dished x Dished

D000845688 Rev B - Hydroburst System

Design Report - Passive Intake Screens

Hydroburst Component Cut Sheets

Attached, for your review and approval, is seven (7) hard copies and one

(1) CD digital copy of Bilfinger Water Technologies Inc. Approval

Drawing(s) D000845661 Rev A, D000845663 Rev A & D000845688 Rev

B which will be used to fabricate the products for the above referenced

purchase order.

If the drawing(s) meets your requirements, please indicate approval by

selecting the appropriate choice listed in the "FOR APPROVAL" Customer

Acknowledgment box on the drawing(s). If any changes or additions are

needed, please notify me immediately, mark-up the drawing(s), sign, date,

and return them to me. You may email a .pdf of the drawing(s) to me at

ehrich.shaw@bilfinger.com, or you may fax them to 651-638-3230.

Our quoted delivery is based on our receipt of the approved drawing(s).

When the approved drawing(s) is received, I will complete engineering

and establish a ship date, and you will then be notified. Please be advised

that any changes outside of the proposed scope of work may delay

delivery and require a price adjustment.

If you have technical questions or concerns about the attached

documents, please contact me, toll-free at 1-800-833-9473 Ext. 238 or via

email at the above mentioned email address.

Bilfinger Water Technologies, Inc.

1950 Old Hwy 8 NW

New Brighton, MN 55112

USA

Phone +1 651 636 3900

Fax +1 651 638 3132

usa.water@bilfinger.com

www.water.bilfinger.com

Page 2 / 2

Thank you for ordering from Bilfinger Water Technologies Inc., and for the

opportunity to be of service to you. We appreciate your prompt reply.

Best regards,

Ehrich Shaw

Project Manager - Water Intake

Bilfinger Water Technologies, Inc.

1950 Old Highway 8

New Brighton, MN 55112

Phone: 651.638.3238

Fax: 651.638.3230

Email: ehrich.shaw@bilfinger.com

8

7

6

5

4

3

2

1

DRAWING NUMBER

D000845661

ITEM

1

QTY

2

2

1

Parts List

DESCRIPTION-APPROVAL

SCREEN CYLINDER:

WIRE = 69, SLOT = 0.125

TEE ASSEMBLY:

3

4

LIFTING LUG:

304

4

1

304

5

1

6

1

MOUNTING FLANGE: 1.00 THK

TO MATE w/ 36" AWWA C-207 TABLE 2 CLASS D FLANGE

ABW FLANGE: 1.00 THK

TO MATE w/ 6" 150# ANSI FLANGE

CONE ASSEMBLY:

7

1

DISHED HEAD:

304

8

1

LIFTING GUSSET:

304

185.33 OVERALL LENGTH

REF.

87.53

59.50 SCREEN LENGTH

2 PLACES

3

D

7.53

REF.

3

1

3

17.80

REF.

1

7

MATERIAL

304

304

D

304

304

3

54.00 NOM

SCREEN DIA

2 PLACES

FOR APPROVAL

Customer Acknowledgment

81.00

REF.

Any changes after approval by customer or customer's

agent will be at the customer's expense unless Johnson

Screens otherwise agrees in writing. Acceptance of

these terms is confirmed by the signature below.

7

6

54.00

5

Approved as is - PROCEED TO MANUFACTURE

2

5

2

C

Change per comments - RESUBMIT FOR APPROVAL

(May affect delivery and price)

C

Accepted as noted - PROCEED TO MANUFACTURE

8

8

Signed __________________________ Dated__________

11.00

4

4

26.00

36.00 DIA.

CUSTOMER INFORMATION:

1) CAPACITY = 17,361 GPM [25 MGD] @ 0.50 ft/sec

MAXIMUM THRU SLOT VELOCITY.

2) INSTALLATION DEPTH = 15 ft.

3

1

3

3) COLLAPSE STRENGTH DESIGNED FOR

MAXIMUM PUMP PRESSURE OR DIFFERENTIAL

HEADLOSS = 6.50 psi [0.45 bar]

1

4) ESTIMATED WEIGHT = 3600 lbs.

6

5) SCREEN OPEN AREA = 63.78%

7

B

B

5

2

4

A

INITIAL RELEASE

EHRICH SHAW

NADINE LACROSSE

6/4/2014

REV

DESIGNATION

ENGINEER

DRAFTER

DATE

INTAKE SCREEN ASSEMBLY

T-54 X 36 HCE w/ 6" ABW CONNECTION

LINEAR DIMENSIONS: INCHES

TOLERANCES UNLESS NOTED

X.XX

DESIGN LOCATION

A

INSTALLATION ORIENTATION

NEW BRIGHTON, MN

USA

THIS PRODUCT AND ITS COMPONENTS ARE PROTECTED

BY ONE OR MORE OF THE FOLLOWING

U.S. PATENTS AND OTHER PATENTS PENDING:

6,712,959, 6,051,131

8

7

6

5

4

± 0.008

X.X

± 0.04

0-60

± 0.12

60-120

± 0.25

OVER 120

± 0.50

ANGLES

± 0.5°

THIS DRAWING AND THE INFORMATION CONTAINED IS CONFIDENTIAL

AND PROPRIETARY. IT MAY NOT BE COPIED OR DIVULGED IN WHOLE OR

IN PART WITHOUT WRITTEN PERMISSION FROM BILFINGER WATER

TECHNOLOGIES. COPYRIGHT - ALL RIGHTS RESERVED

3

BOSSIER CITY, LA

SOUTH INLAND RAW WATER PUMP STATION

REFERENCE

PROJECT NUMBER

THIRD ANGLE

PROJECTION

SHEET SIZE

DO NOT SCALE

2

CONTENT

17176-1

D

SHEET

1 OF 1

REV

APPROVAL

DRAWING NUMBER

A

D000845661

1

A

8

7

6

5

4

3

2

1

DRAWING NUMBER

D000845663

175.05 OVERALL LENGTH

REF.

D

87.53

7.53

REF.

59.50 SCREEN LENGTH

2 PLACES

3

1

3

3

7.53

REF.

1

6

ITEM

1

QTY

2

2

1

Parts List

DESCRIPTION-APPROVAL

SCREEN CYLINDER:

WIRE = 69, SLOT = 0.125

TEE ASSEMBLY:

3

4

LIFTING LUG:

304

4

1

304

5

1

6

2

MOUNTING FLANGE: 1.00 THK

TO MATE w/ 36" AWWA C-207 TABLE 2 CLASS D FLANGE

ABW FLANGE: 1.00 THK

TO MATE w/ 6" 150# ANSI FLANGE

DISHED HEAD:

7

1

LIFTING GUSSET:

304

3

304

D

304

304

FOR APPROVAL

54.00 NOM

SCREEN DIA

2 PLACES

Customer Acknowledgment

Any changes after approval by customer or customer's

agent will be at the customer's expense unless Johnson

Screens otherwise agrees in writing. Acceptance of

these terms is confirmed by the signature below.

81.00

REF.

6

MATERIAL

304

6

Approved as is - PROCEED TO MANUFACTURE

5

Change per comments - RESUBMIT FOR APPROVAL

54.00

(May affect delivery and price)

Accepted as noted - PROCEED TO MANUFACTURE

C

2

C

2

Signed __________________________ Dated__________

5

7

7

11.00

CUSTOMER INFORMATION:

1) CAPACITY = 17,361 GPM [25 MGD]@ 0.50 ft/sec MAXIMUM

THRU SLOT VELOCITY.

4

4

26.00

2) INSTALLATION DEPTH = 15 ft.

36.00 DIA.

3) COLLAPSE STRENGTH DESIGNED FOR

MAXIMUM PUMP PRESSURE OR DIFFERENTIAL

HEADLOSS = 6.5 psi [0.45 bar]

4) ESTIMATED WEIGHT = 3600 lbs.

3

1

3

5) SCREEN OPEN AREA = 63.78%

1

6

6

B

B

INSTALLATION ORIENTATION

2

5

4

A

INITIAL RELEASE

EHRICH SHAW

NADINE LACROSSE

6/4/2014

REV

DESIGNATION

ENGINEER

DRAFTER

DATE

INTAKE SCREEN ASSEMBLY

T-54 X 36 HCE w/ 6" ABW CONNECTION

LINEAR DIMENSIONS: INCHES

TOLERANCES UNLESS NOTED

X.XX

DESIGN LOCATION

A

NEW BRIGHTON, MN

USA

THIS PRODUCT AND ITS COMPONENTS ARE PROTECTED

BY ONE OR MORE OF THE FOLLOWING

U.S. PATENTS AND OTHER PATENTS PENDING:

6,712,959, 6,051,131

8

7

6

5

4

± 0.008

X.X

± 0.04

0-60

± 0.12

60-120

± 0.25

OVER 120

± 0.50

ANGLES

± 0.5°

THIS DRAWING AND THE INFORMATION CONTAINED IS CONFIDENTIAL

AND PROPRIETARY. IT MAY NOT BE COPIED OR DIVULGED IN WHOLE OR

IN PART WITHOUT WRITTEN PERMISSION FROM BILFINGER WATER

TECHNOLOGIES. COPYRIGHT - ALL RIGHTS RESERVED

3

BOSSIER CITY, LA

SOUTH INLAND RAW WATER PUMP STATION

REFERENCE

PROJECT NUMBER

THIRD ANGLE

PROJECTION

SHEET SIZE

DO NOT SCALE

2

CONTENT

17176-2

D

SHEET

1 OF 1

REV

APPROVAL

DRAWING NUMBER

A

D000845663

1

A

1950 Old Highway 8, New Brighton, MN 55112 (Physical Address)

P.O. Box 64118, Saint Paul, MN 55164 (Mailing Address)

(651)-638-3230 (Fax)

(651)-636-3900 x-238 (Phone)

(651)-638-3238 (Direct Dial, Ehrich Shaw)

ehrich.shaw@bilfinger.com

www.water.bilfinger.com

Passive Intake Screen Design Report

The following calculations are intended to provide verification that the design used in the above

referenced project is suitable for the intended application. It is assumed that the reader is familiar with

the methods and parameters adapted from the various standards referenced. The application of these

calculation shown in this document should be considered proprietary, and should not be published or

generally reproduced without the written permission of Bilfinger Water Technologies.

References

Project:

Bossier City, LA

Scope of Supply:

(2) T-54 Intake Assembly

Customer References:

PO# 275-11100

Bilfinger Water Technologies Order:

4745 SO

Design:

Per conditions provided.

Rev

A

Comments

Initial Release

C O M P A N Y

Date

6/5/2014

6/5/2014

Contents:

1. Specifications

1.1. Conditions

1.2. Screen Dimensions

2. Open Area Calculation

3. Slot Velocity

4. Structural Calculations

4.1. Wire Collapse Strength

4.2. Wire Maximum Span

4.3. Wire Burst Strength (air backwash resistance)

4.4. Rod Maximum Span

4.5. Number of Support Rings

4.6. Stress In Ring

4.7. Stability of Ring

5. Conclusions

Bilfinger Water Technologies

2 of 9

1. Specifications

1.1 Conditions

Differential Hydrostatic Collapse Pressure

H2Oft ≡ 15⋅ ft

Design Load

1 foot H2O = 0.433 psi

Load ≡ 0.433

psi

⋅ H2Oft

ft

Load = 6.495⋅ psi

Water Variables

lb

ρH2O ≡ 62.4⋅

ft

3

Design Stresses

σyield ≡ 30000⋅ psi

σdesign ≡ σyield⋅ 80%

σdesign = 24000⋅ psi

Material Variables

Material = 304 SS

6

E ≡ 28.3⋅ 10 ⋅ psi

μ ≡ 0.3

Flow

Flow ≡ 17361⋅

gal

min

Bilfinger Water Technologies

3 of 9

1.2 Intake Assembly Dimensions

These values were taken directly from the drawing or are standard

calculations of structural properties.

Global Dimensions

Screendia ≡ 54.00⋅ in

Effective Screen Length of One (1) Cylinder

Screenlg ≡ 59.50⋅ in

Slot ≡ 0.125⋅ in

Wire (69)

Wirewidth ≡ 0.071⋅ in

WireI ≡ 2.18⋅ 10

−5

WireZ ≡ 2.17⋅ 10

4

⋅ in

−4

Wirearea ≡ 9.12⋅ 10

3

⋅ in

−3

2

⋅ in

Rod (.074 x 1.00)

Rodwidth ≡ 0.074⋅ in

Rodheight ≡ 1.00⋅ in

RodI ≡

RodZ ≡

Rodwidth⋅ Rodheight

3

4

RodI = 0.006⋅ in

12

Rodwidth⋅ Rodheight

2

3

RodZ = 0.012⋅ in

6

Rodarea ≡ Rodwidth⋅ Rodheight

2

Rodarea = 0.074⋅ in

Rodcenters ≡ 1.00⋅ in

Support Rings

Ringthick ≡ 0.25in

Ringheight ≡ 1.50⋅ in

Bilfinger Water Technologies

4 of 9

2. Open Area

OA% ≡

Slot

Slot + Wirewidth

OA% = 63.78⋅ %

2

Screenarea ≡ π⋅ Screendia ⋅ Screenlg

Screenarea = 10094⋅ in

Screenoa ≡ Screenarea⋅ OA%

Screenoa = 6437⋅ in

2

3. Slot Velocity

Velocityslot ≡

0.5⋅ Flow

Screenoa

Velocityslot = 0.433⋅

ft

s

Maximum Thru-Slot Velocity has been found to be approximately 1.126 times the

Average Thru-Slot Velocity.

Velocitymax_slot ≡ Velocityslot⋅ 1.126

Velocitymax_slot = 0.487⋅

ft

s

4. Structural Calculations

4.1 Wire Collapse Strength

General Safety Factor Applied to this

Calculation

SF ≡ 1.5

Pcr ≡ 24⋅ E⋅

WireI

( Wirewidth + Slot) ⋅ Screendia3⋅ SF

Pcr = 0.32⋅ psi

Because this load is less than the Design Load, the screen will be

augmented by support rings

4.2 Wire Maximum Span

Since the wire will be supported by the support rods and ring structure, the

wire will need to span the distance between adjacent rods

2

σ=

ω⋅ l

12⋅ z

Based on Fixed End Condition of a

Beam

Load⋅ ( Wirewidth + Slot) ⋅ Rodcenters

σwire ≡

12⋅ Wire

2

Z

σwire = 488.9⋅ psi

Bilfinger Water Technologies

5 of 9

4.3 Wire Burst Strength

Burst∆P ≡

σdesign⋅ Wirearea

Screendia

⋅ Wirewidth + Slot

2

(

)

Burst∆P = 41.4⋅ psi

The backwash ejects water at 3 screen volumes in a 2-3 second period

2

Screendia

Screenvolume ≡

⋅ π⋅ ( Screenlg)

2

3

Screenvolume = 136268⋅ in

Backwash ≡

3⋅ Screenvolume

3⋅ sec

Backwash = 79⋅

ft

3

sec

The velocity at the screen surface of this fluid can be determined

as follows:

Backwashvel ≡

Backwash

Screenarea

Backwashvel = 1.12⋅

ft

sec

Assuming a drag coefficient of 1, the dynamic fluid force on the screen

can be estimated as follows:

Backwashload ≡

1

2

2

⋅ ρH2O⋅ Backwashvel

Backwashload = 0.009⋅ psi

The expected load from the backwash is far below the allowable

burst strength of the assembly.

Bilfinger Water Technologies

6 of 9

4.4 Rod Bending Stress

The maximum spacing of any support ring will be determined by the maximum

span of the screen rods

2

σ=

ω⋅ l

8⋅ z

Left End Simply Supported, Right End Simply

Supported

Based on Multiple

Simple Support

Condition of a

Beam

Given

σdesign =

( Load⋅ Rodcenters) ⋅ Rodspan2

8⋅ RodZ

(

)

Rodspan := Find Rodspan

Rodspan = 19.09⋅ in

This is the maximum spacing for the support ring.

4.5 Number of Support Rings

Using the value for the maximum rod span, the number of support rings

required in each cylinder can be determined

Screenlg + 1⋅ in

−1

Rodspan

Ringqty := ceil

Ringqty = 3

Ringspacing :=

Screenlg

Ringqty + 1

Ringspacing = 14.875⋅ in

In order to reduce the weld stress at the rod-weld ring interface, the local rod span at each end had to

be reduced. An additional support ring has been added for a total of four (4) rings per cylinder.

Bilfinger Water Technologies

7 of 9

4.6 Stress in Support Ring

(

ScreenID ≡ Screendia − 2⋅ Rodheight

)

Approximate Inside Diameter of Screen

ScreenID = 52⋅ in

1

ScreenID − ⋅ in

8

Ringradius ≡

2

Ringradius = 25.938⋅ in

σring :=

2⋅ Screendia ⋅ Load⋅ Ringspacing⋅ ScreenID

2

2

Ringthick⋅ ScreenID − ScreenID − 2⋅ Ringheight

(

)

σring = 7163⋅ psi

4.7 Support Ring Elastic Stability

The most likely mode of failure for a thin walled cylinder (which the screen is modeled

after) is buckling. The stability of the ring is determined as follows:

RingI ≡

Ringthick⋅ Ringheight

Pcritring ≡

12

3

4

RingI = 0.07⋅ in

3⋅ E⋅ RingI

3

Ringradius

lbf

Pcritring = 342.1⋅

in

Fring := Load⋅ Ringspacing

RingSF :=

Pcritring

Fring

Fring = 96.6⋅

lbf

in

RingSF = 3.54

Bilfinger Water Technologies

8 of 9

5.0 Conclusions

The results of these calculations show that the assembly will be suitable for its intended application.

Please feel free to contact a Bilfinger Water Technologies engineer directly with any comments or

questions regarding this document or the referenced project.

Prepared By:

Ehrich Shaw

Project Manager - Water Intake

Bilfinger Water Technologies

9 of 9

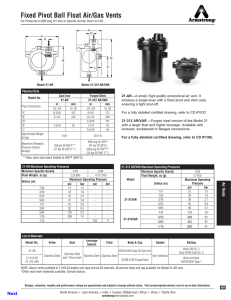

HYDROBURST CUT SHEET LIST:

Saylor Beall 9000 Series Air Compressor Sheet:

- 20 HP Base-Mounted Air Compressor

Model BPL9200

Johnson Controls Low Pressure Control Sheet:

- Air Compressor Low Oil Pressure Switch

Model P29NC-2C

United Electric 100 Series Pressure Switch Sheet:

- Compressor Auto Start-Stop Pressure Switch

155-175 psi

Silvan Air Receiver Sheet:

- 1550 Gallon Vertical Air Receiver

Drawing 100-737

Spence Safety Valve Sheet:

- Main Air Receiver Safety Valve

Figure 41A, ½“ x ¾“

IPAC Auto Condensate Drain Sheet:

- Main Air Receiver Float-Type Auto Drain

Model SAC-120

Control Air Receiver Component Sheet

Wilkerson Filter/Regulator Sheet:

- Control Air Receiver Filter/Regulator

Model B18-02-GLGO

Grasslin MIL72 Series Timer Sheet:

- Hydroburst Cycle Programmable Timer

Model QWUZH-120

United Electric 400 Series Multi-Output Pressure Switch Sheet:

Dual Pressure Switch

- Low Air Pressure - 50 PSI

Adequate Air Pressure 150 PSI

Jomar Series 600/900 Butterfly Valve Sheet:

- 6“ Size Lug Style Butterfly Valve

Series 600

J-Flow JFC Series Pneumatic Actuator Sheet:

- Ball Valve Spring-Return Pneumatic Actuator

Bilfinger Water Technologies, Inc.

1950 Old Hwy 8 NW

New Brighton, MN 55112

USA

Phone +1 651 636 3900

Fax +1 651 638 3132

usa.water@bilfinger.com

www.water.bilfinger.com

Page 2 / 2

Max-Air NAMUR Series Solenoid Valve Sheet:

- Pneumatic Actuator Single Solenoid Control Valve

Model SV61-120

J-Flow 53 Series Limit Switch Sheet:

- Ball Valve Position Indicator with Limit Switches

Code No. LIT-1927190

Issued February 1, 2009

P29 Series

Low Pressure Control (With Time Delay)

Description

Applications

P29NC is a low pressure control with time

delay and lockout, which requires manual

reset. A drop in pressure energizes the time

delay relay and opens a contact after the time

delay, shutting down the equipment. The time

delay prevents nuisance shutdowns due to

momentary fluctuations in system pressures.

•

•

Features

•

•

•

•

direct reading scale indication

dust-protected snap action switch

trip-free manual reset

replacement timing relays available

•

chiller low temperature

industrial equipment, oil pressure

lubrication

low suction pressure

Technical Specifications

•

•

pilot duty rating of 750 VA, 120/240 VAC

external step down transformer for 440 and

550 VAC applications must be of sufficient

capacity to supply 15 VA at 120 VAC or

30VA at 240 VAC for time delay

P29 Series

Accessories

•

•

universal mounting bracket (271-51)

replacement timing relays (Refer to

Replacement Timing Relays for P28 and

P29 Lube Oil Controls Catalog Page,

LIT-1927395.)

Selection Chart

Code

Number

Switch

Action

Pressure

Range

Differential

psi (kPa)

Max Overpressure

psig (kPa)

Max Working Pressure

psig (kPa)

Pressure

Connection

Time Delay

Setting

P29NC-2C

SPST

20 in. HG Vacuum

to 100 psi

(-68 to 690 kPa)

2.2 ±1.5

(15.2 ±10.3)

325

(2241)

250

(1723)

1/4 in. Male

Flare Fitting

60 Seconds

(Factory Set)

36 in. Copper

Capillary Tube

with 1/4 in. Flare Nut

120 Seconds

P29NC-3C

P29NC-49C

P29NC-53C

90 Seconds

120 Seconds

P29NF-1C1

1. With alarm contacts

Example: Setpoint @ 10 psig. On a rise in pressure, the timing circuit opens at 10 psig and time out ends. On a fall in pressure, the timing

circuit energizes at 6-9 psig and the time out begins. If the pressure fails to reach 10 psig within the 60 sec. time delay, the main contacts open,

shutting down the controlled equipment.

The performance specifications are nominal and conform to acceptable industry standards. For applications at conditions beyond these specifications, consult the local Johnson Controls office.

www.johnsoncontrols.com

Johnson Controls, Inc. shall not be liable for damages resulting from misapplication or misuse of its products. © 2009 Johnson Controls, Inc.

1 of 1

10 0 S e r i e s

100 Seri es

Pressure, Vacuum, Differential Pressure

AND Temperature SWITCHES

features

• Single Switch Output

• Epoxy Coated and Gasketed Cast Aluminum

Enclosure Type 4X

• Tamper-Resistant Set Point “Lock”

• Heat Trace and Freeze Protection Thermostats

• Proof Pressures to 10,000 psi (689,5 bar)

• Adjustable Ranges:

Pressure:

30 “Hg Vac to 5000 psi

(-1 to 344,7 bar)

“wc Ranges:

300 “wc Vacuum to 250 “wc Pressure

(-746,7 to 622,3 mbar)

Differential Pressure:

0.2 “wcd to 500 psid

(0,5 mbar to 34,5 bar)

Temperature:

-180 to 650°F

(-117.8 to 343.3°C)

1 0 0 - B - 0 8

100 Seri es

100 S e r i e s

features

overview

The 100 Series is a cost-effective pressure and temperature switch

for process plants and OEM equipment. The rugged, one piece

enclosure features a slanted cover for wiring accessibility.

A wide variety of microswitch and process-connection options

make this versatile series ideal for applications requiring a rugged

weather-proof mechanical switch.

Typical applications that utilize the 100 Series are heat tracing,

freeze protection, processing equipment (pumps, compressors),

inputs for annunciator panels, and fire suppression systems.

• UL listed and cUL certified.

• CE compliant to low voltage

directive and pressure

equipment directive.

• Optional ATEX or GOST intrinsic

safety compliance

• Single switch (SPDT or DPDT)

output

• Welded stainless steel

diaphragm models

• Ultra low pressure, “wc models

• Optional sensor material for

corrosive media

• Polished stainless steel flushmount connection

• Pump switch models with wide

adjustable deadband

“Clam shell” design

allows for ease in wiring

(pressure model shown)

Bulb and capillary

temperature model with

manual reset option

Differential

pressure model

2

w w w . u e o n l i n e . c o m 1 0 0 - B - 0 8

10 0 S e r i e s

specifications

Storage temperature

-65 to 160°F (-54 to 71°C)

Ambient TEMPERATURE

limits

-40 to 160°F (-40 to 71°C); models 520-525, 540-548, 700-706, 15731-15736: 0 to

160°F (-18 to 71°C); Set point typically shifts less than 1% of range for a 50°F (28°C)

ambient temperature change

Set point repeatability

Temperature models: ± 1% of adjustable range

Pressure models 15623, 15731-15737, 171-174, 218, 270-376, 520-535, 540-543, 700706, 560-564: ± 1% of adjustable range; models 190-194, 183-189, 483-494, 544-548,

565-567, 610-680, 15884: ±1.5% of adjustable range

Internal set point lock on all pressure models

Shock

Set point repeats after 15 G, 10 millisecond duration

Vibration

Set point repeats after 2.5 G, 5-500 Hz

Enclosure

Die cast aluminum, epoxy powder coated, gasketed, captive cover screws

Enclosure classification Enclosure type 4X

Switch output

One SPDT snap action switch; switch may be wired “normally open” or “normally closed”

Electrical rating

Weight

15A 125/250/480 VAC resistive except for H100-15623, 15731-15737, 15884, 20A 125/250/480 VAC resistive, B100-13546 and E100-13545, 22A/480 VAC. Electrical switches have limited DC capabilities at 24-30 VDC, 2A resistive and 1A inductive. 125 VDC, 0.5A resistive, 0.03A inductive. Consult factory for additional information.

2-7 lbs; Varies with model

Electrical connection

1/2” NPT (female); Two 7/8” diameter knockouts

Pressure connection

Models 15623, 218, 270-376, 610-680, 701-706, 15731-15884: 1/4” NPT (female); Models 171-194, 483-494, 520-535, 15737: 1/2” NPT (female); Models 540-

548: 1/8” NPT (female); Models 560-564: 2” Sanitary Fitting; Models 565-567: 1.5” Sanitary Fitting (Sanitary fittings mate with Tri-Clamp® fitting systems)

Bulb and capillary: 6 feet 304 stainless steel except for E100-13545, 10 feet 304

stainless steel

Immersion stem: nickel-plated brass (standard) except for B100-13546 stainless steel;

optional 316L stainless steel

Temperature assembly

Fill

Models 1BS/BC are solvent filled, models 2-8 non-toxic oil filled

Temperature deadband

Type F typically 1% and type B, C, and E typically 2% of range under laboratory conditions (70°F ambient circulating bath at rate of 1/2°F per minute change)

Heat tracing or

Freeze protection

Thermostats designed specifically for heat tracing and freeze protection ambient sensing

applications are available with types B100 and E100

1 0 0 - B - 0 8 w w w . u e o n l i n e . c o m 3

Catalog 9EM-TK-190-3

Basic 3/8" Body

Filter / Regulator

B18

= “Most Popular”

Specifications

Flow Capacity*

1/4 88 SCFM (41.5 dm3 /s)

3/8

117 SCFM (55.2 dm3 /s)

1/2

121 SCFM (57.1 dm3 /s)

Adjusting Range Pressure

0 to 30 PSIG (0 to 2.1 bar)

0 to 60 PSIG (0 to 4.1 bar)

0 to 125 PSIG (0 to 8.6 bar)

0 to 250 PSIG (0 to 17.2 bar)

NPT / BSPP-G

1/4

Gauge Port (2)

Maximum Supply Plastic Bowl

150 PSIG (10.3 bar)

Pressure

Metal Bowl

250 PSIG (17.2 bar)

Operating

Plastic Bowl -13° to 125°F (-25° to 52°C)

Metal Bowl -13° to 150°F (-25° to 65.5°C)

Temperature

Port Size

NPT / BSPP-G

1/4, 3/8, 1/2

Standard Filtration

5 Micron

1.48 lb. (0.67 kg)

Weight

B

Filters, Regulators, Lubricators

B18-02-FKG0

Features

* Inlet pressure 100 PSIG (6.9 bar). Secondary pressure 90 PSIG (6.2 bar).

• 5 Micron Filtration

“F” Series Filters, Type “A” 5 micron elements: All Wilkerson

Type “A” 5 micron elements meet or exceed ISO Class 3 for maximum

particle size and concentration of solid contaminants.

• Balanced Valve Design

• Spring Loaded Diaphragm

Materials of Construction

• 1/2" NPT / BSPP-G Over-Ported

Adjustment Knob

Acetal

Body

Zinc

Body Cap

ABS

Bowl

Plastic Bowl

Polycarbonate

Metal Bowl

Aluminum

Bowl Guard

Nylon

Diaphragm Assembly

Nitrile / Zinc

Element Retainer / Baffle

Acetal

Filter Element

Sintered Polyethylene

Panel Nut

Acetal

Seals

Plastic Bowl

Nitrile

Metal Bowl

Nitrile

Sight Gauge

Metal Bowl

Polyamide (Nylon)

Springs

Main Regulating / Valve

Steel / S.S.

Valve Assembly

Brass / Nitrile

• Quick-Disconnect Bowl / Bowl Guard

• Light Weight

• High Flow Capacities

! WARNING

Product rupture can cause serious injury.

Do not connect regulator to bottled gas.

Do not exceed maximum primary pressure rating.

H

A

B

G

C

E

CAUTION:

E

REGULATOR PRESSURE ADJUSTMENT – The working

range of knob adjustment is designed to permit outlet pressures

within their full range. Pressure adjustment beyond this range

is also possible because the knob is not a limiting device. This

is a common characteristic of most industrial regulators, and

limiting devices may be obtained only by special design.

For best performance, regulated pressure should always be set

by increasing the pressure up to the desired setting.

D

Use 3/8"

or 10mm

Flex Tubing

Automatic

Drain

F Bowl

Removal

Clearance

.19" (4 mm)

I.D. Tube

Barb Fitting

Manual

Drain

Dimensions

Models

Inches

(mm)

Standard Unit with Manual Drain

B18-XX-FK00

Automatic Drain

B18-XX-FG00

Metal Bowl with Sight Gauge / Manual Drain

Metal Bowl with Sight Gauge / Automatic Drain

B212

A

B

C

D

E

F

G

H

2.36

(60)

2.36

(60)

3.66

(93)

6.34

(161)

10.00

(254)

1.60

(41)

1.20

(30)

3.74

(95)

2.36

(60)

2.36

(60)

3.66

(93)

6.11

(155)

9.77

(248)

1.60

(41)

1.20

(30)

3.74

(95)

2.36

(60)

2.36

(60)

2.70

(69)

2.70

(69)

3.66

(93)

3.66

(93)

6.34

(161)

6.11

(155)

10.00

(254)

9.77

(248 )

1.60

(41)

1.60

(41)

1.20

(30)

1.20

(30)

3.74

(95)

3.74

(95)

Pneumatic Division

Richland, Michigan

www.wilkersoncorp.com

Catalog 9EM-TK-190-3

Intermediate Modular Filter / Regulator B18

= “Most Popular”

Replacement Bowl Kits

bar

80

5.0

4.0

3.0

20

0

0

20

40

0

10

60

80

20

30

AIR FLOW RATE

SCFM

40

dm3/s

bar

PSIG

7.0

100

Inlet Pressure = 100 PSIG (6.9 bar)

6.0

80

5.0

4.0

3.0

60

40

2.0

1.0

0

20

0

0

20

0

10

40

20

60

80

100

30

40

50

AIR FLOW RATE

120

60

140 SCFM

dm3/s

bar

B18-04-FK00

7.0

Inlet Pressure = 100 PSIG (6.9 bar)

100

6.0

80

5.0

4.0

3.0

60

40

2.0

1.0

0

20

0

0

20

40

0

10

20

60

30

80

100

40

50

120

140 SCFM

60

dm3/s

AIR FLOW RATE

Ordering Information

Model Type

Manual Drain

Automatic

Drain

Plastic Bowl / Plastic Bowl /

Metal Bowl /

Bowl Guard

Bowl Guard

Sight Gauge

Port

With Gauge

With Gauge

With Gauge

Size

5 to 125 PSIG

3 to 60 PSIG 10 to 250 PSIG

(0.4 to 8.6 bar) (0.2 to 4.1 bar) (0.7 to 17.2 bar)

1/4

3/8

1/2

1/4

3/8

1/2

B18-02-FKG0

B18-03-FKG0

B18-04-FKG0

B18-02-FGG0

B18-03-FGG0

B18-04-FGG0

B18-02-DKG0

B18-03-DKG0

B18-04-DKG0

B18-02-DGG0

B18-03-DGG0

B18-04-DGG0

B18-02-GLG0

B18-03-GLG0

B18-04-GLG0

B18-02-GHG0

B18-03-GHG0

B18-04-GHG0

Plastic Bowl / Plastic Bowl /

Metal Bowl /

Bowl Guard

Bowl Guard

Sight Gauge

Without Gauge Without Gauge Without Gauge

5 to 125 PSIG

3 to 60 PSIG 10 to 250 PSIG

(0.4 to 8.6 bar) (0.2 to 4.1 bar) (0.7 to 17.2 bar)

B18-02-FK00

B18-03-FK00

B18-04-FK00

B18-02-FG00

B18-03-FG00

B18-04-FG00

B18-02-DK00

B18-03-DK00

B18-04-DK00

B18-02-DG00

B18-03-DG00

B18-04-DG00

B18-02-GL00

B18-03-GL00

B18-04-GL00

B18-02-GH00

B18-03-GH00

B18-04-GH00

Options - To order an option supplied with the unit model, add the appropriate coded suffix letter in the designated position of the model number.

B213

Pneumatic Division

Richland, Michigan

www.wilkersoncorp.com

Filters, Regulators, Lubricators

SECONDARY PRESSURE

Automatic Drain –

Fluorocarbon......................................................... GRP-95-981

Nitrile..................................................................... GRP-95-973

Drain, Manual Override............................................. GRP-96-000

Manual Drain............................................................. GRP-96-685

Panel Mount Nut –

Aluminum............................................................. RRP-96-673

Plastic.................................................................. RRP-96-675

Pressure Gauge –

0 to 30 PSIG, 1-1/2" Dial Face, 1/4 NPT CBM... K4515N14030

0 to 60 PSIG, 1-1/2" Dial Face, 1/4 NPT CBM... K4515N14060

0 to 160 PSIG, 1-1/2" Dial Face, 1/4 NPT CBM..K4515N14160

0 to 300 PSIG, 1-1/2" Dial Face, 1/4 NPT CBM.K4515N14300

0 to 2.0 bar, 1-1/2" Dial Face, G 1/4 CBM.......... K4515G14030

0 to 4.1 bar, 1-1/2" Dial Face, G 1/4 CBM........... K4515G14060

0 to 11 bar, 1-1/2" Dial Face, G 1/4 CBM.............K4515G14160

0 to 21 bar, 1-1/2" Dial Face, G 1/4 CBM........... K4515G14290

Tamper Resistant Kit............................................... RRP-96-671

Sight Gauge Kit....................................................... GRP-96-825

Wall Mounting Bracket

L-Type (Body)....................................................... GPA-96-604

L-Type (Bonnet)................................................... GPA-96-606

T-Type.................................................................. GPA-96-602

B

40

B18-03-FK00

SECONDARY PRESSURE

Accessories

60

2.0

0

Adjusting Knob................................................... RRP-16-340-000

Diaphragm Assembly –

Non-relieving......................................................... RRP-96-657

Relieving................................................................ RRP-96-656

Spring, Regulating –

0 to 30 PSIG (0 to 2.1 bar).................................... RRP-96-659

0 to 60 PSIG (0 to 4.1 bar).................................... RRP-96-660

0 to 125 PSIG (0 to 8.6 bar).................................. RRP-96-661

0 to 250 PSIG (0 to 17.2 bar)................................ RRP-96-662

Valve Assembly......................................................... RRP-96-658

100

6.0

1.0

Replacement Kits

Inlet Pressure = 100 PSIG (6.9 bar)

PSIG

Type “A”, 5 Micron......................................................FRP-96-639

Retainer, Deflector, and Element Kit......................... FRP-96-641

7.0

SECONDARY PRESSURE

Replacement Element Kits

PSIG

B18-02-FK00

Metal Bowl –

Sight Gauge, Automatic Drain.............................. GRP-96-637

Sight Gauge, Manual Drain................................... GRP-96-636

Plastic Bowl –

Bowl Guard, Automatic Drain................................ GRP-96-635

Bowl Guard, Manual Drain.................................... GRP-96-634

Bowl Guard, Closed Bottom.................................. GRP-96-638

MIL72 Series

Electromechanical Time Switches

Project:

Location:

MIL72 Series

Product Type:

Surface/DIN Rail or Flush Mount Time Switches

Contact/Phone:

The MIL72 Series 24-Hour/7-Day Time Switches are designed to be

mounted inside a control panel and can accommodate surface/DIN Rail Model #:

or flush/panel mounting. The time switches are light-duty commercial

switches ideal for 24, 120, or 208/240 VAC single phase applications,

such as lighting control, HVACR, pumps, motors, fan controls, access

controls, OEM applications, agricultural facilities, and general purpose

electrical circuits.

Features

• Synchronous drive or quartz drive with battery backup

• 21 Amp SPDT switch

• Captive trippers with 15-minute intervals on 24-Hour models and

2-hour intervals on 7-Day models

• Available with or without override

• True clock face, easy to set

• Surface/DIN Rail or Flush Mount

• Clear plastic dust-cover

• 24-Hour or 7-Day applications

Ratings

Switch Rating:21A Resistive @ 120-250 VAC

1 HP @ 120 VAC

2 HP @ 250 VAC

1350 W Tungsten @ 240 VAC

MIL72ASWUZH

Wiring Connections:Screw terminal connections (MIL72A)

1

⁄4" quick connects (MIL72E) accepts up

to #12GA wire

Operating Temperature:-40ºF to 185ºF (-40ºC to 85ºC)

with battery backup -4ºF to 131ºF

(-20ºC to 55ºC)

Operating Humidity: 0 to 95% non-condensing

Battery Backup Option:

7-Days carryover

Supply Voltage: 24, 120, and 208/240 VAC, 60 Hz models

Quartz:12, 24 VAC/DC, 120 and 208/240 VAC

50/60 Hz

Power Consumption: 24 VAC: 0.1 VA

120 VAC: 0.5 VA

240 VAC: 1.0 VA

Shipping Weight:

1 lb.

MILE Cutout:

2 5⁄8" x 2 5⁄8"

MIL72ESTUZ

HVACR

#LR3730

#E10694

Energy Controls

MIL72 Series

MIL72 Series Ordering Data

Complete Model Number = MIL72A or E followed by suffix code and voltage, Example: MIL72A STuZ-24

Synchronous

Without Override

Quartz-7 Day Carryover*

With Override

Without Override

MIL72A-Surface Mount/DIN Rail

MIL72E-Flush Mount

Input

Voltage

With Override

Switch

Rating

Minimum

ON/OFF Time

24 Hour Time Control

STuZ-24

STuZH-24

QTuZ-24

QTuZH-24

24 VAC

SPDT 21A

15 Minutes

STuZ-120

STuZH-120

QTuZ-120

QTuZH-120

120 VAC

SPDT 21A

15 Minutes

STuZ-240

STuZH-240

QTuZ-240

208/240 VAC

SPDT 21A

15 Minutes

MIL72A-Surface Mount/DIN Rail

MIL72E-Flush Mount

7 Day Time Control

SWuZ-24

SWuZH-24

QWuZH-24

24 VAC

SPDT 21A

2 Hour

SWuZ-120

SWuZH-120

QWuZ-120

QWuZH-120

120 VAC

SPDT 21A

2 Hour

SWuZ-240

SWuZH-240

QWuZ-240

QWuZH-240

208/240 VAC

SPDT 21A

2 Hour

*Quartz models operate on 12, 24 VAC/DC, 120 and 208/240 VAC and 50/60 Hz

Specifications

Furnish and install a Grässlin MIL72 ________ (24-Hour)(7-Day) time switch with______(15-Minute)(2-Hour) interval

captive trippers and____________(Quartz)(Synchronous) drive. Input voltage shall be_______(120)(24)(208/240) VAC and

SPDT switch contacts shall be rated at 21A Resistive, 2 HP @ 250 VAC. To set the starting time and provide time indication, the unit shall incorporate an authentic clock face. Installation available for surface, flush, DIN Rail mounting. The

time switch shall contain a 3-way OFF/AUTO/ON override. For carryover: the time switch shall have a quartz drive with

7-Day reserve carryover from a rechargeable battery.

Diagrams

Timer

T

1

3

COM

2

4

N.O.

5

N.C.

LOAD

120 VAC

H

N

or

or

-(DC)

+(DC)

12-24 VDC (Quartz Only)

With clear

dust-cover

2.83"

[72 mm]

With clear

dust-cover

2.83"

[72 mm]

2.06"

[52 mm]

1.56"

[39.5 mm]

I

I

0

4.00"

[102.5 mm]

2.60"

[66 mm]

0

.80"

[20.5 mm]

MIL72A

Energy Controls

2.60"

[66mm]

1.50"

[38 mm]

MIL72E

www.intermatic.com

1.36"

[34.5 mm]

4 0 0 S e r i es

400 Seri es

Pressure, Vacuum, Differential Pressure

AND Temperature SWITCHES

features

• 1, 2 & 3 switch outputs

• Epoxy-coated enclosure designed

to meet enclosure type 4X

• Wide variety of pressure sensors and

materials

• Setting via reference dial or hex

screw adjustment

• FM approved

• Adjustable Ranges:

"WC ranges: 300 "wc vacuum to 250 “wc

pressure (-746,7 to 622,3 mbar)

Pressure: 30 “Hg Vac to 6000 psi

(-1,0 to 413,7 bar)

Differential pressure: 1"wcd to 200 psid

(2.5 mbar to 13,8 bar)

Temperature: -180 to 650 °F

(-117.8 to 343.3 °C)

4 0 0 - B - 0 7

400 Seri es

400 S e r i e s

overview

features

The 400 Series is a versatile family of vacuum, pressure, differential

pressure and temperature switches for applications that require single

or multiple switching capabilities. Dual and triple switch versions

provide multi-output for alarm and shutdown, pre-alarm and alarm,

high/low limit or level staging functions.

• UL listed and cUL certified.

A wide variety of microswitch and process connection options, along

with a weather-tight enclosure, make the 400 Series an ideal choice

for most ordinary location applications. Its worldwide use is assured

with approvals and certifications to agency standards.

• Optional ATEX or GOST intrinsic

Widely used throughout the process industries, the 400 Series

provides threshold protection and control for many critical functions.

Typical installations are found in industrial gas production, energy

generation including pumps, turbines and compressors, pulp and

paper, and water and wastewater treatment.

FM approved.

• CE compliant to low voltage

directive and pressure equipment

directive.

safety compliance.

• One, two or three switch outputs

may be separated up to 100% of

range.

• Wide variety of available options

and pressure sensor modules.

• Most models available for

immediate delivery.

Reference scale, for types B, E & H

with option M321

Differential Pressure

Model with M210

Option - Dial Indication

Enlarged View

Temperature Model with Remote Bulb

& Capillary and M321 option Gasketed Lexan® Window

Dual Switch, Low Water

Column Differential

Pressure Model

Lexan® is a registered trademark of Sabic Innovative Plastics

2

w w w

.

u e o n l i n e

.

c o m

4 0 0 - B - 0 7

400 Series

specifications

Storage temperature

-65 to 160°F (-54 to 71°C)

Ambient TEMPERATURE

limits

-40 to 160°F (-40 to 71°C); set point typically shifts less than 1% of range for

a 50°F (28°C) ambient temperature change

Set point

repeatability

Temperature models: ± 2% of full scale range

Pressure: models 126-376, 520-535, 540-547, 570-572, S126B-S164B: ± 2% of full scale range; models 440-457, 550-559: ± 1% of full scale range; models

610-614: ± 3% of full scale range

Shock

Set point repeats after 15 G, 10 millisecond duration

Vibration

Set point repeats after 2.5 G, 5-500 Hz

Enclosure

Die cast aluminum, epoxy powder coated, gasketed, captive cover screws

Enclosure

classification

Designed to meet enclosure type 4X requirements

Switch output

One, two or three SPDT switches, may be separated up to 100% of range except

models 521-524, 531-534: 50%; models 520, 525, 530, 535, 570-572: 30%; switches may be wired “normally open” or “normally closed”

Electrical rating

15 A 125/250/480 VAC resistive. Electrical switches have limited DC capabilities. Consult factory for additional information.

Weight

Approx. 3 to 7.5 lbs.; varies with model

Electrical

connection

One 3/4” NPT and two 7/8” diameter knockouts

Pressure

connection

All models 1/4” NPT (female) except models S126B-S164B, 520-535: 1/2” NPT

(female); models 540-547: 1/8" NPT (female) Temperature

assembly

‘E’ types use the same assemblies as ‘F’ types, however, range spans are limited

due to use of reference dials

Bulb and capillary: 6 feet 304 stainless steel

Immersion stem: models 120 &121: nickel-plated brass; optional 316L stainless steel available

Fill

Temperature Models: Model 1BS: solvent filled; models 2-8: non-toxic oil filled

Temperature

deadband

Type F typically 1% and type E, B & C typically 2% of range under laboratory

conditions (70°F ambient circulating bath at rate of 1/2°F per minute change)

Differential

pressure indicator

(option M210)

Differential pressure indication available J400K, J402K models 147-S157B; accuracy approximately 1-1⁄2% mid 50% of range, 3% at ends; window is plexiglass and gasketed; indicator may be field adjusted for approximately ±1% accuracy at any set point within range

4 0 0 - B - 0 7 w w w

.

u e o n l i n e

.

c o m

3

Namur/ISO Mounted

Pneumatic SR and DA Actuators

●

●

●

●

●

●

●

● Stainless steel end cap and travel stop fasteners

●

● Highly visible beacon indicator for 2 and 3 way

operation

050

065

075

085

110

125

140

160

210

250

280

050 050160

065 065190

075 075210

085 085250

095 110280

110 125300

125 140350

140 160

210

250

280

44psi

58psi

73psi

87psi

3×3

4×4

5×5

6×6

Operating Principle - Standard Rotation

Double Acting

CCW

CW

Air to Port A forces the pistons outwards,

causing the pinion to turn counter-clockwise

while air is being exhausted from Port B.

Air to Port B forces the pistons inwards,

causing the pinion to turn clockwise while air

is being exhausted from Port A.

Spring Return

CCW

CW

Air to Port A forces the pistons outwards,

causing the springs to compress. The pinion

turns counter-clockwise while air is being

exhausted from Port B.

During loss of air pressure, the stored energy in the spring forces the pistons inwards,

the pinion turns clockwise while air is being

exhausted from Port A.

2

Dimensions

Size

A

B

C

D

F

I

L

M

P

R

S

T

NPT

Z1

Double Acting

Spring Return

to

tc

lbs

to

tc

lbs

050 6.06 2.76 2.32 M5X8

3.15 0.47 1.14

1.63

0.79

1.26

0.94

1/4"

1.57

0.20

0.25

2.53

0.25

0.30

2.79

065 7.44 3.50 2.87 M5X8

3.15 0.63 1.50

2.03

0.79

1.26

0.94

1/4"

1.57

0.25

0.30

3.74

0.30

0.35

4.18

075 8.27 3.94 3.37 M5X8

3.15 0.63 1.71

2.32

0.79

1.26

0.94

1/4"

1.57

0.30

0.40

6.38

0.35

0.50

7.26

085 8.86 4.45 3.78 M5X8

3.15 0.67 1.93

2.50

0.79

1.26

0.94

1/4"

1.57

0.40

0.50

9.02

0.50

0.60

10.34

095 10.39 4.84 4.25 M5X8

3.15 0.75 2.17

2.80

0.79

1.26

0.94

1/4"

1.57

0.50

0.70

12.32

0.60

0.90

14.30

110 11.02 5.35 4.80 M5X8

3.15 0.83 2.44

3.01

0.79

1.26

0.94

1/4"

1.57

0.70

0.90

19.14

0.80

1.10

22.00

125 12.76 6.34 5.45 M5X8

5.12 0.87 2.83

3.35

1.18

1.26

0.94

1/4"

2.28

0.90

1.20

24.20

1.10

1.40

28.60

140 13.62 7.01 6.14 M5X8

5.12 1.06 3.19

3.82

1.18

1.26

0.94

1/4"

2.28

1.20

1.50

33.00

1.40

1.80

39.60

160 16.22 7.87 6.77 M5X8

5.12 1.06 3.54

4.17

1.18

1.26

0.94

1/4"

2.28

1.50

1.80

39.60

1.70

2.10

50.60

190 20.08 9.13 7.91 M6X10 5.12 1.50 3.50

4.41

1.18

1.77

1.57

1/4"

2.28

2.00

2.40 59.40

2.20

2.80

72.60

210 21.65 10.04 8.94 M5X8

5.12 1.50 4.55

4.61

1.18

1.77

1.57

1/4"

3.35

2.70

3.50

3.20

4.00

96.80

250 26.77 12.01 9.94 M6X10 5.12 1.97 5.51

6.10

1.18

1.77

1.57

1/2"

3.35

3.50

4.10 158.40 3.70

3.90 176.00

280 29.06 12.99 11.97 M6X10 5.12 1.97 5.98

6.57

1.18

1.77

1.57

1/2"

3.35

3.70

4.00 215.60

300 31.97 13.94 12.76 M6X10 5.12 1.97 5.94

6.81

1.18

1.77

1.57

1/2"

3.35

4.00

4.20 193.60 3.90

4.00 242.00 4.00

5.00 275.00

350 34.53 16.14 14.96 M6X10 5.12 1.97 7.28

7.68

1.18

1.77

1.57

1/2"

3.35

8.00

8.00 453.20 6.00

10.00 523.40

77.00

t o = opening time, in seconds

t c = closing time, in seconds

lbs = weight in pounds

* = available on request

The above mentioned operating times are obtained under the following conditions:

Air supply pressure minimum 80 psi, at room temperature, medium clean air, actuator stroke 90°, actuator without resistance load

3

Dimensions

□C

H

□ CH

Size

ISO 5211

Q1

Q

W

W1

050

F03/05

1.97

1.42

10-24 UNC

1/4-20 UNC

065

F05/07

2.76

1.97

1/4-20 UNC

5/16-18 UNC

0.43

0.55

075

F05/07

2.76

1.97

1/4-20 UNC

5/16-18 UNC

0.55

085

F05/07

2.76

1.97

1/4-20 UNC

5/16-18 UNC

0.67

095

F07/10

4.02

2.76

5/16-18 UNC

3/8-16 UNC

0.67

110

F07/10

4.02

2.76

5/16-18 UNC

3/8-16 UNC

0.67

125

F07/10

4.02

2.76

5/16-18 UNC

3/8-16 UNC

0.87

140

F10/12

4.92

4.02

3/8-16 UNC

1/2-13 UNC

1.06

160

F10/12

4.92

4.02

3/8-16 UNC

1/2-13 UNC

1.06

190

F10/14

5.51

4.02

1/2-13 UNC

5/8-11 UNC

1.42

210

F10/14

5.51

4.02

3/8-16 UNC

5/8-11 UNC

1.42

250

F16

6.50

-

-

3/4-10 UNC

1.81

280

F16

6.50

1.81

F16

6.50

-

3/4-10 UNC

300

-

3/4-10 UNC

1.81

350

F25

10.00

-

-

5/8-11 UNC

1.81

4

Spring Return Exploded View

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

Description

Indicator

Spring Clip

Thrust Washer

Outside Washer

Body

Inside Washer

Cam

O-Ring (Pinion Top)

Bearing (Pinion Top)

Pinion

Bearing (Pinion Bottom)

O-Ring (Pinion Bottom)

Plug

O-Ring (Adjusting Screw)

Washer (Adjusting Screw)

Nut (Adjusting Screw)

Adjusting Screw

Piston

Guide (Piston)

O-Ring (Piston)

Bearing (Piston)

Spring

O-Ring (End Cap)

End Cap

Cap Screw

Materials of Construction

Quantity

1

1

1

1

1

1

1

1

1

1

1

1

2

2

2

2

2

2

2

2

2

6-12

2

2

8

* Available optional material: Viton or Silicone.

5

Standard material

Plastic/Stainless Steel

Stainless Steel

Stainless Steel

Engineering Plastics

Extruded Aluminum Alloy

Engineering Plastics

Stainless Steel

NBR *

Engineering Plastics

Alloy Steel

Engineering Plastics

NBR *

NBR *

NBR *

Stainless Steel

Stainless Steel

Stainless Steel

Cast Aluminum

Engineering Plastics

NBR *

Engineering Plastics

Spring Steel

NBR *

Cast Aluminum

Stainless Steel

Double Acting Exploded View

No.

Description

1

Indicator

Spring Clip

2

3

Thrust Washer

4

Outside Washer

Body

5

6

Inside Washer

7

Cam

O-Ring (Pinion Top)

8

Bearing (Pinion Top)

9

10

Pinion

Bearing (Pinion Bottom)

11

O-Ring (Pinion Bottom)

12

Plug

13

O-Ring (Adjusting Screw)

14

Washer (Adjusting Screw)

15

Nut (Adjusting Screw)

16

Adjusting Screw

17

18

Piston

Guide (Piston)

19

O-Ring (Piston)

20

Bearing (Piston)

21

O-Ring (End Cap)

22

End Cap

23

Cap Screw

24

* Available optional material: Viton or Silicone.

Materials of Construction

Quantity

1

1

1

1

1

1

1

1

1

1

1

1

2

2

2

2

2

2

2

2

2

2

2

8

6

Standard material

Plastic/Stainless Steel

Stainless Steel

Stainless Steel

Engineering Plastics

Extruded Aluminum Alloy

Engineering Plastics

Stainless Steel

NBR *

Engineering Plastics

Alloy Steel

Engineering Plastics

NBR *

NBR *

NBR *

Stainless Steel

Stainless Steel

Stainless Steel

Cast Aluminum

Engineering Plastics

NBR *

Engineering Plastics

NBR *

Cast Aluminum

Stainless Steel

Torque Rating

•

Spring Return Actuators [ lb-in ]

Size

Springs

per side

Air Supply in psi

45 psi

60 psi

75 psi

80 psi

90 psi

Spring [ lb-in ]

116 psi

0°

52

90°

36

0°

82

70

90°

65

49

0°

112

99

88

90°

96

78

61

0°

126

114

102

90

90°

110

93

75

58

0°

141

129

117

105

90°

125

107

90

73

0°

199

188

175

164

90°

183

166

149

132

90°

51

69

86

104

0°

35

48

59

72

3

4

5

6

96

66

149

129

118

89

201

181

161

170

140

110

227

207

187

167

196

165

136

106

252

233

213

194

222

192

162

132

356

336

317

297

326

296

266

236

89

122

150

179

50

79

118

118

3

4

5

6

191

125

295

255

228

166

397

358

319

331

270

209

449

410

371

332

382

321

260

198

500

461

422

383

434

373

312

250

706

667

628

589

640

579

518

456

186

245

306

367

118

157

196

235

085

3

4

5

6

291

180

453

389

342

239

615

550

485

504

401

299

696

631

566

502

548

482

380

278

777

712

647

582

666

563

461

358

1097

1035

974

903

991

885

788

681

307

409

512

613

195

259

325

389

095

3

4

5

6

437

288

673

582

523

383

912

818

728

761

610

480

1027

938

846

756

876

736

597

458

1142

1053

965

876

991

854

715

575

1611

1522

1434

1345

1460

1328

1186

1044

419

558

697

836

269

358

449

538

110

3

4

5

6

704

534

1089

938

826

594

1469

1319

1177

1204

974

743

1655

1513

1363

1221

1398

1168

929

699

1850

1699

1558

1407

1584

1354

1124

894

2611

2460

2319

2168

2345

2115

1885

1478

696

929

1159

1389

435

580

726

871

125

3

4

5

6

912

596

1407

1221

1089

794

1894

1708

1522

1575

1283

991

2142

1956

1770

1584

1823

1531

1239

947

2381

2195

2009

1823

2062

1779

1487

1195

3363

3177

2991

2805

3044

2752

2460

2168

876

1168

1460

1752

140

3

4

5

6

1434

938

2204

1912

558

743

929

1115

1708

1257

2974

2682

2390

2478

2027

1566

3354

3071

2779

2487

2867

2407

1956

1496

3744

3452

3159

2867

3248

2797

2336

1885

5283

4991

4699

4381

4788

4337

3876

3416

1372

1823

2283

2735

874

1168

1460

1752

160

3

4

5

6

1823

1248

2823

2425

2257

1664

3832

3434

3036

3257

2673

2080

4328

3929

3540

3142

3761

3168

2584

1991

4832

4434

4036

3637

4257

3673

3089

2496

6841

6443

6045

5646

6284

5691

5089

4505

1761

2354

2938

3531

1195

1593

1982

2381

190

3

4

5

6

3

4

5

6

2628

1708

4115

3505

3204

2274

5611

4991

4381

4691

3770

2841

5257

4337

3416

8850

8239

7319

6399

6682

5452

4221

5434

4514

3593

2664

7708

6487

5257

4027

6487

5868

5257

7868

7036

6213

6354

5735

5124

4505

8912

8080

7257

6425

9116

8284

7461

7514

6292

5062

12434

11602

10434

9213

2761

3690

4611

5531

3682

4903

6133

7363

1850

2460

3080

3690

2487

3310

4142

4965

3

4

5

6

6230

13178

11779

10381

11310

9275

7257

14921

13523

12125

10717

13045

11018

8983

6965

15266

13850

12452

12753

10726

8700

17691

15656

6089

8115

10142

12178

4213

5620

7018

8425

3

4

5

6

9177

19727

17514

15293

16603

13346

10089

22364

20151

17930

15709

19249

15983

12726

9470

22780

20567

18346

18629

15364

12107

6664

8885

11107

13319

3

4

5

6

12629

30409

27506

24594

21700

27391

23488

19576

15656

31064

28161

25258

27037

23125

19222

9779

13036

16302

19559

11735

15647

19559

23461

8717

11620

14523

17435

3

4

5

6

17426

37621

33834

30046

30294

24665

19045

42436

38639

34851

35099

29471

23851

16868

22497

28116

33745

11372

15160

18948

22745

050

3

4

5

6

065

075

210

250

280

300

350

3726

3416

4354

6053

9611

11921

5806

4974

9708

8301

14496

12231

4602

3381

7823

5806

11337

8071

19744

16833

16727

12815

26860

23948

21045

23842

19936

16019

27019

23231

19443

21523

15895

10275

36621

32825

29037

31125

25497

19877

25249

14249

7

20815

19408

31125

28904

57835

54047

25931

22656

48675

43046

Torque Rating

•

Double Acting Actuators [ lb-in ]

Air Supply in psi

Size

45 psi

60 psi

75 psi

80 psi

90 psi

116 psi

032

32

42

53

58

64

85

050

89

118

147

162

176

235

065

156

208

259

285

312

415

075

309

412

515

566

618

824

085

486

648

810

894

974

1292

095

706

938

1177

1292

1416

1885

110

1142

1522

1903

2106

2283

3044

125

1469

1965

2451

2699

2938

3921

140

2310

3080

3850

4230

4620

6160

160

3009

4018

5018

5522

6027

8036

190

3018

6390

7098

8160

9585

12779

210

6018

8027

10036

11036

12213

16054

250

10664

14222

17780

19559

21329

28444

280

15833

20957

26400

29028

31665

42232

300

21382

19656

35639

39197

42763

57012

350

28798

38391

47994

52790

57569

76791

HYDROBURST COMPONENTS

Skid Mounted Package Includes:

1 – Saylor-Beall 20HP, Base Mounted, Pressure Lubricated,

Reciprocating Type Air Compressor with a Capacity of 76.1 ACFM

@ 175 PSIG and the following:

3/60/460V, TEFC High Efficiency Electric Motor

OSHA Style, Totally Enclosed Belt Guard

Auto Start-Stop Pressure Switch, NEMA 4X

Low Oil Pressure Shutdown Switch

Hydraulic Unloader

10 Micron Inlet Air Filter

Flexible Discharge Hose & Check Valve

Vibro Isolation Pads

Factory Fill of Synthetic Lubricant

1 – Control Panel, NEMA 4 Enclosure with:

3/60/460V Motor Starter

U/L Label

Fusible Disconnect Switch

Control Voltage Transformer

7-day Programmable Backwash Timer

Overload Reset Push Button

Control Power On-Off Selector Switch

Compressor Test-Off-Auto Selector Switch

Cycle Local-Remote Selector Switch

Two (2) Valve Open-Close-Auto Selector Switch

Cycle Start Push Button

Control Power On Pilot Light

Cycle In Progress Pilot Light

Adequate Air Pressure Pilot Light

Two (2) Backwash Valve Fully Open Pilot Light

Two (2) Backwash Valve Fully Closed Pilot Light

Low Air Pressure Alarm Pilot Light

Low Oil Pressure Alarm Pilot Light

Auxiliary Contacts

Extra Set of Motor Fuses

Extra Set of Primary Transformer Fuses

Extra Control Fuse

Bilfinger Water Technologies, Inc.

1950 Old Hwy 8 NW

New Brighton, MN 55112

USA

Phone +1 651 636 3900

Fax +1 651 638 3132

usa.water@bilfinger.com

www.water.bilfinger.com

Page 2 / 3

1 – Control Air Receiver with:

Inlet Check Valve

Pressure Gauge

Safety Valve

Filter/Regulator with Gauge

Manual Drain Valve

1 – Dual Pressure Switch, NEMA 4X, for Valve Sequencing and

System Air Pressure Pilot Light Initiation

The Above Components to be Mounted, Piped & Wired on a 54“ x

60“ Rigid Steel Skid with Full Deck Plate and Fork Pockets. Skid to

be Primed and Finish Painted with Industrial Enamel.

The Following Items are to be Shipped Loose for Site Installation:

1 – 1550 Gallon Vertical Air Receiver, ASME Coded for 200 PSIG

MWP with:

Safety Valve

Pressure Gauge

Float Type Auto Drain

One (1) 6” Size Flanged Discharge Port

All Standard Openings

2 – 6” Size High-Performance Lug Style Butterfly Valve with:

Construction: 225 PSIG MWP, Ductile Iron Body,

Stainless Steel Disc & Stem, EPDM Seals

Spring-Return Pneumatic Actuator

Single Solenoid Control Valve w/ Manual Override

Position Indicator with Limit Switches

Page 3 / 3

Site Wiring to Include:

Wiring of 3/60/460V Main Power to Control Panel

Wiring of Control Panel to Butterfly Valve Solenoid

Control Valve & Limit Switches

Site Piping to Include:

1.25” Piping from Air Compressor to Main Air Receiver

0.50” Piping of Safety Valve, Pressure Gauge, Dual

Pressure Switch & Auto Drain Valve to Main Air

Receiver

0.50” Piping from Main Air Receiver to Control Air

Receiver

0.25” Piping from Control Air Receiver to Butterfly

Valve Solenoid Control Valve

6” Flanged Piping from Main Air Receiver to Butterfly

Valves

6” Flanged Piping from Butterfly Valves to Intake

Screens