Master V2 Tech Specs 20022006

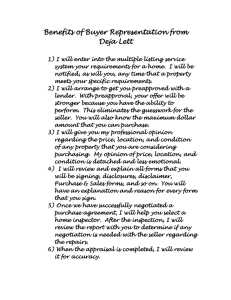

advertisement