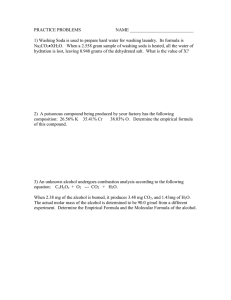

16. Washing 1 16.1 Purpose 1 16.2 Factors to Consider 1 162.1

advertisement