CleanLogix Application Note AN1002

Scouring and Surface Preparation of Silicone

Rubbers (and other materials)

APPLICATION NOTE

By David Jackson

Application Note AN1002

© CleanLogix

All Rights Reserved

\

Introduction to Silicone Rubbers

Figure 1 shows a molecular model for polydimethylsiloxane or PDMS, a common

silicone polymer. Cured silicones are an elastomer (a rubber-like material)

composed of siloxanes; silicon together with carbon, hydrogen, and oxygen.

Silicone rubbers are widely used in industry, and there are multiple formulations.

Silicone rubbers are often one- or two-part polymers, and may contain fillers or

additives to improve properties or reduce cost. Silicone rubber is generally nonreactive, stable, and resistant to extreme environments and temperatures from

−55 °C to +300 °C while still maintaining its useful mechanical and chemical

properties. Due to these properties and its ease of manufacturing and shaping,

silicone rubbers can be found in a wide variety of products, including: aerospace

Figure 1

3-D Molecular Model for PDMS

applications such as electronic cabling, vibration dampers and electrical device

insulators; biomedical devices and implants; and pharmaceutical devices such as

seals, liners and septa. During manufacture, heat may be required to vulcanize

(set or cure) the silicone into its rubber-like form. This is normally carried out in a

two stage process at the point of manufacture into the desired shape, and then in

a prolonged post-cure process. Silicones can also be injection molded and can

include special monomer chemistries and properties such as fluorinated

chemistry, steam resistant, metal detectable, fluorescent, electrically conductive,

chemically resistant, low-smoke emitting, and flame-retardant. Example physical

properties of a silicone rubber (e.g., LSR Polymax 2005) are shown in Table 1.

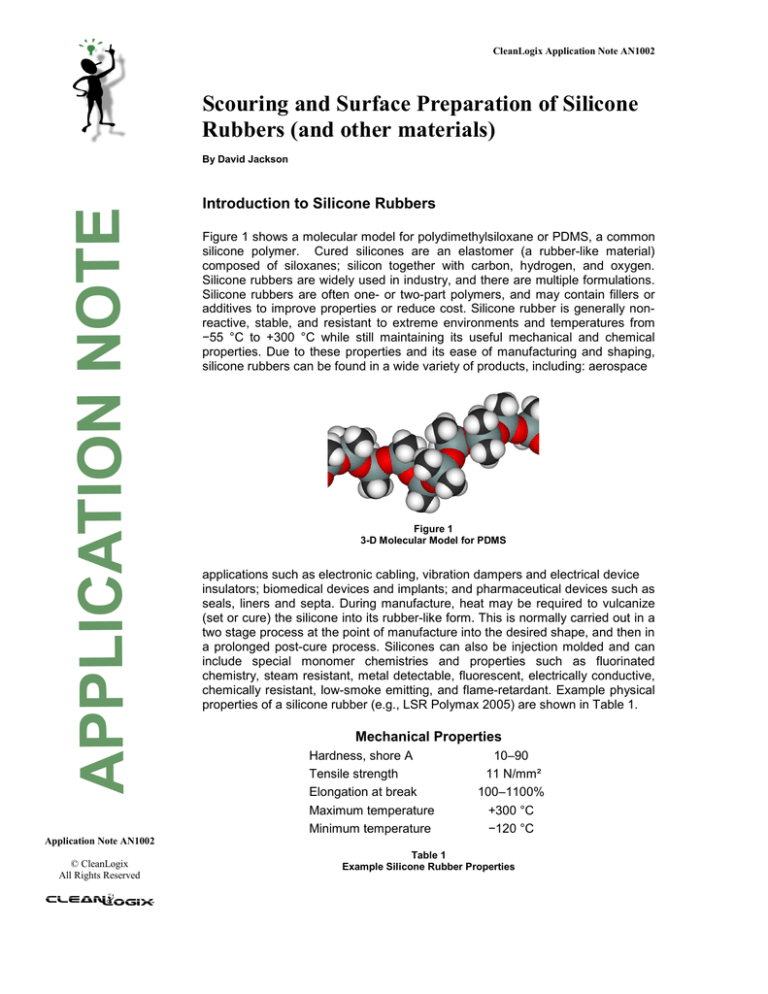

Mechanical Properties

Hardness, shore A

Tensile strength

Elongation at break

Maximum temperature

Minimum temperature

10–90

11 N/mm²

100–1100%

+300 °C

−120 °C

Table 1

Example Silicone Rubber Properties

CleanLogix Application Note AN1002

Silicone Rubber Contamination

Following conventional liquid silicone rubber (LSR) molding and curing

processes, and depending upon the type and amount of additives, cure cycle

times and conditions; solidified rubber products can contain up to 10% (by

weight) residual unreacted monomer fragments (called “oligomers”), fillers and

other interstitial residues; more simply termed “silicone contamination” for the

purposes of this application note. Silicone contamination is generally non-toxic,

biocompatible, non-corrosive, and non-volatile under standard temperature and

pressure conditions (STP). However portions of it can migrate to the surface or

out of the material entirely, when the surface is cleaned or exposed to non-steady

state environmental conditions in accordance with Fick’s molecular diffusion

principle. Residual silicone contamination can usually be left within the bulk

solidified material for many industrial and commercial applications, and may in

fact be required for the desired performance properties. However silicone

contamination, in particular volatile or mobile forms, can be problematic in certain

applications or systems involving biomedical, aerospace, and pharmaceutical

devices employed in aqueous, solvent or vacuum environments. For example,

silicone oligomers (considered a “leachable” contaminant) can be extracted from

silicone rubbers located within aqueous or solvent environments and volatilized

(considered an “outgas” contaminant) when situated within hot and/or vacuum

environments.

Examples of situations and environments where silicone

contamination poses a potential threat include vacuum systems, thermal

systems, space environment, the human body, or as components of containers

used to store liquids. Moreover, silicone contamination can present problems

during manufacturing processes such as plasma surface modifications and

materials joining. Silicone contamination is also a contamination concern in

critical manufacturing environments, for example cleanrooms used to fabricate

semiconductor chips and hard disk drives.

Aerospace,

Pharmaceutical, and

Medical Products

Application Note AN1002

© CleanLogix

All Rights Reserved

\

For example, in spacecraft applications silicone oligomers will “outgas” from the

pores of the bulk material under the absolute vacuum of space, migrating along

internal thermal gradients created by the spacecraft rotation into and away from

the Sun.

This can relocate silicone contamination into or onto critical

optoelectronic systems such as navigational or observation devices, causing

potential optical surface obscuration. In another example, the performance of

heat exchange surfaces can be negatively affected if coated with thin heatinsulating layers of silicone contamination and other forms of “volatile

condensable matter” or VCM. In pharmaceutical applications, silicone

contamination can be leached from container seals or septa by solvent-based

diluents. In medical applications, silicone contamination can leach from a silicone

rubber device such as tubing or sleeves and cause unwanted cellular responses

or cellular adhesion problems. Still moreover, subsurface silicone contamination

will migrate from the interior of the bulk substrate and onto the surface regions

during vacuum-based processes such as plasma treatment, interfering with the

formation of clean functionalized surfaces or shortening the longevity of same.

Finally, surfaces containing silicone contamination interfere with adhesive

bonding mechanisms, preventing the formation of strong chemical and

mechanical adhesive bonds.

One of the difficulties in modifying silicone surfaces relates to the mobile nature of

amorphous polymer molecules. For example, during surface modification, for

example oxidation, of a silicone rubber surface, molecular motions can (over a

period of time) cause the modified surface to intermingle and diffuse into the

CleanLogix Application Note AN1002

polymer matrix. This tendency is most pronounced in silicone elastomers which

have very mobile polymer chains. To overcome this problem, plasma treatments

may be used to crosslink and stabilize the polymeric surface. However, within

hours or even minutes after plasma treatment, the surface begins to revert back

to its original hydrophobic state. Uncrosslinked oligomers and low molecular

weight oils begin to migrate to the polymeric surface in accordance with Fick’s law

of molecular diffusion - migration of polymers from interior regions of high

concentration to exterior surface regions having a low concentration. These oils

tend to interfere with attachment or grafting of coatings to the polymer surface in

the case of plasma coating. These oils also prevent the formation of strong

chemical and mechanical adhesive bonds in adhesive bonding applications.

Conventional Silicone Rubber Treatment Solutions

There are generally three conventional treatment methods used to clean, scour,

or fully-react silicone substrates, respectively, described as follows:

•

•

•

Solvent Extraction

Thermal Vacuum Bakeout

Enhanced Silicone Curing Processes

Solvent extraction using organic solvents or solvent blends can be a very slow

process, and can alter the mechanical properties of certain silicone devices.

Extraction with toxic or flammable solvents on a large scale is dangerous and

consumes significant amounts of energy. Moreover, residual extraction solvent

residues left in the pores of the silicone rubber can be problematic to the function

or performance of the extracted device.

An alternative to solvent extraction is thermal vacuum bakeout or TVB. The TVB

process extracts oligomers from the bulk polymer using a high vacuum (i.e. less

-5

than 1x10 Torr) and heat (i.e., 125 deg. C) over an extended period of time.

TVB extraction proceeds somewhat slowly - for example up to 80 hours or more and usually degrades the mechanical properties of the silicone rubber due to

accelerated thermal aging. In addition, TVB-treated silicone rubbers can burn or

exhibit color change.

Conventional Solvent

Extraction using a

“Soxhlet Extractor”

An alternative to post-treat methods is more complete vulcanizing or curing to

convert most of the silicone monomer into solid polymer. These methods include

peroxide (free radical) and platinum (addition) curing techniques. However, these

curing processes create constraints as well. Peroxide curing can lead to

microscopic bubbles, surface darkening and a tackier surface (i.e., can pick up

more dirt). Platinum curing is a cleaner but a more expensive treatment process

and is typically used only in critical applications such as medical implants – socalled medical grade silicones. Also, platinum-cured silicones exhibit higher wear

rates and spallation relative to peroxide-cured silicones when used in mechanical

devices such as pumps.

As such, all conventional silicone rubber treatment methods (i.e., post-treatment

and curing methods) offer tradeoffs in terms of processing time, life-cycle costs

and end-product performance.

Application Note AN1002

© CleanLogix

All Rights Reserved

\

A newer treatment technique that is generally unknown or not well understood by

silicone device manufacturers is carbon dioxide processing, or simply “CO2

Processing”. CO2 processing uniquely employs one or a combination of solid,

liquid, supercritical, and plasma CO2 chemistries and processes to treat silicones,

CleanLogix Application Note AN1002

as well as many other types of substrates requiring dry scouring and/or surface

treatment. CO2 processing offers silicone device manufacturers a robust, lean

and green cleaning (and surface treatment) option that can provide distinct

economic and performance advantages relative to the conventional treatment

processes. CO2 processing of silicone rubbers using supercritical and liquid CO2

was first developed in the 1980’s at Hughes Aircraft to prepare materials for use

in high reliability commercial and military communications satellites and spacebased warfare systems, enabling silicone devices to operate in the harsh

environment of space without contaminating and degrading the performance of

critical flight hardware.

The CO2 Alternative

Our CO2 processing technology provides silicone (and other biomedical polymer)

device manufacturers a robust platform of post-cure or post-process substrate

treatment options, and includes:

•

•

•

Centrifugal CO2™ Immersion-Extraction Cleaning

CO2 Composite Spray™ Cleaning

CO2 Plasma Blast™ Surface Modification

Centrifugal CO2™ Immersion-Extraction Cleaning

Dense phase (liquid and supercritical) CO2 is a non-toxic solvent that dissolves

many types of organic films and oils, and is particularly suited to dissolving and

removing unreacted silicone oils. Near-zero or zero (supercritical state) surface

tension and low viscosity allows dense phase CO2 to penetrate microscopic pores

and crevices, delivering solvent cleaning power deep into the interior of silicone

rubber. With our patented Centrifugal CO2™ immersion-extraction cleaning

processes, contamination is rapidly removed from silicone rubber under both

physical (centrifugal pumping and scouring) and chemical cleaning actions.

Figure 2 shows a typical immersion-extraction profile for PDMS using a

Centrifugal CO2 cleaning process employing liquid CO2.to meet ASTM E 595

outgas performance criteria - total mass loss (TML) of < 1.00 % and collected

volatile condensable material (CVCM) of < 0.10%.

CO2 Treatment

Chemistries

Solid, Liquid,

Supercritical and

Plasma

(Top-to-Bottom)

Application Note AN1002

© CleanLogix

All Rights Reserved

Centrifugal CO2 cleaning processes employ either liquid or supercritical CO2 and

require no special permits even from the tough SCAQMD or EPA because it is

non-toxic, non-flammable, and non-VOC. Integrated CO2 distillation recycles

nearly 100% of the CO2 extraction solvent while separating and concentrating

silicone oils (and solvent modifiers if present). Optionally, Centrifugal CO2

processes can be hybridized with other treatment processes such as lowpressure plasma to provide cleaned-surface modifications, bio-burden reduction,

or to assist with outgassing and decomposing residual interstitial contaminants.

Any “Industry Approved” or “Mil-Spec” extraction cleaning solvent additive may be

used with the Centrifugal CO2 process as a “carbonated” prewash-extraction

agent or CO2 chemistry modifier, providing numerous novel and dry immersionextraction cleaning chemistries. This would be important when a particular

cleaning-extraction chemistry is needed that mimics a particular solvent

environment (polar, non-polar, ionic) in which the processed substrate will be

exposed; for example a specific pharmaceutical drug solvent carrier. This allows

for the continued use of a “spec’d in” immersion-extraction cleaning solvent

chemistry – but in a safer and more robust cleaning process.

CleanLogix Application Note AN1002

Finally, our CO2 Composite Spray™ and CO2 Plasma Blast™ Particle-Plasma

surface treatment processes serve as adjuncts or alternatives to the Centrifugal

CO2 process; providing a very robust surface treatment platform capability, and

are described below.

Silicone Extraction Profile

2.50%

% TML

2.00%

1.50%

ASTM E 595

1.00%

TML

CVCM

WVR

0.50%

0.77%

0.01%

0.29%

0.00%

0

10

20

30

40

50

Time (minutes)

Figure 2

TML Profile for PDMS

CO2 Composite Spray™ Cleaning

CO2 Composite

Spray™

Treatment

The cleaning phenomenon involved in our CO2 Composite Spray™ cleaning

technology are analogous to (line-of-sight) high-pressure spray cleaning using

halogenated solvents such as HFE 7100. For example, one similarity is the high

density (1.6 g/cm3) of the solid CO2 solid particles entrained in an inert heated

propellant fluid such as CDA. CO2 Composite Spray surface cleaning is a

nonabrasive process because of the low hardness of the CO2 particles (less than

1 Mohs) as compared to most conventional manufacturing substrates. Moreover,

and similar to high-pressure solvent spray cleaning, CO2 Composite Spray

cleaning provides physical momentum transfer (shear stress) and unique phase

change phenomenon (solidliquid) – providing scouring liquid solvent cleaning

action at the contact surface to simultaneously remove both particulate and thin

film oily contamination from a surface.

A CO2 Composite Spray exhibits halogenated solvent-like chemistry which

provides both physical scouring and chemical cleaning action for contaminated

surfaces. A CO2 Composite Spray can be adjusted in several dimensions – with

key process variables including pressure, temperature, particle size and

concentration – to provide a range of impact shear stresses and cleaning effects.

In addition, a CO2 Composite Spray can be modified with liquid, gas and solid

additives to provide a range of surface cleaning chemistries and modification

capabilities. Figure 3 demonstrates the removal of microscopic inorganic metal

oxidation residues from the surfaces of a laser welded titanium neurostimulator

lead using a CO2 Composite Spray.

Application Note AN1002

© CleanLogix

All Rights Reserved

Finally, the CO2 Composite Spray process can be further enhanced by

hybridizing it with atmospheric plasma - a patented and patents-pending method

called CO2 Plasma Blast™.

CleanLogix Application Note AN1002

Figure 3

Removal of Ti Weld Soot (Metal Oxides on Neurostimulator Lead)

CO2 Plasma Blast™ Treatment

The surface scouring and solvent cleaning actions of a CO2 Composite Spray™

are used in cooperation with atmospheric plasma CO2 (and other types of

plasma) to form a very robust surface cleaning and preparation treatment called

The CO2 Plasma Blast™ process is an atmospheric

CO2 Plasma Blast™.

hybrid particle-plasma surface ablation (i.e., treatment, transformation and

modification) process that combines electron and/or photon driven surface

ablation phenomena comprising an ionizing-heating plasma plume with

simultaneous surface scouring and cooling actions provided by the CO2

Composite Spray. Figure 4 demonstrates the significant improvement in light

cured acrylic adhesive bond strength for a low surface energy polymer (e.g.,

LDPE) using the CO2 Plasma Blast treatment process.

CO2 Particle-Plasma

Treatment

In this patent-pending surface treatment technique, the CO2 Composite Spray is

used to both precisely control surface temperature and cleanliness; the

simultaneous removal of heat contamination and processing debris such as

oxidation residues, gases, and ablated surface particles generated by the

atmospheric plasma process. Working in cooperation, atmospheric plasma

cracks and chemically alters the surface while CO2 particles and fluids

simultaneously vector surface debris and excess heat from the treated surface.

Application Note AN1002

© CleanLogix

All Rights Reserved

Figure 4

Improvement in Shear Strength

CleanLogix Application Note AN1002

Conclusion

Conventional pre- and post-treatment options for silicone rubbers pose different

constraints in terms cost of ownership, environmental, and material performance.

The CO2 alternative offers a robust platform for processing silicone rubbers for

medical, aerospace and pharmaceutical applications, as well as many other

types of polymers and surfaces requiring scouring and surface modification for

manufacturing processes such as bonding, coating and precision assembly. For

example, low energy polymers such as LDPE have been processed successfully

using CO2 processes.

Applicable Industries

Aerospace/Defense

Medical

Electro-Optical

Microelectronic

Applicable CO2 Technology

Centrifugal CO2™

CO2 Plasma Technology

CO2 Composite Spray™ Technology

Related Assembly Products/Processes

Surface Cleaning

Thermal Vacuum Bakeout

Solvent Extraction

Adhesive Bonding, Surface Modification and Coating

Select Industry Testing Standards

ASTM E 595

References

CO2 Processing

Application Note AN1002

© CleanLogix

All Rights Reserved

1. “Effect of Sterilization on the Mechanical Properties of Silicone Rubbers”,

Saint-Gobain Performance Plastics, Northboro R&D Center

2. ASTM E 595 Outgas Test Reports (Silicone Cable Extraction), Pacific Testing

Laboratories, Valencia, CA, Customer/Application Confidential

3. ASTM E 595-93, Standard Test Method for Total Mass Loss and Collected

Volatile Condensable Materials from Outgassing in a Vacuum Environment

4. “Peroxide or Platinum? Cure System Considerations for Silicone Tubing

Applications”, Dow Corning Healthcare

5. “Anatomy of an Ethylene oxide Sterilization Process”, Technical Tip #10,

Steris Isomedix Services

6. “The Leachable Challenge in Polymers used for Pharmaceutical Applications”,

Rubber World, Nov 2008.

Keywords

Silicone Rubber, TVB, Outgas, TML, CVCM, WVR, ASTM E 595

CleanLogix Application Note AN1002

Another clean idea…

Think Clean.

U.S. Sales and Applications R&D Group:

27636 N. Ave. Scott Unit C

Valencia, California 91355

(661) 257-7667

Asia Manufacturing and Sales Office:

CleanLogix Asia Pte. Ltd.

No. 2 Pioneer Sector 1

Singapore, 628414

www.cleanlogix.com

Cleanlogix LLC

Do not reproduce this document in whole or part.

Centrifugal CO2, CO2 Composite Spray, and

CO2 Plasma Blast are Trademarks of

CleanLogix LLC

All Rights Reserved

Patented and Patents-Pending

Cleanlogix Application Note AN1002 Surface Prep of Silicone Rubbers.PDF