The autofluorescence of plastic materials and chips

advertisement

PAPER

www.rsc.org/loc | Lab on a Chip

The autofluorescence of plastic materials and chips measured under laser

irradiation

Aigars Piruska,a Irena Nikcevic,a Se Hwan Lee,b Chong Ahn,b William R. Heineman,a Patrick A. Limbacha

and Carl J. Seliskar*a

Received 13th June 2005, Accepted 10th October 2005

First published as an Advance Article on the web 1st November 2005

DOI: 10.1039/b508288a

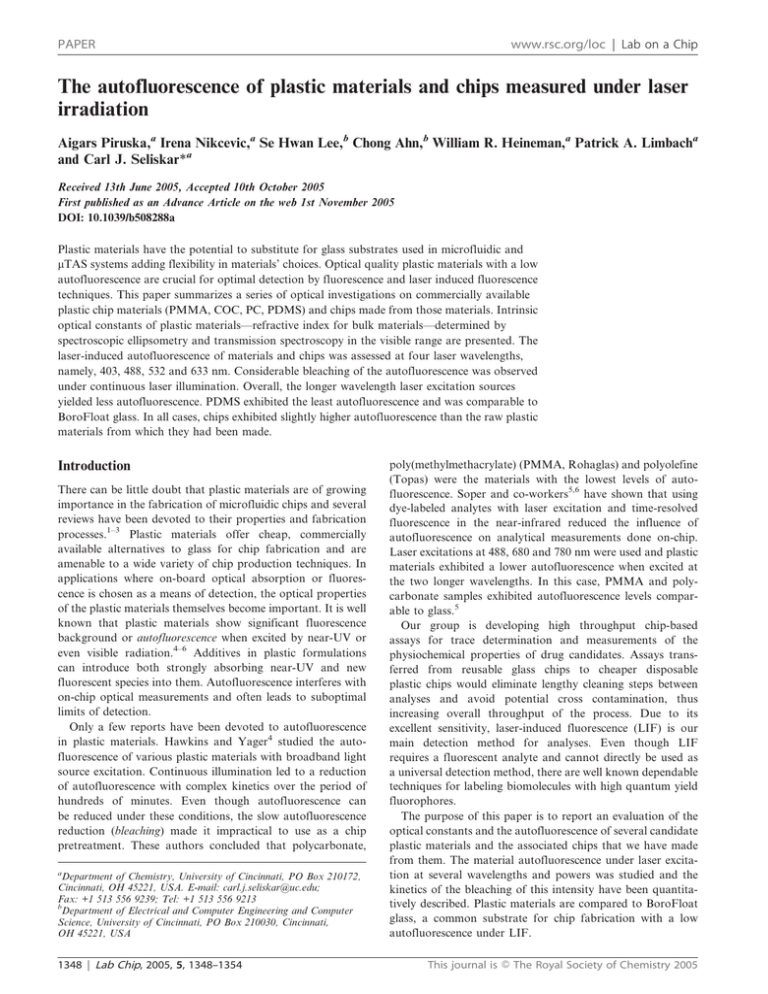

Plastic materials have the potential to substitute for glass substrates used in microfluidic and

mTAS systems adding flexibility in materials’ choices. Optical quality plastic materials with a low

autofluorescence are crucial for optimal detection by fluorescence and laser induced fluorescence

techniques. This paper summarizes a series of optical investigations on commercially available

plastic chip materials (PMMA, COC, PC, PDMS) and chips made from those materials. Intrinsic

optical constants of plastic materials—refractive index for bulk materials—determined by

spectroscopic ellipsometry and transmission spectroscopy in the visible range are presented. The

laser-induced autofluorescence of materials and chips was assessed at four laser wavelengths,

namely, 403, 488, 532 and 633 nm. Considerable bleaching of the autofluorescence was observed

under continuous laser illumination. Overall, the longer wavelength laser excitation sources

yielded less autofluorescence. PDMS exhibited the least autofluorescence and was comparable to

BoroFloat glass. In all cases, chips exhibited slightly higher autofluorescence than the raw plastic

materials from which they had been made.

Introduction

There can be little doubt that plastic materials are of growing

importance in the fabrication of microfluidic chips and several

reviews have been devoted to their properties and fabrication

processes.1–3 Plastic materials offer cheap, commercially

available alternatives to glass for chip fabrication and are

amenable to a wide variety of chip production techniques. In

applications where on-board optical absorption or fluorescence is chosen as a means of detection, the optical properties

of the plastic materials themselves become important. It is well

known that plastic materials show significant fluorescence

background or autofluorescence when excited by near-UV or

even visible radiation.4–6 Additives in plastic formulations

can introduce both strongly absorbing near-UV and new

fluorescent species into them. Autofluorescence interferes with

on-chip optical measurements and often leads to suboptimal

limits of detection.

Only a few reports have been devoted to autofluorescence

in plastic materials. Hawkins and Yager4 studied the autofluorescence of various plastic materials with broadband light

source excitation. Continuous illumination led to a reduction

of autofluorescence with complex kinetics over the period of

hundreds of minutes. Even though autofluorescence can

be reduced under these conditions, the slow autofluorescence

reduction (bleaching) made it impractical to use as a chip

pretreatment. These authors concluded that polycarbonate,

a

Department of Chemistry, University of Cincinnati, PO Box 210172,

Cincinnati, OH 45221, USA. E-mail: carl.j.seliskar@uc.edu;

Fax: +1 513 556 9239; Tel: +1 513 556 9213

b

Department of Electrical and Computer Engineering and Computer

Science, University of Cincinnati, PO Box 210030, Cincinnati,

OH 45221, USA

1348 | Lab Chip, 2005, 5, 1348–1354

poly(methylmethacrylate) (PMMA, Rohaglas) and polyolefine

(Topas) were the materials with the lowest levels of autofluorescence. Soper and co-workers5,6 have shown that using

dye-labeled analytes with laser excitation and time-resolved

fluorescence in the near-infrared reduced the influence of

autofluorescence on analytical measurements done on-chip.

Laser excitations at 488, 680 and 780 nm were used and plastic

materials exhibited a lower autofluorescence when excited at

the two longer wavelengths. In this case, PMMA and polycarbonate samples exhibited autofluorescence levels comparable to glass.5

Our group is developing high throughput chip-based

assays for trace determination and measurements of the

physiochemical properties of drug candidates. Assays transferred from reusable glass chips to cheaper disposable

plastic chips would eliminate lengthy cleaning steps between

analyses and avoid potential cross contamination, thus

increasing overall throughput of the process. Due to its

excellent sensitivity, laser-induced fluorescence (LIF) is our

main detection method for analyses. Even though LIF

requires a fluorescent analyte and cannot directly be used as

a universal detection method, there are well known dependable

techniques for labeling biomolecules with high quantum yield

fluorophores.

The purpose of this paper is to report an evaluation of the

optical constants and the autofluorescence of several candidate

plastic materials and the associated chips that we have made

from them. The material autofluorescence under laser excitation at several wavelengths and powers was studied and the

kinetics of the bleaching of this intensity have been quantitatively described. Plastic materials are compared to BoroFloat

glass, a common substrate for chip fabrication with a low

autofluorescence under LIF.

This journal is ß The Royal Society of Chemistry 2005

Experimental

Materials

The following commercially available materials were used:

1 mm BoroFloat (Schott), 5.0, 3.0 and 0.25 mm poly(methylmethacrylate) (PMMA, GoodFellow), 0.25 and 2.0 mm

polycarbonate (PC, GoodFellow), poly(dimethylsiloxane)

(PDMS, Dow Corning Sylgard 184 kit). PDMS sheets were

made by mixing base to curing agent at a 10 : 1 ratio (w/w),

degassing, pouring into a Petri dish, and degassing again.

PDMS sheets obtained were cured on a hotplate for 2 h at

80 uC. 1 mm thick sheets from cyclic olefin copolymer (COC,

Topas) were made by injection molding (IM). COC, PMMA

(GE Polymerland) and PC (GE Plastic) chips were fabricated

using injection molding.7 Additionally, PMMA (GoodFellow)

chips were made by hot embossing (HE).

Transmission spectra of materials were recorded on a HP

8453 diode array spectrophotometer and refractive indices

determined on a variable angle spectroscopic ellipsometer

(J.A.Woollam, Inc.).

translated on the sample stage to ensure a fresh unbleached

sample spot for illumination. All measurements were done

with a 106 microscope objective and at 1, 3 and 5 mW laser

power at the sample. For thin samples (0.25 mm sheets)

locations of the sample bottom and top surfaces were

determined and the objective adjusted to focus light midway

between these surfaces.

To examine how the autofluorescence changed with microscope objective-to-sample distance the following procedure

was used. The sample was placed on the calibrated microscope

stage and the positions of the bottom and top sample surfaces

located. Then the objective was backed off from the sample

(image plane closer to the objective than the sample bottom

surface). The objective was then moved toward the sample

in 250 mm steps and the autofluorescence signal recorded

continuously.

The long term recovery of material autofluorescence was

examined in the following way. A sample was aligned and

illuminated for 10 min as described above. The same spot was

then illuminated for an additional 10 min approximately 12 h

later while recording the autofluorescence.

Laser-induced fluorescence instrumentation

Material autofluorescence was measured using a Nikon TE

2000 epifluorescence microscope equipped with a H6780-20

PMT module (Hamamatsu) and a CoolSnap HQ CCD camera

(Roper Scientific). Current from the PMT was amplified with

a SR570 (Stanford Research) low current preamplifier and

digitized using a PCI P6036 DAQ card (National Instruments)

with software written in LabView (National Instruments). The

CCD camera was interfaced with a personal computer through

a PCI card and data were acquired using MetaMorph

(Universal Imaging Corporation) software. Four lasers

(20 mW, 403 nm, IQ2C20 (PTI Inc.); 50 mW, 488 nm,

(Melles Griot); 20 mW, 532 nm, 85-GCB-020 (Melles Griot);

35 mW, 633 nm, 25LHP928-249 (Melles Griot)), and a

Lambda LS xenon arc lamp (Sutter Instrument Company)

were used as light sources. The fluorescence and excitation of

the fluorescence were filtered by appropriate laser filter

sets (Chroma Inc.) for 405 nm (excitation filter z405/206;

dichroic mirror z405rdc; emission filter hq460/50m), 488 nm

(z488/106; z488rdc; hq525/50m), 532 nm (z532/106; z532rdc;

hq580/60m) and 633 nm (z633/106; z633rdc; hq685/70m).

Laser power was measured at the sample with a PM-300

(Kimmon Electric Co.) power meter.

Results and discussion

Optical properties of materials

A fundamental optical property of a material is the complex

refractive index, ñ = n + ik, where ñ, n, k are the complex

refractive index, the real part, and the imaginary part of the

index, respectively. The constant k is proportional to the

extinction coefficient of the material and thus gives information on the attenuation of light by the material itself. We have

evaluated the refractive index of materials by spectroscopic

ellipsometry and values at the laser wavelengths used are

summarized in Table 1. The real parts of the refractive index

values obtained agree with transmission data presented in

Fig. 1. The samples with absorbance bands closer to the visible

range (PC and thin PMMA materials) have significantly higher

refractive indices. On the other hand, PDMS with high

absorbance located furthest in the UV has the lowest refractive

index. Additionally we attempted quantitative evaluation of

the extinction coefficients at these same wavelengths by

globally fitting ellipsometry and transmission data. Several

factors, namely, the low optical losses of materials, surface and

bulk imperfections, and light source fluctuations prevented us

from obtaining reliable values of extinction coefficients in the

Measurements of material autofluorescence

Table 1

Prior to analysis, candidate materials were sonicated in ethanol

for 10 min. A piece of plastic material or chip sample was

placed on the microscope stage and the microscope objective

was aligned to give a sharp image of the sample’s bottom

(closer to objective) surface on the CCD camera. Then, the

objective was moved y250 mm closer to the sample resulting in

a focal point about this distance into the material. This last

step ensured that the laser excitation was focused into the bulk

of the material. The microscope was then switched to use a

Hamamatsu phototube as the detector. Then data acquisition

and illumination were started while recording the autofluorescence. Before each new measurement the sample was

This journal is ß The Royal Society of Chemistry 2005

Refractive indices of materials at various laser wavelengths

l/nm

Sample

Materials

Chips

BoroFloat

PMMA 0.25

PMMA 3.0

PMMA 5.0

PC 0.25

PC 2.0

COC

PDMS

PMMA IM

PC IM

403

488

532

633

1.494

1.621

1.495

1.506

1.620

1.627

1.544

1.428

1.510

1.636

1.483

1.599

1.490

1.496

1.598

1.602

1.534

1.418

1.498

1.612

1.480

1.592

1.488

1.493

1.591

1.594

1.530

1.415

1.495

1.604

1.475

1.581

1.486

1.488

1.580

1.582

1.525

1.410

1.489

1.592

Lab Chip, 2005, 5, 1348–1354 | 1349

Fig. 1 The transmission spectra taken at normal incidence of the

plastic materials are shown. Top panel: (A) – 0.25 mm, (B) – 3.0 mm

and (C) – 5.0 mm PMMA. Bottom panel: (D) – BoroFloat, (E) – COC,

(F) – 0.25 mm and (G) – 2.0 mm PC, (H) – PDMS.

visible range. Instead, normal incidence transmission spectra

of plastic materials are presented in Fig. 1. Typically, 10 to

15% of the losses over the visible range are due to reflections at

sample interfaces and these losses increase for higher refractive

index value materials. The only exception to this was COC

that had the lowest transmission over the visible range.

This could be attributed to scattering by surface and bulk

imperfections which are considerably more abundant in COC

than in any other material studied.

the graph represent the autofluorescence starting at very early

times where one can see a sharp decrease followed by a more

gradual decay of the intensity. After a period of a few

hundreds of seconds the autofluorescence intensity approaches

a limiting value. The autofluorescence intensity generally

scales linearly with applied laser power. In contrast the

autofluorescence of BoroFloat, used as a reference material,

remained essentially unaffected by illumination time (see

bottom curve in Fig. 2).

The comparison of the autofluorescence of several materials

is shown in Fig. 3. The absolute response of the PMT for

BoroFloat at each excitation wavelength is shown in the inset

in Fig. 3. The autofluorescence intensity of all materials is

indicated relative to the autofluorescence of BoroFloat at a

particular excitation wavelength and represents the autofluorescence of the material after 60 s of continuous laser

illumination (indicated by vertical line in Fig. 2). The presentation of autofluorescence intensity after 60 s of illumination was

chosen for two reasons. First, this time period allowed the

autofluorescence to approach steady state. Second, such an

illumination period could be used to optically pre-treat the

detection spot prior to an analysis.

A few general conclusions follow from these measurements.

First, the BoroFloat autofluorescence was slightly higher

(y3 times) at 403 nm than the essentially constant level at

other laser excitation wavelengths. Second, for most plastic

materials the autofluorescence tended to decrease as laser

excitation wavelength increased. The most dramatic decrease

was observed in going from 403 to 488 nm laser irradiation.

Third, the lowest autofluorescence was exhibited by PDMS.

At 633 nm excitation, it was comparable with BoroFloat; at

other wavelengths 2 to 3 times higher than BoroFloat. Additionally, PDMS exhibited an essentially constant, invariant to

Autofluorescence of materials

A typical plastic material autofluorescence time profile under

continuous laser illumination is shown in Fig. 2. The points on

Fig. 2 Autofluorescence of COC with 488 nm excitation at 1 (B), 3

(C) and 5 (D) mW laser power. BoroFloat autofluorescence at 1 mW

(A) is shown for comparison.

1350 | Lab Chip, 2005, 5, 1348–1354

Fig. 3 Autofluorescence of plastic materials under 1 mW laser power

after 60 s of illumination. Intensity is relative to BoroFloat under the

same conditions. The absolute intensity of BoroFloat autofluorescence

is shown in the inset.

This journal is ß The Royal Society of Chemistry 2005

Fig. 4 The autofluorescence of COC as a function of distance normal

to the surface of the material. $ represents experimentally determined

points, the dashed line is provided to guide the eye. The positions of the

back and front surfaces of the material are indicated. The horizontal

axis indicates the image plane relative to the bottom surface (sample

surface closest to objective). The COC physical thickness (nominally

1 mm) is larger than the apparent thickness (y0.5 mm) because of the

difference in the refractive index between air and the plastic material.

The apparent thickness is 1/n times the physical thickness, where n is

the refractive index of the material.

illumination, glass-like autofluorescence. The rest of the

materials had autofluorescence levels y3 to 5 times higher

than BoroFloat, except for 403 nm excitation where the

autofluorescence for any plastic material was significantly

higher than BoroFloat. Even though the thin 0.25 mm PC was

comparable to PMMA and COC materials, the thicker 2.0 mm

PC material exhibited significantly higher autofluorescence

(not shown in figure). The least difference was observed at

633 nm excitation where 2.0 mm PC autofluorescence exceeded

BoroFloat by y40 times. The difference was even larger at

shorter excitation wavelengths.

The results presented are typical of these plastic materials.

In certain cases, considerable spot-to-spot variation of the

autofluorescence was observed. To examine the nature of

these variations we evaluated how optical alignment with

the material influenced the measured autofluorescence.

Autofluorescence was recorded varying the vertical positions

of the microscope objective relative to the sample. Typical

results are presented in Fig. 4. The two vertical lines in the

figure represent the top (on the right) and bottom (left)

surfaces of sample. The lowest autofluorescence was observed

when excitation was focused into the bulk of the material. In

this case the autofluorescence intensity was significantly

diminished by material bleaching due to the high power

density inside the material. The magnitudes of the intensity

variations agreed well with the analyses of dynamic data.

Thus, the vertical alignment was one of the important factors

that affected the autofluorescence signal observed. The sample

surface and bulk material defects and illumination history were

other factors that influenced the measurement reproducibility.

Fig. 5 The relative autofluorescence of plastic chips under 1 mW of

laser power after 60 s of illumination (intensity relative to BoroFloat).

injection molded and PC injection molded chips. Typical

autofluorescence data for chips under continuous laser

illumination were very similar to the materials presented

in Fig. 2. Comparison of various chip samples after 60 s of

illumination is depicted in Fig. 5. The autofluorescence

intensity is given relative to BoroFloat autofluorescence at

the same excitation wavelength.

Overall, the autofluorescence of chips exhibited trends

similar to the associated materials. The shorter the laser

excitation wavelength, the higher the autofluorescence of chips

observed. The only exception was the PMMA injection molded

chip that showed a significant increase in autofluorescence

when excited at 633 nm. This behavior was unexpected and the

cause of this behavior remains unclear to us.

The vertical alignment of the focus point of the laser

(discussed in more detail for materials previously) led to

significant variation in the autofluorescence measurements.

The standard deviation of the autofluorescence signal was

determined for all chips at 488 nm excitation and typically

was from 10 to 20%. The autofluorescence intensity at 488 nm

shown in Fig. 5 is the average of 5 measurements; the

associated error bars represent standard deviations for these

measurements.

The important thing to note is the difference in autofluorescence intensities between Fig. 3 and 5. In general, all

plastic chips studied had higher autofluorescence levels than

the associated materials. For most of the materials, autofluorescence was 3 to 5 times higher than BoroFloat. On the

other hand chips exhibited approximately 5 to 10 times higher

autofluorescence levels than BoroFloat. The PMMA chips

showed the lowest autofluorescence levels followed by COC

and then PC chips. Due to its physical properties PDMS is not

an appropriate material for our applications and no attempt

was made to characterize a PDMS chip. Nonetheless, superior

chip autofluorescence levels might be anticipated based on our

PDMS material studies.

Dynamics of autofluorescence

Autofluorescence of chips

Autofluorescence of chips was evaluated for 4 different chip

types: PMMA hot embossed and injection molded, COC

This journal is ß The Royal Society of Chemistry 2005

In general, on laser illumination the autofluorescence of plastic

materials and chips decreased until a near steady-state was

reached. For practical purposes we chose to characterize this

Lab Chip, 2005, 5, 1348–1354 | 1351

bleaching phenomenon by fitting the experimental decay data

to the following empirical expression:

3

P

t

I ðtÞ~A0 z

Ai exp {

Ti

i~1

where A0 represents the final steady-state intensity of the autofluorescence, Ai, the magnitude of decay components, Ti, the

characteristic decay time in seconds, and t the laser illumination

time in seconds. This equation is analogous to that used by

Hawkins and Yager.4 However, in their work A0 accounted for

CCD dark count; in our work the parameter A0 was fitted to

indicate the final steady-state autofluorescence level.

For all samples (materials and chips) studied three different

decay components were sufficient to characterize the dynamics

of the autofluorescence bleaching. The BoroFloat and PDMS

materials exhibited the lowest autofluorescence variations

and could be fitted with fewer exponential decay terms.

Since our main interest was in the properties of fabricated

chips, we have chosen to present the data for chips, PDMS,

and the reference glass BoroFloat. Even though the mechanical properties of PDMS are not appropriate for our needs,

its excellent autofluorescence properties are worth noting.

Additionally, the chip dynamic data are a good representation

of the autofluorescence dynamics of the materials, the main

difference being that materials have relatively lower magnitudes of the fitting terms. Table 2 summarizes the fit

parameters for all chips and selected materials along with the

associated correlation coefficients and x2 values to indicate the

goodness of the fits.

Table 2

Fit parameters of autofluorescence bleaching components for plastic chips at 1 mW laser power

Sample

403 nm

BoroFloat

3.1 6 1025 a

0.124c

0.038d

—e

—f

6.9 6 1025

0.308

0.182

0.122

0.073

9.3 6 1024

1.176

3.397

1.850

1.209

1.8 6 1024

0.481

1.336

0.593

0.318

6.7 6 1024

1.439

1.706

1.281

1.546

2.0 6 1023

2.511

5.185

3.083

2.234

PDMS

COC IM chip

PMMA IM chip

PMMA HE chip

PC IM chip

a

x2;

b

It was pointed out earlier that BoroFloat exhibited essentially constant autofluorescence; this is reflected in the fitting

parameters. The autofluorescence of BoroFloat could be

described by just a single exponential decay term with short

lifetime. More importantly, the magnitude is quite small

in comparison with other values of the constant term A0.

PDMS was the best of the studied plastic materials showing

a somewhat similar behavior to BoroFloat. At the two

longest wavelengths PDMS has only a single decay term

with a low magnitude, but somewhat longer lifetime. For the

two shortest wavelengths the results are more typical of

the rest of the materials. More exponential decay terms

were required and their magnitudes are comparable with the

constant term A0.

The correlation coefficients for the fits deviated considerably

from 1 for BoroFloat, PDMS and several other materials

at longer wavelengths. In all these cases, changes of the

autofluorescence were relatively small and, as a result,

the magnitude of the constant term A0 dominated the other

Ai terms. The changes in the recorded signal were comparable to the noise in the autofluorescence signal, thus

yielding poor correlation coefficients despite reasonable fits to

the data.

The autofluorescence dynamics of all chips are similar. The

fitted decay time constants fall into three broad categories:

short (0 to 6 s), medium (10 to 40 s), and long (120 to 500 s)

times. A pattern was observed for autofluorescence at different

excitation wavelengths. The shorter the excitation wavelength

the larger in magnitude were all three decay terms. At 403 nm

R2; c A0;

d

A1; e A2; f A3;

488 nm

g

T1;

0.635b

5.6g

—h

—i

0.941

2.0

22

319

0.996

1.1

15

178

0.990

0.7

11

153

0.998

1.7

25

214

0.998

1.3

17

205

h

4.9 6

0.024

0.003

—

—

7.7 6

0.036

—

0.011

0.008

7.2 6

0.164

0.211

0.146

0.106

3.8 6

0.088

0.168

0.106

0.061

3.4 6

0.119

0.084

0.061

0.048

1.5 6

0.277

0.321

0.234

0.179

532 nm

1027

0.441

1027

9.2

—

—

0.896

1026

—

11

170

0.997

1026

2.1

24

233

0.995

1026

1.5

17

172

0.991

1025

2.0

21

206

0.998

2.2

22

212

7.1 6

0.032

0.006

—

—

1.1 6

0.043

—

—

0.011

6.9 6

0.199

0.172

0.148

0.146

5.2 6

0.156

0.166

0.127

0.101

3.2 6

0.125

0.073

0.066

0.062

1.9 6

0.698

0.191

0.222

0.345

633 nm

1027

0.759

1026

11.6

—

—

0.865

1026

—

—

129

0.998

1026

2.4

27

242

0.997

1026

2.2

23

229

0.995

1025

2.9

28

236

0.999

4.3

39

333

6.0 6

0.028

0.003

—

—

5.5 6

0.025

—

—

0.002

2.1 6

0.071

0.025

0.035

0.039

2.6 6

0.510

0.276

0.206

0.361

1.8 6

0.063

0.019

0.016

0.020

1.1 6

0.286

0.035

0.067

0.125

1027

0.395

1027

15.1

—

—

0.334

1026

—

—

127

0.989

1025

2.6

23

222

0.998

1026

0.9

24

307

0.971

1025

7.3

69

515

0.993

3.2

34

279

T2; i T3, this pattern is used throughout the table.

1352 | Lab Chip, 2005, 5, 1348–1354

This journal is ß The Royal Society of Chemistry 2005

the total magnitude of the decay terms for any of the chips

exceeded by several times the constant term A0. On the other

hand, at longer wavelengths this ratio was reduced. Finally at

633 nm the sum of the decay terms was almost equal to the

constant term.

Autofluorescence recovery

The permanency of the bleaching of the autofluorescence was

studied in the following way. At first, the selected material was

illuminated at 488 nm at 1 mW laser power for 10 min. After

12 h in the dark the laser illumination was repeated on exactly

the same spot (sample was unmoved between illuminations).

Typical results are depicted in Fig. 6. The decay curve on the

left represents the autofluorescence during the first laser

illumination; the curve on the right shows the autofluorescence

during the second illumination. Clearly, the most dramatic

changes observed were during the initial illumination.

Autofluorescence intensity rapidly decayed and at the end of

the first illumination reached essentially a steady-state value.

The second exposure to laser light led to similar kinetics except

for a marked difference in the magnitude of the autofluorescence and the associated changes. Although the initial

autofluorescence under the repeated illumination was considerably less, the steady-state autofluorescence at the end of

both illuminations coincided to within experimental error. To

quantify this phenomenon we defined an autofluorescence

recovery, r, as:

r:

Iinitial ð2Þ {Ifinal ð2Þ

Iinitial ð1Þ {Ifinal ð1Þ

where Iinitial and Ifinal represent initial and final autofluorescence

intensities, the number in parentheses indicates first or second laser

illumination. Using this relationship the autofluorescence recovery

for various plastic chips is presented in Fig. 7. Overall, given the

uncertainty in the experimental data, the recovery of each material

was essentially constant falling into the range 15 to 20% over the

12 h period. It is important to note that despite a modest recovery

of the autofluorescence the same low level of autofluorescence

Fig. 7 Autofluorescence recovery for plastic microchips. All measurements were performed with 488 nm laser at 1 mW power. For

definition of recovery, see text.

could be achieved with a short additional laser irradiation. In turn,

this suggests that once plastic chips have their autofluorescence

laser bleached, one can use these chips over an extended period of

time without significant return of the autofluorescence.

Although our immediate interest has been to examine the

possibility of quickly laser bleaching the autofluorescence of

plastic chips before making analytical measurements, one

might speculate as to the origin of the autofluorescence. It

seems plausible that the autofluorescence arises from additives

and impurities within the plastic materials themselves and,

on fabrication, chip processing could introduce more of these.

The finding that the autofluorescence bleaches to a steadystate value and recovers somewhat in time suggests that

photolytic products of the bleaching might partially recombine

restoring some of the initial autofluorescence. However, we

hasten to add that one might offer other equally plausible

explanations for this interesting and practically important

behavior. Given the future of plastic materials in chip fabrication, it would be worthwhile to explore the origin of this

behavior with the goal of further reducing the autofluorescence

of freshly made chips.

Conclusions

Fig. 6 Typical data for autofluorescence recovery over time; PC IM

chip illuminated at 488 nm, 1 mW. The curve on the left represents the

autofluorescence on initial illumination; the curve on the right, the one

recorded after 12 hours of no laser illumination.

This journal is ß The Royal Society of Chemistry 2005

The autofluorescence of BoroFloat glass, several plastic

materials and the associated plastic chips were studied at

four different laser excitation wavelengths. BoroFloat glass

exhibited the lowest, essentially constant autofluorescence at

all wavelengths studied. The autofluorescence of plastics,

though generally higher than BoroFloat, showed significant

changes in magnitude and dynamics. The highest autofluorescence and most severe changes were observed at

403 nm, the shortest wavelength studied. For longer laser

wavelengths both the autofluorescence and its changes were

reduced. PDMS and PMMA were materials with the lowest

autofluorescence. In all cases chips yielded significantly

higher autofluorescence levels than the associated materials.

Autofluorescence decay under laser irradiation could be

quantitatively described using a three component exponential

decay function. In turn, these components account for

Lab Chip, 2005, 5, 1348–1354 | 1353

background decays on the order of a few seconds, a few tens of

seconds and a few minutes. The laser induced bleaching of the

autofluorescence was shown to remain essentially constant up

to 12 h after initial laser illumination.

Acknowledgements

The authors thank Erik Peterson for help with PDMS

materials preparations, Dr Kenneth R. Wehmeyer, Dr Brian

H. Halsall and Justin Mecomber for valuable discussions.

This work was supported by a grant from the NIH (1 R01

GM069547-01,02) and by an Ohio Board of Regents Doctoral

Investment Award.

1354 | Lab Chip, 2005, 5, 1348–1354

References

1

2

3

4

A. de Mello, Lab Chip, 2002, 2, 31N–36N.

G. S. Fiorini and D. T. Chiu, Biotechniques, 2005, 38, 429–446.

H. Becker and L. E. Locascio, Talanta, 2002, 56, 267–287.

K. R. Hawkins and P. Yager, Lab Chip, 2003, 3, 248–252.

wSignificant reference.

5 M. B. Wabuyele, S. M. Ford, W. Stryjewski, J. Barrow and

S. A. Soper, Electrophoresis, 2001, 22, 3939–3948. wSignificant

reference.

6 S. D. Llopis, W. Stryjewski and S. A. Soper, Electrophoresis, 2004,

25, 3810–3819.

7 R. Trichur, S. Kim, S. H. Lee, Y. A. Abdelaziez, D. E. Starkey,

H. B. Halsall, W. R. Heineman and C. H. Ahn, Micro Total

Analysis Systems 2002, Proceedings of the mTAS, Kluwer Academic

Publisher, Nara, Japan, 2002, vol. 1, pp. 560–562.

This journal is ß The Royal Society of Chemistry 2005