GHV20-GHV30-GHV40 Series

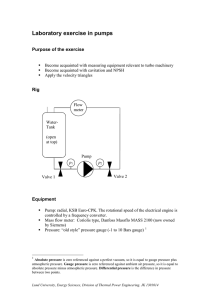

advertisement