Technical Solutions Guide

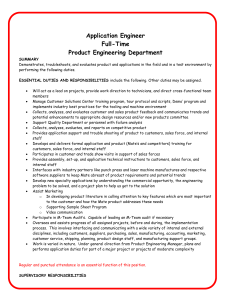

advertisement