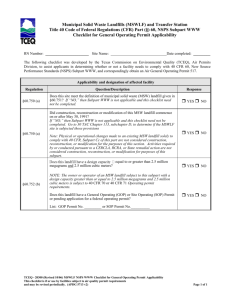

M-13 - the Oklahoma Department of Environmental Quality

advertisement