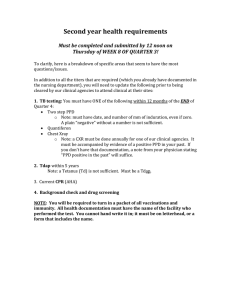

Technical Specifications

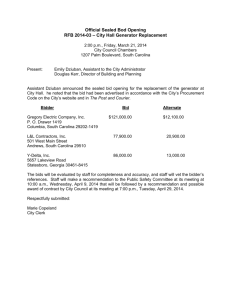

advertisement