Scanning Electron Microscopy

advertisement

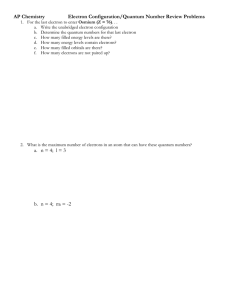

SEM Scanning Electron Microscopy Laboratory session in the course “Modern Imaging Methods” Lab assistants: Haiping Lai, Amine Yousfi and Anna Jansson 1 !m “SEM-image of an etched feature made in a Dual Beam-FIB-SEM” !"#$%&&&&&&&&&&&&&&&&''(((((((()"*$%&&&&&&&&&&&&&'''( ( +,-$./012.31(1045"*,.$%&&&&&&&''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''''( Introduction The scanning electron microscope (SEM) is a powerful and frequently used instrument, in both academia and industry, to study, for example, surface topography, composition, crystallography and properties on a local scale. The spatial resolution is better than that of the optical microscope although not quite as good as for the transmission electron microscope (TEM). The SEM has an extremely large depth of focus and is therefore well suited for topographic imaging. Besides surface topographic studies the SEM can also be used for determining the chemical composition of a material, its fluorescent properties, the formation of magnetic domains, and more. Historical Background The first SEM instrument was designed by Stinzing and Knoll in Germany in the early 30’s. Zworykin and his collaborators in the US further developed the instrument but they were still not able to achieve an acceptable signal-to-noise ratio. The design of the modern SEM is based mainly on the development work by Oatley and Nixon in Cambridge and the first commercial version of a SEM was designed by Stewart and Snelling in 1965. The more recent computer development has also strongly increased the performance of SEMs as well as the possibilities of image analysis. Principle The specimen is bombarded by a convergent electron beam, which is scanned across the surface. This electron beam generates a number of different types of signals, which are emitted from the area of the specimen where the electron beam is impinging, see Figure 1. Figure 1 67"#-8$(29(12#$(29(*:$(;099$.$5*(*<-$1(29(1045"81(-.2;,=$;(>:$5(:04:?$5$.4<($8$=*.251( 0#-054$(25("(#"*$.0"8'(( The induced signals are detected and the intensity of one of the signals (at a time) is amplified and gives rise to the intensity of a pixel in the image on the computer screen. The electron beam then moves to the next position on the sample and the detected intensity gives the intensity in the second pixel and so on. The working principle of the SEM is shown in Figure 2. Study this figure and try to understand how a SEM works. 2 ((( ( Figure 2 Schematic diagram of a SEM For improved signal-to-noise ratio in the image, one can use a slower scan speed. This means that the electron beam stays a longer time at one position on the sample surface before moving to the next. This gives a higher detected signal and increased signal-tonoise ratio. Operating Modes The SEM can be operated in many different modes where each mode is based on a specific type of signal. The choice of operating mode depends on the properties of the sample and on what features one wants to investigate. Some of the more common modes are: a) Secondary electron mode (SE) Electrons with energies between 0 – 30 eV are detected and used to form the image. These electrons are knocked out from the specimen by the incident electron beam and come from a layer within 5 nm of the surface. b) Backscattered electron mode (BSE) Electrons with energies ranging from a few keV to the energy of the incident electrons (typically 15 – 30 keV) are detected. Such electrons are electrons from the electron beam that are elastically scattered back from the sample. The scattering takes place in a volume extending down to 0.5 µm below the surface and therefore gives information also about the “bulk” properties of the material. c) Energy dispersive X-ray spectroscopy (EDX) (See further down) 3 Resolution The highest resolution obtainable is limited by the spot size but there are also other factors that affect the resolution. Factors affecting the resolution are: 0@ A:$(;0"#$*$.(29(*:$($8$=*.25(B$"#( 00@ +="**$.054(>0*:05(*:$(1-$=0#$5( 000@ A:$(1045"8?*2?5201$(."*02( 0/@ 67*$.5"8(;01*,.B"5=$1(;,$(*2( C' 68$=*.0=(2.(#"45$*0=(90$8;1( D' E$=:"50="8(/0B."*0251( Electrons penetrating the sample will undergo scattering, see Figure 3, which will result in an “effective beam diameter”, which is larger than the diameter of the incident beam. The size of this interaction volume depends on the energy of the primary electrons and on the elemental composition of the specimen. Figure 3 F5*$."=*025(/28,#$1(92.(;099$.$5*(*<-$1(29(1045"81'( 4 The image quality depends critically on the signal-to-noise ratio. It can be improved by increasing the beam current but this usually means an increased beam diameter with corresponding lower resolution. Electron and magnetic stray fields can also affect the resolution, as can mechanical vibrations. These effects are usually only of concern when one needs a resolution better than 10 -20 nm. Secondary electrons (SE) The secondary electrons emitted from the surface region can be generated in two ways; either by the incident primary electrons or by the backscattered electrons as they leave the surface, see Figure 4. Figure 4(+:2>1(:2>(1$=25;".<($8$=*.251(".$(4$5$."*$;'( The secondary electrons excited by the incident beam originate from a small volume and give information about the fine details of the specimen. The resolution in this mode is 1 – 10 nm and main limiting factor are i) and iii). The secondary electrons excited by the backscattered electrons originate from a considerably larger volume and contribute mainly to the background intensity. Backscattered electrons (BSE) The resolution in the backscattered electron mode is limited by factor ii) as the signal is generated in a larger volume. It is also influenced by the energy of the electron beam. A higher energy gives a larger interaction volume, which gives a lower resolution. The resolution is of the order of 20-100 nm. Contrast mechanisms Examples of specimen features that can generate image contrast are: Surface topography Atomic number variation Magnetic surface fields Conductivity variations Crystallographic orientation variations We will be dealing with the first two modes, secondary electron and backscatter electron mode, as these are most commonly used. Then EDX will be discussed. 5 Secondary electrons Lets us assume that we gradually increase the specimen tilt angle, !, as shown in Figure 5. We will then observe a monotonous increase of the SE signal. The main reasons for this increase in SE yield are: 1) Most of the emitted SE originate from a surface layer about 5 nm thick. The path length of the incident electrons in the surface layer increases with increasing tilt angle, !, so the fraction of generated SE, that can leave the surface, increases. For the same reason a larger fraction of backscattered electron can also leave the surface and the secondary electrons they generate also contribute to the increased secondary electron signal. 2) The number of emitted SE will be proportional to cos", where " is the angle between the observation direction and the surface normal. Due to this relationship the intensity maximum comes closer to the detector when the specimen is tilted towards the detector. (( Figure 5 A:$(-"*:(29(*:$(05=0;$5*(B$"#(92.(;099$.$5*(*08*("548$1'( ( Figure 6 shows the variation in secondary electron intensity as the electron beam is scanned across a surface with various features. The circle with radius R, indicates the range of the primary electrons within the material. Figure 6 A:$(05*$510*<(29($#0**$;(1$=25;".<($8$=*.25(92.("(805$(1="5(2/$.(12#$(;099$.$5*(1,.9"=$(9$"*,.$1'(( 6 Surface topography can thus be observed either in the SE mode or in the BSE mode. Both modes of operation have their advantages. The advantages of using the SE mode are: 1) Higher resolution (because of a smaller interaction volume) 2) Higher signal-to-noise ratio G@ Ability to “look around the corner” as the SE don’t follow straight trajectories ( ( Figure 7 demonstrates the analogy between optical microscopy, using different illumination geometries, and SEM image formation using SE and BSE respectively. Figure 7 H2#-".0125(B$*>$$5(0#"4054(05("5(2-*0="8(#0=.21=2-$("5;("(+6E(,1054(*:$(+6("5;(I+6( #2;$(.$1-$=*0/$8<'(J(-210*0/$(B0"1(01("--80$;(25("(4.0;("*(*:$($5*."5=$(29(*:$(+6(;$*$=*2.(05(2.;$.(*2( 05=.$"1$(*:$(5,#B$.(29(;$*$=*$;(+6'(+05=$(*:$(+6(:"/$("(#,=:(82>$.($5$.4<(*:"5(*:$(I+6K(258<(*:$( +6(".$(L/"=,,#$;M(05*2(*:$(;$*$=*2.'( Backscattered electrons Compositional (or elemental) contrast is observed when the specimen has features with different composition. It has been empirically demonstrated that the backscattering coefficient, #, increases with increasing atomic number, Z, but is almost independent of the acceleration voltage in the range 10-40kV. Figure 8 gives # as a function of Z and it shows that the Zdependence is strongest for Z< 40. The secondary electron yield shows a much weaker Z-dependence, and is usually not used to form compositional contrast. Figure 8 A:$(B"=N1="**$.054(=2$990=0$5*K(#K("1((( (((((((((((((("(9,5=*025(29(*:$("*2#0=(5,#B$.'(( 7 a) b) Figure 9 SEM images of a MoSi2 composite with a thin oxide layer on top. a) SE image whichgives the topographic contrast. b) BSE image of the same area giving the atomic numbercontrast. White region contains WO3 and dark region contains SiO2 . EDX Energy Dispersive X-ray Spectroscopy (EDX) is a technique where you can find out the chemical composition of a material. The information is obtained from characteristic X-ray lines, generated by the electron beam. An electron beam interacting with a specimen generates X-rays through two mechanisms: 1. The continuous slowing down of the incident electrons by interaction with free and loosely bound electrons generates a continuous X-ray spectrum (bremsstrahlung). The energy range goes from zero to that of the energy of the incoming electrons, see Figure 9. Figure 9 Energy dispersive X-ray spectrum from Fe recorded at 8 kV accelerating voltage with a beryllium detector. Note the shape of the background and the cut-off at the incident beam energy. 8 2. An inner shell (core) electron is ejected from an atom by the incident, high energy electron beam leaving an excited atom behind. A characteristic X-ray, i.e. X-ray with an energy characteristic of the energy levels of that specific element, can be emitted when the excited atom rearranges its shells, see figure 9. The Xray energies are labelled K, L or M depending on from which shell the electron was ejected and sub indexed according to how the relaxation occurs. E.g. Kα and Kβ mean that first an electron was knocked out from the K-shell and then it was replaced by an electron from the L-shell or M-shell, respectively, see Figure 10. 10. Shows the origin of the labelling Figure EM< EL<EK for a given element and the energies of the K, L and M lines, respectively, increase with increasing atomic number, see Figure 11. Figure 11 Plot of the X-ray emission lines observed in the range 0.75-10 keV by energy dispersive spectrometry. Quantification in EDX is done by comparing the intensities of the peaks, after subtracting the background and integrating the peaks. Rather accurate analyses can be obtained for heavier elements, Z$11, but lighter elements can cause some problems. Their characteristic X-ray radiation is rather soft (low energy) and is therefore easily absorbed by non-active layers in the detector. A relatively small volume of the specimen can be analyzed if the beam is positioned at a point. The lateral extension of the source of X-rays is often considerably larger than the 9 actual cross section of the beam and the resolution is usually of the order of 1 µm for bulk samples. The spatial resolution is very much improved if a thin foil is used instead. For a TEM specimen with a thickness of about 100 nm the beam broadening is normally not more than 10-20 nm. Specimen limitations In the SEM, the specimen resides in a high vacuum chamber to prevent scattering of the electron beam and to avoid damage to the microscope. However, operating in a high vacuum poses some limitations on the types of specimens that we can observe with the SEM. Specimens should be electrically conductive – otherwise the electron beam may build up a static charge in the material due to the inability to dissipate the charge. Furthermore, the specimen must not contain water or other volatile components that may destroy the vacuum in the sample chamber and potentially damage the microscope. Specimens that do not meet these requirements may still be observed after suitable sample preparation, e.g. metal coating with a conductive layer to reduce charging or freeze-drying to remove water. There is a type of SEM, called Environmental Scanning Electron Microscope (ESEM), which circumvents these limitations by allowing a relatively small amount of gas in the sample chamber. This opens up new possibilities in terms of specimens that can be observed and experiments that can be performed. The need for coating electrically insulating materials, e.g. plastics, is removed and biological specimens can be imaged in their native, moist state. In addition, different gases can be used to perform dynamic experiments, e.g. inducing a chemical reaction with the gas or investigating what happens to a water-based paint as it dries. 10 Questions (These theory questions should be completed BEFORE the session; otherwise you may not join the session!!!) 1. What is the function of the scanning coils in a SEM? 2. What is the main difference between the contrast in an SE image and a BE image? 3. Why can non-conductors not be directly examined in a SEM? 4. How can you increase the depth of focus in a SEM? 5. Describe how a K! X-ray is produced by an incident electron beam? 6. Which parameter do you change to improve spatial resolution in EDX analyses? 7. What are the applications of SEM? Lab assignments will be handed out when the lab starts. If you have an interesting sample to study in the SEM, you are welcome to bring it with you! 11