SUMIKAEXCEL PES TECHNICAL NOTE

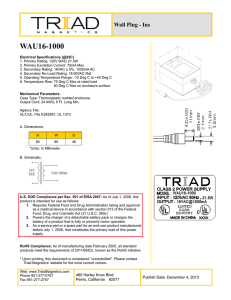

advertisement