Broadcast Cables

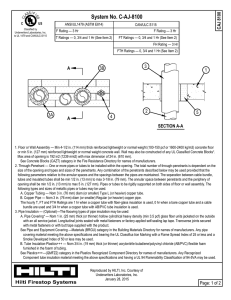

advertisement