Etibreak - HK Electric BV

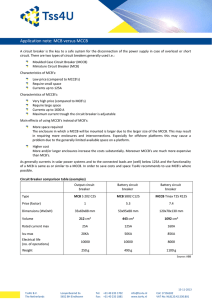

advertisement