High Density Rectangular Catalog

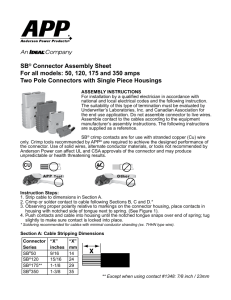

advertisement