Petroleum Industry in Japan 2009

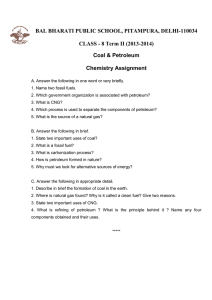

advertisement