Six Reasons to Choose Denstone® Support Media - Saint

advertisement

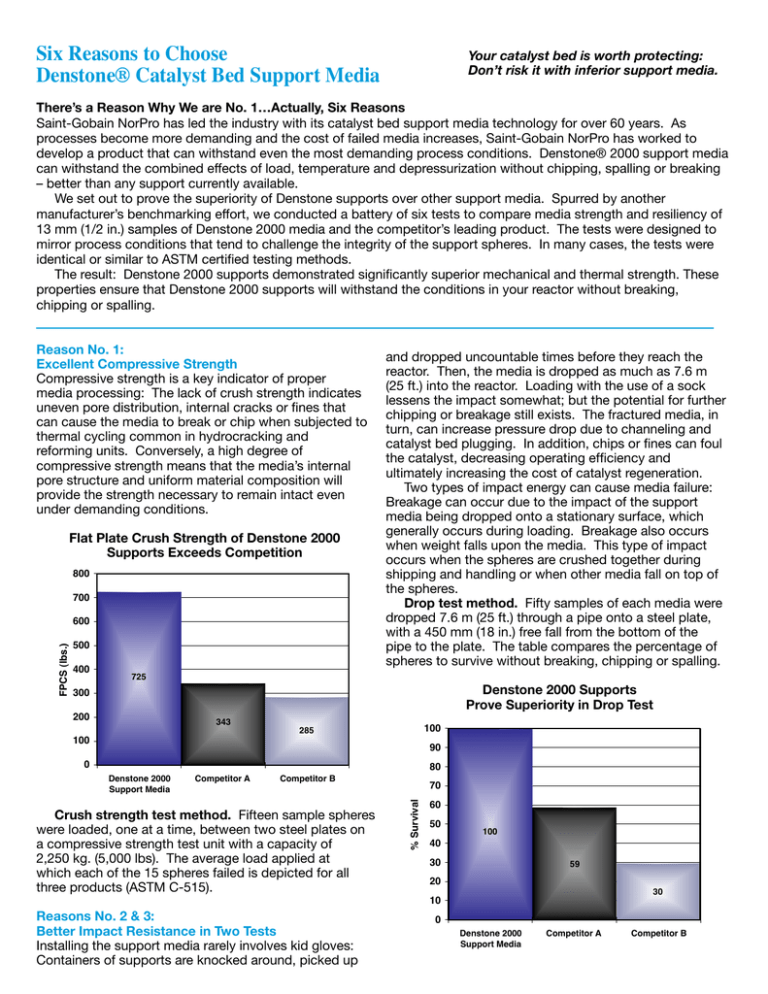

Six Reasons to Choose Denstone® Catalyst Bed Support Media Your catalyst bed is worth protecting: Don’t risk it with inferior support media. There’s a Reason Why We are No. 1…Actually, Six Reasons Saint-Gobain NorPro has led the industry with its catalyst bed support media technology for over 60 years. As processes become more demanding and the cost of failed media increases, Saint-Gobain NorPro has worked to develop a product that can withstand even the most demanding process conditions. Denstone® 2000 support media can withstand the combined effects of load, temperature and depressurization without chipping, spalling or breaking – better than any support currently available. We set out to prove the superiority of Denstone supports over other support media. Spurred by another manufacturer’s benchmarking effort, we conducted a battery of six tests to compare media strength and resiliency of 13 mm (1/2 in.) samples of Denstone 2000 media and the competitor’s leading product. The tests were designed to mirror process conditions that tend to challenge the integrity of the support spheres. In many cases, the tests were identical or similar to ASTM certified testing methods. The result: Denstone 2000 supports demonstrated significantly superior mechanical and thermal strength. These properties ensure that Denstone 2000 supports will withstand the conditions in your reactor without breaking, chipping or spalling. Reason No. 1: Excellent Compressive Strength Compressive strength is a key indicator of proper media processing: The lack of crush strength indicates uneven pore distribution, internal cracks or fines that can cause the media to break or chip when subjected to thermal cycling common in hydrocracking and reforming units. Conversely, a high degree of compressive strength means that the media’s internal pore structure and uniform material composition will provide the strength necessary to remain intact even under demanding conditions. Flat Plate Crush Strength of Denstone 2000 Supports Exceeds Competition 800 700 FPCS (lbs.) 600 500 400 and dropped uncountable times before they reach the reactor. Then, the media is dropped as much as 7.6 m (25 ft.) into the reactor. Loading with the use of a sock lessens the impact somewhat; but the potential for further chipping or breakage still exists. The fractured media, in turn, can increase pressure drop due to channeling and catalyst bed plugging. In addition, chips or fines can foul the catalyst, decreasing operating efficiency and ultimately increasing the cost of catalyst regeneration. Two types of impact energy can cause media failure: Breakage can occur due to the impact of the support media being dropped onto a stationary surface, which generally occurs during loading. Breakage also occurs when weight falls upon the media. This type of impact occurs when the spheres are crushed together during shipping and handling or when other media fall on top of the spheres. Drop test method. Fifty samples of each media were dropped 7.6 m (25 ft.) through a pipe onto a steel plate, with a 450 mm (18 in.) free fall from the bottom of the pipe to the plate. The table compares the percentage of spheres to survive without breaking, chipping or spalling. 725 Denstone 2000 Supports Prove Superiority in Drop Test 300 200 343 100 100 285 90 0 Competitor A 80 Competitor B Crush strength test method. Fifteen sample spheres were loaded, one at a time, between two steel plates on a compressive strength test unit with a capacity of 2,250 kg. (5,000 lbs). The average load applied at which each of the 15 spheres failed is depicted for all three products (ASTM C-515). Reasons No. 2 & 3: Better Impact Resistance in Two Tests Installing the support media rarely involves kid gloves: Containers of supports are knocked around, picked up 70 % Survival Denstone 2000 Support Media 60 50 40 100 30 59 20 30 10 0 Denstone 2000 Support Media Competitor A Competitor B Impact test method. Using 20 samples of each media, a 90-gram (3.15 oz.) tup was dropped from 300 mm to 600 mm (12 in. to 24 in.) onto individual spheres. Impact resistance was determined using the mean failure height (ASTM D-3029). Denstone 2000 Supports Have Significant Edge in ASTM Test 0.3 Impact ft - lbs. 0.25 0.2 0.15 0.277 0.1 0.116 0.05 0 Reason No. 6: Passes the Ultimate Test: Rapid Depressurization A hydrocracking tower experienced an extreme rapid drop in pressure. Already weakened by repeated thermal cycling, the catalyst bed support media shattered. The catalyst migrated downward through the broken support media. Within a short time, the refiner was forced to shut down the unit for an emergency changeout. The time and money involved was tremendous and could have been avoided had the refiner been using a support media that could withstand rapid depressurization. That is why Saint-Gobain NorPro developed this test. Autoclave Procedure: Approximately 200 samples of each media were heated to 454° C (850° F) at 10.3 MPa (1500 psia) in an autoclave chamber containing hydrogen. The chamber was then depressurized instantaneously to ambient pressure. The chart below lists the percentage of spheres surviving without breakage. Denstone 2000 Supports Pass the Ultimate Autoclave Test 0.067 Denstone 2000 Support Media Competitor A 100 Competitor B 90 80 800 FPCS (lbs.) 600 725 300 0 100 88 40 30 20 10 0 25 Denstone 2000 Support Media Competitor A Competitor B Saint-Gobain NorPro GmbH Steinefrenz, Germany +49 6435 9657 0 norpro.steinefrenz@saint-gobain.com 500 100 50 Saint-Gobain NorPro Stow, Ohio USA +1 330 677-7228 norpro.stow@saint-gobain.com 700 200 60 Denstone® Support Media – Always Reliable Support Denstone 2000 Supports Maintain Strength After Thermal Shock 400 70 % Survival Reasons No. 4 & 5: Stands Up to Thermal Shock Even gradual changes in temperature, whether moderate or extreme, can weaken support spheres. Process conditions common in fixed-bed catalytic applications weaken the supports over time and make them increasingly susceptible to breakage or chipping. To see how the supports stand up against thermal shock, we heated 15 sample spheres of each media to 427° C (800° F), then dropped them into water at room temperature. The surviving spheres were then tested for compressive strength as outlined above. The test was repeated using spheres heated to 815° C (1500° F). 456 343 285 222 207 74 Initial FPCS FPCS after 800˚ F (427˚ C) Denstone 2000 Support Media www.denstone.com Competitor A 142 86 FPCS after 1500˚ F (815˚ C) Competitor B Saint-Gobain KK Tokyo, Japan +81 3 3263 0334 norpro.tokyo@saint-gobain.com © Copyright 1998 Saint-Gobain NorPro, 7/06 DenSix-2 The information presented herein is believed to be accurate and reliable, but is presented without guarantee or warranty on the part of Saint-Gobain NorPro. Further, nothing contained herein shall be taken as an inducement or recommendation to manufacture or use any of the herein described materials or processes in violation of existing or future patents.