Genetic Algorithm Based Proportional Integral Controller Design for

advertisement

Journal of Computer Science 7 (3): 416-420, 2011

ISSN 1549-3636

© 2011 Science Publications

Genetic Algorithm Based Proportional Integral Controller Design for Induction Motor

1

Mohanasundaram Kuppusamy and 2Rajasekar Natarajan

1

Department of Electrical and Electronics Engineering,

Sree Sastha Institute of Engineering and Technology, Chembarambakkam,

Chennai, 600123, India

2

School of Electrical Sciences,VIT University, Vellore, Tamilnadu, India

Abstract: Problem statement: This study has expounded the application of evolutionary computation

method namely Genetic Algorithm (GA) for estimation of feedback controller parameters for

induction motor. GA offers certain advantages such as simple computational steps, derivative free

optimization, reduced number of iterations and assured near global optima. The development of the

method is well documented and computed and measured results are presented. Approach: The design

of PI controller parameter for three phase induction motor drives was done using Genetic Algorithm.

The objective function of motor current reduction, using PI controller, at starting is formulated as an

optimization problem and solved with Genetic Algorithm. Results: The results showed the selected

values of PI controller parameter using genetic algorithm approach, with objective of induction motor

starting current reduction. Conclusions/Recommendation: The results proved the robustness and easy

implementation of genetic algorithm selection of PI parameters for induction motor starting.

Key words: Genetic algorithm, induction motor, evolutionary computation, controller parameters

There are many advantages that make GA attractive.

GA does not require the use of derivatives. They offer a

parallel searching of the solution space rather than the

point-by-point searching in a small region (Wieczorek

et al., 1998). Since the location of the optimal solution

is unknown before the search, it is very likely that the

point-by-point search needs to search through the entire

solution space in order to find the optimal solution, not

mention the traps of the local optima. Hence, GA can find

near-optimal solution for a complex problem very quickly.

INTRODUCTION

The squirrel cage induction motor is basically a

simple, less costly and reliable drive and can provide

excellent characteristics at a constant shaft speed.

Probably the cheapest and most reliable scheme of

speed control of induction motors is stator voltage

control using back-to-back connected SCRs. This

scheme is widely used for certain types of loads such as

fan and pump drives. It was shown that speed ranges of

5-1 can be easily obtained using this method (Paice,

1968; Lipo, 1971). However, little attention is being

paid to the design of controller for closed loop variable

speed operation using the above scheme. The drawback

of is that an analytical relationship could not be

established between induction motor torque and applied

voltage with thyristor excitation and only an empirical

approach was used (Shepherd and Stanway, 1967).

Further, motor parameter variation with different

operating points is not considered.

Genetic Algorithm is a stochastic search techniques

based on the mechanism of natural selection and natural

genetics. GA (Kangrang and Chaleeraktrakoon,

2007) perform search for a multidimensional space

containing a hyper surface known as the fitness surface.

Problem formulation: Induction motor starting at

rated current (Say, 1958) is formulated as an

optimization problem and is given below:

Minimize:

F ( ) =│Ir-I│

(1)

Subjected to:

min ≤

Where:

Ir =

≤

max

rated motor current

Corresponding Author: Mohanasundaram Kuppusamy, Department of Electrical and Electronics Engineering, Sree Sastha

Institute of Engineering and Technology, Chembarambakkam, Chennai, 600123, India Tel: +91

9600047399

416

J. Computer Sci., 7 (3): 416-420, 2011

I =

Φs =

min and

max

motor current

{Kp, Ki}

= refer to minimum and maximums of

For the evaluation of objective function F ( ), the

MATLAB model of induction motor is developed to

work in the closed loop starting mode (Sundaram et al.,

2009) and this is shown in the Fig. 1. Here, PI

controller block (Hassanzadeh et al., 2008) refers to

controller constants to be identified.

Implementation of GA for optimization: The primary

concept of GA was first proposed by Dr. Holland in

1975.

GA

constitutes

biologically

inspired

multiparameter

search/optimization

algorithms

(Subramanian et al., 2010) that have proven to be effective

in solving a variety of complex problems where other

algorithms have either failed or faced difficulties.

The following steps describe how the GA is designed

and applied to the present problem. Various components

of GA (Wurtz et al., 1997) such as chromosomes, fitness

function, reproduction, crossover and mutation as applied

to the present work are illustrated.

Step1: Create a population of initial solution of

parameters (kp, ki): This step primarily requires the

population size. Each variable in the problem is called

as a gene and in the present problem, there are two (i.e.,

kp, ki) genes. A Chromosome consists of the genes and

thus each chromosome represents a solution to the

problem. This is illustrated in Fig. 2.

The population consists of a set of chromosomes. It

is well articulated in literature that a population size of

5-30 is an ideal one and hence population size is

selected as 8 in this study.

Step 2: Evaluation of objective function: In the

present problem, the starting current of induction motor

is to be maintained at rated value while starting. For

each chromosome, the MATLAB model given in

Fig. 1. is simulated and F ((φ)) is computed.

Step 3: Evaluation of fitness function: The degree of

“goodness” of a solution is qualified by assigning a

value to it. This is done by defining a proper fitness

function to the problem. Since GA can be used only for

maximization problems, the following fitness function

is used:

Fitness function =1/ (1+ F ( ))

(2)

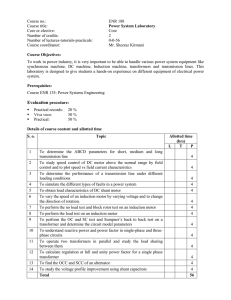

Fig. 1: Matlab/Simulink model of A.C. voltage

controller fed induction motor with PI

controller

Fig. 2: Chromosome structure

Step 4: Generation of offspring: Offspring is a new

chromosome obtained through the steps of selection,

crossover and mutation. After fitness of each

chromosome is computed, parent solutions are selected

for reproduction. It emulates the survival of the fittest

mechanism in nature. The Roulette wheel selection is

the most common and easy-to-implement selection

mechanism. A virtual wheel is implemented for this

selection process. Each chromosome is assigned a

sector in this virtual wheel and the area of the sector is

proportional to their fitness value. Thus the

chromosome with largest fitness value will occupy

largest area, while the chromosome with a lower value

takes the slot of a smaller sector. Let there be five

chromosomes labeled as A, B, C, D and E and their

fitness value increases in the order of D, B, A, E and C.

Then Fig. 3 shows a typical allocation of five sectors of

chromosomes in the Roulette wheel.

In Roulette wheel selection, an angle is generated

randomly and the chromosome corresponding to

this angle is selected. Figure 3b shows a randomly

417 J. Computer Sci., 7 (3): 416-420, 2011

(a)

(b)

Fig. 3: (a) Typical allocation of sectors for

Chromosomes; (b) Roulette wheel selection

generated angle of 4 π /3 rad. In this case, chromosome

C is selected. The chromosomes thus selected are called

parent population and are subjected to undergo

crossover and mutation to produce offspring for the

next generation. Roulette wheel selection is the

conventional method adopted in GA for selection.

Following the selection of parent population, crossover

and mutation are performed to generate offspring

population. In crossover, randomly selected subsections of two individual chromosomes are swapped to

produce the offspring. In this study, single point

crossover is used for children generation.

Mutation is another genetic operation by which a

bit within a chromosome may toggle to the opposite

binary. Figure 4 illustrates crossover and mutation. The

crossover and mutation are performed based on the

probability of crossover and mutation.

Step5: Replace the current population with the new

population.

Step6: Terminate the program if termination criterion is

reached; else go to step 2

RESULTS

For the implementation of GA to the present

problem, dedicated software in MATLAB is developed.

The parameters of GA such as crossover probability,

mutation probability, population size and number of

generations are usually selected by means of trial and

error process to achieve the best solution set. The

parameters used in the implementation of GA are listed

below:

(a)

Population size:

Coding:

Number of generations:

Selection scheme:

Crossover operator:

Crossover probability:

Mutation probability:

Termination criterion:

(b)

Fig. 4: (a) Crossover and (b) mutation

8

Binary

80

Roulette wheel

Selection

Single point

Crossover

0.7

0.01

80 iterations.

Dedicated software is developed in MATLAB for

this optimization problem and the results are analyzed.

The convergence characteristics with GA are plotted in

Fig. 5 and 6. It can be seen that the objective function

value converges to a reasonably low value of 0.03

against its ideal value of zero at 45th iteration.

418 J. Computer Sci., 7 (3): 416-420, 2011

With these controller constants, induction motor

starting is simulated using MATLAB model shown in

Fig. 1. It is seen that the motor current is almost kept

constant at its rated value during starting. This

demonstrates the effectiveness of the proposed approach.

CONCLUSION

Fig. 5: Variation of objective function

The main objective of this study is tuning of the PI

controller parameters by Genetic algorithm. Simulation

results with PI controller are included. The parameters

of PI controller are tuned using the proposed

optimization algorithm.

REFERENCES

Hassanzadeh, I., S. Mobayen and A. Harifi, 2008.

Input-output feedback linearization cascade

controller using genetic algorithm for rotary

inverted pendulum system. Am. J. Applied Sci., 5:

1322-1328. DOI: 10.3844/ajassp.2008.1322.1328

(a)

(b)

Fig. 6: Variation of parameters (a) Kp; (b) Ki

The convergence is observed to be at a stable and faster

rate. The variation of controller parameters is delineated

in Fig. 6.

DISCUSSION

It is interesting to study the convergence behavior

of GA as given in Fig. 6. It is seen that, the number of

iterations required for all chromosomes to reach this

near-global optima is reasonably low. It is also seen that

the parameters of controller are suitably modified at

iterative step with the sole aim of minimizing the

objective function value. At the end of 50 generations,

the constants of controller are obtained as:

Kp= 10.3 and Ki= 2.2

Kangrang, A. and C. Chaleeraktrakoon, 2007.

Genetic algorithms connected simulation with

smoothing function for searching rule curves.

Am. J. Applied Sci., 4: 73-79. DOI:

10.3844/ajassp.2007.73.79

Lipo, T.A., 1971. The analysis of induction motors with

voltage control by symmetrically triggered

thyristors. IEEE Trans. Power Apparatus Syst., 90:

515-525. DOI: 10.1109/TPAS.1971.293053

Paice, D.A., 1968. Induction motor speed control by

stator voltage control. IEEE Trans. Power

Apparatus

Syst.,

87:

585-590.

DOI:

10.1109/TPAS.1968.292056

Say, M.G., 1958. The Performance and Design of

Alternating Current Machines: Transformers

Three-Phase Induction Motors and Synchronous

Machines. 3rd Edn., English Language Book

Society, London, pp: 664.

Shepherd, W. and J. Stanway, 1967. An experimental

closed-loop variable speed drive incorporating a

thyristor driven induction motor. IEEE Trans. Ind.

General

Appl.,

3:

559-565.

DOI:

10.1109/TIGA.1967.4180833

Subramanian, R., S.N. Sivanandam and C. Vimalarani,

2010. An optimization of design for s4-duty

induction motor using constraints normalization

based violation technique. J. Comput. Sci., 6: 107111. DOI: 10.3844/jcssp.2010.107.111

Sundaram, K.M., N. Rajasekar, J.B. Edward and G.

Saravanailango, 2009. A Fuzzy logic approach for

speed controller design of A.C. voltage controller

fed induction motor drive. Proceedings of the 5th

International Conference on MEMS, NANO, and

Smart Systems, Dec. 28-30, Dubai, United Arab

Emirates,

pp:

133-136.

DOI:

10.1109/ICMENS.2009.26

419 J. Computer Sci., 7 (3): 416-420, 2011

Wieczorek, J.P., G. Ozdeir and M. Zbigniew, 1998. An

evolutionary algorithm for the optimal design of

Wurtz, F., M. Richomme, J. Bigeon and J.C. Sabonnadiere,

1997. A few results for using genetic algorithms in

the design of electrical machines. IEEE Trans.

Mag., 33: 1892-1895. DOI: 10.1109/20.582656

induction motors. IEEE Trans. Mag., 34: 3882-3887.

DOI: 10.1109/20.728298

420