Cutler-Hammer_C514FDOC_SoftStart

advertisement

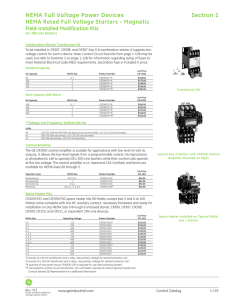

Cutler-Hammer Reduced Voltage Motor Control Motor Starters – NEMA Magnetic January 1999 J4-1 General Description Starter Selection Guide than one type starter will meet the application requirements, reference to the table below will show which starter is best suited for the application. In general, the application will determine the type of starter required. In cases where more Starter Type Starting Characteristics Expressed in % of Rated Values (Approx.) Motor Voltage Remarks Motor Current Line Current Torque 80 65 50 80 65 50 67➀ 45➀ 28➀ 64 42 25 The adjustable voltage taps permit wide adjustment of characteristics in the field. Part Winding Class ECA45 100 65 65 50 Requires part winding closed transition motor. A nine-lead 230/460-volt dual voltage motor may be used in 230-volt applications. Closed transition. Wye-Delta Class ECA48 Class ECA51 100 33 33 33 Requires delta wound motor with wye connections. Ideal for long accelerations. Closed transition is available. Autotransformer Class ECA42 80% Tap 65% Tap 50% Tap General Application The following factors should be considered when applying reduced-voltage starters to a squirrel cage motor-driven load. 1. The motor characteristics which will satisfy the starting requirements of the load. 2. The source of power and the effect the motor starting current will have on the line voltage. 3. The load characteristics and the effect the motor starting torque will have on the driven parts during acceleration. The starter protection required to protect the load, motor, starter, cables and power source during overload, undervoltage and fault conditions. A typical NEMA B motor started with full voltage will develop as much as 150% full-load torque when started with a starting current of around 600% full-load current. These values may exceed the mechanical limitations of the load or electrical limitations of the source, or both. A reduced-voltage or reduced-inrush starter will reduce both starting current and starting torque. Care must be taken when meeting power company limitations that the motor will produce sufficient torque to accelerate the load to near rated speed. Part-winding starters are suited to low starting torque loads such as fans, blowers and m-g sets. Autotransformer starters should be used with “hard to start” loads such as reciprocating compressors, grinding mills, and pumps. Wye-Delta starters are applicable to high inertia loads with long acceleration times which as centrifugal compressors and centrifuges. All starters, in addition to overload protection, will provide either low-voltage release or low-voltage protection depending upon the pilot device used with the starter. Low-voltage release, where power is applied to the motor after a power failure, can be obtained by using a 2-wire pilot device (temperature, switch, etc.). Low-voltage protection, where power is not applied to the motor after a power failure until restarted by an operator, can be obtained by using 3-wire control such as START STOP push buttons. Closed transition Wye-Delta types require adequate ventilation to remove resistor heat. Cutler-Hammer also offers a line of solidstate reduced-voltage starters known as Easy-start. Solid-state starters are ideally suited for many loads including conveyor applications since they provide controlled acceleration from zero to full load. UL Listing – Combination E176513, Non-Combination E19224 J Starting Characteristics 500 400 300 100 Autotransformer Starting on 65% Tap Full Load Current 0 Motor Speed Full Load Speed Autotransformer Starting ➀ Includes autotransformer magnetizing current. CAT.71.01.T.E Full Voltage Starting 600 500 Part Winding Starting 400 300 Wye-Delta Starting (Closed Transition) 200 Full Load Current 100 0 Motor Speed Wye-Delta or Part Winding Starting Full Load Speed Line Current, % of Full Load 600 Line Current, % of Full Load Line Current, % of Full Load Full Voltage Starting 200 700 700 700 600 500 400 300 KVA 200 100 0 Torque 20 Motor Speed Solid-State Starter 40 60 80 100 Full Load Speed J4-2 Cutler-Hammer Reduced Voltage Motor Control Motor Starters – NEMA Magnetic January 1999 Part-Winding Type Description Part-Winding starting provides convenient, economical one-step acceleration at reduced current where the power company specifies a maximum or limits the increments of current drawn from the line. These starters can be used with nine-lead dual-voltage motors on the lower voltage and with special partwinding motors designed for any voltage. When used with dual-voltage motors, it should be established that the torque produced by the first half-winding will accelerate the load sufficiently so as not to produce a second undesirable inrush when the second half-winding is connected to the line. Most motors will produce a starting torque equal to between 1/2 to 2/3 of NEMA standard values with half of the winding energized and draw about 2/3 of normal line current inrush. Opening the STOP button or other pilot device de-energizes contactors (1M), (2M) and timer (TR), removing the motor from the line. Operation (Refer to schematic diagram) Closing the START button or other pilot device energizes the start contactor (1M) which seals in through its interlock (1M) and energizes the timer (TR). The (1M) contacts connect the first half-winding of the motor across the line. After a preset time interval, the timer (TRTC) contact closes energizing contactor (2M). The (2M) contact connect the second half-winding of the motor across-the-line. Contactor Sequence Contactor Start Run 1M ● ● ● 2M Typical Schematic Diagram Part Winding L1 L2 L1 L2 L3 L3 1M OL T2 T3 #3 2M Select Overload Heater Packs for 50% of Rated Full Load Motor Current T1 #1 #2 CKT BKR or SW & FU OL Motor T7 T8 T9 Design Features 7 1M TBX2 Stopped 8 G Contactors – (1M) (2M) A three-pole contactor (1M) connects only the first half-winding of the motor for reduced inrush current on starting (see table below for size). A three-pole contactor (2M) connects the second half-winding of the motor for running (see table below for size). Run R TB1 Stop TB1 TB2 Start On-Delay 1M PS Auto A1 TB3 TB1 TB1 2 TB3 Off T.C. = Timed Closing Hand 8 TR 6 5 A1 1M A2 1.5 – 15 Sec. TR 7 E 2M (1M) OL TB4 95 96 (2M) OL A 95 96 A2 T.C. Maximum Hp NEMA Size Starter Contactor (1M) (2M) 1 2 3 4 5 6 1 2 3 4 5 6 230 Volts, 60 Hz 15 25 50 75 150 300 1 PW 2 PW 3 PW 4 PW 5 PW 6 PW Size 460-575 Volts, 60 Hz J 15 40 75 150 350 600 1 PW 2 PW 3 PW 4 PW 5 PW 6 PW Reduced Voltage Enclosures (Refer to page J4-5 for dimensions) 1 2 3 4 5 6 1 2 3 4 5 6 Freedom ECN Box Number Freedom ECN Box Numer NEMA 1 3R, 4X, 12 NEMA 1 3R, 4X, 12 Class 45: Partwinding – Non-combination 2PW 3 7 7➁ 7 3PW-4PW 9 9 9➁ 9 5PW E E E➁ E E E Class 46: Partwinding – With Disconnect Class 47: Partwinding – With Thermal Magnetic Trip CB 2PW-4PW E E Overload Relay – (OL) Two three-pole type B overload relays provide starting and running overcurrent protection. Timing Relay – (TR) An electrically operated pneumatic relay provides accurate, adjustable start-to-run transfer timing. Other Types Part-winding Type ECN45 starters are also available in combination (Type 46 and 47), reversing and three point (primary resistor) types. ➀ 76- and 90-inch enclosures are floor mounted. ➁ Advantage utilizes a NEMA 12 enclosure. CAT.71.01.T.E Cutler-Hammer Reduced Voltage Motor Control Motor Starters – NEMA Magnetic January 1999 J4-3 Wye-Delta Type Description Wye-Delta type starters are applied extensively to industrial air conditioning installations because they are particularly suited for starting motors driving high inertia loads with resulting long acceleration times. They are not, however, limited to this application. When six- or twelve-lead delta-connected motors are started wye-connected, approximately 58% of line voltage is applied to each winding and the motor develops 33% of full-voltage starting torque and draws 33% of normal locked-rotor current from the line. When the motor is accelerated, it is reconnected for normal data operation. de-energizes the timer (TR) opening timer (TRTC) thus energizing contactor (2S). Operation (Refer to schematic diagram) Closing the START button or other pilot device energizes contactor (1S) whose contacts connect the motor in a wye connection. Interlock (1S) closes, energizing contactor (1M) and timer (TR). The (1M) contacts energize the motor windings in a wye. After a preset time interval, timer (TRTC) contact closes energizing contactor (2S). Interlock (2S) opens, dropping out contactor (1S). The motor is now energized in series with the resistors. Interlock (1S) closes, energizing contactor (2M), bypassing the resistors and energizing the delta connected motor at full voltage. Interlock opens, An overload, opening the STOP button or other pilot device de-energizes contactors (1M) and (2M), removing the motor from the line. (TRP) de-energizes and locks out the control circuit if the duty cycle of the transition resistors is exceeded. Wye-Delta Class ECN51 closed transition starters are also available in combination types and Class ECN48 open transition non-combination and combination starters. Typical Schematic Diagram Design Features Contactors – (1S) (1M) (2S) (2M) A three-pole contactor (1S)➀ shorts the motor leads T4-T5-T6 during starting to connect motor in wye (see table below for size). Wye-Delta Closed Transition L1 CKT BKR #1 #2 L2 or L3 SW & FU #3 L1 L2 L3 2M T6 T4 T5 1S 1S 2S 1M T3B Select Overload Heater Coils for 58% of Rated Full Load Motor Current Resistor T1B Resistor A three-pole contactor (1M) energizes motor leads T1-T2-T3 for both wye and delta connections (see table below for size). Resistor T2B 1S OL T1 T2 T3 T1A A three-pole contactor (2S) connects resistors in series with the motor windings during the start-to-run transition period (see table below for size). T2A 1S 5 5 7 Stopped 2M 8 R TB1 Stop TB1 On-Delay 1.5 – 15 Sec. TR 2 E Start TB2 TB3 1S 2M 2S 51 52 A1 53 2 1 TR 3 Contactor (1M) (2M) (1S) (2S) TB1 230 Volts, 60 Hz 10 25 50 75 150 300 500 800 1 YD 2 YD 3 YD 4 YD 5 YD 6 YD 7 YD 8 YD 1 YD 2 YD 3 YD 4 YD 5 YD 6 YD 7 YD 8 YD 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 4 5 6➀ 7➀ 1 1 1 2 3 4 5 6 1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 1 2 3 4 4 5 6➀ 7➀ 1 1 1 2 3 4 5 6 7 A2 TB4 1 TRP 4 TRP E 2S 95 96 7 A2 TB3 1S 54 A1 56 A1 1M A2 T.O. = Timed Opening T.C. = Timed Closing 1M 8 TR 6 55 1S 2M A2 T.C. J Reduced Voltage Enclosures (Refer to page J4-5 for dimensions) Size ➀ 1S is two pole on sizes 7 and 8. CAT.71.01.T.E Off A1 Hand 460-575 Volts, 60 Hz 15 40 75 150 300 700 1000 1500 TB1 T.C. PS Auto 1S T.O. 1M NEMA Size Starter TBX2 G Run A three-pole contactor (2M) energizes the motor leads T4-T5-T6 during running to connect the motor in delta (see table below for size). Max. Hp Motor T3A Freedom ECN Box Number Freedom ECN Box Number NEMA 1 NEMA 1 3R, 4X, 12 E E 3R, 4X, 12 Classes 48, 51: Wye Delta – Non-combination Classes 49, 52: Wye Delta – With Disconnect Classes 50, 53: Wye Delta – With Thermal Magnetic Trip CB WYD-4YD E E J4-4 Cutler-Hammer Reduced Voltage Motor Control Motor Starters – NEMA Magnetic January 1999 Autotransformer Type Typical Schematic Diagram R L2 L2 L3 L3 #1 #2 CKT BKR or SW & FU R #3 5E 5D 7 Duty cycle of these starters is as follows: up to 200 hp, 15 seconds on each 4 minutes for 1 hour, repeated after 2 hours. Over 200 hp, three periods of 30 seconds on, 30 seconds off repeated after 1 hour. 8 T2 Motor T3 1S 0% 50% 1E 1S 1D TBX2 10 G Run R TB1 TB1 Stop TB2 Start On-Delay 1.5 – 15 Sec. TR 2 7 TB3 E Design Features 8 TR Contactors - (1S) (2S) (Run) A three-pole (1S)➂ and a three-pole contactor (2S) connect the motor to the autotransformer for reduced-voltage starting (see table below for size). T1 Stopped R 9 OL 3D 2S 1S 65% 100% 2S 0% L1 1S 1C 3E 0% L1 5C 100% R 100% Closed transition is standard on all sizes assuring a smooth transition from reduced to full voltage. Since the motor is never disconnected from the line there is no interruption of line current which can cause a second inrush during transition. 3C 2S RVNR AUTOXFMR (3-coil) 50% 28%➁ 45%➁ 67%➁ 50% 25% 42% 64% 80% 50%➀ 65% 80% Other Types Autotransformer starters are also available in combination and reversing types. 65% Line Inrush % Locked Ampere An overload, opening the STOP push button or other pilot device de-energizes the (R) contactor removing the motor from the line. 65% Starting Torque % Locked Torque contactor (R) which seals in through its interlock (R). The run contacts are now closed, and the motor is running at full voltage. Start contactor (2S) and relay (TR) are de-energized when interlock (R) opens. 80% Tap Operation (Refer to schematic diagram) Closing the START button or other pilot device energizes the start contactor (1S). The interlock (1S) closes, energizing the timing relay (TR) and contactor (2S) which seal in through the interlock (2S). With the (1S) and (2S) contactors closed, the motor is connected through the autotransformer for reducedvoltage start. After a preset time interval, the (TRTO) contacts time open, de-energizing contactor (1S) and connecting the autotransformer as a reactor in series with the motor. Interlock (1S) immediately energizes the run 80% Description Autotransformer type starters are the most widely used reduced-voltage starter because of their efficiency and flexibility. All power taken from the line, except transformer losses, is transmitted to the motor to accelerate the load. Taps on the transformer allow adjustment of the starting torque and inrush to meet the requirements of most applications. The following characteristics are produced by the three-voltage taps: 5 51 R 1S 52 A1 TB4 OL 95 A2 OTT "C" OTT "E" OTT "D" 96 B C D Auto-Transformer Overtemp SWa T.O. 2S TB1 TB1 A1 2S A2 2S TB3 Off 8 TR Hand 53 1S PS Auto 6 54 1S 55 A1 R A2 T.O. = Timed Opening T.C. = Timed Closing T.C. A three-pole contactor (Run) bypasses the autotranformer and connects the motor for fullvoltage across-the-line running (see table below for size). J Maximum Hp Size NEMA Size Starter Contactor Run Reduced Voltage Enclosures (Refer to page J4-5 for dimensions) Starting (1S) (Three Pole) (2S) (Three Pole) 2 3 4 5 6 7 8 2 3 4 5 6 6➂ 7➂ 2 3 4 5 6 6 7 2 3 4 5 6 7 8 2 3 4 5 6 6➂ 7➂ 2 3 4 5 6 6 7 Freedom ECN Box Number Freedom ECN Box Number NEMA 1 NEMA 1 3R, 4X, 12 E2 E2 3R, 4X, 12 Class 42: Autotransformer – Non-combination Class 43: Autotransformer – With Disconnect Class 44: Autotransformer – With HMCP 2-4 E2 E2 230 Volts, 60 Hz 15 30 50 100 200 300 450 2 3 4 5 6 7 8 460-575 Volts, 60 Hz 25 50 100 200 400 600 900 2 3 4 5 6 7 8 ➀ Not included 50 hp and below. ➁ Includes transformer magnetizing current. ➂ 1S is two pole on sizes 7 and 8. CAT.71.01.T.E Cutler-Hammer Reduced Voltage Motor Control Motor Starters – NEMA Magnetic January 1999 J4-5 Dimensions Dimensions in Inches (mm) Box Number Wide A High B Deep C Wide D High E E 28.00 (711) 61.75 (1569) 12.88 (327) 22.50 (572) 60.15 (1528) E2 28.00 (711) 56.10 (1425) 12.76 (324) 22.50 (572) 54.50 (1384) 190 7 16.25 (413) 14.37 (365) 7.51 (191) 11.00 (279) 13.50 (343) 24 9 25.50 (648) 29.10 (739) 3 12.65 (321) 14.40 (366) 9.31 (237) 7.31 (186) Mounting 180 20.00 (508) 27.50 (699) 72 9.75 (248) 11.25 (286) 17 B Reduced Voltage Enclosures Size A Ship Weight lbs. Freedom ECN Box Number Freedom ECN Box Number NEMA 1 NEMA 1 3R, 4X, 12 E2 E2 E2 3R, 4X, 12 E Class 42: Autotransformer – Non-combination Class 43: Autotransformer – With Disconnect Class 44: Autotransformer – With HMCP 2-4 E2 D Class 45: Partwinding – Non-combination 2PW 3 7 7➀ 7 3PW-4PW 9 9 9➀ 9 5PW E E E➀ E Class 46: Partwinding – With Disconnect Class 47: Partwinding – With Thermal Magnetic Trip CB 2PW-4PW E E C Box E E E E E Classes 48, 51: Wye Delta – Non-combination Classes 49, 52: Wye Delta – With Disconnect Classes 50, 53: Wye Delta – With Thermal Magnetic Trip CB 2YD-4YD E E J Boxes 7, 9 Boxes 3 ➃ Advantage utilizes a NEMA 12 enclosure. CAT.71.01.T.E J4-6 Cutler-Hammer Reduced Voltage Motor Control Solid-State Motor Starters January 1999 General Description Applications Cutler-Hammer’s Easy Start solid-state products can be applied in a wide array of customer applications. Typical benefits of solid-state include: ● Reduced starting torque stress on mechanical equipment allowing longer life of belts, gears, pulleys, and motor shafts commonly weakened during “across-theline” starting. ● Reduction of voltage drop during starting on weak utility systems where the performance of nearby equipment would be negatively affected. ● Reduced inrush current during starting which will allow better management of utility peak demand charges. ● Energy savings where light load conditions allow the phase-back of voltage during “idle” periods. ● Smooth, stepless starting with an infinite amount of torque and ramp time settings allowing superior flexibility over typical electromechanical starting methods. Typical applications include: Centrifugal and Screw Compressors Material Handling Equipment Pumps, Fans and Blowers Food Processing Machinery Cranes and Hoists Enclosure Type J Cutler-Hammer offers a complete family of UL listed solid-state reduced voltage starters from 1-750 hp at 460 volt. Ratings at 208/230 and 575 volt 60 Hz and 380 volt 50 Hz are also available. Units can be mounted in NEMA 1, NEMA 12 and open panel construction. Motor control center mounting is also possible utilizing the Easy Start EA allowing mounting of up to 600 hp in a 20-inch wide Motor Control Center section. Starters in specialty enclosures such as NEMA 4 and 4X, are also available using a unique and electrically efficient method of power semiconductor bypass. Available in 4 different product classes, these starters provide soft-starting of ac induction motors. Motor voltage is adjustable by means of back-to-back SCRs (silicon controlled rectifiers) providing a smooth, stepless start (and stop) of the motor driven load. C514 – Solid-State Controller Typically retrofited between an existing electromechanical starter and motor. No overload protection is included. Available from 10-100 amperes. Easy Start EJ – Solid-State Starter Complete starter with Class 10 electronic overload protection. Ideal for applications where few advanced protection features are required. Available from 10-390 amperes. Easy Start ES – Solid-State Starter Full featured starter with Class 20 electronic overload and advanced motor protection package (phase loss, current unbalance, undervoltage, and overtemperature protection). Door mounted status and diagnostic LEDs and an abundance of standard options. Available from 6-950 amperes. Easy Start EA – Solid-State Starter with Advantage Contactor Bypass. This unique product utilizes the SCRs during the start sequence only, and then a contactor is closed in parallel to handle continuous current during run duty, significantly reducing power losses. This extremely small efficient product is ideal for the space conscious user. Available from 11-760 amperes. Airborne particulate may be detrimental to starter performance and reliability, so caution must be exercised in choosing the enclosure best suited to the environment. The NEMA rating of the enclosure defines its ability to withstand the ingress of foreign particulate as described below: NEMA 1 A general purpose, indoor-type enclosure. NEMA 12 A dust-tight and drip-tight enclosure for indoor industrial applications. NEMA 4 A watertight and dust-tight enclosure for either indoor or outdoor use. NEMA 4X Identical to NEMA 4, with the additional requirement that the enclosure be corrosionproof as well. All Easy Start products include standard adjustments such as adjustable starting torque, ramp time, and current limit settings. A patented load sensing circuit that reduces applied voltage during “light load” conditions is included on all EJ/ES units and can result in energy savings when duty cycles allow. The EA product achieves lower losses by bypassing the less efficient semiconductors. CAT.71.01.T.E Cutler-Hammer Reduced Voltage Motor Control Solid-State Motor Starters January 1999 J4-7 General Description Solid-State Starters Product Comparison Description Series C514 Easy Start EJ Easy Start ES Easy Start EA Range Type Voltage Overload Ramp Type Ramp Time Current Limit Initial Torque Phase Sensitive Energy Saver Phase Loss LEDs Smooth Stop Pulse Start Extended Start 10-100A Controller 200-600V No Voltage 1-45s No 40-80% V No No No 1 Option No No 10-390A Starter 200-600V Class 10 Voltage 2-70s 250-500% 20-90% V Yes Yes No 1 Option No No 6-950A Starter 200-600V Class 20 Voltage or Current 1-40s 200-500% 20-90% V Yes Yes Standard 9 Option No Option 11-760A Starter 200-600V Class 10/20 Current 1-45s 100-500% 100-200% I Yes No Standard 3 Option Option No Continuous Duty 100% 100% 120% 115% Paralleling Bypass Open Chassis NEMA 12 NEMA 3R NEMA 4 NEMA 4X Circuit Breaker No Yes Yes Yes No No No No Yes Yes (130A Max.) No No No No No Yes Yes (500A Max.) No No No Option Standard Yes Yes Yes Yes Yes Option Application and Environmental Considerations The installation environment for a solid-state reduced voltage starter is of prime concern. Conditions such as ambient temperature, altitude and the presence of corrosives or moisture must all be considered when choosing an enclosure and applying the starter. Ambient Temperature Easy Starts are rated for 40°C (104°) ambient temperature. For above 40°C derate by 5% for every 5°C rise over 40°C up to 50°C (122°F) maximum. Altitude Easy Starts are rated for 1000 meters [3300 ft.]. Use Derate formula for derating above 1000 meters. DERATE % (meters) = [Actual Altitude – 1000] [7%]/1000 Multi-Motor Operation Easy Starts can be used to control multiple motors if the following conditions are met: ● The current rating of Easy Start should be equal to or greater than the total of individual motor full load amperes and Easy Start must be set for the cumulative full load amperes of the motors. CAT.71.01.T.E ● Individual motor overcurrent protection is provided by others. ● Energy Saver circuit is turned OFF. ● The motors should not be mechanically coupled together, i.e., two motors on same shaft. ● NEC and local code requirements for individual motor protection and branch circuit protection are met. Frequent Starting/Stopping The number of starts and stops allowable depends upon many factors. The most important ones are: 1. Set level of the starting current limit 2. Start time. 3. Run time. 4. Off time before next start. The number of starts per hour is based on the current carrying capacity of the SCRs. A high start/stop duty may require the oversizing of the Easy Start. If a high number of multiple starts occur, the starter may trip due to the inverse time overload current protection function. In this situation, it is advisable to wait a period of 10 minutes before restarting to avoid damage to the Easy Start and allow the thermal sensor to reset. The motor manufacturer should be consulted about the effect of a high number of multiple starts on motor life. Starting Torque The reduced voltage applied to the motor results in reduced inrush current and a soft start. However, it reduces the starting torque of the motor. The relationship is as follows: Torque at reduced current = Torque at full current Current at reduced voltage 2 Current at full voltage EXAMPLE: A 100 hp 1800 rpm 460V NEMA B motor draws six times full load amperes for starting, and starting torque is 150% of full load torque. If the same motor is started with Easy Start at 300% current limit, then the available torque would be: 300 600 2 = 1/4 of full voltage torque = 1/4 x 150% full load torque = 37.5% full load torque available. Open Units Open panel units should be mounted in a box so the temperature inside the box does not exceed 50°C (122°F). For sizing the enclosure the heat loss in watts can be estimated at 3 times the full load current. EXAMPLE: For ES-180-4NR the maximum current rating is 180 amperes. The approximate watts loss at maximum current rating is 3 x 180 = 540 watts. For units with non-isolated heat sinks, all the watt loss must be dissipated through the box surface. For units with isolated heat sinks; the heat sink fins should be brought out in open air through a properly gasketed cutout in the enclosure. Approximately 50% watt loss is dissipated through the heat sinks and the remaining 50% should be dissipated through the remainder of the box surface, not counting the heat sink. NEMA Design C and D Motors, Wound Rotor Motors These motors are used due to their high starting torque characteristics. When high starting currents and high starting torques are required, the extended time current option must be supplied with an oversized Easy Start ES unit. Consult the factory for application considerations. J Cutler-Hammer Reduced Voltage Motor Control Solid-State Motor Starters J4-8 January 1999 C514 Soft Start Controller Standard Design Features Description The C514 requires no separate control power wiring when wired between a starter and the motor. All customer power connections and adjustments are easily accessible. Simple installation makes the C514 ideal for new or retrofit applications. 3-Phase Supply L1 L2 L3 Motor Starter “Soft Start” Controller OL T1 C514 Soft Start Controller The Cutler-Hammer C514 is a solid-state motor controller providing reduced voltage “Soft” starting for three-phase ac induction motors. Installation is easy — the C514 is simply connected in series with the existing electromechanical motor starter. An optional version provides a controlled deceleration ramp for Soft-Stop applications and a separate 120V control scheme for additional control flexibility where required. T2 T3 T1 T2 T3 Motor Typical Wiring Diagram for Basic C514 Controller C514 Soft Start Controller – Horsepower Rating, Dimensions and Weights Current Rating Amperes➀ Maximum HP Rating Motor Volts Catalog Number➁ Dimensions in Inches (mm) Wide High Deep Mounting A B C D Screw Size E Shipping Weight Lbs.(Kgs) F Open Type J 11/9.6/11 3/3/7.5 200/230/460 C514BNOC 7.02 (178) 9.51 (242) 5.45 (138) 5.63 (143) 8.50 (216) 1/4" 9 (4.08) 11/11 7.5/10 460/575 C514BNOD 7.02 (178) 9.51 (242) 5.45 (138) 5.63 (143) 8.50 (216) 1/4" 9 (4.08) 17.5/22/21 5/7.5/15 200/230/460 C514CNOC 7.08 (180) 13.20 (335) 5.66 (144) 6.53 (166) 11.00 (279) 1/4" 11 (5.0) 21/22 15/20 460/575 C514CNOD 7.08 (180) 13.20 (335) 5.66 (144) 6.53 (166) 11.00 (279) 1/4" 11 (5.0) 32.2/42/40 10/15/30 200/230/460 C514DNOC 9.75 (248) 12.00 (305) 6.09 (155) 8.01 (204) 11.00 (279) 1/4" 14 (6.35) 40/41 30/40 460/575 C514DNOD 9.75 (248) 12.00 (305) 6.09 (155) 8.01 (204) 11.00 (279) 1/4" 14 (6.35) 48.3/54/52 15/20/40 200/230/460 C514ENOC 9.75 (248) 12.00 (305) 6.09 (155) 8.01 (204) 11.00 (279) 1/4" 14 (6.35) 52/52 40/50 460/575 C514ENOD 9.75 (248) 12.00 (305) 6.09 (155) 8.01 (204) 11.00 (279) 1/4" 14 (6.35) 92/80/96 30/30/75 200/230/460 C514FNOC 9.05 (230) 14.50 (368) 7.87 (200) 6.42 (163) 7.42 (189) 1/4" 27 (12.3) 96/99 75/100 460/575 C514FNOD 9.05 (230) 14.50 (368) 7.87 (200) 6.42 (163) 7.42 (189) 1/4" 27 (12.3) NEMA 3R/12 Enclosed 11/9.6/11 3/3/7.5 200/230/460 C514BDOC 8.09 (206) 11.64 (296) 5.84 (148) 6.44 (164) 10.80 (274) 10 - 32 17 (7.7) 11/11 7.5/10 460/575 C514BDOD 8.09 (206) 11.64 (296) 5.84 (148) 6.44 (164) 10.80 (274) 10 - 32 17 (7.7) 17.5/22/21 5/7.5/15 200/230/460 C514CDOC 7.44 (189) 15.13 (384) 5.91 (150) 5.79 (147) 14.13 (359) 1/4" 21 (9.5) 21/22 15/20 460/575 C514CDOD 7.44 (189) 15.13 (384) 5.91 (150) 5.79 (147) 14.13 (359) 1/4" 21 (9.5) 32.2/42/40 10/15/30 200/230/460 C514DDOC 10.64 (270) 16.13 (410) 6.83 (174) 9.00 (229) 15.00 (381) 1/4" 27 (12.3) 40/41 30/40 460/575 C514DDOD 10.64 (270) 16.13 (410) 6.83 (174) 9.00 (229) 15.00 (381) 1/4" 27 (12.3) 48.3/54/52 15/20/40 200/230/460 C514EDOC 10.64 (270) 16.13 (410) 6.83 (174) 9.00 (229) 15.00 (381) 1/4" 27 (12.3) 52/52 40/50 460/575 C514EDOD 10.64 (270) 16.13 (410) 6.83 (174) 9.00 (229) 15.00 (381) 1/4" 27 (12.3) 92/80/96 30/30/75 200/230/460 C514FDOC 20.40 (518) 31.36 (797) 12.51 (318) 18.37 (467) 29.65 (753) 1/4" 125 (56.7) 96/99 75/100 460/575 C514FDOD 20.40 (518) 31.36 (797) 12.51 (318) 18.37 (467) 29.65 (753) 1/4" 125 (56.7) ➀ C514 controllers are designed for use with 1.15 service factor motors having full load current ratings not exceeding values shown ➁ Separate 120 volt control with deceleration ramp, add suffix letter “A” to catalog number. Example C514BDOCA. CAT.71.01.T.E Cutler-Hammer Reduced Voltage Motor Control Solid-State Motor Starters January 1999 J4-9 Easy Start E J Soft Start Controller Catalog Numbering System Description EJ 026 — 4 EP Factory option S - Smooth stop Easy Start EJ The Easy-Start EJ is a solid-state reduced voltage motor starter with built-in electronic overload protection. The EJ starter is used to reduce starting current and high starting torque. The starter’s load-sensing circuit reduces the voltage to lightly loaded motors to save energy. EJ starters are available for ac motors 5 to 300 hp 460 volt in open panel, NEMA 1 and NEMA 12 enclosures. 208/230, 575 volt, 60 Hz and 380 volt, 50 Hz units are also available. Enclosure EP – Open panel isolated heat sink. (EJ026, 052, 068, 075, 100 and 130) NP – Open panel non-isolated heat sink. (EJ190, EJ270 and EJ390) NC – Open panel non-isolated heat sink. Suitable for mounting in 20-inch wide MCC structure. (EJ190, EJ270 and EJ390) ER – NEMA 12 NR – NEMA 1 Full load ampere rating 026 052 Voltage 068 3 – 380/415V 075 4 – 208/230/460V 100 5 – 500/575V 130 190 270 390 Features ● ● ● ● ● ● ● Complete Starter Adjustable current limit 250-500% Energy saving circuit Six space device panel on enclosure door Class 10 electronic overload protection 500% for 10 seconds overload capability Suitable for mounting in 20-inch wide MCC structure ● UL and CUL listed EJ Soft Start Controller – Horsepower Rating, Approximate Dimensions and Weights Ampere Range Maximum Horsepower Motor Volts Catalog Number Dimensions (In.) Height Width Clearance (In.) Depth Side Top/Bottom Weight (Lbs.) Open Type 10- 26 5/7.5/15 208/230/460 EJ026 15 14 8 22 20- 52 10/15/30 208/230/460 EJ052 15 14 8 22 25- 68 20/25/50 208/230/460 EJ068 15 14 8 26 28- 75 20/30/60 208/230/460 EJ075 15 14 8 37-100 30/30/75 208/230/460 EJ100 15 14 8 47-130 40/50/100 208/230/460 EJ130 27 14 70-190 60/75/150 208/230/460 EJ190 39 (47.68)➀ 26.75 (18.5)➀ 26 Does not apply 8 26 40 14 (9.5)➀ 100 100-270 75/100/200 208/230/460 EJ270 39 (47.68)➀ 26.75 (18.5)➀ 14 (9.5)➀ 100 142-390 125/150/300 208/230/460 EJ390 39 (47.68)➀ 26.75 (18.5)➀ 14 (9.5)➀ 110 NEMA 12 Enclosed 10- 26 5/7.5/15 208/230/460 EJ026 17.6 13.5 10.75 6 35 20- 52 10/15/30 208/230/460 EJ052 17.6 13.5 10.75 6 35 25- 68 20/25/50 208/230/460 EJ068 28.5 25.25 10.75 6 86 28- 75 20/30/60 208/230/460 EJ075 28.5 25.25 10.75 37-100 30/30/75 208/230/460 EJ100 28.5 25.25 47-130 40/50/100 208/230/460 EJ130 33.8 24.5 Does not apply 6 86 10.75 6 86 13 6 107 NEMA 1 Enclosed 70-190 60/75/150 208/230/460 EJ190 46.38 18.5 9.5 12 100-270 75/100/200 208/230/460 EJ270 46.38 18.5 9.5 12 142-390 125/150/300 208/230/460 EJ390 46.38 18.5 9.5 12 ➀ Dimension in parenthesis is for NC type open panel for MCC mounting. CAT.71.01.T.E 100 Does not apply 100 110 J J4-10 Cutler-Hammer Reduced Voltage Motor Control Solid-State Motor Starters January 1999 Easy Start ES Soft Start Controller Description Line A Line B Motor Line C To SCR Reset Control Power Stop Start Gates Control Logic & Protection Typical Solid-State Reduced Voltage Starter Schematic The Easy Start ES is a solid-state reduced voltage motor starter with built-in electronic overload protection. The ES starter is used to reduce starting current and high starting torque. The starters load-sensing circuit reduces the voltage to lightly loaded motors to save energy. ES starters are available for ac motors 5 to 750 hp 460-volt in open, NEMA 1 and NEMA 12 enclosures. 208/230, 575-volt, 60 Hz, and 380-volt, 50 Hz units are also available. Easy-Start ES Horsepower Rating Unit Ampere Ratings Min. Base 7 10 18 36 51 71 45 70 120 250 360 500 26 38 80 107 135 180 260 560 750 950 Nominal Horsepower or kW Max.➀ Hp 208V Hp 230V kW 380/415V Hp 460V kW 500V Hp 575V 54 84 144 300 432 600 5- 10 15- 20 25- 40 40- 75 75-100 100-150 5- 15 20- 25 30- 40 50-100 100-150 125-200 4- 22 30- 37 45- 55 75-110 110-200 200-250 5- 30 40- 50 60-100 150-200 200-300 250-400 4- 30 37- 45 55- 75 90-160 200-250 300-355 7- 40 50- 60 75-100 200-250 250-300 300-500 216 312 672 900 1140 40- 60 60- 75 100-200 250-300 350-400 40- 60 75-100 125-200 250-300 300-350 75- 90 110 160-230 355-400 450 75-150 150-200 250-450 500-600 600-750 55-110 160 200-400 450-500 600 100-150 200-250 300-500 600-750 800-900 NEMA 12 ES045➁ ES070➁ ES120➁ ES250 ES360 ES500 NEMA 1 ES180 ES260 ES560 ES750 ES950 Easy-Start ES Dimensions and Weights Approximate only. Not to be used for construction purposes. J Catalog Number➂ Mounting Enclosure Height (In.) Width (In.) Depth (In.) Weight (Lbs.) Line/Load Lugs➃ Sides (In.) Top and Bottom (In.) ES045-__EP ES070-__EP ES070-__EC ES120-__EP ES120-__EC ES180-__NP➅ ES180-__NC➅ ES260-__NP➅ ES250-__NC➅ ES560-__NP➅ ES750-__NP➅ ES950-__NP➅ — — — — — — — — — — — — Open Open Open Open Open Open Open Open Open Open Open Open 16 16 15 16 27 39 48 39 48 39 45 78 19 19 14 19 14 26.75 18.5 26.75 18.5 26.75 30.75 33.00 11.5 11.5 8.3 11.5 8.3 14 9.5 14 9.5 14 17 21 32 33 33 35 60 100 100 112 100 137 320 400 #2 #2 1/0 2/0 250 kcmil 250 kcmil 350 kcmil 500 kcmil 350 kcmil 500 kcmil (2) 600 kcmil (4) 600 kcmil (4) ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ES180-__NR➅ ES260-__NR➅ ES560-__NR➅ Wall Wall Wall NEMA 1 NEMA 1 NEMA 1 46.5 46.5 46.5 31 31 31 15.5 15.5 15.5 220 232 257 250 kcmil 500 kcmil 500 kcmil (2) 12 12 12 ... ... ... ES180-__NL➅➆ ES260-__NL➅➆ ES560-__NL➅➆ ES750-__NL➅➇ ES950-__NL Floor Floor Floor Floor Floor NEMA 1 NEMA 1 NEMA 1 NEMA 1 NEMA 1 90 90 90 90 90 32 32 32 32 38 21 21 21 21 22.5 500 510 525 720 800 250 kcmil 500 kcmil 500 kcmil (2) 600 kcmil (4) 600 kcmil (4) ... ... ... ... 12 ... ... ... ... ... ES045-__ER ES070-__ER Wall Wall NEMA 12 NEMA 12 28.5 28.5 25 25 14 14 ES045-__EL ES070-__EL ES120-__EL Wall Wall Wall NEMA 12 NEMA 12 NEMA 12 43.5 43.5 43.5 24.5 24.5 24.5 ES250-__EL➅ ES360-__EL➅ ES500-__EL➅ Floor Floor Floor NEMA 12 NEMA 12 NEMA 12 90 90 90 32 32 32 ➀ Maximum rating is 1.2x base rating due to 120% continuous capability. ➁ Utilizes isolated heat sinks. ➂ __ in Cat. No. is 4 for 208/230/460V models, 3 for 380/415V models, 5 for 460/500/575V models. ➃ Line lug sizes shown are for Easy-Start ES lug. If circuit breaker option is ordered line connections Minimum Clearance Required➄ 95 95 #2 #2 6 6 6 6 15.5 15.5 15.5 120 120 121 #2 #2 2/0 6 6 6 6 6 6 21 21 21 520 525 550 500 kcmil (2) 500 kcmil (2) 500 kcmil (2) will be made on circuit breaker. Wall mounted units arranged for top entry, bottom exit. ➄ Minimum clearance sides is minimum clearance required between adjacent units. For NEMA 1 enclosure this clearance should be provided between unit and sidewall also. For NEMA 12 enclosures the clearance between unit and sidewall is not required. Minimum clearance top and 12 12 12 ... ... ... bottom is required for NEMA 12 models only. Minimum clearance required for open models will depend upon enclosure provided by others. ➅ Use non-isolated heat sinks. Heat is dissipated via the enclosure surfaces. ➆ MCC structure with 4-inch wire-way, could have cable entry/exit top or bottom. ➇ ES750 arranged for top entry and exit only. CAT.71.01.T.E Cutler-Hammer Reduced Voltage Motor Control Solid-State Motor Starters January 1999 J4-11 Easy Start ES Soft Start Controller Catalog Numbering System ES 120 — 4EL - XXX Options (any sequence) Easy Start ES Base ampere rating 045 070 120 180 250 260 360 500 560 750 950 Enclosure ER – Regular NEMA 12 NR – Regular NEMA 1 EL – Large NEMA 12 NL – Large NEMA 1 EP – Open panel isolated heat sink EC – Open panel isolated heat sink suitable for mounting in 20-inch wide MCC structure (ES045, ES070 and ES120) NP – Open panel non-isolated heat sink NC – Open panel non-isolated heat sink suitable for mounting in 20-inch wide MCC structure (ES180 and ES250) Voltage 3 – 380/415V 4 – 208/230/460V 5 – 460/500/575V For product description refer to Descriptive Bulletin 8650. Line DIP Switch Current Feedback CT Rectifier Inverse Time Trip Instant Trip Curr. Limit Init. Step Time Max Volts Curr. Trip Gates SCR’s Voltage Ramp Current J Undervoltage Min. Volts Voltage Feedback Amplifier Stab Phase Rotation Phase Loss Lockout Digital Trigger Current Unbalance Over Temp Aux. Trip Remote Contact Easy-Start ES Block Diagram CAT.71.01.T.E Motor J4-12 Cutler-Hammer Reduced Voltage Motor Control Solid-State Motor Starters January 1999 Easy Start EA Description Easy Start Advantage The Easy Start EA combines the performance benefits of a solid-state starter with the electrical efficiencies and small physical size typically associated with electromechanical devices. The Easy Start EA uses six back-to-back silicon controlled rectifiers (SCRs) to provide smooth, stepless, acceleration to an ac induction motor. Once the motor reaches full speed, an Advantage bypass contactor is energized in parallel to the SCRs to handle the motor’s continuous duty requirements. Since the SCRs are only conducting current for a short period of time, electrical losses are greatly reduced. The elimination of bulky heat sinks allows the Easy Start EA to be packaged in a wide selection of space saving enclosures. J Specifications Features and Benefits ● Line voltage . . . . . . . . . . . . . . . .200-600V ac, 3-phase, 60 Hz ● Output . . . . . . . . . . . . . . . . . . . .6 SCR’s full wave during start; bypass contactor during run ● Control voltage . . . . . . . . . . . . .120V ac, +10%/-15% ● Ramp time . . . . . . . . . . . . . . . . .1-45 seconds, 16-position hexadecimal switch ● Initial torque . . . . . . . . . . . . . . .100-200% current, 16-position hexadecimal switch ● Current limit. . . . . . . . . . . . . . . .100-500% of base rating, 16-position hexadecimal switch ● Overload capacity . . . . . . . . . . .115% continuous (of base rating) ● Overload protection . . . . . . . . .Inverse time-trip, DIP switch adjustable; Class 10/20 selectable ● Phase rotation . . . . . . . . . . . . . .ABC only start prohibit ● Phase loss/unbalance . . . . . . . .35% or greater difference between any two phases ● RC snubber . . . . . . . . . . . . . . . .SCR protection for dv/dt characteristics ● LED indications . . . . . . . . . . . . .Phase unbalance, current trip and phase rotation ● Trip relay . . . . . . . . . . . . . . . . . .NO contact Ratings . . . . . . . . . . . . . . . . . . . .60 VA resistive load, 20 VA inductive load Maximum switching voltage . .125V ac Maximum switching current . .1 ampere Closes on . . . . . . . . . . . . . . . . . .phase unbalance or overload trip ● Ambient temperature: Open. . . . . . . . . . . . . . . . . . . . . -20° to 50°C Enclosed. . . . . . . . . . . . . . . . . . -20° to 40°C Storage. . . . . . . . . . . . . . . . . . . -50° to 65°C ● Smooth stop (option) . . . . . . . 1-75 seconds ● Pulse start (option) . . . . . . . . . 0.2-3 seconds Feature ● Smooth Start/Stop Benefit Stepless motor acceleration/deceleration, reduced initial torque and inrush currents ● Adjustable Wide range of initial step Torque settings for various load starting requirements ● Adjustable Ability to control rate of Ramp Time current ramp ● Small Physical Reduced panel space, Size smaller enclosures ● Reduced Heat Better efficiencies/no heat Losses dissipation concerns ● 600V Rating One product for systems from 208 to 575V ● Emergency The Advantage starter is Backup rated to handle full starting current in an across-theline mode, if a problem is encountered ● Current Limit Limits current inrush and current draw during ramp ● Electronic Flexibility of use with Overload various motor sizes. More accurate than bimetallic methods ● Class 10 or 20 Overload curve can be Overload tailored to application Protection requirements ● Advantage Reduced contact bounce Starter and contact wear; lifetime Bypass coil warranty; contactor closes and opens at 1 times current ➃ ➁ ➂ ➀ User supplied Remote Reset can be installed by removing jumper between terminals 2 and 3. ➁ End-of-ramp Relay (K201) and Trip Relay (K200) are part of Logic Board; a remote fault device, such as Shunt Trip, may be connected in series with the N.O., K200 contact at point 8. ➂ Starter is reset by interrupting 120-volt supply at remote reset; or, by using the “RESET” pushbutton on the main logic board, which is at low level voltage. ➃ CPT and operator devices to be supplied by users unless ordered with enclosed units. Models EA045 through EA135 require 150VA minimum CPT. Models EA270 through EA760 require 300VA minimum CPT. CAT.71.01.T.E Cutler-Hammer Reduced Voltage Motor Control Solid-State Motor Starters January 1999 J4-13 Easy Start EA Catalog Numbering System Open Panel (60 Hz): E A PN Enclosed Units: ESEA 1 Ø G – Options: B1, A5, A6, T, C, etc. Options: S = Smooth Stop P = Pulse Start G = General Duty FLA — 045, 090, 135, 270, 360, 540, 760 FLA — 045, 090, 135, 270, 360, 540, 760 Voltage: D = 200-600V, 60 Hz G = 200-600V, 50 Hz Open Panel (50 Hz): E A PN5 Type: Ø = Standard Design 40°C Enclosures: S = NEMA 1, D = NEMA 12 W = NEMA 3R/4, C = NEMA 4X Options: S = Smooth Stop P = Pulse Start Series: 1 = Version 1 FLA — 045, 090, 135, 270, 360, 540, 760 Easy Start EA Enclosed Ratings Catalog Number Amperes Base Rating Maximum Continuous Minimum Horsepower 208V 230V 460V 575V 380V Kilowatts 415V EA045 EA090 EA135 EA270 EA360 EA540 EA760 45 90 135 270 360 540 760 52 104 155 311 414 621 874 12 23 34 69 92 137 193 15 30 50 100 125 200 250 15 30 50 100 125 200 300 30 60 100 200 250 450 600 40 75 125 250 350 500 750 22 45 55 110 160 250 400 22 45 75 110 160 300 450 Approximate Dimensions and Shipping Weights Model EA045 EA090 EA135 EA270 EA360 EA540 EA760 CAT.71.01.T.E Open Starter Panel Enclosed Starter W H D Lbs. W H D Lbs. 10.5 10.5 10.5 15.0 15.0 16.0 18.0 14.0 16.0 16.0 24.0 24.0 30.0 32.0 6.6 7.5 7.5 9.7 9.7 10.7 11.6 12 18 18 70 81 210 260 25.6 25.6 25.6 37.6 37.6 37.6 39.8 30.4 30.4 30.4 48.4 48.4 60.4 72.0 11.2 11.2 11.2 13.2 13.2 13.2 15.4 80 135 160 270 270 325 400 D W H J J4-14 Cutler-Hammer Reduced Voltage Motor Control Solid-State Motor Starters January 1999 Typical Specifications Soft Start Controller Type C514 1. Controller shall be Cutler-Hammer type C514. 2. The solid-state low-voltage controller shall consist of a power section mounted on an electrically isolated heat sink, a logic board located above the power section and shall be used in series with a separately specified electromagnetic starter with class 10 overload protection. 3. The power section shall be three-phase, 60 hertz, and rated for the hp, current and voltage as shown on the drawings. It shall consist of three (3) sets of back-to-back phase controlled power semiconductors. 4. Power semiconductors shall be rated with peak inverse voltage at least 2.5 times rated line-to-line voltage. Suitably rated snubbers for voltage suppression shall be included. 5. The one-piece logic board shall be mounted for easy testing and adjustment with quick disconnect plugs. Logic circuitry shall include: J a. Voltage ramp-up time adjustment – 5 to 45 seconds b. Initial voltage adjustable from 20% to 80% of rated voltage to provide for optimum starting torque c. The logic boards of all current ratings for a given voltage shall be interchangeable d. Each unit to be capable of multiple voltage operation e. Optional smooth stop time adjustment from 5 to 45 seconds with an interlock to release starter seal-in lock upon completion of stop cycle. Unit shall automatically reset upon removal of line power. 6. The solid-state logic shall be phase sequence insensitive. 7. A cover plate shall be mounted above the logic board to provide: a. An insulating safety barrier b. Warning labels c. Adjustment and setup instructions for current limit, time, torque, and horsepower (ampere) ratings d. Identified holes shall be located above adjustment pots so that screwdriver adjustments can be achieved without removing the cover. 8. Ground lug shall be furnished mounted on the isolated heat sink. 9. Enclosures a. Enclosures shall be NEMA 3/12. Solid-State Reduced Voltage Motor Starter Type EJ 1. Motor starter shall be Cutler-Hammer type EJ. 2. The solid-state reduced voltage motor controller shall consist of a power section, a one-piece printed circuit logic board and field wiring interface terminals. 3. The power section shall be three-phase, 60 hertz, and rated for the hp, current and voltage as shown on the drawings. It shall consist of three (3) sets of back-to-back phase-controlled power semiconductors. Maximum current limit shall be 500% for standard units. 4. Resistor/capacitor snubber networks shall be used to prevent false firing of SCRs due to dv/dt effects. 5. Fan cooled units shall be supplied with thermal sensors on the heat sink to trip the control protective logic for overtemperature condition. 6. The one-piece logic board shall be mounted for easy testing, service and replacement. 7. Three-phase current sensing via current transformers for closed loop control to insure motor stability shall be provided. 14. Tripped functions shall be designed to be cleared by removing power from the solidstate logic board. 15. The starter shall have a light emitting diode (LED) to indicate incorrect phase rotation. 16. Two (2) ground lugs shall be furnished, one (1) for incoming and one (1) for outgoing ground connections. 17. Power terminations shall consist of pressure type terminals for top or bottom entrance. 18. Enclosure a. Unit shall be supplied as an [open panel] [NEMA 1 enclosed] [NEMA 12 enclosed]. b. A door-mounted device panel shall be provided for [field] [factory] mounting of operator’s devices. 19. Units enclosed in motor control centers shall be of the same manufacturer as that of the circuit breaker and motor control center for coordination and design issues. 20. The manufacturer of the solid-state starter shall employ a field-based factory service organization for the purpose of start-up and repair of units. Third party service contractors are not acceptable. 8. The logic board shall use quick disconnect plug-in connectors for current transformer inputs, line-and-load voltage inputs, SCR gate firing output circuits, and status panel. Solid-State Reduced-Voltage Motor Starter Type ES 9. The logic circuitry shall include as a minimum: 2. The solid-state reduced voltage motor controller shall consist of a power section, a one-piece printed circuit logic board and a field wiring interface terminal board. a. Inverse time running overcurrent protection b. Auxiliary trip circuitry c. Gate firing circuit lockout protection on trip d. Fault relay lockout protection e. 250% to 500% current limit adjustment f. Initial voltage adjustment g. Acceleration time adjustment. 10. The logic board soldering shall be treated with a conformal protective coating system. 11. The logic board shall include, as standard, current and motor slip sensing circuitry that continually monitor motor load and regulate motor voltage to minimize motor kWh energy consumption. 12. The solid-state logic shall provide phase sequence protection. 13. External interface circuitry shall include 120-volt relay logic interface capability. 1. Motor starter shall be Cutler-Hammer type ES. 3. The power section shall be three-phase, 60 hertz, and rated for the hp, current and voltage as shown on the drawings. It shall consist of three (3) sets of back-to-back phase controlled power semi-conductors. Maximum current limit shall be 500% for standard units. 4. Resistor/capacitor snubber networks shall be used to prevent false firing of SCRs due to dv/dt effects. 5. Fan-cooled units shall be supplied with thermal sensors on the heat sink to trip the control protective logic for overtemperature condition. Thermal sensors shall be rated 90 degree C maximum. 6. The one-piece logic board shall be mounted for easy testing, service and replacement. CAT.71.01.T.E Cutler-Hammer January 1999 Reduced Voltage Motor Control Solid-State Motor Starters J4-15 Typical Specifications 7. Three-phase current sensing via current transformers for closed loop control to insure motor stability shall be provided. 8. The logic board shall use quick disconnect plug-in connectors for current transformer inputs, line-and-load voltage inputs, SCR gate firing output circuits and status panel. 9. The logic circuitry shall include as a minimum: a. Short-circuit electronic trip overcurrent protection. Time not to exceed 1/2 cycle b. Inverse time running overcurrent protection c. Auxiliary trip circuitry d. Gate firing circuit lockout protection on trip e. Fault relay lockout protection f. 250% to 500% current limit adjustment g. Minimum and maximum voltage adjustments h. Voltage stability adjustment. 10. The logic board soldering shall be treated with a conformal protective coating system. 11. The logic board shall include, as standard, current and motor slip sensing circuitry that continually monitor motor load and regulate motor voltage to minimize motor kWh energy consumption. 12. The solid-state logic shall provide phase sequence protection. 13. External interface circuitry shall include 120-volt relay logic interface capability. 14. Tripped functions shall be designed to be cleared by removing power from the solid-state logic board. 15. The starter shall have additional features as follows: a. Individual light emitting diodes (LEDs) to indicate run, undervoltage, phase loss, phase current unbalance, overcurrent trip, overtemperature, current limit, end of ramp, and incorrect phase rotation b. Single-phase protection with built-in short time delay c. Undervoltage protection with built-in short time delay d. The power section shall have metal oxide varistor (MOV) type surge suppressors across the SCRs rated 10% above the rated voltage. The power semiconductors shall be rated with peak inverse voltage at least 2.5 times SCR rated line-to-line voltage. Suitably rated snubbers for voltage suppression shall be included. e. 100% to 120% full load running current trip adjustment CAT.71.01.T.E f. 200% to 500% current limit adjustment. 16. Two (2) ground lugs shall be furnished, one (1) for incoming and one (1) for outgoing ground connections. 17. Power terminations shall consist of pressure-type terminals for top or bottom entrance. 18. Enclosure a. Unit shall be supplied as an [open panel] [NEMA 1 enclosed] [NEMA 12 enclosed] b. Enclosures shall not be less than 16gauge steel. Type 12 enclosures shall be of welded construction with gasketed heat sink and doors c. Doors shall include plastic device holders for mounting up to six (6) (eight (8) for above 200 hp motors) operator devices d. The following shall be included: 1. The operating handle of the disconnect, when supplied, shall always remain connected to the breaker or switch. The operating handle shall not be mounted on the door of the enclosure, but on the controller for safe “standaside” operation. The position of the operating handle will indicate ON or OFF position of switch or circuit breaker and include provision for padlocking in the OFF position. 2. Interlock provisions shall prevent unauthorized opening or closing of the starter door with the disconnect in the ON position. 3. The structure, when floor-mounted, shall be provided with adequate lifting means and shall be capable of being rolled or lifted into installation position and bolted to the floor. 4. A door-mounted status panel shall provide individual light emitting diodes (LEDs) to indicate run, undervoltage, phase loss, phase current unbalance, overcurrent trip, overtemperature, current limit, end of ramp, and incorrect phase rotation. 19. Units enclosed in motor control centers shall be of the same manufacturer as that of the circuit breaker and motor control center for coordination and design issues. 20. The manufacturer of the solid-state starter shall employ a field-based factory service organization for the purpose of start-up and repair of units. Third party service contractors are not acceptable. 21. Maximum continuous operation shall be at 120% of base amp rating. Reduced Voltage Bypass Motor Starter Type EA 1. Motor starter shall be Cutler-Hammer type EA. 2. The solid-state reduced voltage starter shall be UL and CUL listed and consist of an SCR based power section, logic board and paralleling bypass contactor. 3. The SCR based power section shall consist of six (6) back-to-back SCRs and shall be rated for a minimum peak inverse voltage rating of 1500 volts PIV. 4. Units using triacs or SCR/diode combinations shall not be acceptable. 5. Resistor/capacitor snubber networks shall be used to prevent false firing of SCRs due to dv/dt effects. 6. The logic board shall be mounted for ease of testing, service and replacement. It shall have quick disconnect plug-in connectors for current transformer inputs, line and load voltage inputs and SCR gate firing output circuits. 7. The logic board shall be identical through all ampere ratings and voltage classes and shall be conformally coated to protect for environmental concerns. 8. The paralleling bypass contactor shall energize when the motor reaches full speed and close/open under one (1) times motor current. 9. The contactor shall be fully rated for across-the-line starting duty should this be desired. 10. The contactor shall utilize an energy balanced contact closure to limit contact bounce and an intelligent coil controller to optimize coil voltage during varying system conditions. 11. The coil shall have a lifetime warranty. 12. The overload protection shall be electronic and be based on an inverse timecurrent algorithm. 13. Overload protection shall be adjusted via logic board. 14. Class 10 or 20 overload characteristic shall be selectable. 15. Units using bimetal overload relays are not acceptable. 16. Overtemperature protection (on heat sink) shall be standard. J J4-16 Reduced Voltage Motor Control Solid-State Motor Starters Cutler-Hammer January 1999 Typical Specifications 17. The solid-state logic shall be phase sensitive, and shall inhibit starting on incorrect rotation. 18. Improper phase rotation shall be indicated on the starter logic board. 19. Starters shall protect against a phase loss/unbalance condition shutting down if a 35% current differential between any two phases is encountered. 20. A normally open (NO) contact shall annunciate fault conditions, with contact ratings of 60 VA (resistive load) and 20 VA (inductive load). In addition, an LED display on the logic board shall indicate type of fault (current trip, phase loss, phase rotation). 21. The following logic board adjustments are required: a. Ramp Time; 1 to 45 seconds, on a hexadecimal switch b. Initial Torque; 100 to 200% current, on a hexadecimal switch c. Current limit; 100 to 500% current, on a hexadecimal switch d. FLA of motor; 4 to 1 range of starter, on a DIP switch. 22. Optional smooth stopping shall provide a linear voltage deceleration should the load require it. It is to be adjustable from 1 to 75 seconds. 24. Starters and breakers/HMCPs are to rated per UL 508D for a withstand rating of 65 kAIC RMS. 25. Units enclosed in motor control centers shall be of the same manufacturer as that of the circuit breaker and motor control center for coordination and design issues. 26. The manufacturer of the solid-state starter shall employ a field-based factory service organization for the purpose of start-up and repair of units. Third party service contractors are not acceptable. 27. Maximum continuous operation shall be at 115% of continuous ampere rating. 23. Enclosed units shall include a thermal magnetic circuit breaker or HMCP for short-circuit protection and quick disconnect means. J For a complete product specification in CSI format, see Cutler-Hammer Product Specification Guide, section 16481. CAT.71.01.T.E