Package Pump Stations & Controls

Package Pump Stations & Controls

Verticle Multi-Stage

Variable Speed Drive Panels

Verticle Turbine

End Suction Centrifugal

Split Case Centrifugal

Soft Starter Panels

NEMA Pump Panels

Multi-Pump Control Panels

Remote Connectivity

Engineered Systems

MCI Product Brochure: AGPC 111414

© 2014 Motor Controls Inc. All rights reserved

Motor Controls Incorporated

2818 Virgo Lane

Dallas Texas, 75229

1-800-735-1097

www.motorcontrols.com

mciwater@motorcontrols.com

Optional VFD

6

YEAR Warranty

Including

lightning strikes

MCI Advantage

MCI begin in 1980 to provide quality designed pump control panel solutions that is driven by

our policy “meeting our Customer’s requirements, every requirement, every time”.

MCI has supplied over 200,000 UL listed panels to our global customers.

Quality as our top priority is exhibited by our certifications and compliance standards :

ISO 9001-2008 CERTIFIED

UL 508a Control Panels

UL 698a Hazardous Locations

UL 778

Packaged Pump Stations

UL 50/E Industrial Enclosures

UL 1640 Portable Power Distribution

UL 891

Switch Boards

CAPABILITY

Experienced Engineering staff in pump controls applications to ensure the product you received is

application suited and programmed so the panel is ready out of the box.

Manfucter enclosures to provide standard and custom enclosures to meet any application

Investment in production capabilities to bring latest in technologies to reduce lead-time and cost

Partnerships with industry leading control components manufactures such as AB, SQ D and Danfoss

Product designs to ensure up time operation, longevity and ease of use by you

Leading edge enhancements such remote monitoring, power disconnects, multi-pump controls

125,000 Sq Facility w/Automated Fabrication Equipment

Graphics Department w/silk screen, overlays and engraving capability

STANDARDS

ENCLOSURES

TEMPERTURE RAITINGS

120 DEG F

ROBUST DESIGNS

MATERIAL: Carbon Steel , 304 & 316 SS, Aluminum

FINISH: Zinc Primer with 5 Stage Powder Coat Process w/Heat Guard Finish

SEALING: Foam in Place Gasket

WEATHER RESISTANT: Covers for All Keypads

Flanged Disconnects w/optional service rating

30 mm Panel Devices

VSD & SS Protection-High Speed Fuses & Line Surge Protection

NEMA Rated Components

Wide Range of Options

“Meeting our Customer’s requirements, every requirement, every time”

MPC Multi-Pump Controller

MPC is our configurable mult-pump control system

with optional cloud based remote monitoring and

notifications with any web enabled smart device such

as a table or cell phone.

The MPC can be used on new or to upgrade your

existing pump station with control operation designed

to maximize energy savings and operate your pump

station in the most efficient manner.

LEADING EDGE TECHNOLOGY

AB Compact Logic PLC

AB 10” PV+ Color Touch Screen

Monitor from any PC, Smart Phone/Tablet

OPERATIONAL EASE

Parameter changed Touch Screen

Multiple configurations

Protective Safeties

Operation & Alarm Information

WEB Based Remote Monitoring

FLEXIABLE SETUP

Touch Screen setup

Pump Station Types

Pump Types & Sizes

VFDs, Soft Starts & XL

Filtration Systems

Fertigation Systems

Level, Pressure & Flow Controls

Communication: Serial & Ethernet

Access all Screens

Monitor & Control Pump Station

Modify Settings

Text & Emails for Alarm and Data Reporting

Remote Program Upgrades

OPERATION INTELLIGENCE

Parameters to fine tune system

Event & Alarm Logs

Flow Total & Pump Run Time Logs

Intelligent Line Fill algorithm

Trend Screens

Multi-PID Setups

“Meeting our Customer’s requirements, every requirement, every time”

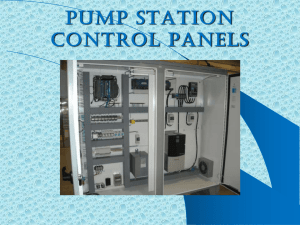

CONSTANT SPEED PANELS

SSP SOFT START PANEL Sizes up to 600 HP

RUGGED SOFT STARTER PACKAGE INCLUDES HIGH PERFORMANCE SOFT STARTER using the Danfoss MCD 500 Soft Starter

The SSP series panel comes standard enclosed in a NEMA 3R UL listed

enclosure with powder coat Heat Guard finish.

A heavy duty flanged disconnect switch is provided to eliminate door closure

issues with rotary type through the door disconnects.

Danfoss MCD500 Soft Starter provides many outstanding features including

AAC, the Adaptive Acceleration Control that automatically employs the best

starting and stopping profile for your pump application .

Extended warranties for the Danfoss Soft Starter is available up to 6

years. The warranty provides coverage of accidental damage including

lightning strikes.

PWP PART WIND START PANEL Sizes up to 350 HP

REDUCE INRUSH CURRENT WITH STARTING

PWP series part wind starter consists of two across-the-line-starters and a timer.

The first starter is used to connect one winding of the motor across the line. The

starting current from one winding will be about 50% of the starting current if both

windings were connected. The starting torque is correspondingly 50%.

Enhanced Overload protection is available using Symcom 777, Motortronics and

FE Submonitor electronic overloads.

A heavy duty flanged disconnect switch is provided to eliminate door closure

issues with rotary type through the door disconnects.

30 mm Heavy Duty Selector Switches, Pilot Lights and Push Buttons are

standard on the PWP to meet the rugged demands of water industry

NPP NEMA PUMP PANEL Sizes up to 200 HP

RELIABLE STARTER PACKAGE WITH SOLID STATE OVERLOADS

NPP series NEMA Pump panel using NEMA Starters with SS Overloads.

Enhanced Overload protection is available using Symcom 777, Motortronics and

FE Submonitor electronic overloads.

A heavy duty flanged disconnect switch is provided to eliminate door closure

issues with rotary type through the door disconnects.

30 mm Heavy Duty Selector Switches, Pilot Lights and Push Buttons are

standard on the PWP to meet the rugged demands of water industry

VSDP VARIABLE SPEED DRIVE PANELS

MCI VSDP line of Variable Speed Drive Panels are state of

the art NEMA 3R/4 rated UL listed Center Pivot Pump and

Well Control Solutions.

At the heart of this solution lies the most robust variable speed

drive in the world… the Danfoss VLT Aqua Drive with the

most built-in standard features to protect the drive and the

associated motors which allows them to offer the only optional

6 year warranty.

Additionally, the Danfoss VLT Aqua Drive Pump Control logic

gives you the most comprehensive combination of durability

and intelligence available in the irrigation industry today.

INDUSTRY LEADING FEATURES

Motor Cable Length –1000 FT

IEEE-519 Harmonic Reduction

Standard—Dual DC Link Reactor 3 ½%

Optional– IEEE-519 Harmonic Filter

UL Listed Single Phase Conversion

High Temperature Range 120 Deg F

Extended Optional Warranty to 6 YEARS

Conformal Coated PCBs

NEMA 4 & 4X SS Enclosed Drives

AMS to tune VSD to Motor

Manual Speed Control from Keypad

VARI-SMART Pump Control

Multiple Pivots control w/single/multiple Wells

Multiple Wells control w/single/multiple Pivots

Constant Pressure with end gun operation

Empty Pipe Fill Control

Maximize/Protect Well w/draw down control

Broken Pipe Protection

1

AWARD WINNING KEYPAD

1 Graphical Display

Backlit for Increased Visibility

Display 6 Points of Operational Data

Engineering and Text Display

2 Quick Menus

Personnel Menu for Common Accessed Parameters

Simplistic switch between programming, monitoring and alarms

INFO provides on board VSD manual

3 LED Status Indication

Easily Identify what Mode is active for the VSD

3 Mode Buttons

“Meeting our Customer’s requirements, every requirement, every time”

HAND/OFF/AUTO Buttons just like most pump control panels

“Meeting our Customer’s requirements, every requirement, every time”

VSDP VARIABLE SPEED DRIVE PANELS

N3R VARIABLE SPEED DRIVE PANEL To 600 HP

RUGGED Variable Speed Drive Package in a NEMA 3R enclosure.

Advanced Fan Cooling Design

115 Deg F Outdoor Temperature Rating

Filtered Intake/Exhaust Fan Openings

Flanged Disconnect-Circuit Breaker or Fused

Type 1 Surge Arrestor w/Indicator Lights

Drive Protection w/ High Speed J Class Fuses

NEMA 4X VSD Keypad with Sun Shield Cover

Wall, Stand or Free Standing Mounting

Carbon Steel with Powder Coat Finish

Optional 304 & 316 SS Construction

UL Listed Single Phase VSDP Available

N3R-HF VARIABLE SPEED DRIVE PANEL To 600 HP

IEEE-519 Compliant Variable Speed Drive Package

MTE Matrix AP Passive Harmonic Filter

VSDP VARIABLE SPEED DRIVE OPTIONS

OUTPUT FILTERS

Installed in VSDP Enclosure

Optional External Enclosures

Protection of motor insulation

Reduce Motor Temperature

Reduction of motor acoustic noise

Reduction of high frequency electromagnetic noise in the motor cable

Reduction of bearing currents and shaft voltage

dV/dt Filter

Sine Wave Filter

Cable Distances to 1000 Ft

Application with older and submersible motors

Reduces stress on motor insulation

VSD BY-PASS Systems

Installed in VSDP Enclosure

Optional External Enclosures

XL & Soft Starter Bypass

2 & 3 Contactor Bypass

THD 8% Max at 30% Load 5% Max at Full Load

Advanced Fan Cooling Design

115 Deg F Outdoor Temperature Rating

Filtered Intake/Exhaust Fan Openings

Flanged Disconnect-Circuit Breaker or Fused

Type 1 Surge Arrestor w/Indicator Lights

Drive Protection w/ High Speed J Class Fuses

NEMA 4X VSD Keypad with Sun Shield Cover

Wall, Stand or Free Standing Mounting

Carbon Steel with Powder Coat Finish

Optional 304 & 316 SS Construction

N4 VARIABLE SPEED DRIVE PANEL To 125 HP

Cable Distances to 3000 Ft

Application with older and submersible motors

Provides Sinusodial Voltage Waveform

VSD Line Isolation Systems

Installed in VSDP Enclosure

Optional External Enclosures

Disconnect Line Power to VSD

Contactor Auto/Manual OO/OFF Disconnect

CB Shunt Trip Auto/Manual OFF Disconnect

VSD Switched Power Outlets

VSD

Line

Power

Main Circuit Breaker

Optional Shunt Trip for

Auto/Manual OFF

Line Disconect

Optional Line

Disconnect Contactor

for Auto/Manual

ON/OFF

Line Disconect

Installed in VSDP Enclosure

Outputs for Fertizer injection Pumps

Voltages: 120/230/460

RUGGED Variable Speed Drive Package in a NEMA 4(X) enclosure.

NEMA 4 provides sealed enclosure for VSD

115 Deg F Outdoor Temperature Rating

VSD Heat Sink extends rear of enclosure– NO COOLING RQD

Flanged Disconnect-Circuit Breaker or Fused

Type 1 Surge Arrestor w/Indicator Lights

Drive Protection w/ High Speed J Class Fuses

NEMA 4X VSD Keypad with Sun Shield Cover

Wall, Stand or Free Standing Mounting

Carbon Steel with Powder Coat Finish

Optional 304 & 316 SS Construction

“Meeting our Customer’s requirements, every requirement, every time”

VSD Remote Connectivity

Monitor/Remote Control via WEB

Receive alarm/status alerts via txt or email

Multiple VSDP & Pivots

Radio Concentrator for multiple well monitoring

Instrumentation

Pressure/level Transmitters

Magnetic and Propeller Flow Meters

Pressure Switches, Floats

“Meeting our Customer’s requirements, every requirement, every time”

VSDP VARIABLE SPEED DRIVE PANELS

N3R VARIABLE SPEED DRIVE PANEL To 600 HP

RUGGED Variable Speed Drive Package in a NEMA 3R enclosure.

Advanced Fan Cooling Design

115 Deg F Outdoor Temperature Rating

Filtered Intake/Exhaust Fan Openings

Flanged Disconnect-Circuit Breaker or Fused

Type 1 Surge Arrestor w/Indicator Lights

Drive Protection w/ High Speed J Class Fuses

NEMA 4X VSD Keypad with Sun Shield Cover

Wall, Stand or Free Standing Mounting

Carbon Steel with Powder Coat Finish

Optional 304 & 316 SS Construction

UL Listed Single Phase VSDP Available

N3R-HF VARIABLE SPEED DRIVE PANEL To 600 HP

IEEE-519 Compliant Variable Speed Drive Package

MTE Matrix AP Passive Harmonic Filter

VSDP VARIABLE SPEED DRIVE OPTIONS

OUTPUT FILTERS

Installed in VSDP Enclosure

Optional External Enclosures

Protection of motor insulation

Reduce Motor Temperature

Reduction of motor acoustic noise

Reduction of high frequency electromagnetic noise in the motor cable

Reduction of bearing currents and shaft voltage

dV/dt Filter

Sine Wave Filter

Cable Distances to 1000 Ft

Application with older and submersible motors

Reduces stress on motor insulation

VSD BY-PASS Systems

Installed in VSDP Enclosure

Optional External Enclosures

XL & Soft Starter Bypass

2 & 3 Contactor Bypass

THD 8% Max at 30% Load 5% Max at Full Load

Advanced Fan Cooling Design

115 Deg F Outdoor Temperature Rating

Filtered Intake/Exhaust Fan Openings

Flanged Disconnect-Circuit Breaker or Fused

Type 1 Surge Arrestor w/Indicator Lights

Drive Protection w/ High Speed J Class Fuses

NEMA 4X VSD Keypad with Sun Shield Cover

Wall, Stand or Free Standing Mounting

Carbon Steel with Powder Coat Finish

Optional 304 & 316 SS Construction

N4 VARIABLE SPEED DRIVE PANEL To 125 HP

Cable Distances to 3000 Ft

Application with older and submersible motors

Provides Sinusodial Voltage Waveform

VSD Line Isolation Systems

Installed in VSDP Enclosure

Optional External Enclosures

Disconnect Line Power to VSD

Contactor Auto/Manual OO/OFF Disconnect

CB Shunt Trip Auto/Manual OFF Disconnect

VSD Switched Power Outlets

VSD

Line

Power

Main Circuit Breaker

Optional Shunt Trip for

Auto/Manual OFF

Line Disconect

Optional Line

Disconnect Contactor

for Auto/Manual

ON/OFF

Line Disconect

Installed in VSDP Enclosure

Outputs for Fertizer injection Pumps

Voltages: 120/230/460

RUGGED Variable Speed Drive Package in a NEMA 4(X) enclosure.

NEMA 4 provides sealed enclosure for VSD

115 Deg F Outdoor Temperature Rating

VSD Heat Sink extends rear of enclosure– NO COOLING RQD

Flanged Disconnect-Circuit Breaker or Fused

Type 1 Surge Arrestor w/Indicator Lights

Drive Protection w/ High Speed J Class Fuses

NEMA 4X VSD Keypad with Sun Shield Cover

Wall, Stand or Free Standing Mounting

Carbon Steel with Powder Coat Finish

Optional 304 & 316 SS Construction

“Meeting our Customer’s requirements, every requirement, every time”

VSD Remote Connectivity

Monitor/Remote Control via WEB

Receive alarm/status alerts via txt or email

Multiple VSDP & Pivots

Radio Concentrator for multiple well monitoring

Instrumentation

Pressure/level Transmitters

Magnetic and Propeller Flow Meters

Pressure Switches, Floats

“Meeting our Customer’s requirements, every requirement, every time”

CONSTANT SPEED PANELS

SSP SOFT START PANEL Sizes up to 600 HP

RUGGED SOFT STARTER PACKAGE INCLUDES HIGH PERFORMANCE SOFT STARTER using the Danfoss MCD 500 Soft Starter

The SSP series panel comes standard enclosed in a NEMA 3R UL listed

enclosure with powder coat Heat Guard finish.

A heavy duty flanged disconnect switch is provided to eliminate door closure

issues with rotary type through the door disconnects.

Danfoss MCD500 Soft Starter provides many outstanding features including

AAC, the Adaptive Acceleration Control that automatically employs the best

starting and stopping profile for your pump application .

Extended warranties for the Danfoss Soft Starter is available up to 6

years. The warranty provides coverage of accidental damage including

lightning strikes.

PWP PART WIND START PANEL Sizes up to 350 HP

REDUCE INRUSH CURRENT WITH STARTING

PWP series part wind starter consists of two across-the-line-starters and a timer.

The first starter is used to connect one winding of the motor across the line. The

starting current from one winding will be about 50% of the starting current if both

windings were connected. The starting torque is correspondingly 50%.

Enhanced Overload protection is available using Symcom 777, Motortronics and

FE Submonitor electronic overloads.

A heavy duty flanged disconnect switch is provided to eliminate door closure

issues with rotary type through the door disconnects.

30 mm Heavy Duty Selector Switches, Pilot Lights and Push Buttons are

standard on the PWP to meet the rugged demands of water industry

NPP NEMA PUMP PANEL Sizes up to 200 HP

RELIABLE STARTER PACKAGE WITH SOLID STATE OVERLOADS

NPP series NEMA Pump panel using NEMA Starters with SS Overloads.

Enhanced Overload protection is available using Symcom 777, Motortronics and

FE Submonitor electronic overloads.

A heavy duty flanged disconnect switch is provided to eliminate door closure

issues with rotary type through the door disconnects.

30 mm Heavy Duty Selector Switches, Pilot Lights and Push Buttons are

standard on the PWP to meet the rugged demands of water industry

VSDP VARIABLE SPEED DRIVE PANELS

MCI VSDP line of Variable Speed Drive Panels are state of

the art NEMA 3R/4 rated UL listed Center Pivot Pump and

Well Control Solutions.

At the heart of this solution lies the most robust variable speed

drive in the world… the Danfoss VLT Aqua Drive with the

most built-in standard features to protect the drive and the

associated motors which allows them to offer the only optional

6 year warranty.

Additionally, the Danfoss VLT Aqua Drive Pump Control logic

gives you the most comprehensive combination of durability

and intelligence available in the irrigation industry today.

INDUSTRY LEADING FEATURES

Motor Cable Length –1000 FT

IEEE-519 Harmonic Reduction

Standard—Dual DC Link Reactor 3 ½%

Optional– IEEE-519 Harmonic Filter

UL Listed Single Phase Conversion

High Temperature Range 120 Deg F

Extended Optional Warranty to 6 YEARS

Conformal Coated PCBs

NEMA 4 & 4X SS Enclosed Drives

AMS to tune VSD to Motor

Manual Speed Control from Keypad

VARI-SMART Pump Control

Multiple Pivots control w/single/multiple Wells

Multiple Wells control w/single/multiple Pivots

Constant Pressure with end gun operation

Empty Pipe Fill Control

Maximize/Protect Well w/draw down control

Broken Pipe Protection

1

AWARD WINNING KEYPAD

1 Graphical Display

Backlit for Increased Visibility

Display 6 Points of Operational Data

Engineering and Text Display

2 Quick Menus

Personnel Menu for Common Accessed Parameters

Simplistic switch between programming, monitoring and alarms

INFO provides on board VSD manual

3 LED Status Indication

Easily Identify what Mode is active for the VSD

3 Mode Buttons

“Meeting our Customer’s requirements, every requirement, every time”

HAND/OFF/AUTO Buttons just like most pump control panels

“Meeting our Customer’s requirements, every requirement, every time”

MCI Advantage

MCI begin in 1980 to provide quality designed pump control panel solutions that is driven by

our policy “meeting our Customer’s requirements, every requirement, every time”.

MCI has supplied over 200,000 UL listed panels to our global customers.

Quality as our top priority is exhibited by our certifications and compliance standards :

ISO 9001-2008 CERTIFIED

UL 508a Control Panels

UL 698a Hazardous Locations

UL 778

Packaged Pump Stations

UL 50/E Industrial Enclosures

UL 1640 Portable Power Distribution

UL 891

Switch Boards

CAPABILITY

Experienced Engineering staff in pump controls applications to ensure the product you received is

application suited and programmed so the panel is ready out of the box.

Manfucter enclosures to provide standard and custom enclosures to meet any application

Investment in production capabilities to bring latest in technologies to reduce lead-time and cost

Partnerships with industry leading control components manufactures such as AB, SQ D and Danfoss

Product designs to ensure up time operation, longevity and ease of use by you

Leading edge enhancements such remote monitoring, power disconnects, multi-pump controls

125,000 Sq Facility w/Automated Fabrication Equipment

Graphics Department w/silk screen, overlays and engraving capability

STANDARDS

ENCLOSURES

TEMPERTURE RAITINGS

120 DEG F

ROBUST DESIGNS

MATERIAL: Carbon Steel , 304 & 316 SS, Aluminum

FINISH: Zinc Primer with 5 Stage Powder Coat Process w/Heat Guard Finish

SEALING: Foam in Place Gasket

WEATHER RESISTANT: Covers for All Keypads

Flanged Disconnects w/optional service rating

30 mm Panel Devices

VSD & SS Protection-High Speed Fuses & Line Surge Protection

NEMA Rated Components

Wide Range of Options

“Meeting our Customer’s requirements, every requirement, every time”

MPC Multi-Pump Controller

MPC is our configurable mult-pump control system

with optional cloud based remote monitoring and

notifications with any web enabled smart device such

as a table or cell phone.

The MPC can be used on new or to upgrade your

existing pump station with control operation designed

to maximize energy savings and operate your pump

station in the most efficient manner.

LEADING EDGE TECHNOLOGY

AB Compact Logic PLC

AB 10” PV+ Color Touch Screen

Monitor from any PC, Smart Phone/Tablet

OPERATIONAL EASE

Parameter changed Touch Screen

Multiple configurations

Protective Safeties

Operation & Alarm Information

WEB Based Remote Monitoring

FLEXIABLE SETUP

Touch Screen setup

Pump Station Types

Pump Types & Sizes

VFDs, Soft Starts & XL

Filtration Systems

Fertigation Systems

Level, Pressure & Flow Controls

Communication: Serial & Ethernet

Access all Screens

Monitor & Control Pump Station

Modify Settings

Text & Emails for Alarm and Data Reporting

Remote Program Upgrades

OPERATION INTELLIGENCE

Parameters to fine tune system

Event & Alarm Logs

Flow Total & Pump Run Time Logs

Intelligent Line Fill algorithm

Trend Screens

Multi-PID Setups

“Meeting our Customer’s requirements, every requirement, every time”

Package Pump Stations & Controls

Package Pump Stations & Controls

Verticle Multi-Stage

Variable Speed Drive Panels

Verticle Turbine

End Suction Centrifugal

Split Case Centrifugal

Soft Starter Panels

NEMA Pump Panels

Multi-Pump Control Panels

Remote Connectivity

Engineered Systems

MCI Product Brochure: AGPC 111414

© 2014 Motor Controls Inc. All rights reserved

Motor Controls Incorporated

2818 Virgo Lane

Dallas Texas, 75229

1-800-735-1097

www.motorcontrols.com

mciwater@motorcontrols.com

Optional VFD

6

YEAR Warranty

Including

lightning strikes