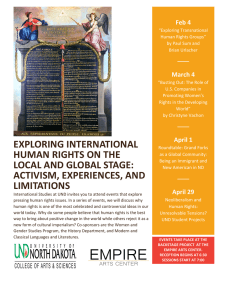

View Now

advertisement

1 Technik und Informatik / Wissens- und Technologietransfer IRON LOSS CALCULATION OF AN INTERNAL PERMANENT MAGNET SYNCHRONOUS MACHINE FOR A FUEL CELL CAR Electric Drive System Research Activities at Bern University of Applied Sciences Engineering and Information Technology Prof. Andrea Vezzini, Switzerland Dr. sc. techn. ETHZ easc-2009, July 7th 2009 2 Technik und Informatik / Wissens- und Technologietransfer About the Speaker Dr. Andrea Vezzini • Professor for Industrial Electronics since 1996 at Bern University of Applied Sciences (BFH TI) Biel • Co-founder and Chairman of the Board of drivetek ag since 2002 • 2003 Visiting Guest Professor at General Motors Advanced Technology Center in Torrance (7 Months) • 2007 Distinguished Visiting Scientist at Commonwealth Science and Industrial Research Organisation (CSIRO), Australia (5 Months) • Together with drivetek ag currently involved in projects with Bombardier Transportation AG, General Motors and Porsche Motorsport 3 Technik und Informatik / Wissens- und Technologietransfer BFH Engineering and Information Technology • • • • • • Established in 1890 Since 1998 Part of Bern University of Applied Sciences 6 Divisions with a total of 1’300 students, second biggest in Switzerland External Turnover with aR&D 2008: approx. 8 Mio. CHF (+ 2.5 Mio. CHF internal funding) Strategic Programs in Fuel Cell Development, Automotive Systems and Renewable Energy Over 10 Innovation prices since 1993 Technik und Informatik / Wissens- und Technologietransfer spin-off Success drivetek ag was founded in 2002 as a fully independent spin-off of the Laboratory of Industrial Electronics. Eleven Engineers work on high efficient drives and power electronics for energy, automotive, space and automation applications. It’s the creation of jobs and industrial impulses which has become one of the most challenging but also exciting tasks of the Berne University of Applied Sciences http://www.drivetek.ch 5 Technik und Informatik / Wissens- und Technologietransfer Content • • • • Internal Permanent Magnet Synchronous Motor Fundamentals Design Flow Core Loss Calculations Examples “The outcome of any serious research can only be to make two questions grow where only one grew before.” Thorstein Veblen US economist & social philosopher (1857 - 1929) 6 Technik und Informatik / Wissens- und Technologietransfer Types of PM Synchronous Motors • The amount of PM-generated magnetic flux linked by the coils of the stator remains fixed. • As a result, the back-electromotive force (back-emf) voltage induced by the PMs increases linearly with the speed of the rotor. • As the rotor speed increases the backemf voltage rises, which results in a rapid reduction in the available voltage, (the difference between the supply voltage and the back-emf). When there is no longer any voltage available to drive current into the stator, the maximum speed has been reached. • Depending on the rotor geometry, PM Synchronous show different torquespeed behavior. a) b) a) Surface Permanent Magnet Motor b) Inset Permanent Magnet Motor c) V-Shaped Single Layer IPM d) V-Shaped Double Layer IPM e) U-Shaped Double Layer IPM d) c) e) 7 Technik und Informatik / Wissens- und Technologietransfer Saliency • Saliency: different d- and q-axis inductance, based of different rotor permeability in q- and daxis • Salient pole machine allow for an extended constant power speed range (CPSR), required in a multitude of application. • Combined with weak flux bonded PM (PM-Assisted SRM) and laminated rotor to reduce rotor losses Lq Ld Technik und Informatik / Wissens- und Technologietransfer Design of PM Synchronous Machines • Normalized System Equations • Surface Mounted PM SM has Saliency = 1 and maximum torque current angle g = 0 • Synchronous Reluctance Machine has Ym = 0 • IPM Design Freedom: • With strong magnetic field from PM Magnets -> conventional IPM • With weak magnetic field from PM Magnets -> PM Assisted SRM Magnetic Torque Reluctance Torque q-axis d-q-axis diagram jwLqIq • Field Weakening Operation • For surface mounted PMs, where Lq = Ld, Id in the negative direction weakens the magnet so that the motor may be driven at higher speeds. However, there is no increase in output power, while the input power must increase to supply the additional resistance heat loss. RI jwLdId I V Vq Iq Vd Eq=wYm j Id g d b d-axis 9 Technik und Informatik / Wissens- und Technologietransfer IPM Constant Power Speed Range / Field Weakening q Tmax = f(Imax, g) base speed point Torque vs. Speed (Normalized) Imax CPSR d 0.8 wc, vmax 0.6 0.4 infinite speed point 0.2 0 0 1 2 3 4 q-axis • The possible operating points are limited within the current circle and the voltage ellipse. The voltage ellipse will decrease its size with increasing speed. • Maximum torque above base speed is only possible by increasing the current angle • Depending on the placement of the infinite speed point three different design options are available: finite speed, optimum infinite speed and infinite speed type q-axis I II q-axis I II gm Y mn Ldn I II gm Y mn Ldn d-axis gm III d-axis Y mn Ldn d-axis 10 Technik und Informatik / Wissens- und Technologietransfer IPM Design Possibilities • IPM magnetic flux and saliency can be matched for ideal fit of machine characteristics to car requirements • Lower magnetic flux can be compensated with higher saliency with the added benefit of lower current per torque requirements (for the same per unit torque and CPSR) Technik und Informatik / Wissens- und Technologietransfer x Wheel torque vs. Vehicle Speed; m=720kg, different Acceleration Profile, Power and Grade 1400 Optimized Motor Choice 0-400m@17.3sec 0% 0-100km/h@10.2sec 0% 1200 • Based on the limits from the different requirements, the possible motor specs (base speed and nominal torque are plotted. The red line is the combined curve all the motor specs, which will fulfill all the requirements. The three crosses are exemplary motor designs. Wheel Torque [Nm] 1000 x 800 68kW 40-80km/h@5sec 8% 64kW 60kW 80-120km/h@8sec 0% 56kW 52kW Superposition 48kW 44kW x 40kW 36kW 600 30% 32kW 28kW 20% 24kW 20kW 400 10% 200 6% 3% Energy [% of total] for 38 km Pendler Cycle 3.5 0% 0 200 1000 3 600 800 1000 Speed / Base Speed [rpm] Speed vs. Power, Torque, CPSR, m=720kg 23kW - Cont Pow er 1400Nm – 40kW 925Nm – 40kW 700Nm – 64kW 2500 2 Torque for a=0 @ 0% 2000 1.5 -500 1 0.5 Torque [Nm] 0 0 20 40 60 80 Speed[km/h] 100 120 ZH-Pendler Drive cycle: Torque and Acceleration 140 100 80 x 1500 60 Pow er 1000 x -1000 0 1400 120 2.5 500 1200 3000 45kW - Peak Pow er Torque[Nm] 400 40 Torque x 500 20 CPSR ((V max - V base) / V base) 0 0 100 200 300 400 500 600 700 Speed / Base Speed [rpm] 800 900 0 1000 Power [kW] and 10*CPSR [ ] 0 Technik und Informatik / Wissens- und Technologietransfer Step FEA Process Overview Design of a lumped parameter Model Model Definition Verification Analysis in Maxwell Verification Parametric Analysis in Maxwell Result Analysis in Matlab Efficiency Analysis Generic Motor Model Design Adjustments on the Motor Model (definition of Geometry, Material, etc.) Simulation of the Model - Analysis in Maxwell If Results are ok: - Parametric Analysis Result Analysis with Matlab Efficiency Map Simulation Technik und Informatik / Wissens- und Technologietransfer Maxwell –Matlab toolchain: Analysis of FEA Result Data • Import Data Import Raw Data from Maxwell (Magnetic Flux, Phase Current, Current, Rotation Data, Torque, Voltage) Transient Simulation of a 2d-Model over 110 different current amplitude and angle cases over one electrical period Simulation data is saved after each transient run (torque, flux) • Ansoft LLC d-q Transformation Transform flux and current into d-q representation Interpolate Data Interpolate Data into uniform distributed arrays Maxwell2DDesign2 InducedVoltage 30.00 Curve Info rms InducedVoltage(phaseA) InducedVoltage(phaseB) 20.00 Calculate Results over Speed Range 14.5148 back_emf : Transient 14.5050 back_emf : Transient InducedVoltage(phaseC) Calculate the Results over the complete Speed Range of the Motor 14.5043 back_emf : Transient Y1 [V] 10.00 0.00 Calculate Parameters for Efficiency Map -10.00 Calculate the Parameters for the Efficiency Map FEA -20.00 Ansoft LLC -30.00 0.00 5.00 Maxwell2DDesign2 Torque 10.00 15.00 Time [ms] 35.00 20.00 25.00 Moving1.Torque load_losses : Transient 30.00 Plot Results 30.00 Curve Info avg 24.0803 Calculate and Display the Result Plots Moving1.Torque [NewtonMeter] 25.00 • 20.00 15.00 10.00 5.00 0.00 0.00 0.50 1.00 1.50 2.00 2.50 3.00 3.50 4.00 Time [ms] 4.50 5.00 5.50 6.00 6.50 7.00 7.50 • A set of matlab functions performs the necessary operations to calculate the Results of the Motor from the FEA Results. The Results will then be displayed and compiled into a pdf Report 14 Technik und Informatik / Wissens- und Technologietransfer Search optimal Current and Current Angle • Calculation of Continuous and Peak Requirement Current and Current Angles with a maximum Torque Per Ampere Approach (minimizing the Copper Losses) • Possible Torque Operation points are reduced with increasing speed, as voltage circle decreases. In this case the current angle has to be increased and/or the current amplitude decreased (Type II) Airgap Torque Tem as a Function of Control Angle g and Peak Current 1 27 50 7 23 40 23 7 30 169 16 9 135 10 1 67 67 10 33 33 -10 -20 33 -30 -40 -50 -60 Control Angle g [°DEG] -70 -80 10 617 -90 339 Base Point: 7900Magnet rpm 305 271 100 27 1 23 7 20 3 203 50 169 169 40 135 135 30 101 101 67 120 : 140°C Iphmax :240A rms 237 60 203 20 67 330 29275317 5 20163193 0 13 5 101 10 1 20 Iphmax :240A rms 203 20 3 13 5 Magnet: 140°C 23 7 333095 27 13 7 2 3 20 9 16 Airgap Torque [Nm] 60 27 1 27 1 339 80 305 271 70 237 5 30 5 30 9 33 5 30 9 33 70 90 Winding: 180°C 30 5 67 23 7 16 9 13 5 q-axis current iq [Arms ] 80 0 Tmax : 88.7 Nm, @ g: -55.2° 33 9 d- and q-axis current for the whole operating speed range 140 Winding: 180°C 100 Peak Torque Tmax [Nm] 90 Maximum Torque Tmax over Speed Range 80 60 Iphmax :240Arms 67 20 Constant Torque Speed Range Constant Power Speed Range mech. and iron losses not included 0 5000 10000 Mechanical Speed [rpm] Magnet: 140°C 40 10 1 10 0 Winding: 180°C 15000 0 -200 -150 -100 d-axis current id [Arms ] -50 0 Technik und Informatik / Wissens- und Technologietransfer Why not calculated Performance Curves from one single point of operation? d-axis Flux d as a Function of Control Angle g and Peak Current d-axis Inductance Ld as a Function of Control Angle g and Peak Current Load and No-Load Phase Voltage over Speed Range 33 10 1 Winding: 180°C -0.02 Magnet: 140°C -0.03 Iphmax :240Arms -10 -20 101 13 5 16 9 20 3 23 7 169 203 27 1 30 5 33 9 23 7 27 1 300 0.08 30 5 200 -30 -40 -50 -60 Control Angle g [°DEG] -70 100 50 -80 -90 -10 33 2 270359 20 3 7 1 3 Magnet: 140°C Iphmax :240Arms 3323079517 2230 3 9 16 5 13 1 10 q-axis Flux q [Vs] 16 9 13 5 67 0.04 33 67 33 0.02 33 573 0 33 01 29237 239 1 1163105 0.01 0 0 -10 -20 -30 -30 -40 -50 -60 Control Angle g [°DEG] -70 -80 -40 -50 -60 Control Angle g [°DEG] -70 -80 67 33 -90 33 67 33 200 150 100 Iphmax :240Arms Magnet: 140°C 50 0 -90 101 135 169 203 237 271 305 339 101 Winding: 180°C 67 0.03 -20 No-Load Peak Phase to Phase Voltage @ 15000rpm: 434.3 V 250 Winding: 180°C 0 5000 10000 Mechanical Speed [rpm] q-axis Inductance Lq as a Function of Control Angle g and Peak Current 10 1 0.05 Magnet: 140°C 900 3 30359 27 23 71 20 3 101 0.06 Winding: 180°C 150 33 9 169 135 0.07 33 67 101 135 169 203 237 271 305 339 Iphmax :240Arms 800 q-axis Inductance Lq [ Henry] 339 30 5 27 1 23 7 20 3 33 67 101 135 169 203 237 271 305 339 250 q-axis Flux q as a Function of Control Angle g and Peak Current 0.09 101 135 169 203 67 237 271 305 33 339 350 67 0 -0.01 33 10 1 13 5 16 9 20 3 23 7 27 1 30 335 9 0.01 0 33 67 13 0.04 165 2093 23 277 0.03 310 335 9 0.02 d-axis Inductance Ld [ Henry] d-axis Flux d [Vs] 0.05 67 Load and No-Load Phase Voltage (Peak Value) Vph [Vp] 400 67 135 q-axis d-q-axis diagram 101 RI 169 jwLdId 203 135 500 169 203 237 271 305 339 400 300 237 271 305 339 Magnet: 140°C 100 Iphmax :240Arms 0 -10 -20 -30 -40 -50 Control Angle g [°DEG] -60 -70 The effects of saturation on Ld and Lq are affecting the voltage equations and as a consequence the calculation of the dq-axis diagram Vq -80 Iq Vd Lq Ld Eq=wYm I V Winding: 180°C 200 jwLqIq 700 600 15000 j Id g d b d-axis Technik und Informatik / Wissens- und Technologietransfer Efficiency Map • Points for efficency Parametric Analysis Calculate Simulation Parameters for Simulation Points 30 Maxiumum Requirements Simulation Points 25 (Current, Current Angle, Rotation Speed, Simulation Time) • Write Parameters as Variables into Maxwellscript file for Simulation Simulation over at least two electrical periods for each operation point in Maxwell Torque [Nm] • 20 15 10 5 Ansoft LLC Maxwell2DDesign2 FluxLinkage 0.06 FluxLinkage(phaseB) load_losses : Transient FluxLinkage(phaseC) load_losses : Transient FluxLinkage(phaseA) load_losses : Transient 0.0523 0.04 0.0523 0.02 0.0523 0.00 -0.02 -0.04 -0.06 0.00 0.50 1.00 1.50 2.00 2.50 3.00 3.50 4.00 4.50 5.00 5.50 6.00 6.50 7.00 7.50 Time [ms] Ansoft LLC Maxwell2DDesign2 CoreLoss 300.00 Curve Info CoreLoss load_losses : Transient avg max 210.6362 238.0068 250.00 CoreLoss [W] 200.00 150.00 100.00 50.00 0.00 0.00 0.50 0 max 1.00 1.50 2.00 2.50 3.00 3.50 4.00 Time [ms] 4.50 5.00 5.50 6.00 6.50 7.00 7.50 Y2 [Wb] Curve Info 0 2000 4000 6000 8000 Speed [rpm] 10000 12000 14000 17 Technik und Informatik / Wissens- und Technologietransfer Comparison of Maxwell Iron Loss Calculation with Measurement Data 100.00 Core Loss Calculation Measured values as dots. Calculated lines are based on Maxwell Coefficients Kh, Kc and Ke, which have been calculated for each frequence accordingly. 80.00 70.00 SPecific Core Losses [W/kg] • Improvement of V12 by using multifrequency data. Eliminates need to change data at each simulation step • Maxwell uses dB/dt approach and not a fourier series Steinmetz based formula. This yields better results but requires at least two electrical periods of simulation data 90.00 60.00 Meas. 100Hz Meas. 200Hz Meas. 400Hz Meas. 1000Hz Meas. 2000Hz Meas. 5000Hz 50.00 Meas. 10000Hz 100Hz 40.00 200Hz 400Hz 30.00 1000Hz 2000 20.00 5000 10000 10.00 0.00 0.00 0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80 0.90 1.00 1.10 1.20 1.30 1.40 1.50 Induction Value [B] Comparison of Maxwell Iron Loss Calculation with Measurement Data 100.00 90.00 Measured values as dots. Calculated lines are based on Maxwell Coefficients Kh, Kc and Ke, which have been calculated 100Hz data. 80.00 SPecific Core Losses [W/kg] 70.00 Meas. 100Hz Meas. 200Hz Meas. 400Hz Meas. 1000Hz 60.00 Meas. 2000Hz Meas. 5000Hz 50.00 Meas. 10000Hz 100Hz 40.00 200Hz 400Hz 30.00 Referenzpaper: D. Lin, P. Zhou, W. N. Fu, Z. Badics, and Z. J. Cendes: “A Dynamic Core Loss Model for Soft Ferromagnetic and Power Ferrite Materials in Transient Finite Element Analysis” 1000Hz 2000Hz 20.00 5000Hz 10000Hz 10.00 0.00 0.00 0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80 Induction Value [B] 0.90 1.00 1.10 1.20 1.30 1.40 1.50 18 Technik und Informatik / Wissens- und Technologietransfer Problems with Core Loss Calculations using different number of triangles 27343 triangles torque (N-m) average coreloss average 56.2 (W) 1903 29591 triangles torque (N-m) average coreloss average 56.3 (W) 1791 48638 triangles torque (N-m) average 56.3 coreloss average (W) 1590 The three models with different number of triangles were used to simulate the same load point using impressed currents in the phases(11k rpm, 250Arms, 77.7 DEG current angle -> meas. torque of 59.875Nm and corelosses of 1412W). Apparently the torque calculation is not changing with the number of triangles, where as the core losses decrease with increasing numbers of triangles. 19 Technik und Informatik / Wissens- und Technologietransfer Ansoft LLC Core Loss Calculation Methods CoreLoss [W] 50.00 Simplest Model, fast convergence P4 Phase Current measured at 5000rpm and 200Nm 600 0.00 0.00 PWM voltage supply model • • Either in Maxwell or combined with Simplorer. Long simulation time, especially if mechanical model is used. 1.00 1.50 2.00 2.50 3.00 3.50 4.00 4.50 5.00 5.50 6.00 6.50 7.00 7.50 Time [ms] 400 Ansoft LLC Maxwell2DDesign2 CoreLoss 2.40 long Convergence time Taken from simulation data, good behavior, medium convergence (2 electrical periods), but needs high resolution Taken from measurement data for verification, needs treatment 0.50 Curve Info 2002.20 CoreLoss current_model_losses : Transient avg max 0.2628 2.4395 2.00 1.80 1.60 01.40 1.20 1.00 0.80 -200 0.60 0.40 0.20 -4000.00 0.00 0.50 1.00 1.50 2.00 2.50 3.00 3.50 4.00 4.50 5.00 5.50 6.00 6.50 7.00 7.50 Time [ms] -600 0 0.2 0.4 0.6 0.8 1 1.2 Sampling Points [] 1.4 1.6 1.8 2 4 x 10 phase voltage over electrical position airgap torque over electrical position 600 500 200 airgap torque [Nm] • • 100.00 Impressed PWM currents • 238.0068 150.00 CoreLoss [kW] • max 210.6362 200.00 Sinusoidal voltage supply and RL-parameter for winding • avg 250.00 Phase Current Ip [Ap] • CoreLoss Impressed sinusoidal stator currents • Curve Info load_losses : Transient phase voltage [Vp] • Maxwell2DDesign2 CoreLoss 300.00 150 100 400 300 200 50 100 0 0.9 1 1.1 1.2 1.3 time [s] 1.4 1.5 0 1.6 x 10 -3 0 0.02 0.04 0.06 0.08 electrical position [°DEG electrical] 0.1 20 Technik und Informatik / Wissens- und Technologietransfer No Load Core/Iron Losses 1400 Results for no load and sinusoidal current excitation 4.00 y = -4.18381E-11x3 + 5.60691E-06x2 + 3.27622E-02x R² = 9.96694E-01 3.50 1200 3.00 • • • No load core losses are easy to calculate and have no influence from stator current or PWM Voltage Supply Drag losses (for example in an electric rear axle hybrid drive at high speed driving) are important. To calculate the influence of active field weakening at no load is therefore important. The Iron Losses decrease with increasing d-current The Copper Losses increase with increasing dcurrent Reduction of 11% of Losses with d-current field weakening Average Power (Watts) 1000 2.50 800 2.00 600 1.50 400 1.00 200 0.50 0 0.00 0 2000 4000 measured data 6000 Speed (rpm) FEA Core Losses 8000 Corrected FEA 10000 12000 Factor 14000 21 Technik und Informatik / Wissens- und Technologietransfer Using measured Signal Approach: Noise reduction in measured Signal Measured Signal: Measured Signal: Double-Sided Amplitude Spectrum 200 40 Y(t) 50 0 -50 -100 50 0 35 30 25 |Z(f)| 100 Apply FFT and plot Double sided Amplitude Spectrum 100 Y(t) Make a sequence of the same signal with a repetition of 25 to increase the resolution of FFT 150 150 20 15 -50 10 -100 -150 5 -150 -200 0 0.5 1 1.5 2 2.5 Time [s] 0 0.05 0.1 0.15 0.2 0.25 0.3 Time [s] -3 x 10 0.35 0.4 0.45 0 4.5 0.5 5 5.5 6 6.5 Frequency (Hz) 7 7.5 8 5 x 10 Cut higher frequency harmonics Maxwell Current Input Signal Filtered Signal 200 50 0 -50 40 Apply inverse FFT and plot Signal 150 100 35 30 50 25 |Z(f)| 100 Y(t) 150 Y(t) Double-Sided Amplitude Spectrum 200 Generate the three input currents for Maxwell with corresponding control angle gamma 0 20 -50 15 -100 -100 10 -150 -150 5 -200 0 0.5 1 1.5 2 2.5 Time [s] 3 3.5 4 4.5 -3 x 10 -200 0 0.5 1 1.5 Time [s] 2 2.5 -3 x 10 0 4.5 5 5.5 6 6.5 Frequency (Hz) 7 7.5 8 5 x 10 22 Technik und Informatik / Wissens- und Technologietransfer Ansoft LLC Maxwell2DDesign2 CoreLoss 400.00 load_losses : Transient avg max 297.9682 334.7978 300.00 250.00 CoreLoss [W] • Core loss computation is treated as "post process" in Maxwell 2D transient, that is, the core loss effects on the field are ignored. • If the core loss effects on the field are taken into account, when there is a spike in an excitation, the core loss spike will reduce the field change, which in tune reduces the core loss spike. • In Maxwell 3D transient, we can consider core loss effects on the field. • Unfortunately, Maxwell 2D transient does not support this at present CoreLoss 350.00 200.00 150.00 100.00 50.00 0.00 7.50 8.00 8.50 9.00 9.50 10.00 10.50 11.00 11.50 12.00 12.50 13.00 13.50 14.00 14.50 15.00 Time [ms] Ansoft LLC Maxwell2DDesign2 CoreLoss 16.00 Curve Info CoreLoss 14.00 current_model_losses : Transient avg max 0.8662 15.9693 12.00 10.00 CoreLoss [kW] Core Loss calculation problems in Ansoft 2D Curve Info 8.00 6.00 4.00 2.00 0.00 0.00 0.50 1.00 Core Losses: Proto II, 360V, 4‘000rpm, 60Nm Average: 336.8352W 1.50 2.00 2.50 3.00 3.50 4.00 4.50 5.00 5.50 6.00 6.50 7.00 7.50 Time [ms] 900 800 700 600 Core Losses [W] • Results on the right: • Core Losses sinusoidal Current: 298W • Core Loss PWM Current from Simulation: 866W • Core Loss PWM Current from Simulation, only Losses up to 8’00W taken into account: 337W 500 400 300 200 100 0 0 0.5 1 1.5 2 2.5 3 3.5 4 time [ms] 4.5 5 5.5 6 6.5 7 7.5 23 Technik und Informatik / Wissens- und Technologietransfer Conclusions • • • • Influence of PWM Supply on core losses is an important factor for the efficiency calculation of the motor as all of today's motor are based on PWM supply. In fully optimized systems efficiency gains in the motor due to higher PWM are optimized versus the higher switching losses in the Inverter. Iron Loss Calculation becomes an important task in the motor simulation process due to need for efficiency map calculation and optimization over the whole torque and speed range Computational Capabilities are still somehow limited and are based on manufacturer data with limited reliability due to old measurement setups. Manufacturer should modify test equipment to include higher frequencies and additional rotational losses Motor designers are used to 2D simulations to limit simulation time, fully transient simulation including taking into account the influence of eddy currents on the magnetic field should be therefore brought to Maxwell 2D as fast as possible Technik und Informatik / Wissens- und Technologietransfer MITRAC Permanent Magnet Motor • Environmentally sound use of resources • Energy costs per Light Rail Vehicle about 40‘000 $US/year (~50t LRV) • Energy costs per Metro train about 200‘000 $US/year (~230t train) • • • Tested and validated, the solution’s innovative motor construction is based on internal permanent magnet technology. It uses a rotor to create its own flux by incorporating magnets. The MITRAC Internal Permanent Magnet Motor meets the highest demands on drive systems for traction application. Bombardier recently tested the MITRAC Permanent Magnet Motor in Sweden. Bombardier replaced four forced air-cooled induction motors in the BOMBARDIER REGINA with two of the PM motors as part of the Gröna Tåget (“Green Train”) project. The successful tests confirmed that a reduction of two induction motors could be achieved while still providing the same performance for the REGINA train. Left: Forced air-cooled Regina induction motor. Right: Permanent Magnet Motor prototype tested on Regina summer 2008. 25 Technik und Informatik / Wissens- und Technologietransfer Research and Development Examples Equinox Fuel cell Car, General Motors, USA New SAM: Cree AG, 2009, Switzerland/Poland ECUV, Sun Ya-Tsen University/HYB, China Angel Interceptor, domteknika AG, Switzerland 26 Technik und Informatik / Wissens- und Technologietransfer Electric Motor Glider ANTARES (Lange Aviation GmbH, Dermany) Brushless PM-Motor • • • • • Outside runner with phase voltage optimized for block commutation providing best torque density high torque (250Nm) at low speed (1‘500 prm) and high efficiency (92%) at low mass (28.5kg) completely integrated rotor design; rotor acts as case with direct mounted propeller blades Air Cooling by large inside diameter Series Production by Servax Landert Motoren AG 27 Technik und Informatik / Wissens- und Technologietransfer Thank you very much for your attention Dr. Andrea Vezzini Laboratory for Industrial Electronics Berne University of Applied Sciences Tf.: +41 32 321 63 72 Fax: +41 32 321 65 72 email: andrea.vezzini@bfh.ch Internet: www.ti.bfh.ch