MVS205

Product Data Sheet

D301079X012

September 2015

MVS205 Multi-Variable Sensor

The MVS205 Multi-Variable Sensor (MVS205R) provides static

pressure, differential pressure, and process temperature

inputs to a ROC800-Series, FloBoss™ 107, ROC300-Series,

FloBoss 407, or FloBoss 500-Series Flow Manager. The inputs

from an MVS205 transmitter are used for differential pressure

type calculations. The MVS205 typically operates as a remote

device that communicates via a serial format.

Transducer and Interface Circuit

Variables

The transducer electronics convert the pressure variables

directly into a digital format, allowing accurate correction and

compensation. A microprocessor linearizes and corrects the

raw pressure signals (from the sensor) using characterization

data stored in non-volatile memory.

Functionally, the MVS205 is a digital transmitter that

measures three flow-related variables simultaneously:

differential pressure, static pressure, and temperature. These

variables are continuously available to the FloBoss or ROC unit

that polls the MVS205.

An external three or four-wire Resistance Temperature

Detector (RTD) senses the process temperature. The RTD

sensor connects directly to the interface circuit board in

the electronics head. Connection requires user-supplied RTD

field wiring. For more information, refer to the RTD Wiring on

page 3.

The MVS205 contains a transducer and an interface circuit.

The transducer, contained in the sensor body, uses

capacitance-cell technology to sense differential pressure and

piezo-resistive technology to sense the static (absolute or

gauge) pressure.

The interface circuit, contained in the electronics head,

converts the raw temperature from an RTD into digital

format. The interface circuit also allows the MVS205 to

communicate the digital pressure signals to a ROC or FloBoss

using a serial EIA-485 (RS-485) connection. An explosionproof electronics head encloses the interface circuit board.

Note:

The MVS205 has a 10-pin terminal block that allows

case isolation. For more information, refer to

MVS205 Case Isolation Installation Sheet (part

D301641X012).

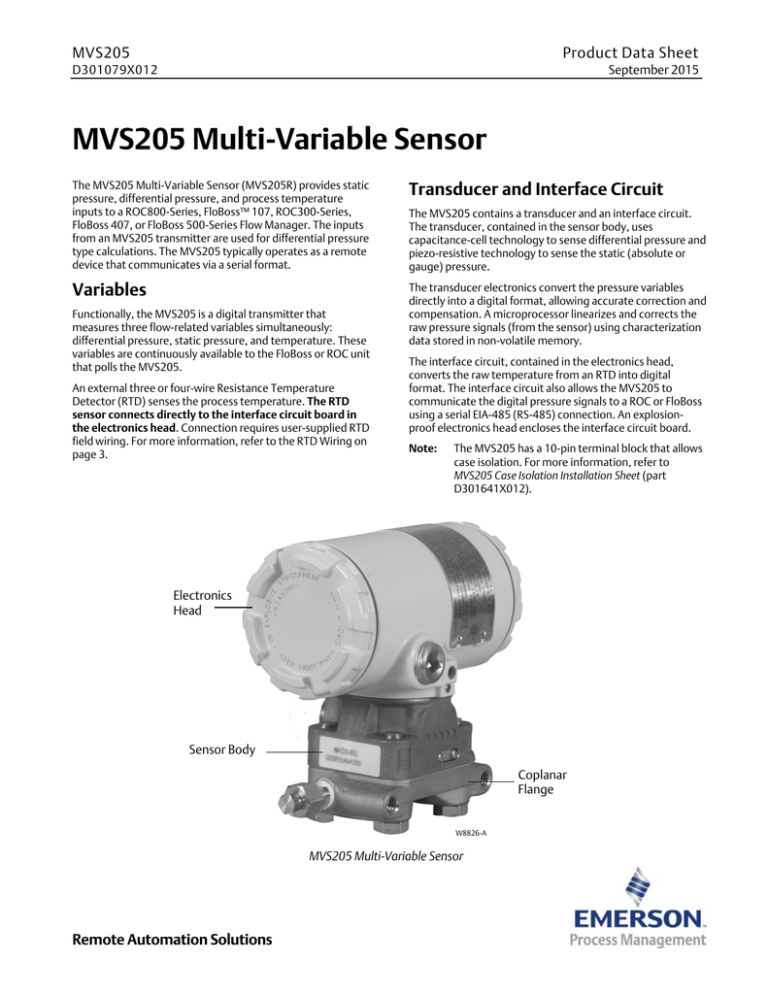

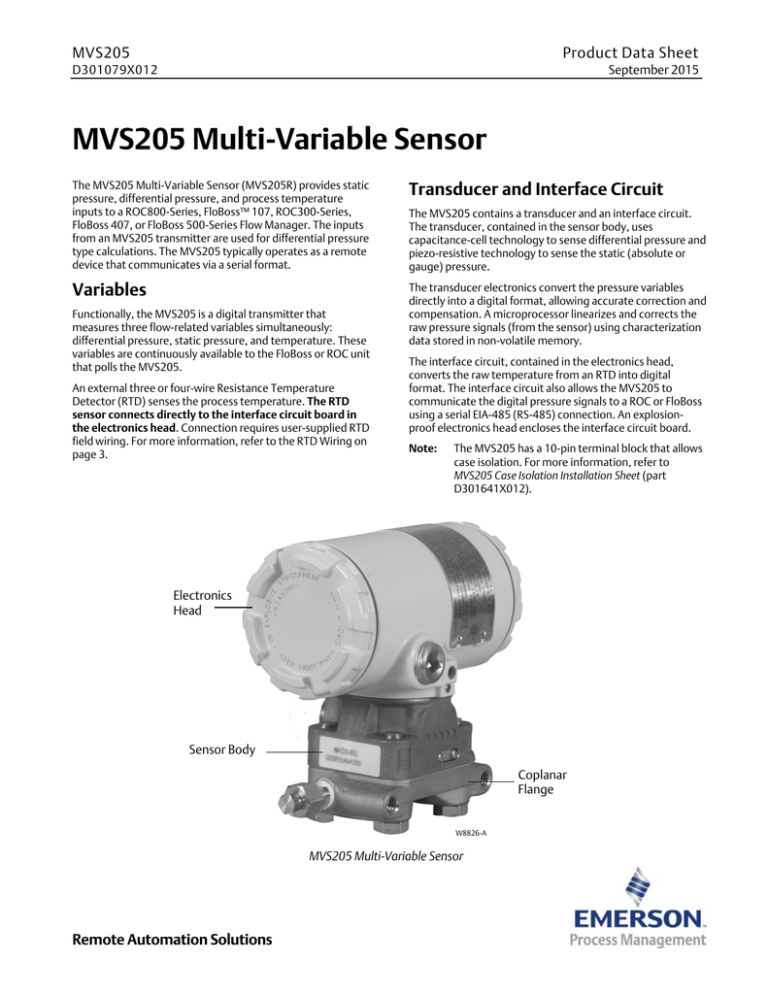

Electronics

Head

Sensor Body

Coplanar

Flange

W8826-A

MVS205 Multi-Variable Sensor

Remote Automation Solutions

MVS205

September 2015

Accuracy

Two versions of the pressure transducer used in the MVS205

transmitter are available:

205P with reference accuracy of 0.075% of the full span.

205E with reference accuracy of 0.10% of the full span.

Mounting

Attached to the bottom of the sensor body is a Coplanar™

flange. This flange, which provides drain and vent valves,

allows the MVS205 to mount on a pipestand, on a wall or

panel, or on an integral orifice assembly or manifold valve.

Note: CE marked assemblies come with cover clamps

installed on both ends of the MVS205 to comply

with ATEX and IECEx.

6.15

(156)

INCH

(mm)

2.81

(71)

4.73

(120)

MVS205aa.dsf

MVS205 Panel Mounting

S

LO

E

P

W

IVE

ATM

OS

ARNI NG

P

-

E

-

H

X

IN

RE

P

K E E

AL

I V E

-

-

H

I

I

T

T

G

T

W H

E N

R

CI

C

U

INCH

(mm)

INCH

(mm)

6.25

(159)

3.54

(90)

MVS205ac.dsf

MVS205a.dsf

MVS205 Pipe Mounting (Horizontal and Vertical Pipe)

2

www.EmersonProcess.com/Remote

MVS205

September 2015

MVS205 Multi-Variable Sensor

Terminations

Terminal

Description

1

Earth Case

1

EARTH DR

Earth Drain

COMM A

RX / TX +

COMM B

RX / TX —

RTD REF

RTD REF

RTD +

RTD +

EARTH CS

RTD —

RTD —

RTD RET

RTD RET

PWR +

Power —

PWR —

Power +

1. See part D301641X012 for

information on isolating the case

from power.

RTD Wiring

To connect a remote MVS205 to an RTD sensor assembly, install the sensor in the pipeline

and connect a RTD cable to the terminations on the interface board inside the remote MVS

sensor head. An armored cable requires no conduit to be used in a Class I, Division 2

hazardous non-incendiary area. In a Class I, Division 1 area, unarmored cable may be used if

installed in conduit that includes seals per hazardous installation practices.

Note: When installing an RTD in the field, any length/gauge combination of wire that adds

measurable resistance to the loop will cause a change in resistance that will affect the

RTD readings. It is recommended that end users calibrate or bias out the excess

resistance. To do this, perform a standard calibration at a process level (calibrate the

RTD input using the desired length of wire). Calibrating the input and not

compensating for the excess resistance caused by the length of the run will result in

inaccurate readings.

2-Wire

3-Wire

4-Wire

www.EmersonProcess.com/Remote

RTD REF

Jumper to RTD+

RTD +

Red with Jumper to RTD REF

RTD —

White

RTD RET

None

RTD REF

Red

RTD +

Red

RTD —

White

RTD RET

None

RTD REF

Red

RTD +

Red

RTD —

White with Jumper to RTD RET

RTD RET

White with Jumper to RTD —

3

MVS205

September 2015

Differential Pressure Input

Range1

0 to 62.2 kPa (0 to 250 InH2O)

0 to 248.8 kPa (0 to 1000 InH2O)

Reference Accuracy

205E (10:1 rangeability

allowed)

205P (100:1 rangeability

allowed)

Turndowns

from 1:1 to

10:1 of URL

0.10% of span

Turndowns

from 10:1 to

100:1 of URL

Not allowed

Turndowns

from 1:1 to

10:1 of URL

0.075% of span

Turndowns

from 10:1 to

100:1 of URL

[0.025 + 0.005(URL/Span)]% of span

Stability

0.125% of URL for five years, with up to 50°F (28°C) ambient temperature changes and up

to 1000 psi (68,9 bar) line pressure

Ambient Temperature Effect per

50°F (28°C)

Spans from 1:1 to 30:1

(0.025% URL + 0.125% of span)

Spans from 30:1 to 100:1

(0.035% URL + 0.175% of span)

Zero error

0.05% of URL per 1000 psi (68,9 bar)

Span error

0.20% of DP Reading per 1000 psi (68,9 bar)

Static Pressure Effects

Over-Pressure Limit

3,626 psi (250 bar) applied on either or both sides without damage to the sensor

Burst Pressure Limit

10,065 psi (694 bar)

1.

Consult factory for special ranges and materials which may be available. For example, 0 to 6.22 kPa (0 to 25 InH2O) at 0.10% reference

accuracy.

Static Pressure Input

Range

Either Absolute or Gauge:

0 to 5516 kPa (0 to 800 psia/psig)

0 to 25,000 kPa (0 to 3626 psia/psig)

Reference Accuracy

205E (10:1 rangeability

allowed)

205P (100:1 rangeability

allowed)

Stability

4

Turndowns

from 1:1 to

10:1 of URL

0.10% of span

Turndowns

from 10:1 to

100:1 of URL

Not allowed

Turndowns

from 1:1 to

10:1 of URL

0.075% of span

Turndowns

from 10:1 to

100:1 of URL

[0.03 + 0.0075(URL/Span)]% of span

0.125% of URL for five years, with up to 50°F (28°C) ambient temperature changes

www.EmersonProcess.com/Remote

MVS205

September 2015

Ambient Temperature Effect per

50°F (28°C)

Over-Pressure Limit

Spans from 1:1 to 30:1

(0.05% URL + 0.125% of span)

Spans from 30:1 to 100:1

(0.06% URL + 0.175% of span)

Same as URL

Process Temperature Input

Type

For 3- or 4-wire platinum 100-ohm RTD (conforming to IEC 751 Class B), with = 0.00385

Range

—40 to 400°C (—40 to 752°F)

Reference Accuracy

±0.28°C (±0.5°F), exclusive of RTD sensor and wiring errors (see Note under Terminations, RTD

Wiring).

Note:

Excitation Current

Includes linearity, hysteresis, and repeatability effects.

1.24 mA

Output

EIA-485 (RS-485)

Asynchronous serial communication using an MVS module-based proprietary

communications protocol for up to 1220 m (4000 ft) distance (wired in daisy-chain pattern

and properly terminated).

Power

Input at 0 to 75°C (32 to 167°F)

8 to 30 Vdc, 200 mW average

Input at —40 to 0°C (—40 to 32°F)

8.5 to 30 Vdc, 200 mW average

Isolation

The power input can optionally be isolated from the case, which may be grounded separately.

For further information, see MVS205 Case Isolation Installation Sheet (part D301641X012).

Physical

Dimensions

147 mm H by 163 mm W by 84 mm D (5.8 in. H by 6.4 in. W by 3.3 in. D)

Weight

3.0 kg (6.7 lb), including head

Vibration Effect

Sensor outputs shall not shift more than +0.1% of upper range limit per g from 5 to 2000 Hz in

any axis when tested per IEC 770, Section 6.2.14.

Construction

Standard

Transducer is all stainless steel construction with silicone fill fluid,

316L diaphragms and glass-filled PTFE o-rings. Electronics head is

A360 Aluminum with urethane coating.

Optional

Transducer includes Hastelloy C-276 wetted parts (construction is

NACE compliant per MR0103 and ISO15156/MR0175), inert fill

fluid

Pipestand

Mounts on 50 mm (2 in.) pipe with U-bolt and optional flange

bracket

Wall or Panel

Mounts with optional flange bracket, bolted on 71 mm (2.8 in.)

centers

Conduit

Head has two 1/2-inch NPT connections

Process

1/4-18 NPT on 2-1/8 inch centers (on coplanar flange)

Mounting

Connections

Environmental

Operating Temperature

—40 to 75°C (—40 to 167°F)

Storage Temperature

—50 to 100°C (—58 to 212°F)

www.EmersonProcess.com/Remote

5

MVS205

September 2015

Operating Humidity

0 to 99%, non-condensing

Process Seals per ANSI/ISA

12.27.01

Meets requirements for a Single Seal device as defined by ANSI/ISA 12.27.01. Installation must

adhere to the following process temperature limits.

Process Temperature (at

transmitter isolator flange)

Standard Silicone Fill

Sensor

—40 to 100°C (—40 to 212°F)

Inert Fill Sensor

—18 to 85°C (0 to 185°F)

Note: Process temperatures above 85°C (185°F) require you to lower the product’s

maximum ambient temperature rating by a 1.5:1 ratio. To determine the adjusted

maximum temperature rating, perform the following calculation:

Adjusted max Tamb = Product Max Tamb — [(Actual Process Tamb — 85°C (185°F)) * 1.5]

Example:

Adjusted Max Tamb = 75°C — [(95°C — 85°C) * 1.5] = 60°C.

Approvals

Product Markings for Hazardous

Locations

CSA C/US

Class I, Division 1, Groups C and D.

Class I, Division 2, Groups A, B, C, and D, T5 (Tamb=70°C [158°F]),

T4 (Tamb=75°C [167°F]).

Type 4X.

CE Marked

Ex d IIB T5 (Tamb=75°C)

Ex tD A21 IP66 T85°C

II 2 GD.

0081.

ATEX Cert. KEMA 04ATEX2182 X

IEC Cert. IECEx KEM 07.0055X

Approval Standards

6

TR CU 012/2011

Certified by NANIO “CCVE” RU C-US.ГБ05.B.01184 valid from 16.06.2015 to 16.06.2020

1Ex d IIB T5X

-40C0≤Ta≤+75C0

IP66 CSA/UL

CSA C22.2 No. 30

CSA C22.2 No. 213

UL 1203, UL 1604

ANSI/ISA 12.27.01-2003

EMC

EN 61000-4-2 (2001)

EN 61000-4-3 (2002)

EN 61000-4-4 (1995)

EN 61000-4-5 (2001)

EN 61000-4-6 (2003)

ATEX

EN 60079-0 (2006)

EN 60079-1 (2007)

EN 61241-0 (2004)

EN 61241-1 (2006)

IECEx

EN 60079—0 (2004 Edition 4)

EN 60079—1 (2007-04 Edition 6)

EN 61241—0 (2004 Edition 1)

EN 61241—1 (2004 Edition 1)

EN 60529 (2001)

www.EmersonProcess.com/Remote

MVS205

September 2015

Miscellaneous Approval

Certificates

Measurement (Industry)

Canada

Approved for use with approved flow computers. Approved as

MVS205R Series Remote Sensors (Measurement Canada approval

#AG-0412).

Canadian Registration to

Category ‘F’ Fittings

CRN 0F7768

Note:

Applies to all Canadian provinces and territories.

Customs Union

TR CU 004/2011, TR CU 020/2011

Certified by “Technoneftegaz”

TC RU C-US.HO03.B.00155 valid from 19.05.2015 to 18.05.2020

www.EmersonProcess.com/Remote

7

MVS205

September 2015

For customer service and technical support,

visit www.emersonprocess.com/remote/support

Headquarters:

Emerson Process Management

Remote Automation Solutions

6005 Rogerdale Road

Houston, TX 77072 U.S.A.

T +1 281 879 2699 | F +1 281 988 4445

www.EmersonProcess.com/Remote

Europe:

Emerson Process Management

Remote Automation Solutions

Unit 8, Waterfront Business Park

Dudley Road, Brierley Hill

Dudley UK DY5 1LX

T +44 1384 487200 | F +44 1384 487258

www.EmersonProcess.com/Remote

North American/Latin America:

Emerson Process Management

Remote Automation Solutions

6005 Rogerdale Road

Houston TX USA 77072

T +1 281 879 2699 | F +1 281 988 4445

www.EmersonProcess.com/Remote

Middle East/Africa:

Emerson Process Management

Remote Automation Solutions

Emerson FZE

P.O. Box 17033

Jebel Ali Free Zone — South 2

Dubai U.A.E.

T +971 4 8118100 | F +971 4 8865465

www.EmersonProcess.com/Remote

Asia-Pacific:

Emerson Process Management

Remote Automation Solutions

1 Pandan Crescent

Singapore 128461

T +65 6777 8211| F +65 6777 0947

www.EmersonProcess.com/Remote

Remote Automation Solutions

© 1995-2015 Remote Automation Solutions, a business unit of Emerson Process

Management. All rights reserved.

Remote Automation Solutions, a business unit of Emerson Process Management, shall not be

liable for technical or editorial errors in this manual or omissions from this manual. REMOTE

AUTOMATION SOLUTIONS MAKES NO WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING THE

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WITH

RESPECT TO THIS MANUAL AND, IN NO EVENT SHALL REMOTE AUTOMATION SOLUTIONS BE

LIABLE FOR ANY INCIDENTAL, PUNITIVE, SPECIAL OR CONSEQUENTIAL DAMAGES INCLUDING,

BUT NOT LIMITED TO, LOSS OF PRODUCTION, LOSS OF PROFITS, LOSS OF REVENUE OR USE

AND COSTS INCURRED INCLUDING WITHOUT LIMITATION FOR CAPITAL, FUEL AND POWER,

AND CLAIMS OF THIRD PARTIES.

Emerson Process Management Ltd, Remote Automation Solutions (UK), is a wholly owned

subsidiary of Emerson Electric Co. doing business as Remote Automation Solutions, a business

unit of Emerson Process Management. FloBoss, ROCLINK, ControlWave, Helicoid, and

OpenEnterprise are trademarks of Remote Automation Solutions. AMS, PlantWeb, and the

PlantWeb logo are marks owned by one of the companies in the Emerson Process Management

business unit of Emerson Electric Co. Emerson Process Management, Emerson and the Emerson

logo are trademarks and service marks of the Emerson Electric Co. All other marks are property

of their respective owners.

The contents of this publication are presented for informational purposes only. While every

effort has been made to ensure informational accuracy, they are not to be construed as

warranties or guarantees, express or implied, regarding the products or services described

herein or their use or applicability. Remote Automation Solutions reserves the right to modify

or improve the designs or specifications of such products at any time without notice. All sales

are governed by Remote Automation Solutions’ terms and conditions which are available upon

request. Remote Automation Solutions does not assume responsibility for the selection, use or

maintenance of any product. Responsibility for proper selection, use and maintenance of any

Remote Automation Solutions product remains solely with the purchaser and end-user.