Operations Management: Introduction & Key Concepts

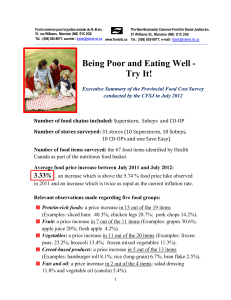

advertisement