Consignment vs. Turnkey Manufacturing

advertisement

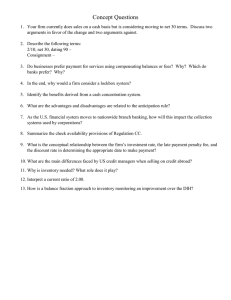

Consignment vs. Turnkey Manufacturing Choosing Between Turnkey and Consignment Manufacturing To remain agile, stay ahead of the market, and react quickly to disruptive changes in the technology environment, many companies outsource the manufacturing of their electronics products. Making the decision to outsource, however, is only part of the choice these companies face – they must also decide on an outsourcing methodology – two common models are consignment manufacturing and turnkey manufacturing. The paper explains, compares and evaluates consignment and turnkey manufacturing to help small- to midsized companies select the electronics manufacturing outsourcing strategy that best fits their needs. Consignment Contract Manufacturing Consignment manufacturing can be best thought of as “partial” outsourcing. In the case of electronics manufacturing, it describes a model in which the technology producer maintains some portion of the overall manufacturing supply chain in-house – typically, purchasing and/or system assembly (box and build). Under a consignment model, in-house purchasing, shipping and receiving groups are responsible to obtain materials, sort and package them for production and deliver them to the contract manufacturer for assembly. Emerging companies often choose to begin production of their electronic components under a consignment model. They may be unaware of the existence of turnkey contract manufacturers, they may believe that no turnkey contract manufacturer can properly handle their particular component or small order sizes, or they may have made an investment in in-house manufacturing supply chain resources that they wish to re-coup. Turnkey Contract Manufacturing Turnkey manufacturing describes a complete manufacturing function that provides all manufacturing and supply chain services, including material acquisition, assembly, test, and aftermarket service and warranty support. Product design and design for manufacturing may also be services that are provided by the contract manufacturer (CM). In other words, the organization outsources all inventory control, receiving, kitting and production management functions – and possible all design and warranty service as well – to a third-party contract manufacturer who is responsible for manufacturing all aspects of the product in question. Advantages of Turnkey Manufacturing: • Access supply chain and production economies of scale • Minimize inventory risk • Take advantage of latest technology without capital expenditure Some of the most innovative companies choose a turnkey model right from the start, recognizing that their business model will be driven by the sales and marketing of innovative products and not by the infrastructure-intensive manufacturing of those products. This model allows new companies to avoid risk, keep a low overhead, and move quickly to meet market demands. Which is Better? The consignment model is today becoming less popular as companies focus on reducing costs and remaining agile to address rapidly changing markets. That said, there are some cases where it may make sense – such as when a product relies on a highly specialized component that may be supplied specifically for that company, or in cases where a company’s intellectual property is contained in a component or a board. But for the majority of product marketing companies in which manufacturing is not a core business practice, turnkey manufacturing is the wisest choice over both the short and long term. By outsourcing all www.ocmmanufacturing.com - 1-800-268-3961 manufacturing functions to a third-party CM these companies can focus on their core competencies while taking advantage of the production economies of scale offered by an established contract manufacturer. While some companies may feel vulnerable in relying on a third party to meet delivery commitments to customers, high-quality turnkey manufacturing is more likely to improve product delivery because established and proven processes are used. Companies relying on turnkey manufacturing also tend to innovate and produce new products more quickly, as they are free to focus on market research, product development and sales and are unhindered by costly manufacturing infrastructures. A CM’s entire focus is on manufacturing, while a tech company will often find that its resources are pulled in many directions when difficulties arise or when delivery crunches occur. Cost-Benefit Analysis In addition to offering enhanced process, quality assurance and delivery capabilities, turnkey manufacturing helps electronics manufacturers reduce production costs by lowering or eliminating many of the supply-chain and overhead costs associated with the manufacturing process. Many of these costs are overlooked or not well understood when companies initially decide to use a consigned model. To calculate the true cost of managing materials under both a consignment and turnkey model, we must first examine all overhead, hard costs, and assumed risks involved in the production supply chain. That supply chain must necessarily involve extensive administrative functions: accounts payable, purchasing, inventory control, receiving and kitting, and management overhead. In each of these areas, the company assumes human resources overhead, hard costs associated with salaries, financing, etc., and risk. • The figures shown in the diagram at left are based on a company with $1.5 million in materials expenditures and 2.5 inventory turns per year. Some key points for this company to consider when assessing its true cost of consignment include: • The significant cost of controlling one’s own inventory. The hard cost in this area includes inventory financing, shrinkage costs, and salary overhead. • The human resources tradeoff. Because only part-time staffing is required in this situation, the company must choose between three suboptimal scenarios: try to find and manage suitable part-time staff; hire one staff member to perform multiple jobs, likely without proper expertise in any of them; or, outsource to various consultants, likely at higher cost. Significant risk is assumed at each stage of the supply chain. Short Paper: Consignment vs. Turnkey Manufacturing 2/3 In addition to eliminating much of the risk, a company such as the one profiled above stands to save more than $107,000/year by using a turnkey model rather than a consigned approach.1 The most impressive cost savings will be found in three key areas: Receiving/Kitting Under the typical consignment model, companies outsource only the assembly portion of the manufacturing process. Thus, organizations must prepare the products for manufacturing in-house, resulting in added inhouse kitting costs – including labour, and redundant shipping and receiving costs (the parts must be delivered to the CM). Contract manufacturers already have the infrastructures in place to prepare products for assembly, so their cost is spread over a number of customers and products. In addition to adding costs, the consignment model can result in duplicated effort at this stage if the products are not prepared properly for the contract manufacturer’s particular processes. In such cases, the manufacturer must adjust the materials or return the components to the company – resulting in wasted time and added costs. Component quality issues and kitting errors cause production delays on the assembly line – it is always best for the CM to receive, test and prepare the components that it will assemble. Inventory Financing & Labour Costs By spreading inventory financing and labour costs across multiple projects, a contract manufacturer’s costper-product is always less than the same costs dedicated to a single company or product. CMs also offer economies of scale as well as various inventory financing options that assist with cash flow. While the turnkey model offers significant inventory and labour cost savings, many early-stage companies that have already invested capital in these areas believe that they must retain their existing supply chain assets to re-coup their investments. The above cost analysis, however, demonstrates that a contract manufacturer can offer lower per-project labour and inventory financing costs than an in-house team, since the manufacturer specializes in those areas and the costs are spread across multiple projects. The Right Decision At OCM Manufacturing, we have observed that turnkey contract manufacturing is the ideal manufacturing model for most early-stage companies and small- to mid-size companies. Even many established companies with in-house supply chain departments are switching to a turnkey model for their new product ideas, or will “test the waters” of turnkey outsourcing with established products that are in maintenance mode. Offering significant labour and inventory cost savings and allowing companies to focus on innovation and their core competencies, the turnkey manufacturing model is a viable choice for companies that have made the decision to outsource the manufacturing of their electronics products to a contract manufacturer. Contact OCM for a customized cost comparison model. We will use our turnkey/consignment comparison cost calculator tool to estimate the expected savings you can realize by taking advantage of our turnkey electronics manufacturing services. Contact one of our Program Managers today, at 1-800-268-3961 1 Estimate is based on industry averages, OCM’s costs, and is output using OCM’s cost calculator tool. Short Paper: Consignment vs. Turnkey Manufacturing 3/3