FEA Good Modeling Practices Issues and examples

advertisement

FEA Good Modeling Practices

Issues and examples

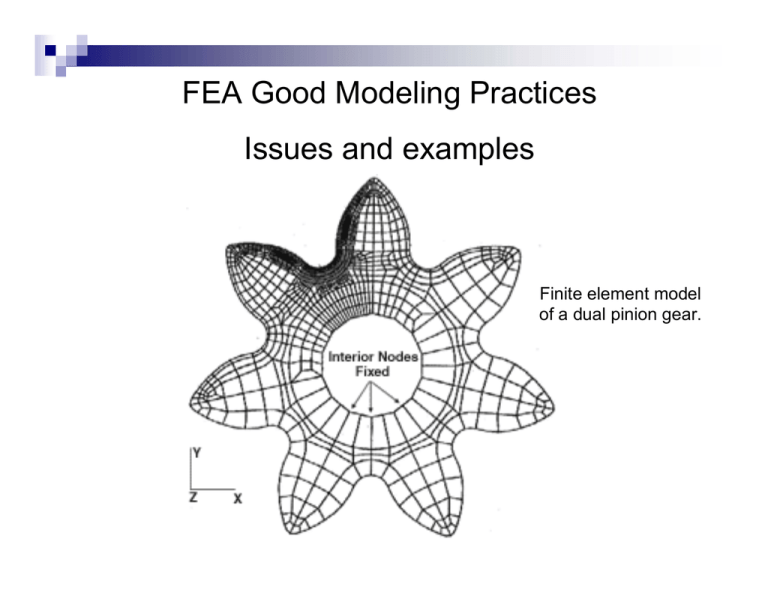

Finite element model

of a dual pinion gear.

Finite Element Analysis (FEA)

Good modeling and analysis procedures

FEA is a powerful analysis tool, but use it with care.

Warnings

ALL MODELS ARE WRONG! - SOME ARE USEFUL.

An FEA program allows an engineer to make mistakes

at a rapid rate of speed. (R. Miller)

An error caused by misunderstanding or oversight is

not correctible by mesh refinement or by use of a

more powerful computer. (Cook)

Finite Element Analysis (FEA)

Good modeling and analysis procedures

FEA is a versatile tool, but not the best

analytical tool for every problem. (Cook)

An analysis is doomed to failure without

sufficient consideration of all available

tools to determine which is most

appropriate, and sufficient pre-analysis

planning to determine the required scope

and level of complexity for the analysis

and the required accuracy of the solution.

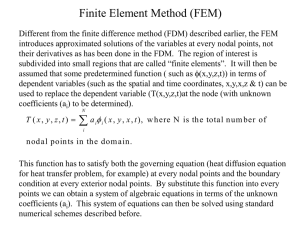

Basic Concepts in Finite Element Analysis

Divide and conquer - Simple linear equations

like F=Kx are not valid on a large scale for a

part with complex geometry but they can be

valid for a small region of material within the

complex part.

Therefore, if we break down a complex physical object into a

large but finite number of small pieces (elements) for

which simple equations can be solved with acceptable

accuracy (where numerical approximations are valid),

then build the structure back up (via nodal connectivity

and transferring solutions from one element to the next to

allow successive computation) we can create a

meaningful solution for the entire complex object.

σ = Eε or

F

A

Basic Concepts in Finite Element Analysis

Finite elements are small interconnected geometrical entities

connected to other elements through nodes (1D),

boundary lines (2D), and boundary surfaces (3D).

Elements contain the material information and determine how

the loads are transferred into displacements for all

connected nodes

FEM is actually displacement analysis {F}=[K]{x} with

node displacements determined by element

"stretching", followed by load and stress calculations

for the elements based on the nodal displacements

and the material properties

σ = Eε or

F

A

Basic Concepts in Finite Element Analysis

Nodes: basically coordinate locations,

they locate/define the endpoints of

all 1D elements and the corners of

all 2D & 3D elements.

Since all info goes into model and is computed for

the model on the nodal level (i.e. input nodal

forces and output nodal displacements), at a

minimum, nodes must be present at all locations

where there are changes in geometry or where

there are applied loads or boundary conditions.

Basic Concepts in Finite Element Analysis

•

•

Degrees of Freedom (DOF) & Associated Loads:

DOFs are the unknown quantities associated with a node,

or the things that must be solved for mathematically.

Associated loads are loads of the same direction and type

as the DOFs.

• For structural FEA the DOFs are displacements (or

rotations) and the associated loads are forces (or

moments).

Boundary Condition (BC): A boundary condition for the

model is the setting of a known value for a

displacement or an associated load. For a particular

node you can set either the load or the displacement

but not both.

Text: Building Better Products with FEA,

by V. Adams & A. Askenazi,

Boundary Conditions: the loads and constraints that represent the effect of the

surrounding environment on the model. (Everything else, that you have not modeled).

UNWANTED EFFECTS (p. 264-270)

Overconstrained, redundant supports, excessive constraint tend to add stiffness to the

model (stiffer than the real system)

Also, prohibits Poisson contraction (making excessive stress)

example of excessive constraint in thermal expansion

Underconstrained, understiffened, insufficient stiffness if rigid-body motion can occur,

cracks, un-"glued" parts (p. 270) "Ask yourself if the parts that were not modeled could

really allow the deformation that you are seeing." (p. 271)

If you notice high stress near the boundary conditions, are they fictitious or real ?

Point load: local stress is infinite, but is meaningless (Fig. 8.6, p.272)

If you are concerned with locations "far" removed from locations which have

singularity, then you can use the point loads.

COMPARISON OF BOUNDARY CONDITION SCHEMES (p. 295-300)

Considers various approaches for modeling a pin-in-a-hole

loading

SUMMARY (p.300-302)

"... boundary conditions are arguably the toughest aspect of FEA"

Basic Concepts in Finite Element Analysis

The number of equations in the mathematical model is equal

to the number of unknown degrees of freedom (each node

introduces 3 DOF for 3D brick elements).

All loadings such as pressures, thermal loadings, etc. must

be converted to associated loads to allow solution of the

displacement equations. This can either be done by the

user or by the software, but all information becomes

nodal information prior to solution.

The method requires the solution of large systems of

simultaneous equations – requires high-speed computers

(#eqns = (#DOF/node)*#nodes - # BCs)

Figure 6: When a refinement point is

defined at the center of the hole in the

bracket model, the mesh is enhanced

surrounding it.

Local mesh refinement

Finite element model of a dual pinion gear.

Frame FEA

Maximum Compression Stress 22 ksi

5 commandments of finite element modeling and analysis

1. Thou shalt use the simplest model (in terms of model

complexity and scope, element type and mesh, etc.) that

provides the information you are looking for.

2. Thou shalt verify the quality of the finite element mesh model

both prior to the analysis and after results have been

generated.

3. Thou shalt completely understand the assumptions inherent

in the finite element method, understand the characteristics of

any automatically constrained joints (especially those created

between parts in an assembly during the automatic meshing

process), and understand and correctly apply the boundary

conditions and nodal loads.

4. Thou shalt verify the results of a finite element analysis both

numerically and physically (plot displaced shape first!).

5. Thou shalt not use the results of an unverified finite element

analysis for making design decisions, and thou shalt not

present the results in a false or misleading way.

Mesh Convergence Help:

http://www.algor.com/service_support/hints_tips/mesh_convergence_study.asp

Help getting specific element and nodal results info:

http://www.algor.com/service_support/hints_tips/inquire_results.asp

ALGOR Keystroke-Specific Tutorials:

http://www.algor.com/service_support/tutorials/default.aspx

What can go wrong with FEA? (ME Magazine article)

http://www.memagazine.org/backissues/may98/features/wrong/wrong.html