1 APPX. `A TO D` TO TENDER DOCUMENT No.VRDE/MMG/OTS

advertisement

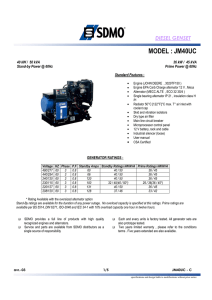

APPX. ‘A TO D’ TO TENDER DOCUMENT No.VRDE/MMG/OTS-05/2012-13 TECHNICAL SPECIFICATIONS FOR DEVELOPMENT, INTEGRATION OF 23 KVA POWER PACK TESTING, SUPPLY AND 1.1 INTRODUCTION 1.1 This Specification is for the guidance for development, testing, integration and supply of 23 KVA Power Source with removable acoustic canopy and required accessories etc. The technical offer should be more elaborate and should contain detailed information on component level. The contractor should submit all the drawings to VRDE for checking & approval regarding its completeness, accuracy before commencement of the fabrication. 1.2 VRDE reserves the right to incorporate any changes/ deviation to this specification as required from time to time until the design is approved. During fabrication, in case any minor deviations in specification or suggested, the same should be incorporated without any additional cost. 1.3 There is a requirement of 2 Nos of 23 KVA Power Source (with air cooled engine) with removable acoustic canopy for each genset. The Genset will be mounted on the shelter (Two different shelters) fabricated on 6x6 vehicle chassis. Genset will provide electrical power for operation of Air conditioners, Battery chargers, BC filtration system, Lighting etc. 1.4 The system is required to be mounted on the vehicle chassis. Hence, the size of canopy and total weight of the system are the crucial parameters to avoid over dimensions & overloading on vehicle axles. The contractor should ensure that the total weight of the complete systems & components mounted on the vehicle chassis should be less than 800kg. Any increase in weight above 800 kg is not acceptable. The estimated weight details of all the systems & components along with overall dimensions are to be submitted to VRDE by the contractor in the technical bid. 2 BRIEF DESCRIPTION 2.1 The 23 KVA Power Source (at NTP condition) comprise of brush less type alternator coupled through close type coupling to air-cooled diesel engine mounted on a common lightweight base frame of high strength steel with suitable anti-vibration mounts. Each Genset shall also include removable diesel tank 60 ltrs capacity inbuilt in base frame, control panels, cold start device, batteries for engine starting, tools & spares box etc. 2.2 To satisfy the sound levels acceptable as per CPCB norms a removable acoustic canopy shall be fabricated. The canopy structure should be fabricated with light weight & high strength material/composite material to withstand the vehicle generated vibrations & loads. The sound insulation (acoustic) material like mineral wool / foam etc. of suitable thickness should be provided so that the noise level should be less than 75 dB at 1 m distance from canopy. Acoustic material should be sandwiched between Aluminum sheet on outside of canopy and perforated Aluminum sheet on inside of the canopy. The doors will be provided to the removable acoustic canopy. These doors will be provided with handle and locking arrangement. The removable acoustic canopy 1 should be 100% rainproof. Detail drawing indicating like dimensions, structural members, sheet thickness should be submitted for approval. 3 SCOPE OF WORK: 3.1 Development & Supply of 2 Nos. of 23 KVA Genset along with accessories and spares. 3.2 Fitment and integration of Genset on shelters fabricated on Vehicle chassis. 3.3 Fabrication & Fitment of removable acoustic canopy (One for each genset). 3.4 Fabrication and provision of Genset Control Panels (Local & remote for each Genset). 3.5 Inspection and testing of Genset along with control panels as per ATP attached at Appendix ‘A’. Requirement is for a genset already qualified in the qualification tests mentioned in Appendix ‘D’. Qualification test certificates must be obtained from authorized agencies (Viz R&DE, Pune, NSTL, Vishakapatnam, RCI, Hyderabad, VRDE, Ahmednagar and ARAI, Pune) 3.6 All the eletrical items (cables, connectors etc.) required for integration should be MIL grade and to be supplied by the contractor. 4 OPERATING CONDITIONS: 4.1 The Generating Set is required to supply power in the following field conditions. a) Operational temperature : - 10°C to + 55 °C b) Storage temperature : - 20°C to + 70°C c) Relative humidity : 18 – 95 % d) Altitude : 3000 m above MSL e) Sound level : Less than 75 dB at 1 m distance from canopy f) Vibration level : ± 1.5 g to be sustained during transportation. 4.2 The Genset with accessories will be mounted on the Shelters fabricated on vehicle chassis. These Genset are likely to be subjected to the vehicle generated vibrations during cross country movement. Hence suitable AV mounts are to be provided for its satisfactory functioning. 2 5 BRIEF DETAILS AND SPECIFICATIONS FOR CANOPY 5.1 The removable acoustic canopy should have the following dimensions: - Length 2000 mm Width 900mm Height without silencer 1200mm 5.2 Suitable number of AC exhaust fans / blowers with switches are to be provided to limit temperature rise (w.r.t. outside temp) inside the acoustic canopy not more than 150C. 6. GENERATOR SET 6.1 The Gen set will be supplied with the following configuration: a) Capacity : 23 KVA at 0.8 Power Factor (P.F.) at NTP b) Output voltage : 415 V ± 5%, 3 Phase, 50 Hz ± 4% c) Dimensions : The Genset (Engine + Alternator) dimensions should be 2000 mm (L) x 900 mm (W) x 1200 mm (H) without AV mounts. d) Control Panels : Control Panel separate for each Genset – To be mounted in Genset/non AC compartment. e) Distribution box make : Distribution box should be provided with necessary MCBs, ELCBs (MIL grade/ ISI make) & Allied /equivalent connectors. f) Battery : 12 V, 100 AH, Lead Acid, Make : Exide or equivalent g) Battery Charger i) The diesel engine should be provided with a suitable alternator with built in regulator and control system for charging the battery. ii) There should also be a provision to charge the Genset batteries from mains supply also. Here it is considered that batteries are in completely discharged condition and 12 V, D.C. Power is not available to make the panel “ON”. Therefore, suitable Switching Mode Power Supply (SMPS) 3 should be provided which will operate directly on Mains (AC) to charge the batteries automatically. h) Mountings: Suitable Anti-Vibration mountings should be provided for complete Genset, control panels & battery charger. i) Earthing spike: Two Nos of earthing spikes for each genset are to be provided with copper braided 10 meter long 25 mm2, cable. These earthing spikes should be mounted at suitable accessible location. j) The cables and wires from removable acoustic canopy to the EMI shielded shelter are made to pass through conduit without affecting the acoustic chamber design. The connections of cables in EMI shielded shelter are to be provided with suitable connectors and gaskets. All the connections going inside the EMI shielded shelter should be through suitable cables & bulk head connectors. The supplier should supply cable & connectors of reputed make & grade suiting our requirements. All other cables should be Teflon / Fiberglass based and confirm to MIL grade. The connectors are to be provided wherever the cables are passing/ entering through the shelter walls. 6.2 FUEL TANKS & FILLING SYSTEM 60 Ltrs capacity tank (one for each Genset) fabricated through 2 mm thick stainless steel (SS-304L) sheet should be provided with float switch for cutting ‘OFF’ the fuel feed pump motor when tank is full. It should be provided with filler neck, drain plug, fuel level indicator on tank and digital level indication in control panel. This fuel tank should be integrated in the base frame of Genset and size to be decided accordingly. Fuel tanks should be removable from base frame for maintenance and cleaning purpose. 6.3 SPECIAL DEVICES: Following special devices are to be provided. i) Hot Air Duct: This is provided in canopy for directing outlet hot air to the atmosphere. ii) Inlet Air Duct: This should be provided for fresh air intake from atmosphere to canopy to avoid mixing of hot outlet air with inlet air. iii) Cold starting device : Heater glow plug electrically operated from 12 V battery is to be provided to operate the Genset at low temperature i.e. up to –100 C iv) v) Residential type silencer with cover : To reduce the sound level. These silencers should be integrated on top of acoustic canopy with covers & provision should be made to route the exhaust from genset to atmosphere. Provision of lub oil draining system. 6.4 SAFETY DEVICES The generator should be provided with the following safety devices: i) ii) Low lubricating oil pressure High cylinder head temp 4 iii) iv) v) vi) vii) viii) Overload “V” Belt failure Over speed and under speed protection High temperature in acoustic canopy Earth leakage circuit Breaker Earthing spike Audio Visual alarm system is required for abnormal condition as mentioned in Sr. No. (i) to (vi) above. 7 DETAILED SPECIFICATION OF MAJOR ITEMS 7.1 PRIME MOVER (ENGINE) 7.1.1 The Prime Mover of the generating sets should be light weight and compact air cooled diesel engine. The engine should be of ISI grade and should conform to IS: 10000 (PtIV) 1980/BS 5514/ISO 3046 IFN. 7.1.2 The engine should be of following specification: a) Continuous power rating at NTP condition: Engine rating shall be such that output rating of the genset .i.e. Alternator will be 23 KVA at 0.8 power factor at NTP c) Cooling system: Air cooled. b) Speed / RPM: 1500 ± 4%. d) Speed governing: ± 4% at no load to full load e) Starting system: Electric start, 12 V D.C. system. f) Cold starting device: To start the engine at low temperature. For this heater glow plug operating on 12 V D.C. is to be provided. g) Automatic shut off device for safety of engine under abnormal operating conditions like cylinder head temp, oil pressure, over loading. h) Battery - 12 V, 100 AH, Lead Acid, Make: EXIDE or equivalent i) Inbuilt charging circuit for charging the battery through an alternator. 7.2 ALTERNATOR The alternator should be self regulated, brush less, ISI grade and should be in accordance with IS 4722. The enclosure and class of insulation are to be provided to satisfy the environmental conditions mentioned in this specification. The specification of the alternator should be as under: a) b) c) Type Rating No of phases : Brushless, 4 Pole : Min. 23 kVA at 0.8 power factor at NTP. : Three phase, four wire system 5 d) e) f) g) h) i) j) k) l) m) n) Output Voltage : Three phase, 415V ± 5%, No of poles :4 Power Factor : 0.8 lag Speed : 1500 rpm± 4%, Voltage regulation : within ± 1% of the rated voltage Output Frequency : 50 Hz ± 2 Hz. THD : at full load ≤ 5% Insulation : Class H TVD & TVR under all conditions of load : not more than 15% Transient response time: 0.5 sec. Overload capability i) 110% overload for 1 hr in every 12 hour cycle. OEM Certificate to be provided ii) 150% momentary over load at 0.5 pf lag for 15 secs. to confirm the overload rating iii) 200% momentary overload at 0.4 pf lag for 5 secs 7.3 CONTROL PANELS FOR GENSET 7.3.1 Control panel should have the following facilities: I. There should be a provision of control panels for starting / stopping of the generator sets via tele operation mode & manual mode. The solid state control panel will be operable between 8-16 Volts from Genset batteries. Each genset will be provided with one manual control panel & other software based (automatic). II. Provision should be there to bypass the control panel and to start/stop the Genset manually during manual mode, the important display units like Ammeter, Voltmeter, Frequency, Engine oil pressure, etc shall be provided. III. The solid state control panel will consist of digital electronic display (Scroll type ) for ease of inspection and observation of various parameters by the operator as follows : a) Engine parameters (All parameters will be programmable for upper and lower limits) i) ii) iii) iv) v) RPM Oil pressure Oil temperature Hour meter Fuel level of engine diesel tank. b) Electrical parameters i) Voltage ii) current iii) Frequency iv) Power factor V) KVA vi) KW c) Battery charging parameters i) Voltage 0 – 20 V ii) Current 0 – 15 A 6 IV. The ruggedized digital temperature indicator (PT-100 thermal sensor) 0-1500 C for measuring inside temperature of acoustic canopy V. The circuit diagrams of the control panel, operating procedure along with Do’s & Don’ts shall be provided on the control panel at a convenient position for reference. VI. The control panel shall be intelligent & Programmable. Timers and controls shall be adjustable. The data communication to remote place (Master controller) in PSU vehicle will be through wireless radio link (wireless radio link will be in VRDE scope of work). Genset shall be controlled from HMI controller using Labview software. Firm has to make following control signals available over Ethernet (along with protocols) in addition to feedback signals mentioned in para (iv) Operator Controls VII. a. Mode selection b. Horn reset c. Emergency stop push button d. Start e. Stop f. Cranking The control panels should be made of SS-304L sheet, 1.6 mm thick and are to be provided with suitable frame and anti vibration mounts. 7.4 ANTI-VIBRATION MOUNTS Suitable anti-vibration mountings are to be provided to absorb the vibrations of the DGsets and to reduce their transmission to other parts. 7.5 DISTRIBUTION BOX & POWER CABLE: 7.5.1 A Distribution box for each genset with ELCB, MCB and connectors are to be provided. Six numbers of 3 phase outputs with MCB (for A/C, B.C. filter, etc.) and six numbers of single phase outputs with MCB (for Mast, utility etc.) should be provided. This distribution box is to be embedded in the lower portion of control panel. 7.5.2 Contractor shall supply 4 core power cable, 15 Mtrs long, UNINYVIN make, equivalent current carrying capacity along with each genset. 7.6 INTEGRATION Integration of Genset along with control panel & are to be carried out by the contractor at site (will be communicated later on). The integration work will consists of following: i) ii) iii) Mounting of Genset & control panels in non AC shelter as per drawing. Provision of cables, junction box, ducts, connectors etc is the responsibility of the contractor. Connectors of suitable size & capacity should be provided on the control panels, Bulk head panels, wherever the cables are passing through the shelter wall. Generally two sets of connectors (approx. 14 Nos.) are required to be provided. However the firm has to estimate the requirement and details to be given in technical bid. 7 iv) v) vi) Fibre optic/Ethernet cables of suitable size should be used for all the connections (except power connections) from genset to Master controller in UGV, PSU Integrated testing / commissioning is to be carried out after completion of integration. The connectors should be of MIL grade and of Allied/Amphetronic make. 8 TRAINING Adequate training shall be provided to the VRDE/user's rep. for operation and maintenance of Genset. a) No. of persons b) No. of days c) Venue : : : 03 persons 02 days VRDE, Ahmednagar 9 CARRIED SPARES The list of carried spares is enclosed at Appendix – ‘B’ to this specification. These spares are to be provided along with the Genset and cost to be included in the offer itself. 10 TOOLS Tools as per Appendix ‘C’ for normal repair & maintenance required are to be provided along with the Genset and cost to be included in the offer itself. 11 TOOL BOX & SPARES BOX One metallic tool box suitable for keeping tools for Normal Repair of Gen Set and another box for keeping spares are to be provided along with the lock and key. Mounting of these boxes are to be done at suitable locations 12 LITERATURE 23 KVA Genset mounted with removable acoustic canopy is to be supplied with a set of following documents hard & soft copies ( 3 Nos each ) as per JSS 0251 format : i) User Hand Book ii) Repair & Maintenance Manual iii) iv) Mechanical drawings (Hard copies as well as soft copies) Electrical diagrams in the form of Table Top Master electrical circuit diagram of complete system , circuit diagrams at system and subsystem level.(Hard copies as well as soft copies) Illustrated Spare Part List (ISPL) for major component v) 13 WORKMANSHIP 13.1 The workmanship of the equipment shall be in accordance with the accepted engineering and production standards of the industry. The set shall be robust to withstand vibrations caused by transport over high ways, unpaved roads and cross 8 country terrains when mounted on a vehicle so that no deformation of a permanent nature sets in during transportation. 13.2 Metals having pitted or corroded surfaces are not acceptable. Shearing and chipping shall be done neatly and accurately. All sharp edges and burrs shall be removed. Burred surfaces and flame cut materials shall be ground smooth. 13.3 Welding shall be done neatly and efficiently and shall be free from all flaws and defects. Welding should be tested for porosity and cracks etc. 13.4 Bolt holes shall be accurately drilled and shall have the burrs removed. Washers and lock washers shall be provided on bolts, studs and cap screws having straight threads. All bolts, Nuts and screws shall be correctly torqued. All bolts should have positive locking i.e. either nylon lock nuts or spring washer with plain nut should be used. 13.5 All electrical connections shall be made proper and connecting strips shall be used wherever the connections are tapped. All the wires shall be provided with numbered ferrules for proper identification. These numbers should be mentioned in the relevant electrical circuit diagram to be supplied by the contractor. 14 PAINTING AND FINISHING 14.1 The surface treatment and painting of entire body is required to protect the body from atmospheric corrosion and also to impart aesthetic appearance. 14.2 Wherever mild steel sheets and sections are used for fabrication of canopy, control panel and Shelter, the red oxide primer coating should immediately be given after proper finishing of the welded joints. No portion of mild steel structure to be left without red oxide coating. The red oxide primer should be of standard make like Asian, Apcolite etc. All welded joints must be cleaned and ground and should be free from fluxes or slag before application of red oxide. 14.3 Apply car patch or metal filling putty wherever necessary to fill the minor gaps or joints of complete fabricated structure and allow the putty to cure or harden sufficiently. Smoothen the patched up surface with file or emery paper. 14.4 After filling the necessary gap and rough surface, the entire body should be given a coating of METAL SURFACER with Duco oil primer (thinner) and be left for drying for four hours. After drying entire surface should be smoothened with fine grain water paper. The surfacer should be of standard make. 14.5 A second layer coat of Duco surfacer to be given again on the entire surface of body and thereafter rubbed with fine grain emery water paper to smoothen the surface. 14.6 After second coat of surfacer, if any dents or uneven surface is left, then again the surfacer to be used and rubbed in such a way that the entire surface is smooth and becomes ready for painting. 14.7 After good surface preparation with Duco surfacer as described above, two coats of Burger Luxol. Hi G/s Synenl paints (sand stone colour) be given. 9 14.8 After coating with above paint the entire body should be polished with car polish wax. 14.9 The underneath of Shelter and flat floor body be painted with conventional method using black coloured paint. 14.10 All the glass surfaces, plastic components etc. Should be protected from paints by masking with paper or grease. 15 DESIGN DOCUMENTS The contractor shall prepare the detailed dimensional drawings. The contractor shall also prepare the detailed design report which should include weight of major sub systems, make & model of major sub systems, total weight of integrated system, Acoustic canopy design, selection of Engine, Alternator, Anti Vibration Mounts, Ventilation / Cooling system etc. and to be submitted to VRDE for approval. Only after the approval of design and drawings the contractor can go ahead with the fabrication and development of the system. Contractor shall submit the design report within a month after placement of S. O. 16 WARRANTY 18 months from the date of supply or 12 months from the date of installation /commissioning / acceptance, whichever is earlier. 17 INSPECTION & TESTING 17.1 The inspection & acceptance testing of genset will be carried out by VRDE or his authorized rep as per approved Acceptance Test Procedure. Detailed ATP & QA plan shall be prepared by contractor and submitted to VRDE for approval and vetting Inspection facilities should be provided to the inspection authority and expenditure (like diesel, hiring of loads etc), if any, for the conduct of inspection / limited trials is to be borne by the contractor. Genset will be tested for functional/acceptance tests as mentioned in appendix ‘A’. 17.2 Power pack shall be already qualified in qualification tests like environmental, altitude, vibration, EMI / EMCl as per the specification enclosed at Appendix ‘D’. Qualification test certificates must be obtained from authorized agencies (like R& DE, Pune, NSTL, Vishakapatnam, RCI, Hyderabad and ARAI, Pune, VRDE Ahmednagar) 18 DELIVERY SCHEDULE i. Design report shall be submitted within a month after placement of S.O. The system is to be delivered within 04 months from the date of placement of supply order. This schedule will be followed strictly. In case of delay the L.D. Clause as given in terms & conditions of contract shall be applicable. The contractor shall submit the realistic production plan along with the dates so as to complete the work within the specified delivery schedule. ii. System is to be delivered within 03 months from acceptance of design. 10 19 Block diagram of the Tele-operation of the Genset UGV PSU RADIO LINK RADIO LINK CONTROLLER CONTROLLER HMI PANEL DIO/AI Modules GENERATOR 11 Appendix – ‘A’ Functionality tests (AT) 1. GEN SET 1.1 The Genset and its accessories shall be first inspected for correctness of major items as per technical specification/ manufacturer's details. After this, each of the Genset shall be subjected to the following tests : i) Fuel Consumption Test – The fuel consumption shall be checked at 3/4 rated load. The fuel consumption of the genset as per manufacturer’s specification will be compared. ii) Endurance Test – The Gen Set should be tested for one cycle of 6 hrs as per details given below:Warm up at 25% rated load 100% rated load 50% rated load No load 100% rated load 50% rated load : : : : : : 1/2 Hr 2 Hrs 1 ½ Hrs 1/2 Hr 1 Hrs 1/2 Hrs The electrical load should be such that it should give a power factor of 0.8 through a suitable induction load. Following data should be recorded during the test at an interval of ½ Hr. a) Electrical parameters : i) Voltage regulation : within ± 1% of the rated voltage ii) Output Voltage : three phase, 415V ± 5%, iii) Frequency range : 50 Hz ± 2 Hz iv) Power factor : 0.8 lagging v) THD : at full load ≤ 5% b) Indication for functioning of safety devices like High cylinder head temp, low lubricating oil pressure, over loading etc. 1.2 The following test certificate should be produced (issued by the manufacturer) by the firm i) Diesel engine - For its performance in conformity with IS-10000 / DIN/ISO 3046. ii) Alternator - For its performance as per IS 4722 or equivalent standard. iii) Manufacturers test certificate for battery, power cables etc. 12 1.3 De-rating factor as per manufacturer's specifications may be considered at working temp more than 270 C. De-rating chart should be provided. 1.4 Noise level of genset in working condition is to be measured and it should be less than75 dB at 1 m distance from stand alone canopy. 1.5 The overall dimension & weight of the genset should be measured and it should be recorded. It should be within the following limits. a) Dimension : 2000 mm (L) x 900 mm (W) x 1200 mm (H) b) Weight : Less than 800 kg. 2. CONTROL PANELS All the major items of control panel i.e. cable, connectors etc. will be inspected for their correctness and proper fitment/assembly. Control panels will be tested for their proper working during endurance testing of Genset. 3. INTEGRATED TESTING Integrated testing of Genset will be carried out at shelter manufacturers site/VRDE (communicated later on) after mounting and integration of the control panels and routing of cables. The connections should be as per approved layout. Cables, connectors etc. will be checked for proper capacity, quality and desired functionality. During this test all the loads shall be made “ON”. This test will be carried out for the duration of 4 hrs. Diesel required for this test shall be provided by the contractor. The results i. e. voltage, current and frequency etc. are to be recorded during integrated testing. 4. ROAD TRIALS The Vehicle with genset integrated shall be run for 25 Km, nearer to shelter manufacturers premises or at VRDE. The genset should work satisfactorily before and after road trials. 13 Appendix – ‘B’ To Specification No: VRDE/VEL/ UGV NBC LIST OF CARRIED SPARES FOR 23 KVA GENSET SYSTEM ENGINE SPARES Sr. No. 1 2 3 4 5 6 7 8 9 10 Description Qty. Lubricating Oil filter Fuel filter V Belt ‘A’ section Gasket oil sump Pressure switch (LOP sensor) Stop solenoid Carbon brush for B. C. Alternator Carbon brush for starter motor Battery terminals +VE and -VE Starter 12 V 2 Nos. 2 Nos. 2 Nos. 1 No. 2 Nos. 1 Nos. 1 Set 1 Set 2 Sets 1 No. ALTERNATOR SPARES Sr. No. 1 2 3 4 5 Description Qty. Rectifier service kit consists of Set of Diodes forwards = 1 Set Set of Diodes reveres = 1 Set Varistor = 1 No. Automatic voltage regulator Non drive end bearing Fuses for Voltage regulator Fuses for Rectifier assembly 2 Sets 2 Nos. 2 Nos. 3 Nos. 3 Nos. GENERAL SPARES Sr.No. 1 2 3 4 5 6 7 8 9 Description Indicating lamp assy. Red Indicating lamp assy. Yellow Indicating lamp assy. Blue Bulb 230 V, 50 Watts, AC & 12 V, 21 Watts, DC Ignition switch Fuses 32 Amps Switch (control panel) illuminated Push button Green illuminated Push button Yellow Qty. 2 Nos. 1 No. 1 No. 2 Each 2 Nos. 2 Nos. 2 Nos. 2 Nos. 2 Nos. 10 illuminated Push button Red 2 Nos. 14 Appendix ‘C’ To Specification No: VRDE/VEL/ UGV NBC LIST OF TOOLS FOR 23 KVA POWER PACK Sl. No. Particulars Make Model Qty. 1. Plier With Insulated Handle 200 mm Handle Taparia - 1 2. Hammer Ball Pin With Handle (500 Gm) Taparia - 1 3. Screw Driver Set Taparia - 1 4. Box Spanner From 6 To 32 Mm (22 Nos) Taparia - 1 5. Ratchet 300 Mm Long Taparia - 1 6. Cutting Plier Taparia - 1 7. Engineering Screw Driver 150 Long Taparia - 1 8. Engineering Screw Driver 250 mm Long Taparia - 1 9. Engineering Screw Driver 350 mm Long Taparia - 1 10. Clamp On Multimeter Taparia - 1 11. Spanner Set From 6 To 32 mm (12 Nos) Taparia - 1 12. Line Tester 500 Volts Taparia - 1 13. Adjustable Spanner 150 mm Taparia - 1 14. Adjustable Spanner 300 mm Taparia - 1 15. Nose Plier With Insulated Handle 200 mm Taparia - 1 16. Oil Can Pressure Type 500 Ml Capacity Taparia - 1 17. Ring Spanner Set From 6 To 32 mm (12 Nos) Taparia - 1 18. Soldering Iron 65 Watts Taparia - 1 19. Solder Wire And Flux Taparia - 1 15 Appendix - ‘D’ To Specification No: VRDE/VEL/UGV-NBC # DGset shall be successfully tested for following qualifications tests &Contractor shall produce test certificates from competent authority within given time ENVIRONMENTAL & EMI/EMC TEST SPECIFICATIONS FOR 23 KVA POWER SOURCE 1. High temperature test at + 55°C with soaking cycle of 16 hours as given below i) ii) iii) + 55°C + 3°C : for 6 Hrs + 65°C + 3°C : for 4 Hrs + 55°C + 3°C : for 6 Hrs a) Pre testing at ambient temp b) Testing inside the chamber for last 30 minutes of soaking period. c) Post testing at ambient temp 2. Low temperature test -10 °C combined with 3000m altitude with soaking cycle of 16 hours as given below a) Pre testing at ambient temp i) - 10°C + 3°C : for 6 Hrs b) Testing inside the chamber for last 30 ii) - 20°C + 3°C : for 4 Hrs minutes of soaking period. iii) - 10°C + 3°C : for 6 Hrs c) Post testing at ambient temp 3. Tropical exposure test (for 14 cycle) i) ii) iii) iv) v) 4. Keep the unit in the chamber at 20 °C ± 5 °C Rise Temperature and RH to 45°C ± 5°C and 95 % respectively in 3 Hrs. Maintain this condition for 12 Hrs. Decrease the temp to 20 °C ± 5 °C over a period of 3 Hrs. Maintain this condition for 6 Hrs. Vibration test ( along single axis) Frequency range in Hz 5 - 8 Hz 8 – 500 Hz 5. a) Pre testing at ambient temp b) Testing inside the chamber at 7th & 14th Cycle. c) Post testing at ambient temp Amplitude ± 6 mm constant displacement ± 1.5 g peak Sweep rate in min/cycle 5 5 Duration in ‘z’ axis 120 (min) 120 (min) EMI / EMC Test : This testswill be as per MIL STD 461E. Vendor has to produce test certificates of the following three tests. Genset shall be qualified in all three tests Sr. No. 1 2 3 Name of test RE 102 : Radiated Emission test RS 103: Radiated Susceptibility CE 102: Conducted emissions Frequency range 30 MHz to 1 GHz 20 MHz to 2.5 GHZ 10 KHz to 10 MHz (BA LANDGE),Sc‐D FOR DIRECTOR,VRDE 16 ENCLOSURE TO TENDER ENQUIRY NO. VRDE/MMG/OTS-04/2012-13 (Pages- 1/3) APPX.-E IMPORTANT COMMERCIAL TERMS & CONDITIONS ( TO BE FILLED BY TENDERER & ENCLOSED WITH TECHNO-COMMERCIALOFFER ) S.NO. TERMS & CONDITIONS 1. DELIVERY TERMS FREE DELIVERY AT VRDE 2. DELIVERY SCHEDULE REQUIRED WITHIN EIGHT MONTH(S) 3. PACKING CHARGES IF EX-WORKS, INDICATE AMOUNT (STATE IF EX.DUTY APPLICABLE/NOT APPLICABLE) 4. FORWARDING CHARGES IF EX-WORKS, INDICATE AMOUNT 5. FREIGHT CHARGES IF EX-WORKS/F.O.R. PLACE OF DESPATCH, INDICATE AMOUNT OR STATE AT ACTUALS 6. TRANSIT INSURANCE IF EX-WORKS/F.O.R. PLACE OF DESPATCH, INDICATE AMOUNT OR STATE AT ACTUALS 7. INSTALLATION COMMISSIONING CHARGES 8. TRAINING CHARGES IF APPLICABLE, INDICATE LUMP-SUMP AMOUNT OR PER DAY, PER PERSON CHARGES WITH DURATION 9. GUARANTEE/ ONE YEAR(S) FROM THE DATE OF ACCEPTANCE AGAINST MANUFACTURING DEFECTS. IN CASE STORES IS REQUIRED TO BE TAKEN TO YOUR WORKS FOR REPAIRS,EXPENSES ON TO & FRO TRANSPORTATION WILL BE ON SUPPLIER’S ACCOUNT WARRANTEE 10 PAYMENT TERMS AND VRDE COMMERCIAL TERMS RESPONSE FROM VENDOR IF APPLICABLE, INDICATE LUMP-SUMP AMOUNT A) 100% PAYMENT WITHIN 30 DAYS OF RECEIPT OF THE STORES IN GOOD CONDITION & ITS ACCEPTANCE. (FOR ITEMS NOT COVERED BY WARRANTY/GUARANTEE) (B)90% PAYMENT WITHIN 30 DAYS AFTER RECEIPT, INSTALLATION, COMMISSIONING, SATISFACTORY DEMONSTRATION AND ACCEPTANCE. BALANCE 10% EITHER ON EXPIRY OF WARRANTY PERIOD OR AGAINST SUBMISSION OF PERFORMANCE BANK GUARANTEE, COVERING WARRANTY PERIOD PLUS CLAIM PERIOD. Not Applicable PAGE – 2/3 11. AFTER SALE SERVICE PLEASE CONFIRM AVAILABILITY OF SPARES & REPAIR FACILITIES ARE AVAILABLE & PROVIDED BY YOU. 12 AMC CHARGES IF APPLICABLE, PLEASE SPECIFY WITH TERMS & CONDITIONS 13. VAT WILL BE PAID AS APPLICABLE. SPECIFY %. IF INCLUDED IN PRICE, SPECIFY % INCLUDED. 14. EXCISE DUTY WILL BE PAID AS APPLICABLE, SPECIFY %. EXEMPTION CERTICIATE (NOTIFICATEION NO. 10/97) MAY BE PROVIDED (FOR MANUFACTURER ONLY). IF INCLUDED IN PRICE, SPECIFY % INCLUDED. 15. CUSTOM DUTY IMPORT THROUGH INDIAN VENDORS = SPECIFY QUANTUM OF DUTY. EXEMPTION CERTIFICATE (NOTIFICATION NO. 39/96) WILL BE PROVIDED DIRECT IMPROT FROM OEM = SPECIFY QUANTUM OF DUTY. EXEMPTION CERTIFICATE (NOTIFICATION NO. 51/96) WILL BE PROVIDED. ADDL. DUTY PAYABLE UNDER NOTIFICATION NO. 24/02 WILL BE REIMBURSED AT ACTUALS. 16. OCTROI DUTY SPECIFY IF OCTROI CHARGES ARE EXTRA TO ISSUE EXEMPTION CERTIFICATE 17. EARNEST DEPOSIT (EMD) 18. SECURITY DEPOSIT 10% OF BASIC COST IS TO BE SUBMITTED BY SUCCESSFUL VENDOR. CONFIRM YOUR ACCEPTANCE 19. LD CLAUSE IN CASE OF DELAYED SUPPLIES,LIQUIDATED DAMAGES AT THE RATE OF 0.5% PER WEEK SUBJECT TO A MAXIMUM OF 5 % WILL BE LEVIED.THIS CLAIM IS MANDATORY & CANNOT BE WITHROAWN 20. REGISTRATION NO. WITH GOVT. DEPTTS. ENCLOSE PHOTO COPY 21. IMPORT CONTENTS IF OFFER INCLUDES IMPORT, DESCRIBE APPROXIMATE COST, NAME OF FGN. OEM. 22. NAME OF FOREIGN FIRM/OEM REPRESENTED PLEASE INDICATE MONEY CONFIRM IF DD/FDR/BG/BANKERS CHEQUE FOR EMD AMOUNT IS ENCLOSED. WITH TECHNO-COMMERCIAL BID, IF NOT, REASONS THEREOF. NAME, QTY., AND Page 3/3 23. AGENCY AGREEMENT PHOTOCOPY IS TO BE ENCLOSED 24. NATURE OF SERVICES TO BE RENDERED PLEASE INDICATE 25. AUTHORISATION LETTER/DISTRIBUTOR/AG ENCY CERTIFICATE PLEASE ENCLOSE COPY 26. PERCENTAGE OF COMMISSION PAYABLE TO INDIAN AGENT/REP BY OEM PLEASE INDICATE 27. END USER CERTIFICATE PLEASE INDICATE IF IT IS REQUIRED. IF YES, PROVIDE FORMAT, IF ANY 28. VAT REGISTRATION N0. PLEASE SPECIFY 29. SERVICE REGISTRATION NO. PLEASE SPECIFY 30. INCOME TAX PAN NO. PLEASE SPECIFY 31. BANK DETAILS FOR RTGS MODE OF PAYMENT NAME OF BANK TAX BRANCH ADDRESS WITH PIN, ACCOUNT NO. TYPE OF ACCOUNT, RFGS/IFS CODE 32. VALIDITY OF QUOTATION PLEASE INDICATE DATE 33. NAME & SIGNATURE OF AUTHORISED SIGNATORY WITH STAMP OF VENDOR SPECIFIY AUTHORITY OF SIGNING – SOLE PROPRIETOR/ PARTNER/ETC,(ENCLOSE AGREEMENT OR POWER OF ATTORNEY)