Model 69UG15 - Florens Container Services

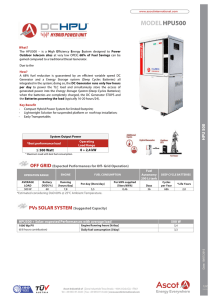

advertisement