Preventing Serious Injury and Fatality Incidents

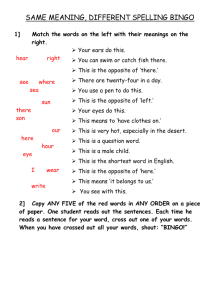

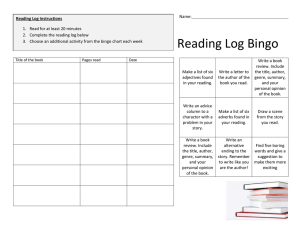

advertisement

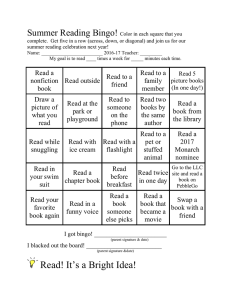

June A Newsletter for RMSC clients Preventing Serious Injury and Fatality Incidents In many of the catastrophic events in recent years—Columbia, Challenger, BP Texas City, Upper Big Branch Mine, Deepwater Horizon —indicators of impending disaster were available but obscured by years of data showing recordable injury rates to be low or improving. Traditional safety efforts often fail to address Serious Injury and Fatalities (SIFs) because they may focus on reducing incidents in general and overlook close scrutiny of potential major accident hazards. These deficiencies are due in part to current measurement systems that create a “blind spot” for SIF prevention. A 2007 Rand study stated that there appears to be no relationship between OSHA injury rates and fatalities. The absence of minor injuries is not predictive of an absence of future serious injury and fatalities. Serious injuries are life-threatening (such as significant loss of blood, trauma to vital organs, and damage to the brain or spinal cord), or life-altering (resulting in permanent or long-term impairment of loss of an internal organ, body function, or body part). The key to prevention is to identify, understand and mitigate SIF precursors. Precursor data are a vitally important tool to assess safety risks, give signals of impending problems and eliminate the “blind spot” created by looking at accidents alone. Precursors represent a leading indicator (not an after-the-incident reactionary measure) that helps identify exposures with high potential for SIFs. An SIF precursor is a high-risk activity or situation in which management controls are either absent, ineffective, or not complied with, and which will result in an event (a serious or fatal injury) if allowed to continue. Special attention to the following may help reduce the likelihood for SIF events: Mobile equipment (operation and interaction with pedestrians) or watercraft Confined space entry Jobs that require lock-out tag-out Lifting operations Working at height/elevations Manual handling Process instability or significant process upsets Unexpected maintenance or changes High potential energy jobs Emergency shutdown procedures Work under suspended loads Machine guarding and barricades Use of hot work permits, equipment and pipe opening of hazardous chemicals (Thomas R. Krause, BST, Inc. and Glenn Murray, Exxon Mobil . Presented at the 2012 American Society of Safety Engineers Professional Development Conference, Denver, Colorado. Copyright © 2012 by the American Society of Safety Engineers. Reprinted with permission.) Make sure your company safety program is looking at any activities and hazards that might have SIF potentials. Liven up Your Safety Training Using safety games to enhance your training is an excellent idea to get trainees more involved. BINGO is an easy game to learn, although most trainees will probably have played it before. If you Google “BINGO Card Creator” you will get many hits that offer free sites where you can create a customizable set of BINGO cards. Different variations of the cards can help make the game challenging and competitive. Filling the individual squares on a BINGO card with words or phrases related to the topic is an excellent learning tool. For example, choose a topic and think of 25 questions and associated answers related to the class and then put the answers inside the different squares on the BINGO cards. Then randomly select one of the 25 questions, read it and ask your trainees to find the correct answer on their BINGO card. If they have the correct answer, they should mark it off with an “X.” The trainees should be told that the first trainee to get 5 X’s straight across, wins. The instructor will continue selecting and reading random questions until someone has completed a “BINGO”. Following the training, solicit feedback from employees asking them what they liked or didn’t like about the training and what they learned that they can take back to their job. Employee interaction and feedback usually relates to more effective training. OSHA Initiatives Reducing Struck-By Vehicle Accidents OSHA has begun a regional outreach program in the states of Iowa, Nebraska, Kansas and Missouri to prevent employee injuries from being struck by passenger vehicles, forklifts and other powered industrial equipment. The program was begun to address the fact that 14% of all workplace fatalities investigated by the Region 7 office from 2008-2011 involved struck-by incidents. Educational materials from the campaign are available through the regional OSHA offices of the respective states involved. Medical Care National Emphasis Program OSHA has launched their National Emphasis Program announced last year aimed at reducing serious hazards common to nursing homes and residential care facilities. According to Bureau of Labor Statistics, healthcare workers have a lost workday rate over twice the private sector average. Overexertion and slips/trips/falls make up over 63% of the reported injuries for this sector. According to the inspection guidelines, any facility with a days-away-from-work rate of more than 10 injuries per 100 full time employees would be subject to inspection. They will key on hazards like bloodborne pathogens, communicable disease exposure, ergonomics involved with patient lifting/moving, workplace violence and slips/trips and falls. ___________________________________________________________________________ For additional information on these topics or for Loss Prevention assistance, contact: Paul Fox (pfox@rmsc.com or 502-708-3111) RMSC has exercised due and customary care in producing this newsletter but has not independently verified information provided by others. No other warranty, express or implied, is made with regard to the content of this newsletter. Therefore, RMSC assumes no liability from any loss resulting from errors, omissions or misrepresentations made by others. The use of this information by third parties shall be at their own risk and RMSC accepts no duty of care to any such third party.